Sensor and detection method for atmosphere corrosion detection of steel member or test piece

A technology for steel components, corrosion detection, used in weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., and can solve problems such as corrosion of electrochemical sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

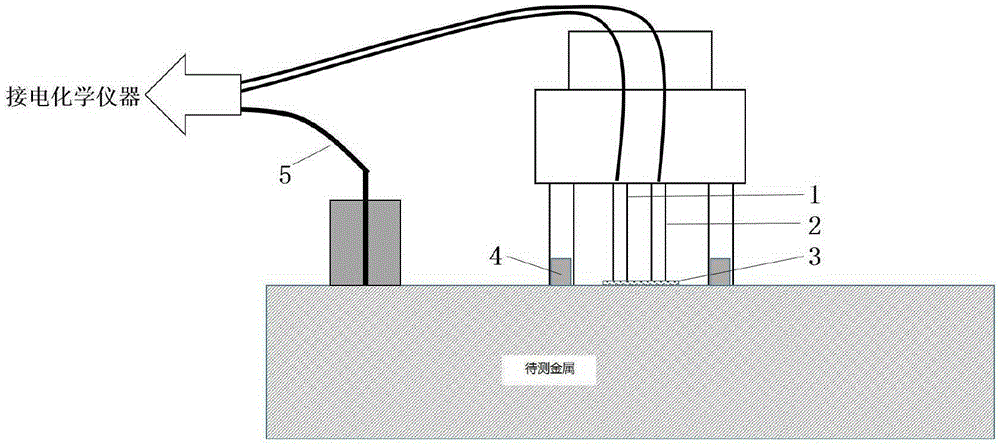

[0017] Example 1. Corrosion monitoring of iron and steel components in marine and atmospheric environments: the reference electrode 2 is a high-purity zinc electrode, and the counter electrode 1 is a platinum-plated titanium electrode. Place a piece of plastic mesh 3 with a thickness of about 500 microns and a diameter of about 2 cm on the surface of the steel member (or test piece) to be tested. Place the sensor and press the plastic net 3, and the sensor is adsorbed on the steel sample to be tested by the magnet 4. Adjust the positions of the reference electrode 2 and the counter electrode 1 until the two electrodes press against the plastic mesh 3 . The working electrode electrical contact lead wire 5 is placed near the sensor, the copper wire in the lead wire 5 communicates with the steel surface to be tested, and the outer magnet 4 is adsorbed on the surface of the steel component (or test piece) to be tested. The electrochemical noise test is carried out by using a dete...

example 2

[0018] Example 2. Corrosion monitoring of iron and steel components in an urban atmospheric environment: The difference from Example 2 is that the reference electrode 2 is a high-purity antimony electrode, and the counter electrode 1 is a platinum-plated titanium electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com