Simulation experiment device for hydrostatic stress corrosion electrochemical action of magnesium alloy and experiment method of simulation experiment device

A simulation experiment device, stress corrosion technology, applied in the field of electrochemistry, can solve the problems of insufficient plastic deformation ability, fast degradation, low strength, etc., to reduce the ohmic drop of the solution, the device structure is simple, and the effect of meeting the experimental needs is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

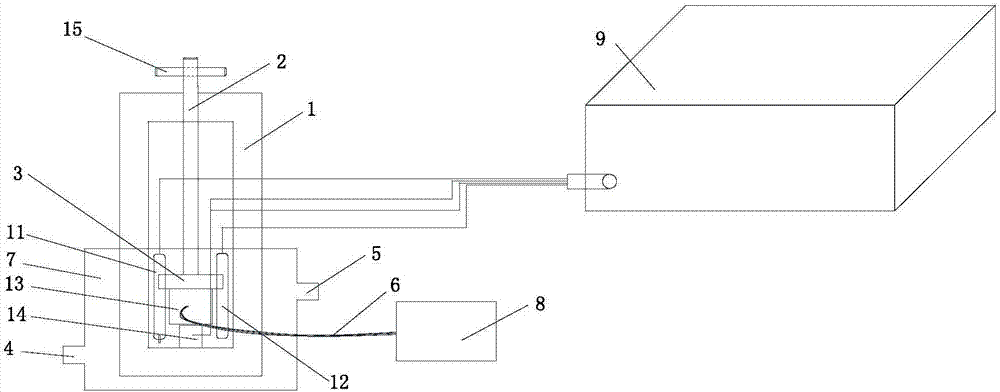

Method used

Image

Examples

Embodiment 1

[0092] The applied static compressive stress is 0.0 MPa.

[0093] The test results are shown in Table 1 below.

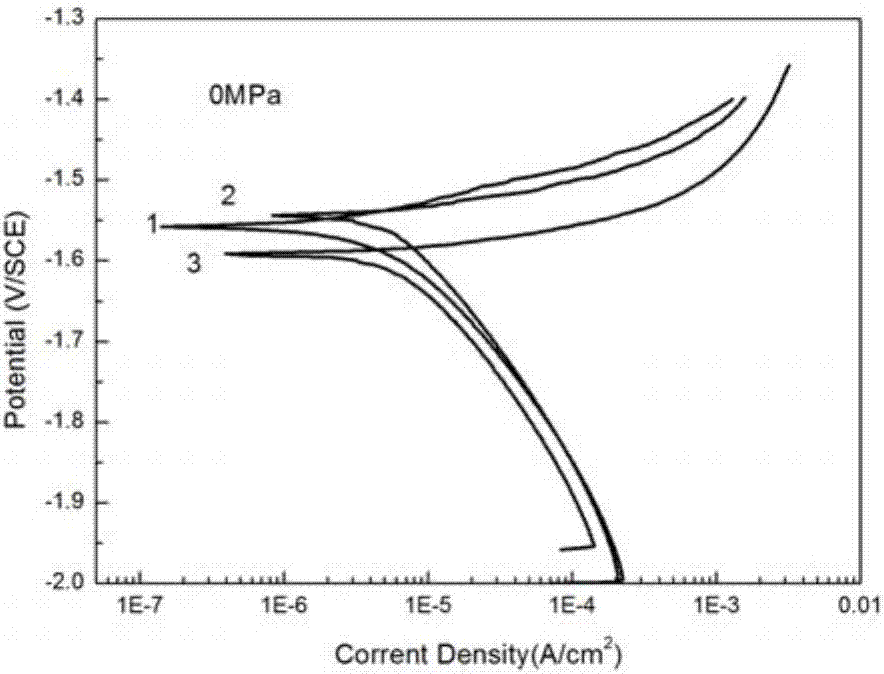

[0094] Such as figure 2 as shown, figure 2 The three curves in the figure are the polarization curves of three parallel samples under the same experimental conditions.

[0095] Polarization curves 1, 2, 3 correspond to the self-corrosion current density I of the Mg-4Li-1Ca alloy sample corr and self-corrosion potential E corr

[0096]As shown in Table 1. The electrochemical parameters in Table 1, combined with the test results of multiple groups of parallel samples show that the self-corrosion current density I measured when the static pressure stress is 0MPa corr and self-corrosion potential E corr Similarly, the reproducibility between parallel samples is good, which can eliminate the influence of accidental factors in the experiment, and the test results of the device are reliable and stable.

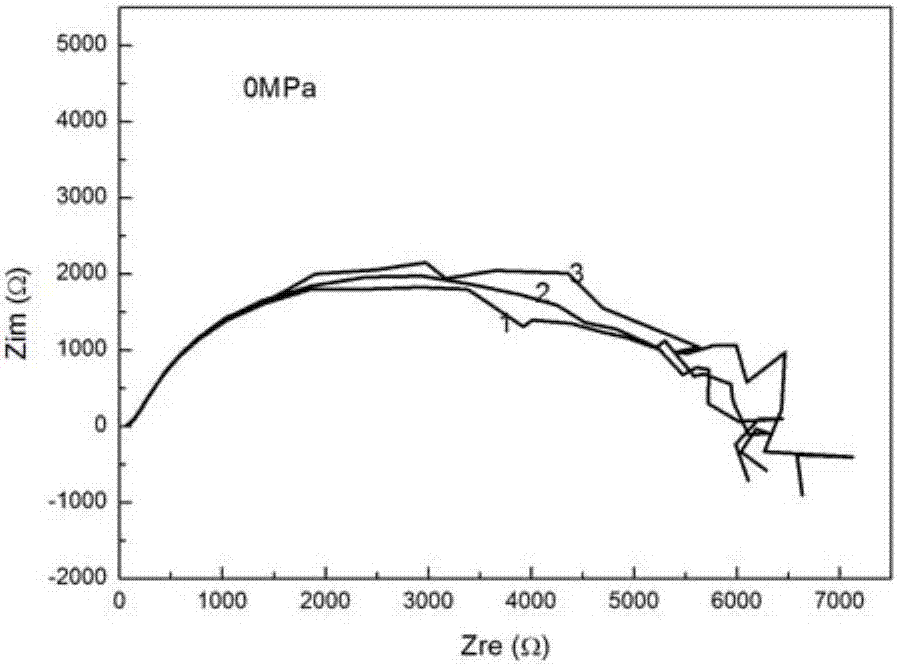

[0097] image 3 and Figure 4 It is the AC impedance spec...

Embodiment 2

[0107] The applied static compressive stress is 1.5MPa.

[0108] The test results are shown in Table 2 below.

[0109] Figure 5 Polarization curves of corrosion electrochemical behavior test results in Hank’s solution for Mg-4Li-1Ca alloy samples loaded with 1.5MPa static pressure stress.

[0110] Such as Figure 5 As shown, the three curves in the figure are the polarization curves of three parallel samples under the same experimental conditions. Polarization curves 1, 2, 3 correspond to the self-corrosion current density I of the sample corr and self-corrosion potential E corr As shown in table 2.

[0111] The electrochemical parameters in Table 2, combined with the test results of multiple groups of parallel samples, show that the self-corrosion current density I measured when the static pressure stress is 1.5MPa corr and self-corrosion potential E corr Similar, the reproducibility between parallel samples is good, the test results of this experimental device are st...

Embodiment 3

[0120] The applied static compressive stresses were 0.0MPa, 1.5MPa, and 3.0MPa, respectively.

[0121] The test results are shown in Table 3 below.

[0122] Figure 8 Polarization curves of the corrosion electrochemical behavior test results in Hank’s solution for Mg-4Li-1Ca alloy samples under different static pressure stress conditions.

[0123] Such as Figure 8 As shown in the figure, under 0MPa, 1.5MPa, 3MPa compressive stress, the electrochemical polarization curves of the Mg-4Li-1Ca alloy sample in Hank's solution, and the polarization curves in the figure were fitted to calculate its own Corrosion potential E corr and self-corrosion current density I corr . Self-corrosion potential E corr is the electrochemical thermodynamic quantity of corrosion, the higher the negative value, the stronger the corrosion tendency of the material in the solution in the system, and the material is prone to electrochemical corrosion; while the self-corrosion current density I corr ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com