Electrochemical noise sensor for metal pipeline outer surface corrosion detection

An electrochemical noise and corrosion detection technology, applied in scientific instruments, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as difficulty in electrochemical detection, and achieve long-distance corrosion detection and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] An electrochemical noise sensor for detecting corrosion on the outer surface of a pipeline is carried out according to the following steps:

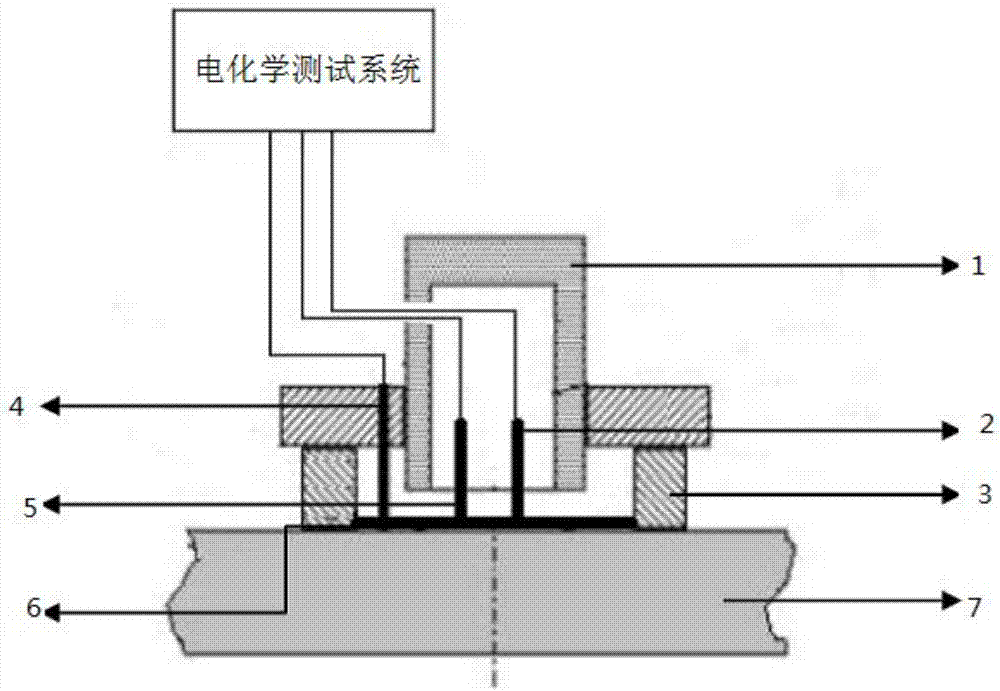

[0011] figure 1 It is a schematic diagram of the electrochemical detection sensor for corrosion on the outer surface of the pipeline. The sensor mainly includes a cavity 1, a reference electrode 2, a counter electrode 5, an electrical contact 4 that is in direct contact with the outer surface of the metal pipe to be tested, and a magnet support 3. It is characterized in that a magnet is fixed at the lower end of the magnet support 3. . The working electrode electrical contact 4 directly communicates electrically with the surface of the metal pipeline to be tested. In order to build a test circuit during the test, a layer of filter paper is placed between the sensor reference electrode 2 and the counter electrode 5 and the steel surface to be tested. The pillar is connected with the housing through threads, and the distance betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com