Fatigue Resistant Coiled Tubing

A linear, metal pipe technology, applied in the field of metal pipes and their manufacturing, can solve problems such as failure of flexible pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention relates to a length of metal pipe and a method for its manufacture.

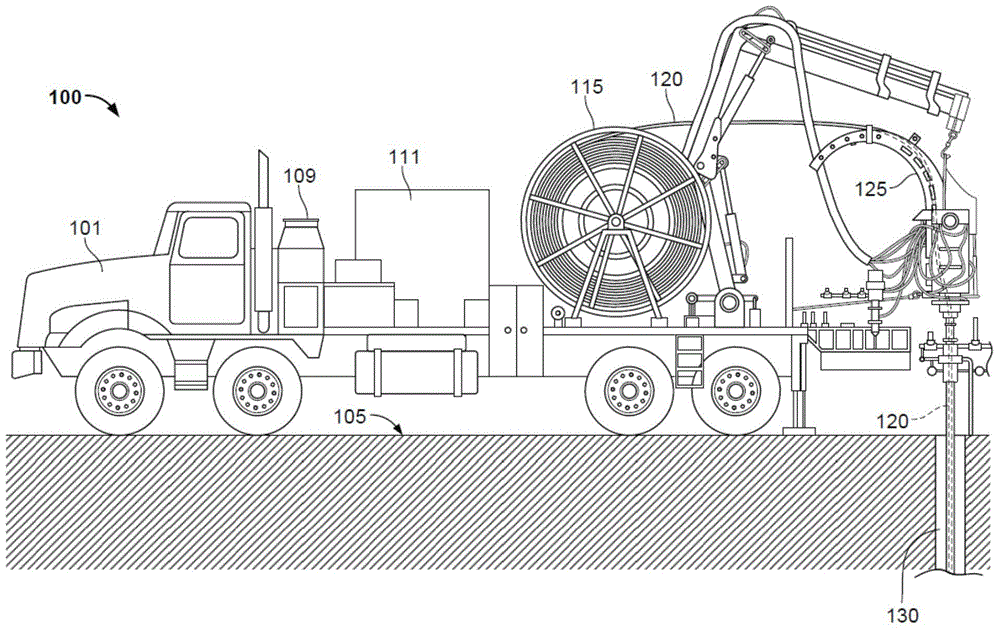

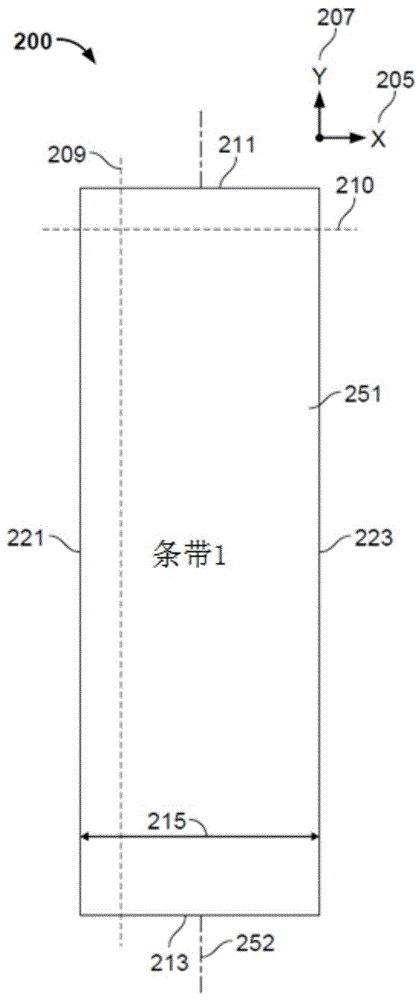

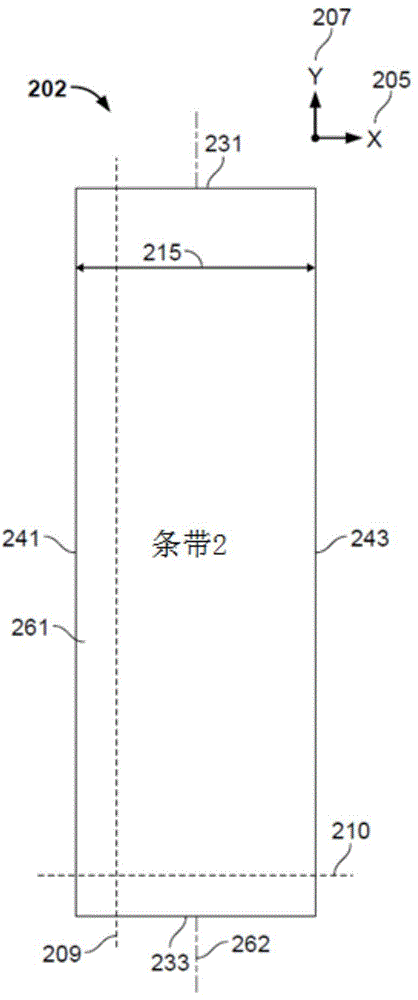

[0056]Typically, during wellbore related operations, such as drilling, the flexible metal tubing is subjected to cyclic loading and various pressurizations due to repeated coiling and / or uncoiling from a reel. The number of coil-up and uncoil cycles without failure (such as a rupture or other leak) can be an indication of the life of the metal tube. When a crack initiates and propagates in flexible metal tubing, premature failure typically occurs near the strip-to-strip weld. Crack initiation may be due to certain stresses and strains as well as welding defects. The present invention describes a section of coilable metal tubing that has a cut profile at the strip-to-strip weld to aid in resistance to fatigue stress and strain states, while having a short weld length to reduce the likelihood of defects. In metal tubes, metal strips are known to be welded in simple straight cut p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com