Method for predicting space between aluminium-silicon alloy eutectic structure lamellas

A technology of eutectic structure and lamellar spacing, applied in the field of metallurgy, can solve the problems of high cost, impact, and long experiment period of lamellar spacing

Inactive Publication Date: 2011-08-17

SHENYANG POLYTECHNIC UNIV

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

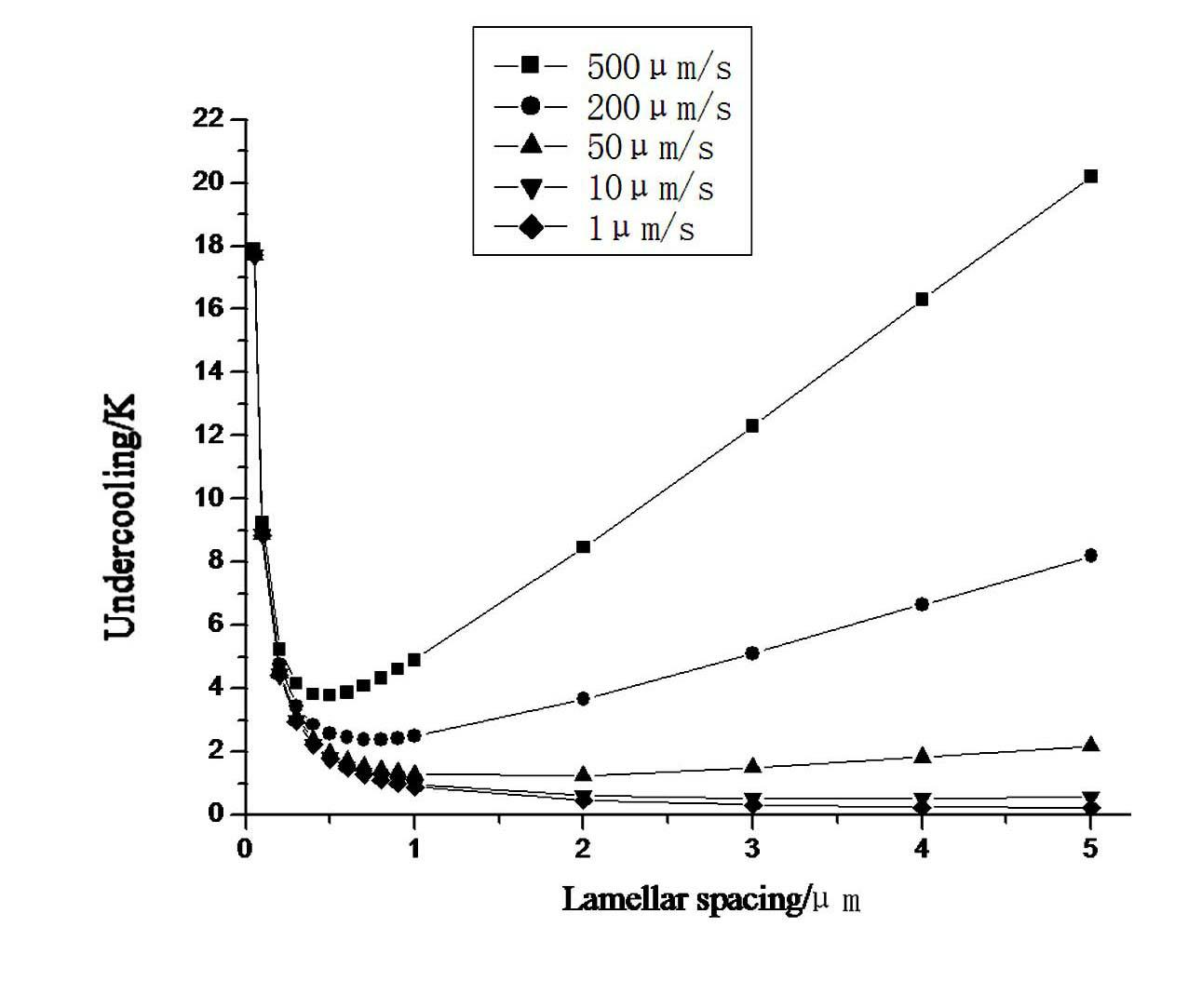

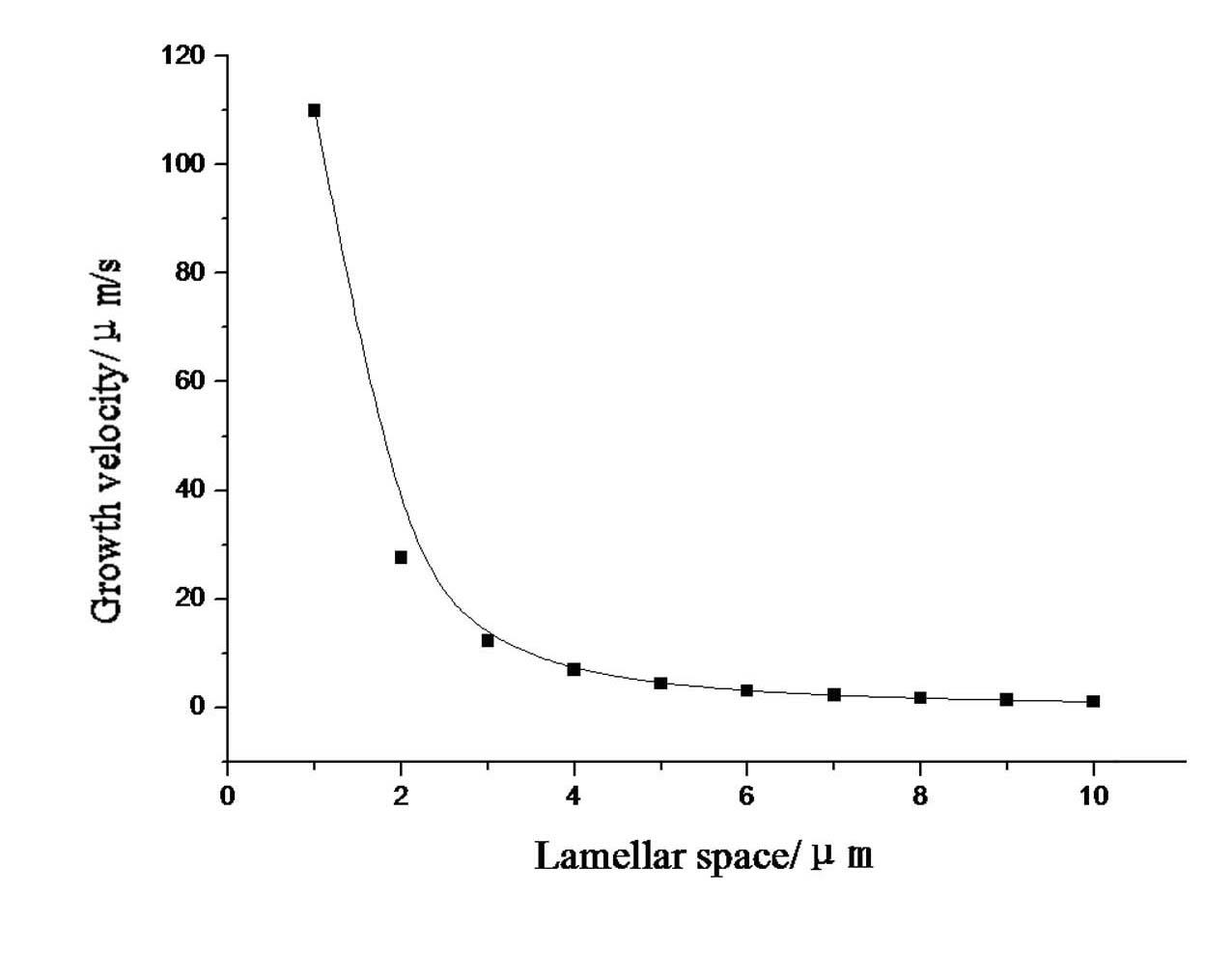

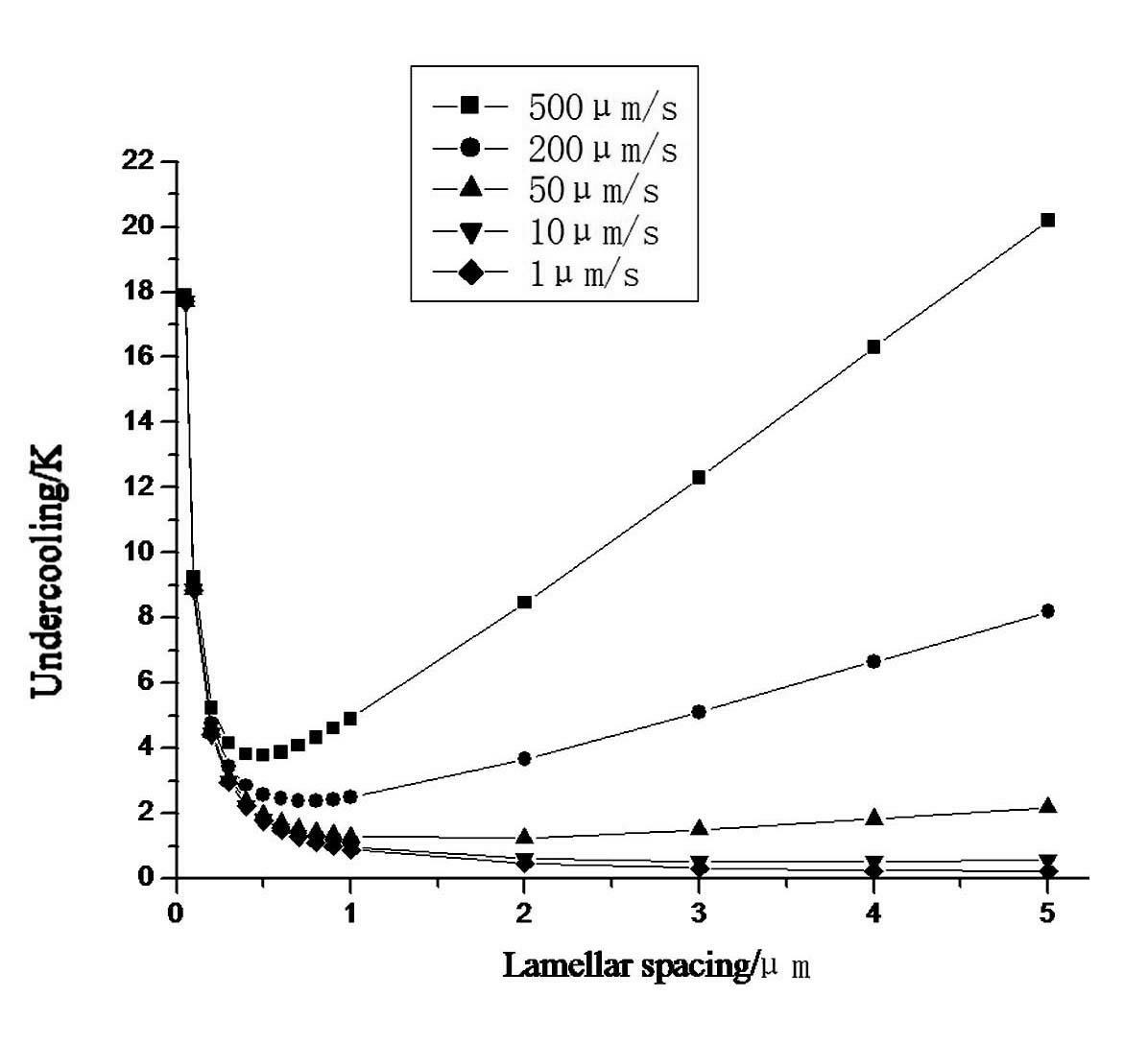

The lamellar spacing of the Al-Si eutectic structure is a major factor directly related to the mechanical properties of casting products. In the past, the eutectic inter-lamellar spacing of Al-Si alloys was mostly measured by experimental methods. The cost of layer spacing is high, the experiment cycle is long, and the experimental results are significantly affected by the experimental conditions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0127] The material parameters used in the above method are as follows: Al-12.6mass%Si, liquidus is 577°C, eutectic composition is 12.6%, =-7.5, =17.5, k 0a =0.13, k 0β =2×10 -4 , =8.9×10 -3 , , , , , , , the pouring temperature of the alloy is 700°C, and the mold temperature is 300°C.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for predicting space between aluminium-silicon alloy eutectic structure lamellas; the method is characterized in that an experimental period can be greatly shortened by using a numerical simulation method to predict the space between aluminium-silicon alloy eutectic lamellas; the cost is low, and the prediction result is not limited by the experimental conditions; and the influences of a certain single factor to the space between the aluminium-silicon alloy eutectic structure lamellas can be inspected. The shortages that the cost of the existing experimental method for measuring the space between aluminium-silicon alloy eutectic structure lamellas is relatively high, the experimental period is long and the experiment results are influenced obviously by the experimental conditions are overcome; the computation is fast; the error is small; and the quantitative prediction to the space between eutectic lamellas can be realized.

Description

1. Technical field: [0001] The invention belongs to the technical field of metallurgy, and mainly relates to a method for predicting the lamellar spacing of eutectic structures, in particular to the prediction method for the lamellar spacing of eutectic structures of aluminum-silicon alloys. 2. Background technology: [0002] Aluminum-silicon alloy is one of the most widely used aluminum alloys, and it is widely used in automobiles, electric power, aviation and other fields. Casting is a main method of aluminum silicon alloy forming. However, in the casting process, the Al-Si eutectic structure is a typical solidification structure. The lamellar spacing of the Al-Si eutectic structure is a major factor directly related to the mechanical properties of casting products. In the past, the eutectic inter-lamellar spacing of Al-Si alloys was mostly measured by experimental methods. The cost of layer spacing is high, the experiment cycle is long, and the experimental results are ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N33/20B22D27/04

Inventor 李强曲迎东李荣德张超逸

Owner SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com