Method and device for monitoring high-cycle fatigue life of steam turbine integral rotor

A technology of integral forging rotor and high cycle fatigue, which is applied in the field of steam turbines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

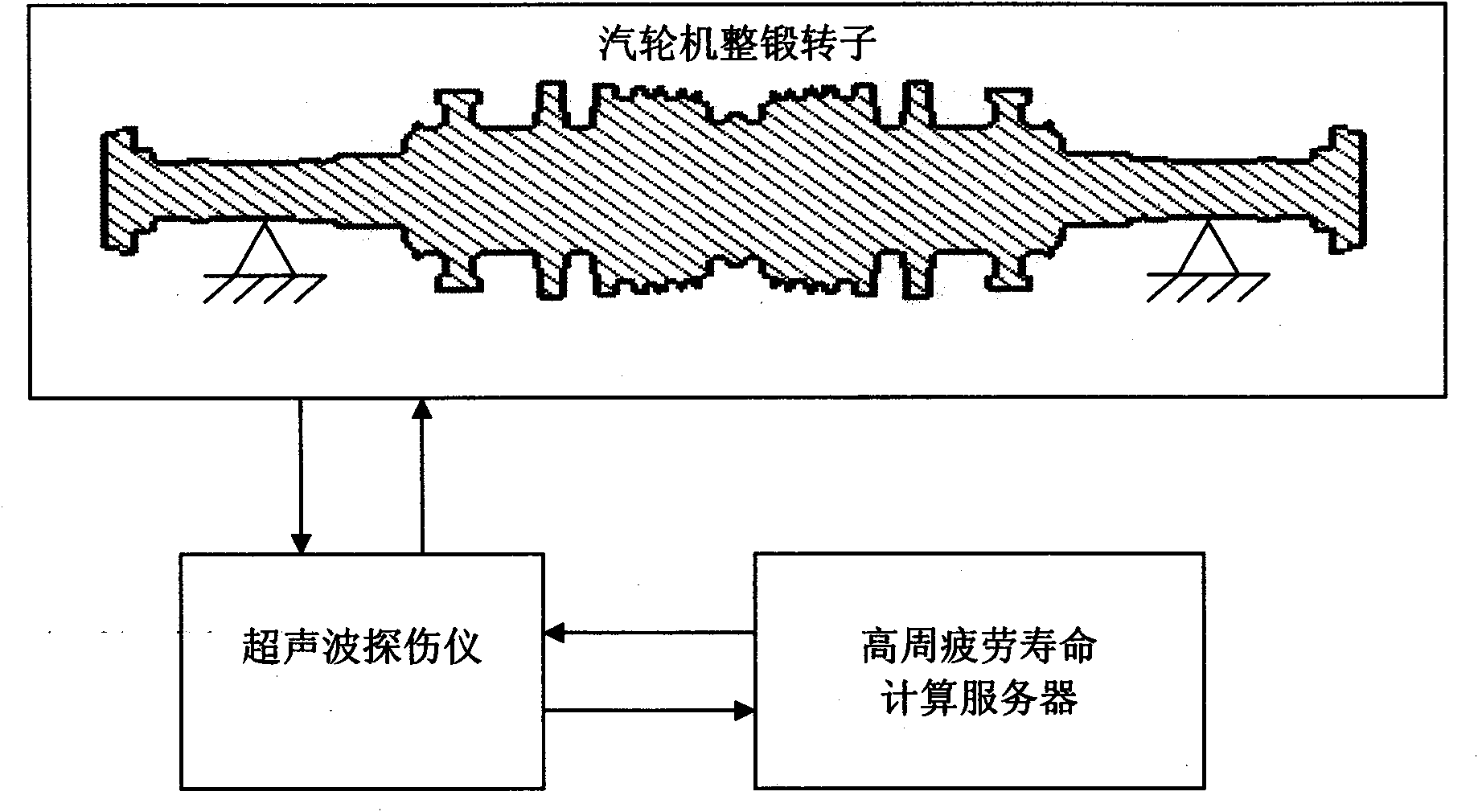

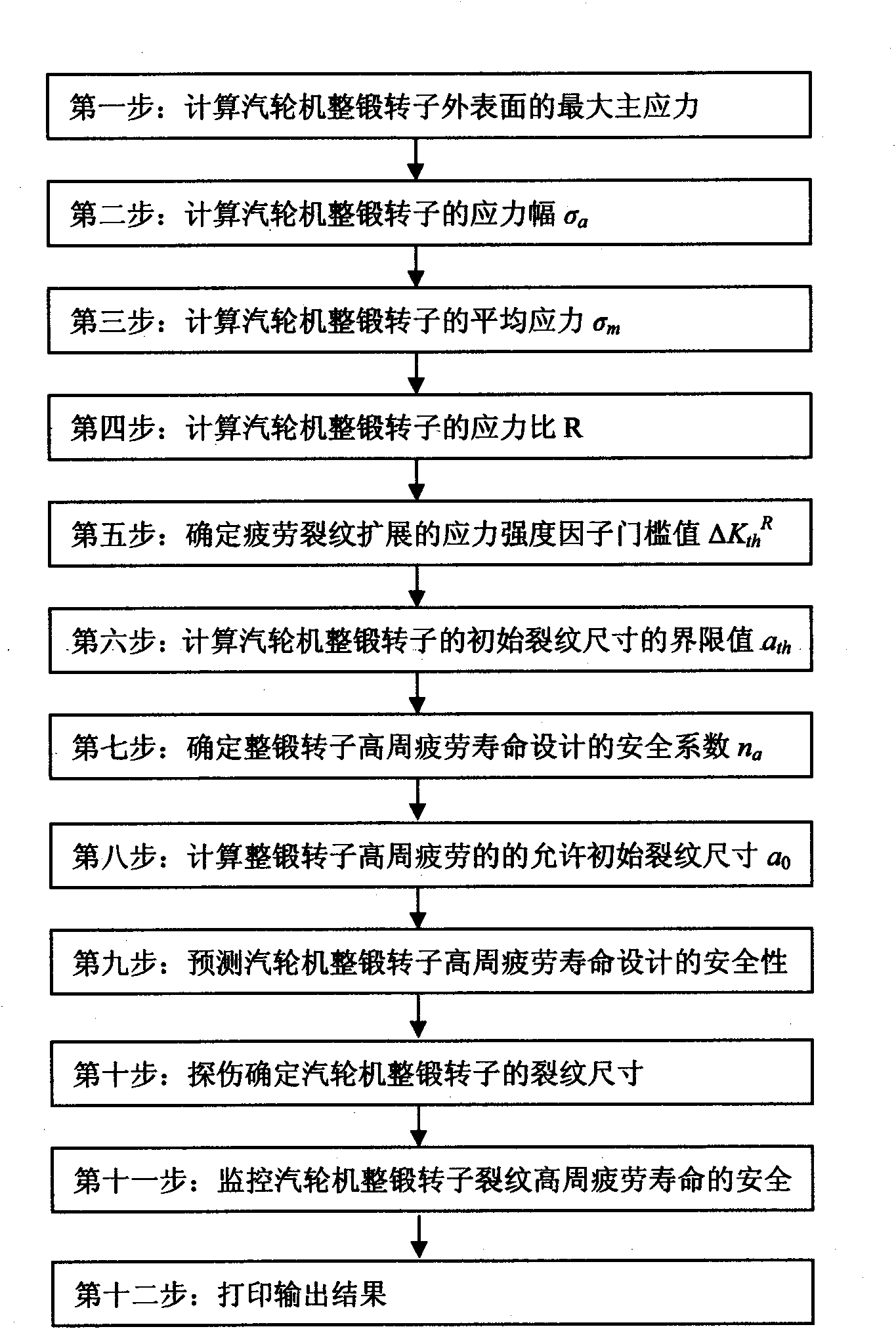

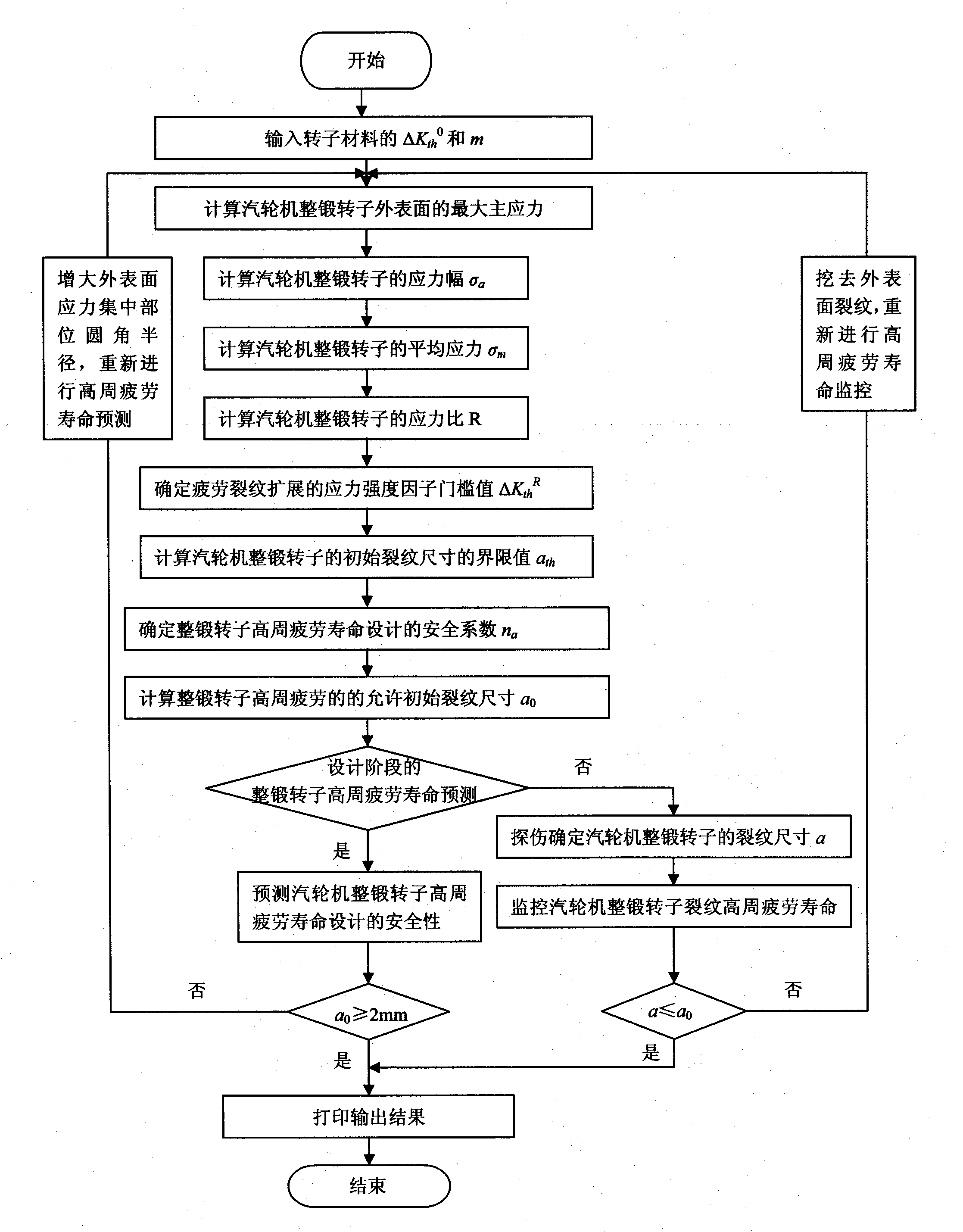

[0065] For a certain type of 600MW thermal power steam turbine, the operating speed is 3000 rpm, and the low-pressure rotor adopts the structure of the integral forged rotor as follows: Figure 4 As shown, the rotor material is 30Cr2Ni4MoV. In the design stage of the whole forged low-pressure rotor of the 600MW thermal power steam turbine, the figure 1 the device shown, figure 2 The flow chart shown and image 3 The computer software shown can calculate the calculation result of the high cycle fatigue life of the whole forged low pressure rotor, and the specific steps are as follows:

[0066] Step 1: Calculate the maximum principal stress on the outer surface of the whole forged rotor of the steam turbine:

[0067] For the steam turbine integral forged rotor, the existing finite element calculation and analysis method is used to calculate the maximum principal stress on the outer surface of the rotor under the steady-state rated load condition. ° position) to determine the...

Embodiment 2

[0116] For a certain type of 600MW thermal power steam turbine, the operating speed is 3000 rpm, and the low-pressure rotor adopts the structure of the integral forged rotor as follows: Figure 4As shown, the rotor material is 30Cr2Ni4MoV. In the manufacturing stage of the whole forged low-pressure rotor of this 600MW thermal power steam turbine, the figure 1 the device shown, figure 2 The flow chart shown and image 3 The computer software shown is used to calculate the monitoring results of the high cycle fatigue life of the whole forged low pressure rotor. The specific steps are:

[0117] The first step to the eighth step: similar to Example 1, the difference is that the outer surface part A of the whole forged low-pressure rotor of the 600MW thermal power steam turbine adopts an optimized and improved design scheme, and the fillet radius of part A is designed to be 300mm. Maximum principal stress σ 1 , projected onto σ 1 The normal stress σ in the direction 1 ′, str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com