Film-sticking mold and film-sticking process

A film and mold technology, which is applied in the field of film film molds and film film technology, can solve the problems of high labor intensity and low film film efficiency, and achieve the effects of reducing labor intensity, improving film film efficiency, and reducing the degree of manual participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

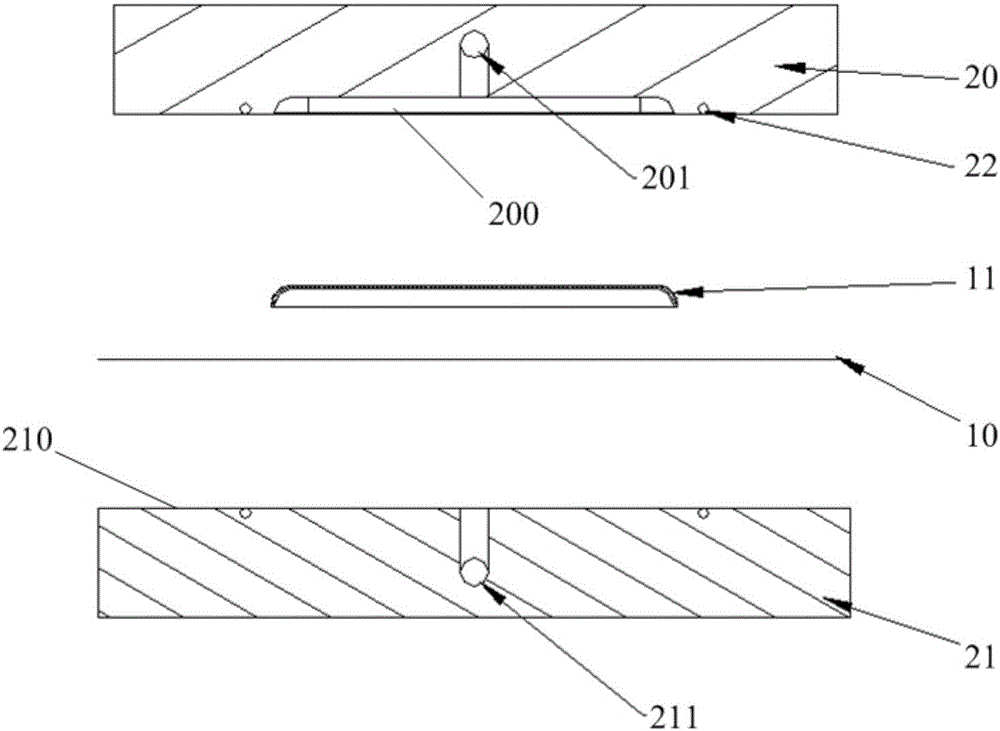

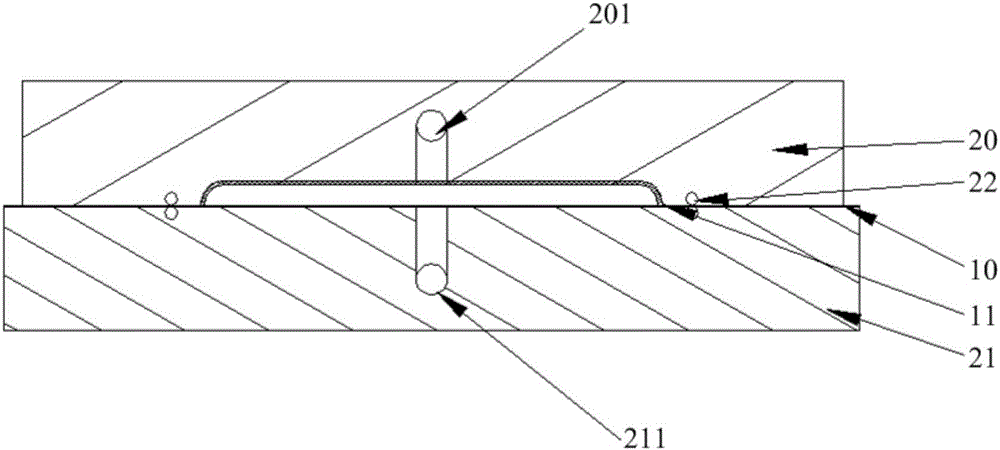

[0037] Such as figure 1 and figure 2 As shown, the embodiment of the present application provides a film lamination mold, which is used to attach a film 10 to a glass plate 11, where the film 10 may be a protective film, a decorative film or a film with other functions. The film sticking mold specifically includes an upper mold, a lower mold and a force medium filling device (not shown in the figure), the upper mold and the lower mold are arranged oppositely, and the two can move relative to each other, and one of the two is installed on a glass plate mold 20, the other is a film positioning mold 21, and the glass plate mounting mold 20 is provided with an installation groove 200 for accommodating the glass plate 11. The film positioning mold 21 has a film positioning surface 210 and a hole that passes through to the film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com