Conveying arrangement device after cutting for packaging bags

A technology for sorting devices and packaging bags, which is applied in the directions of packaging, transportation and packaging, and bag making operations. too messy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

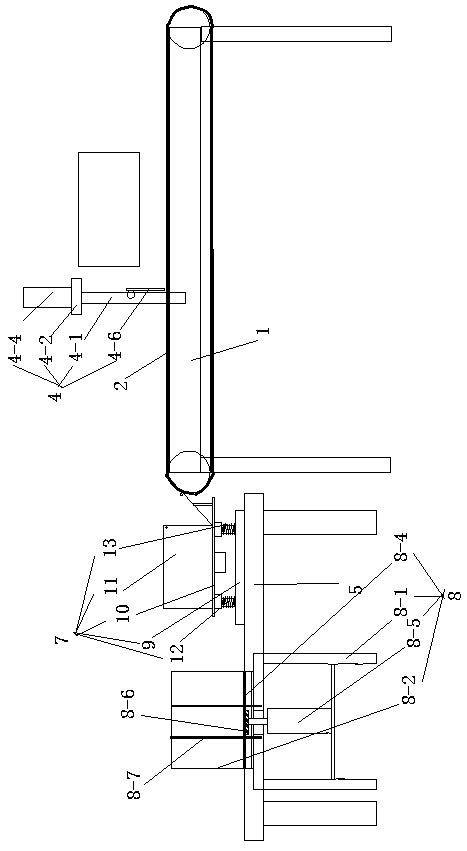

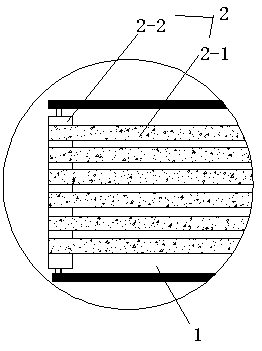

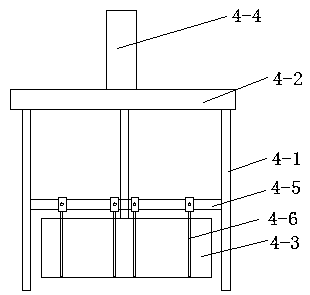

[0022] See attached picture.

[0023] A conveying and sorting device after packaging bags are cut, including a material receiving platform 1 erected under the cutting machine, characterized in that: the material receiving platform 1 is distributed with a circular conveyor belt arranged along the length direction of the material receiving platform 2. The upper end surface of the circulating conveyor belt 2 is close to the material receiving platform 1, and the position above the material receiving platform 1 close to the cutting machine is provided with a packaging bag blanking limit mechanism 4. The discharge end frame is provided with a finishing platform 5, and the discharge end frame of the circular conveyor belt 2 on the said finishing platform 5 is provided with a vibrating type material receiving and finishing mechanism 7, and one side of the said finishing platform 5 is provided with a material receiving frame discharging mechanism 8 , the material receiving frame disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com