PERC solar cell production line

A solar cell and production line technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as ineffective control of production costs, inability to meet the needs of high-efficiency battery technology, insufficient automation and intelligence, and reduce manual participation and production costs, improve the degree of automation and production efficiency, and improve the effect of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

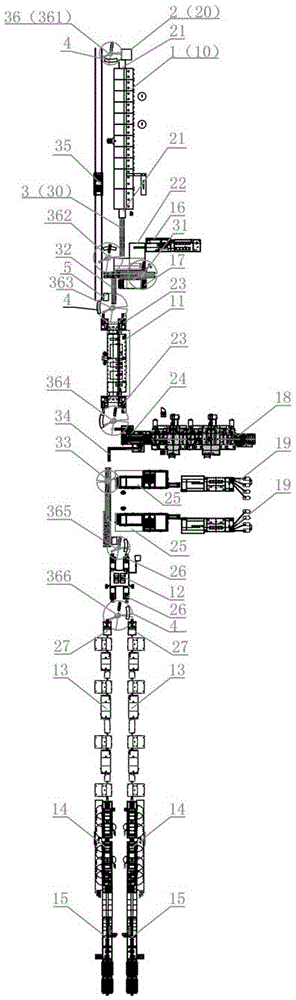

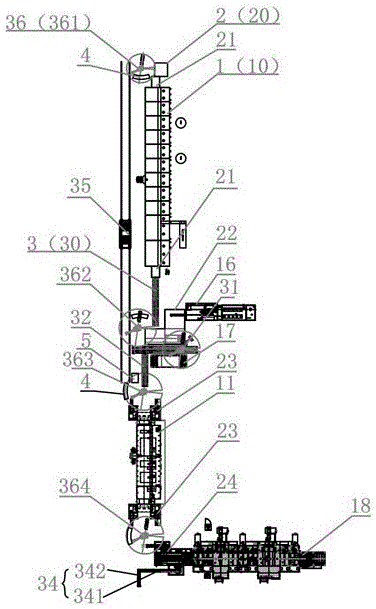

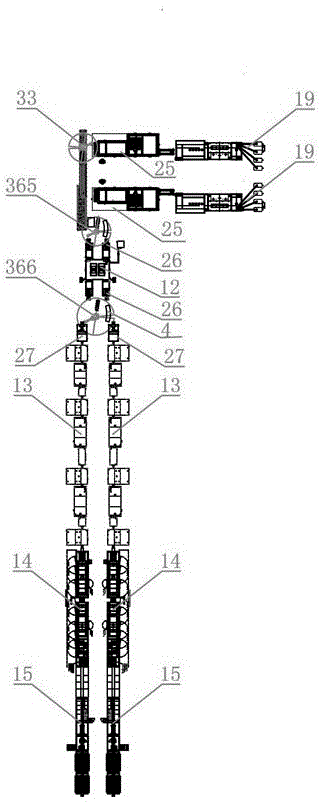

[0021] Such as Figure 1 to Figure 3 As shown, the PERC solar cell production line in this embodiment includes process equipment 1, automatic loading and unloading equipment 2 for material flow within the process, automatic transmission equipment 3 for material flow between processes and materials for carrying flower basket (not shown in the figure), the process equipment 1 includes a texturing machine 10, a cleaning and etching machine 11, a laser ablation machine 12, a screen printing machine 13, a sintering furnace 14, and a testing and sorting machine 15 arranged in sequence along the longitudinal direction, And the diffusion furnace 16, the square resistance detector 17, the back passivation flat plate PECVD18 and the tubular PECVD19 arranged horizontally, the diffusion furnace 16 is arranged at the downstream of the texturing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com