Automatic tin soldering device

An automatic welding and driving device technology, applied in auxiliary devices, welding equipment, soldering irons, etc., can solve problems such as uneven product performance, low production efficiency, and insufficient stability, so as to save production costs and improve solder quality , Improve the effect of soldering tin quality and soldering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

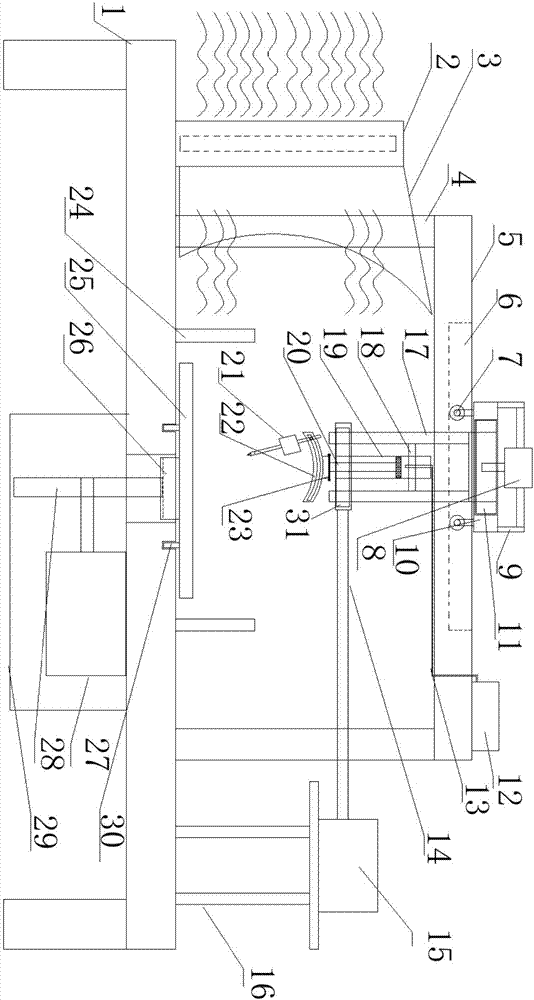

[0013] Such as figure 1 As shown, an automatic soldering device includes an operating table 1 and a driving device, an adjusting device, and a soldering device located on the operating table 1. The operating table 1 is provided with a strip groove and two parallel grooves The slide rail 30, the bottom end of the strip-shaped groove has a through groove communicating with the lower end of the console 1, the solder plate 25 is slidably installed in the slide rail 30, and the lower end surface of the solder plate 25 is provided with parallel The protrusion on the slide rail is welded with a toothed rack 26 facing downwards on the protrusion, and the driving device includes a rotating motor one 27 and a gear 28 installed on the first driving end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com