Circular capacitor production machine

A technology for producing machines and capacitors, applied in capacitors, capacitor manufacturing, circuits, etc., can solve the problems of low precision, low welding precision, and weak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

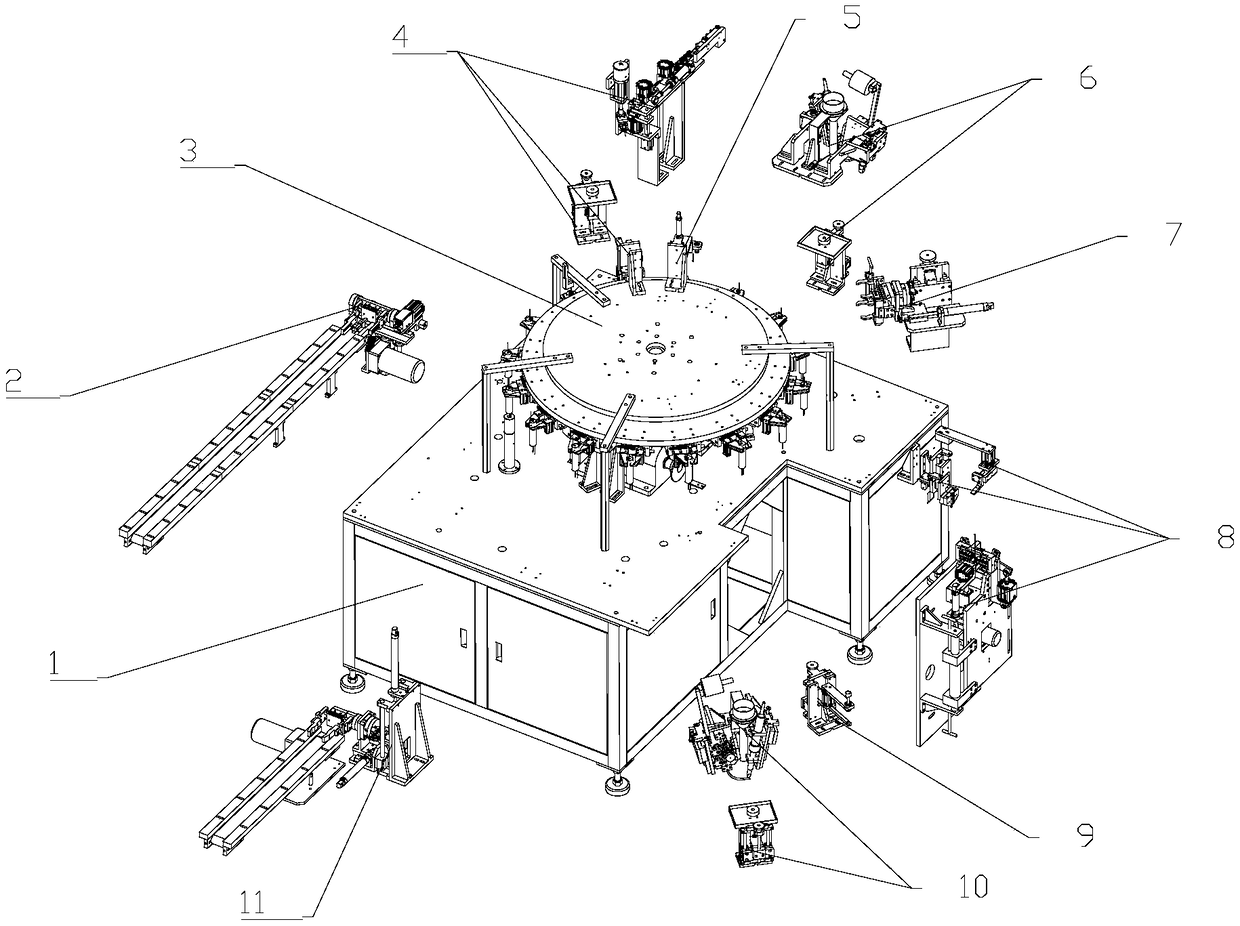

[0070] Such as figure 1 As shown, a circular capacitor production machine includes a frame 1 and a capacitor feeding device 2 installed on the frame 1, a turntable transfer device 3, a tinning wire spot welding device 4, a tinning wire detection device 5, A tinned wire welding device 6 , a capacitor flipping device 7 , a colloidal wire spot welding device 8 , a colloidal wire detection device 9 , a colloidal wire welding device 10 and a finished product unloading device 11 .

[0071] The turntable transfer device 3 is installed on the central part of the frame 1 to drive the workpiece to rotate; along the direction of material movement on the turntable transfer device 3, the capacitive feeding device 2, the tinned line spot welding device 4, and the tinned line detection Device 5, tinned wire welding device 6, capacitor flipping device 7, colloidal wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com