Filter and its coil arrangement frame

A wire management frame and filter technology, applied in the direction of transformer/inductor coil/winding/connection, inductor, fixed inductor, etc., can solve the problems of labor-consuming and time-consuming, poor withstand voltage characteristics, and low process yield. , to avoid skew or different lengths, improve the quality and efficiency of solder, and reduce the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

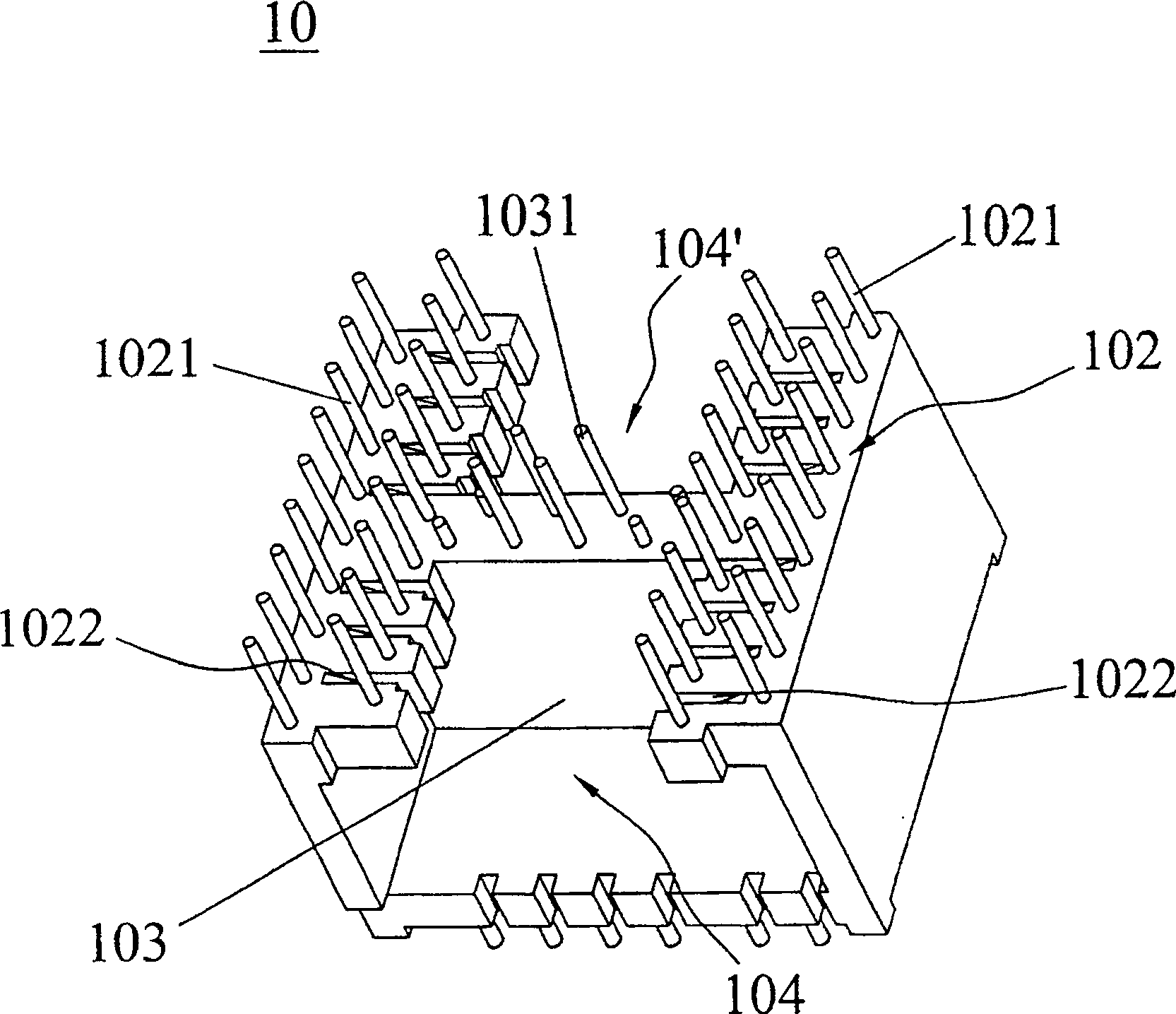

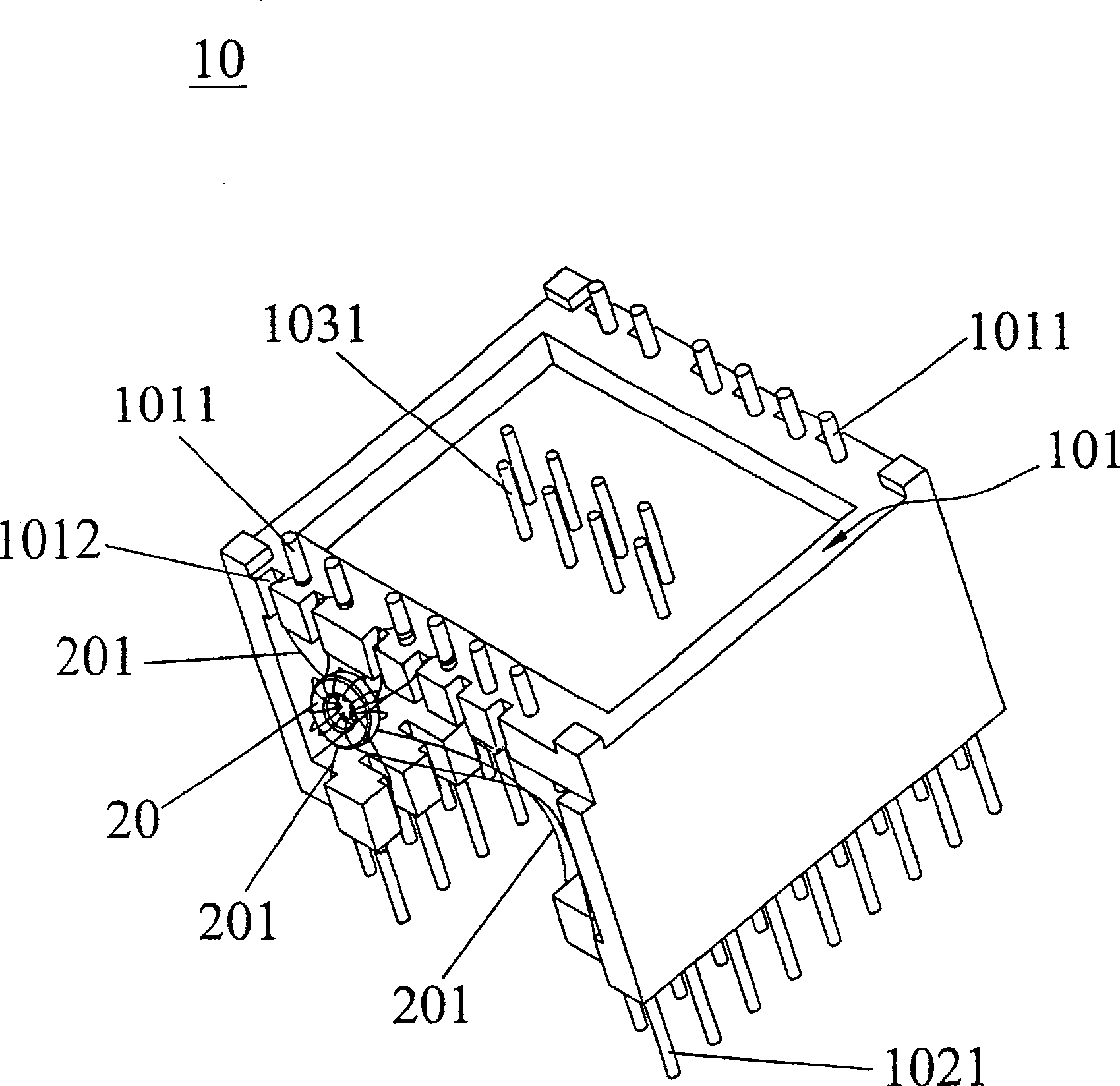

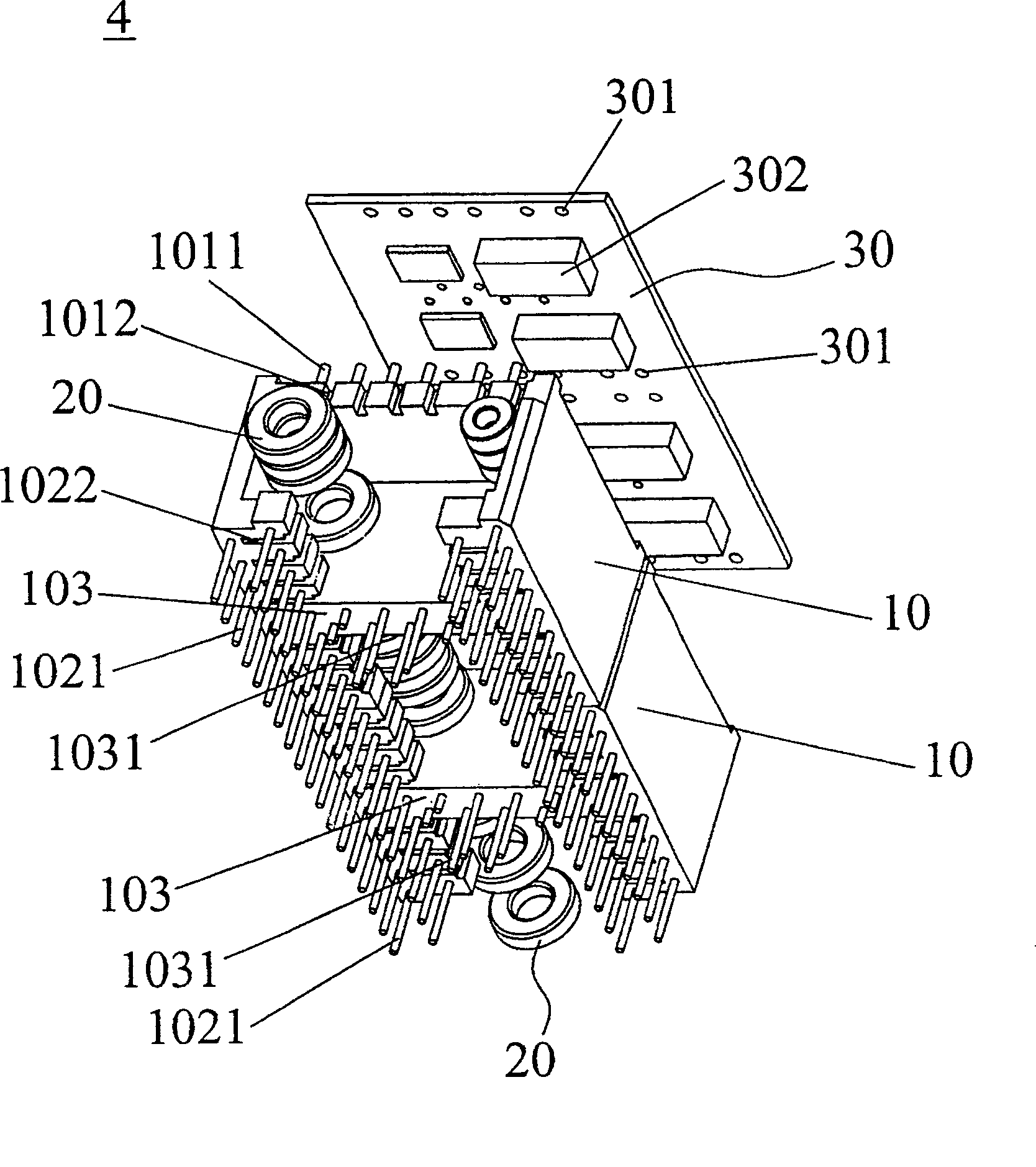

[0032] Please also see figure 1 and figure 2 , The coil management frame 10 of the present invention has a first side 101 and a second side 102 , and the first side 101 and the second side 102 are opposite to each other. The first side 101 of the wire management frame 10 is provided with a plurality of first pins 1011 , and the second side 102 is provided with a plurality of second pins 1021 . The wire management frame includes an electrical connection portion 103, which extends from the first side 101 to the second side 102, and divides the wire management frame 10 into two accommodating spaces 104, 104'. The electrical connecting portion 103 has a plurality of connecting pins 1031 inside, and the connecting pins 1031 pass through and protrude from the first side 101 and the second side 102 of the wire management frame 10 .

[0033] The first side 101 and the second side 102 of the wire management frame 10 also form multiple wire management grooves 1012, 1022 adjacent to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com