Semi-finished roast duck airing device

A technology for drying billets and roasting ducks, which is applied in the fields of freezing/cooling preservation of meat/fish, food preparation, food science, etc., to achieve the effects of uniform billet drying, convenient operation and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described by the following examples:

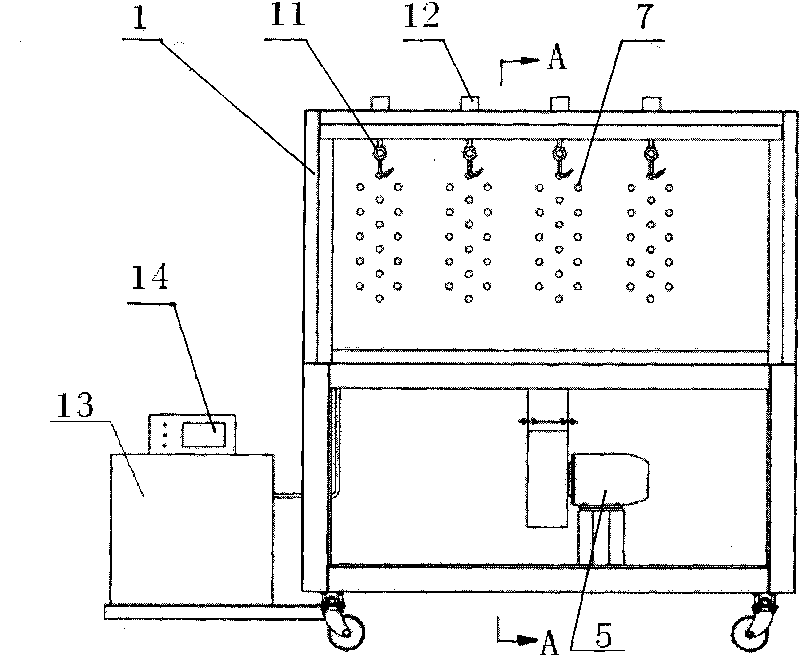

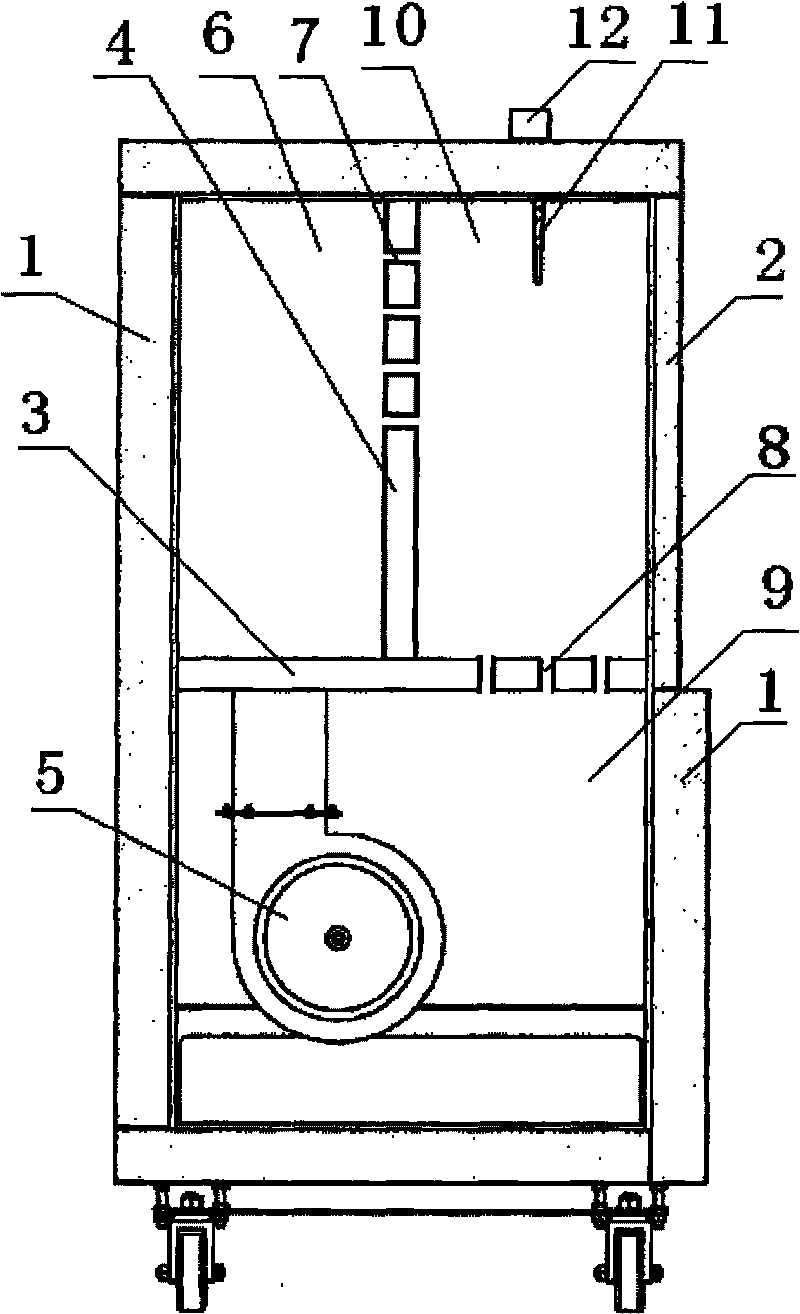

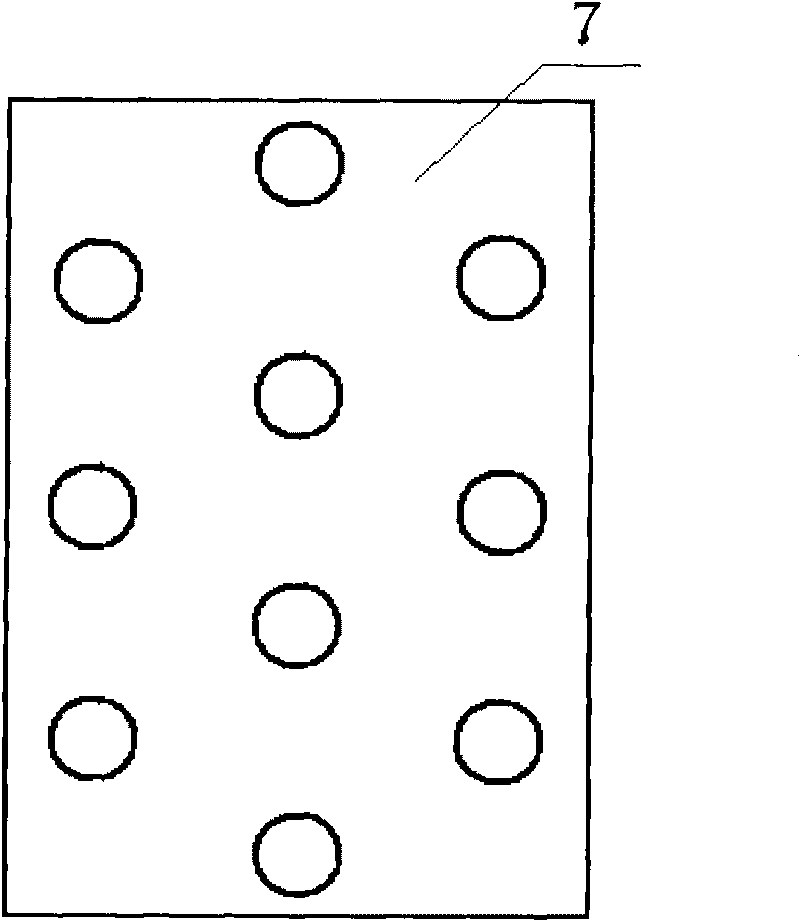

[0019] figure 1 It is a schematic diagram of the structure of the roast duck air-drying device. The roast duck air-drying device includes a box body, an air circulation system, a refrigeration system, a suspension system and a control system, such as figure 2 As shown, the box body is divided into an air distribution chamber 6, a billet drying chamber 10 and a return air chamber 9 by a middle partition 3 and an air distribution plate 4, and the retrieving door 2 is installed on the front of the billet drying chamber 10; a row of 4 suspension systems The duck blank hanging hook 11 is placed on the box top plate in the blank airing chamber 10, the duck blank hanging hook 11 is rotatably connected with the box body top plate, and the duck blank rotating motor 12 is coaxially connected with the duck bad hanging hook 11 on the box body top plate; The centrifugal fan 5 of the air circulation system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com