Coating covering device for cast product and manufacturing method

A technology for covering devices and processing products, which is applied to devices and coatings that apply liquid to surfaces, can solve problems such as increasing the manual consumption of painting time, achieve good paint coverage, increase the scope of application, and improve coating coverage. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

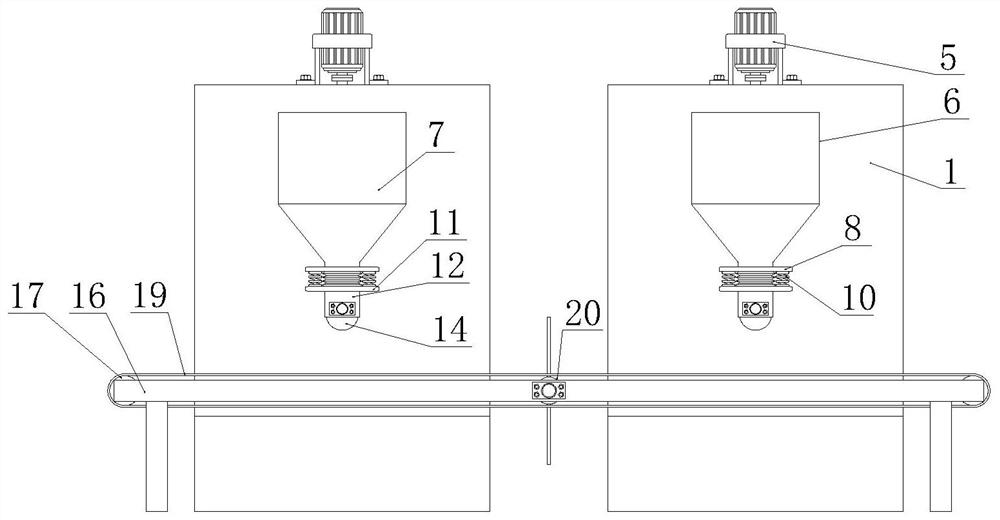

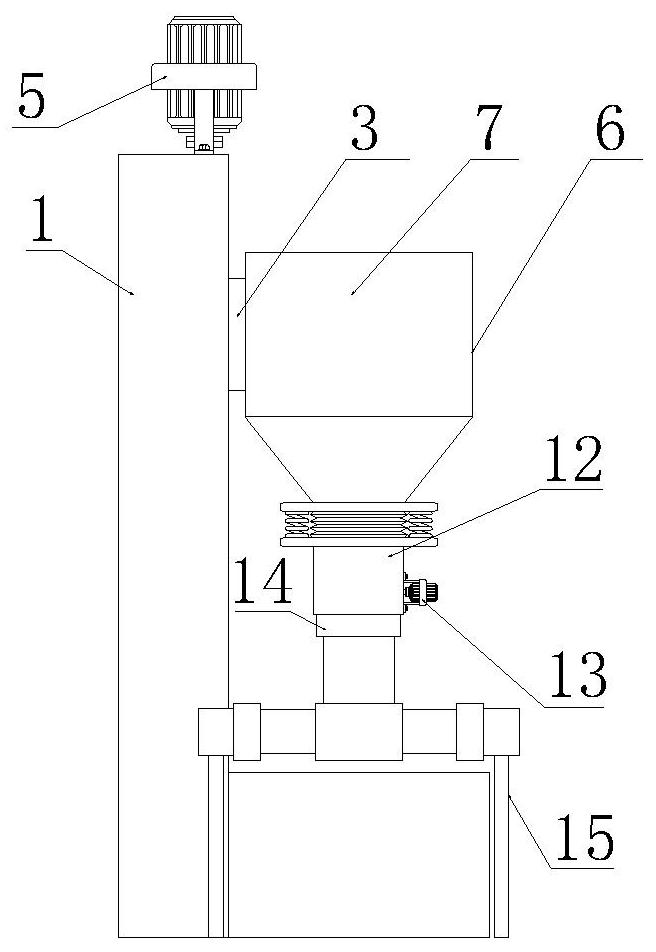

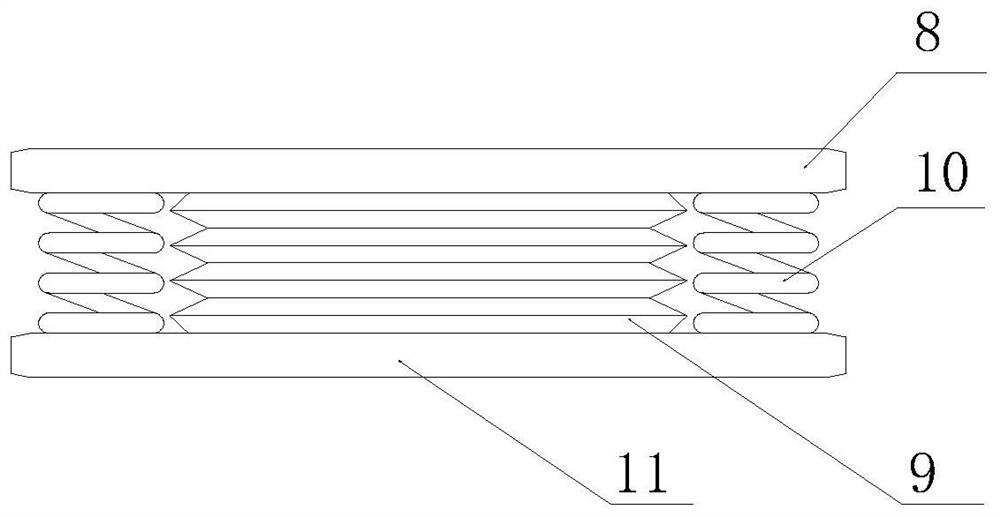

[0026] Such as Figure 1-6 As shown, the specific embodiment adopts the following technical solutions: a coating coating device for casting and processing products, including a lifting frame 1, two lifting frames 1 are provided, and the same side of the two lifting frames 1 is provided with Smearing mechanism 6, described smearing mechanism 6 comprises paint box 7, and the bottom of described paint box 7 is inverted trapezoid, and the below of described paint box 7 is provided with discharge pipe 12, and the inner wall bottom of described discharge pipe 12 is provided with Paint brush 14, the two ends of described paint brush 14 are rotatably connected with discharge pipe 12, and the below of two described smearing mechanisms 6 is provided with transmission mechanism 15, and described transmission mechanism 15 comprises frame 16, and described frame 16 There are two, two No. 1 transmission rollers 17 are arranged between the two ends of the two said frames 16, and the two No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com