Assembly welding device for axle housing

A technology for assembling device and axle housing, applied in auxiliary devices, welding equipment, transportation and packaging, etc., can solve the problems of heavy axle housing, displacement of two half-axle housings, insufficient tightness, etc., and achieve precise welding process, The effect of reducing errors and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

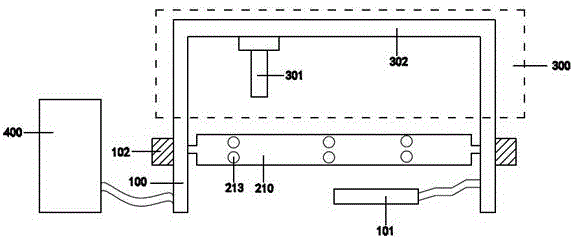

[0020] An axle housing assembly welding device, characterized in that it includes a support 100, an assembly device 200, a welding device 300, and an operation table 400;

[0021] The support 100 includes a first electric welder 101 and two rotating devices 102 .

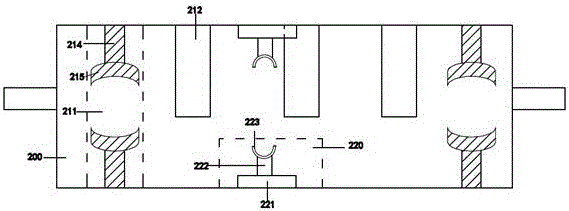

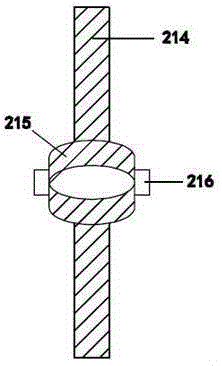

[0022] The assembly device 200 includes a hollow frame 210 and two pushing devices 220; each of the pushing devices 220 includes an air pump 221, a push rod 222, and a mold arm 223; the frame 210 includes two fixing devices 211, 6 There are two telescopic panels 212 and 6 holes 213 on each face, respectively, two telescopic panels 212 and three holes 213; each fixing device 211 includes two telescopic rods 214 and two arc-shaped Clip 215, 2 connecting pins 216.

[0023] The welding device 300 includes a movable and telescopic second electric welder 301 and a fixed rod 302 .

[0024] The first electric welder 101 is located on one side of the support 100 . The two ends of the frame 210 are framed in the support 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com