Device for auxiliary adjusting the cutting nozzle angle of cutting machine

A gas cutting machine and cutting nozzle technology, which is applied to the device field of the cutting nozzle angle, can solve the problems of the accuracy not meeting the requirements and the cutting efficiency being low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

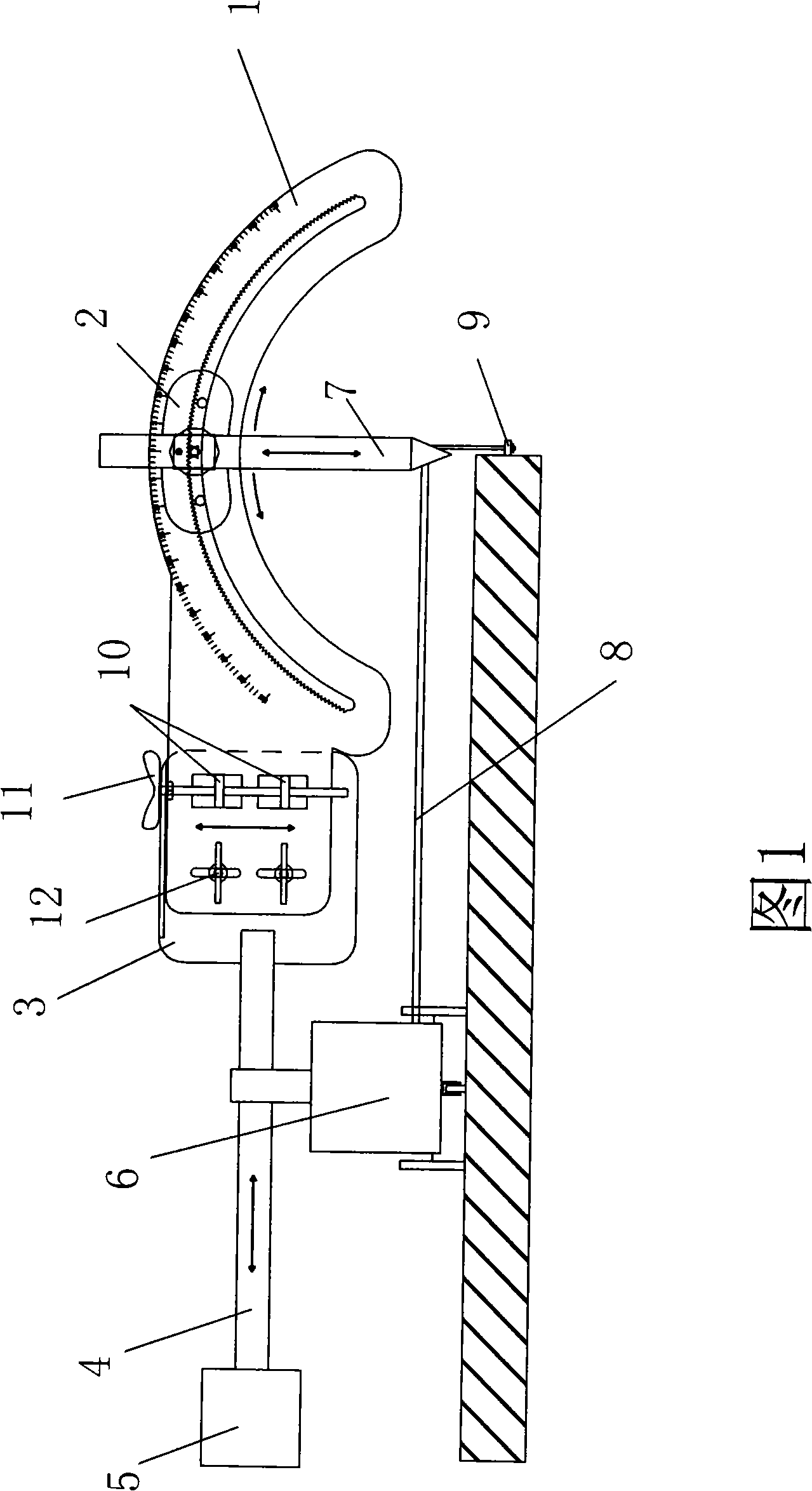

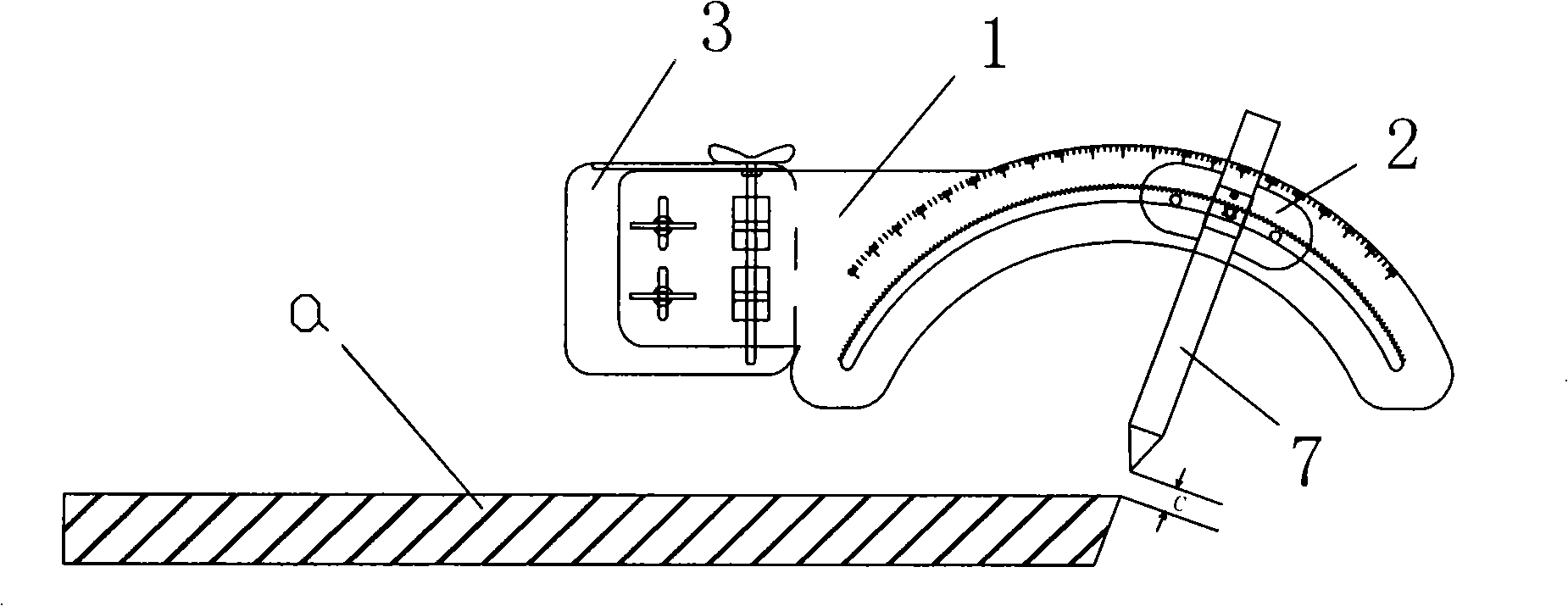

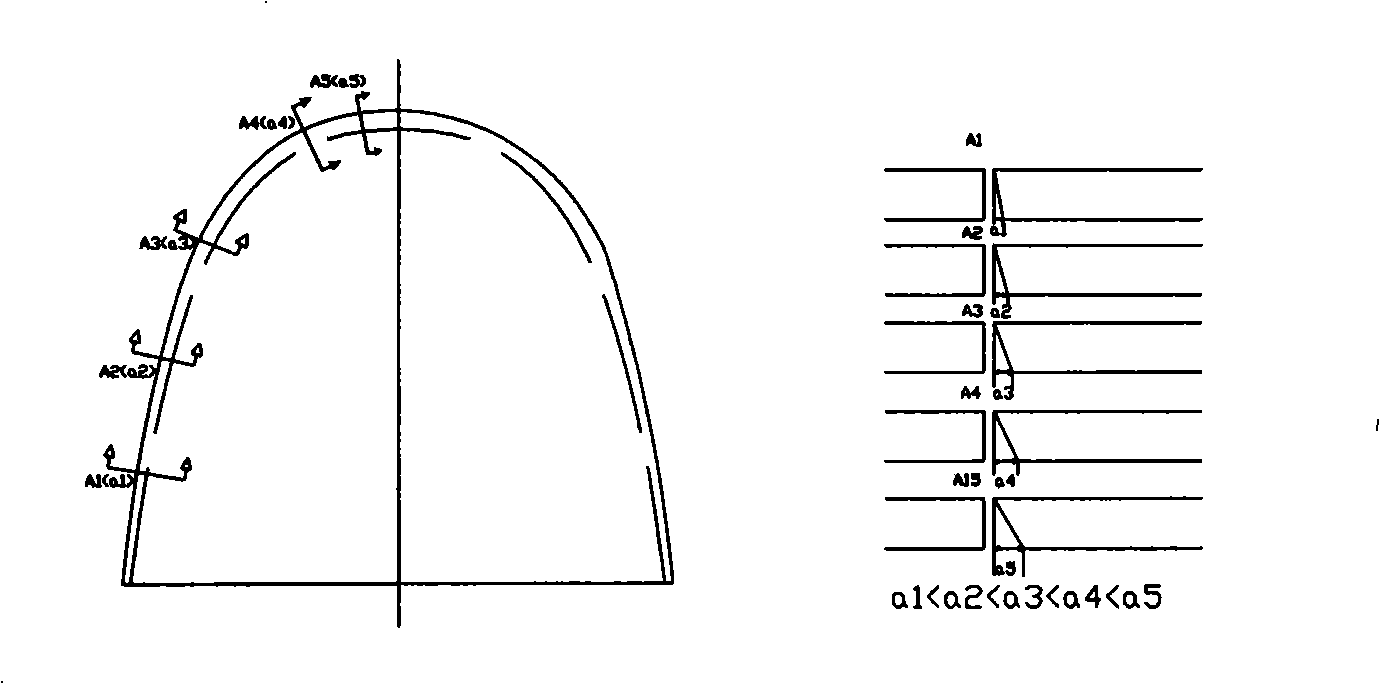

[0029] Taking arc-shaped bevel cutting as an example, the specific application of the device for assisting in adjusting the cutting nozzle angle of a gas cutting machine according to the present invention will be described in detail below.

[0030] When using the device of the present invention to assist in adjusting the angle of the cutting nozzle of a gas cutting machine and the gas cutting machine to cut the arc groove of a large plate, first place the trolley 6 on the upper surface of the plate a to be cut that has been scored, and then place the connecting rod 8 Extend to the side of the groove of the plate to be cut, and put the side wheel 9 against the side; then fix the cutting nozzle 7 of the gas cutting machine on the slider 2, so that the flame ejection hole at the front end of the cutting nozzle 7 is located on the scale floor 1 The center position of the upper arc-shaped plate, which is at the upper edge of the plate a to be cut; turn the adjusting bolt 11 on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com