Flat-opened bottom-hung window

A flat-opening, bottom-hanging, and flat-opening technology, which is applied in the direction of wing fan layout, can solve the problem of opening windows in a single way, and achieve the effect of saving indoor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

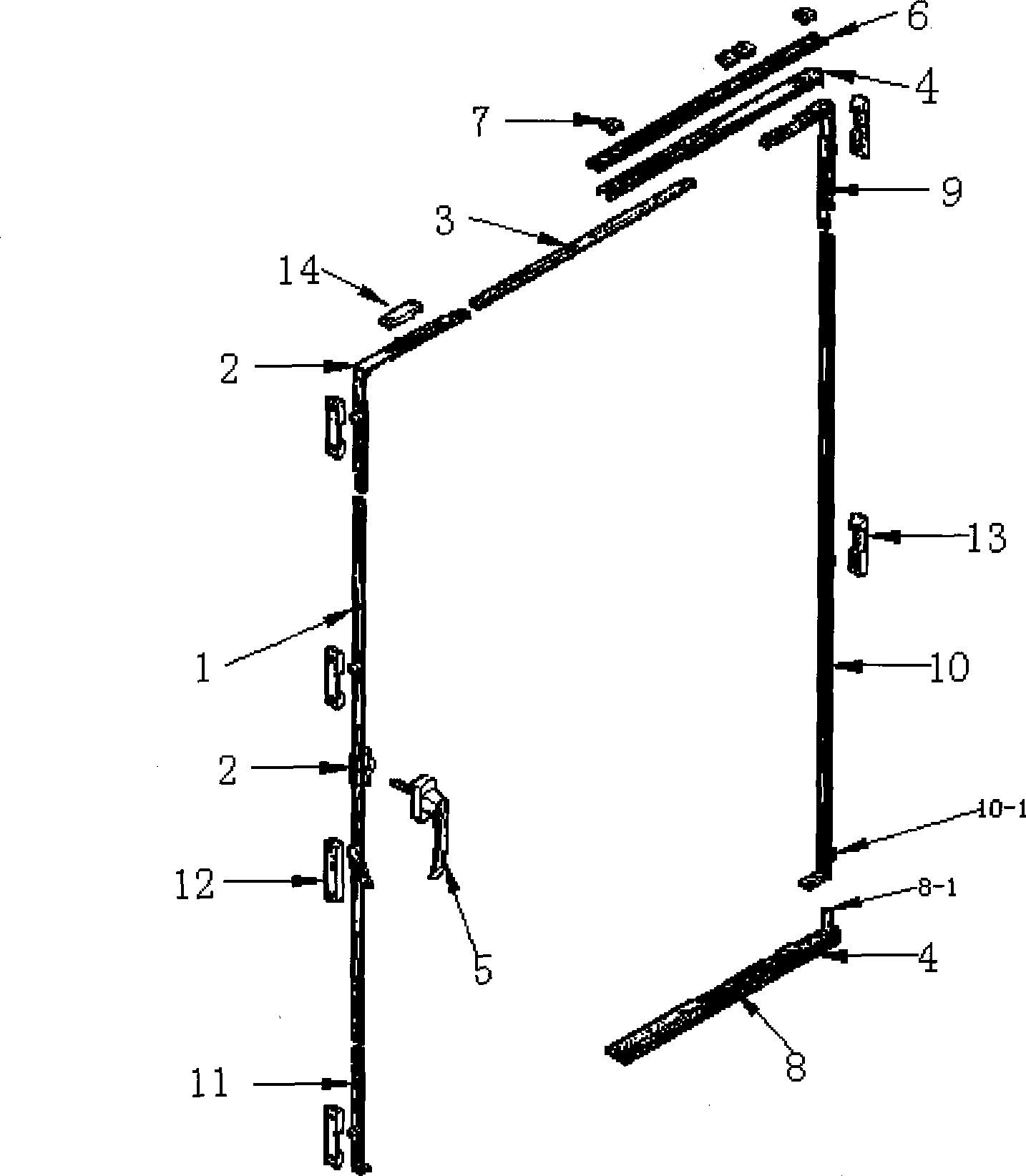

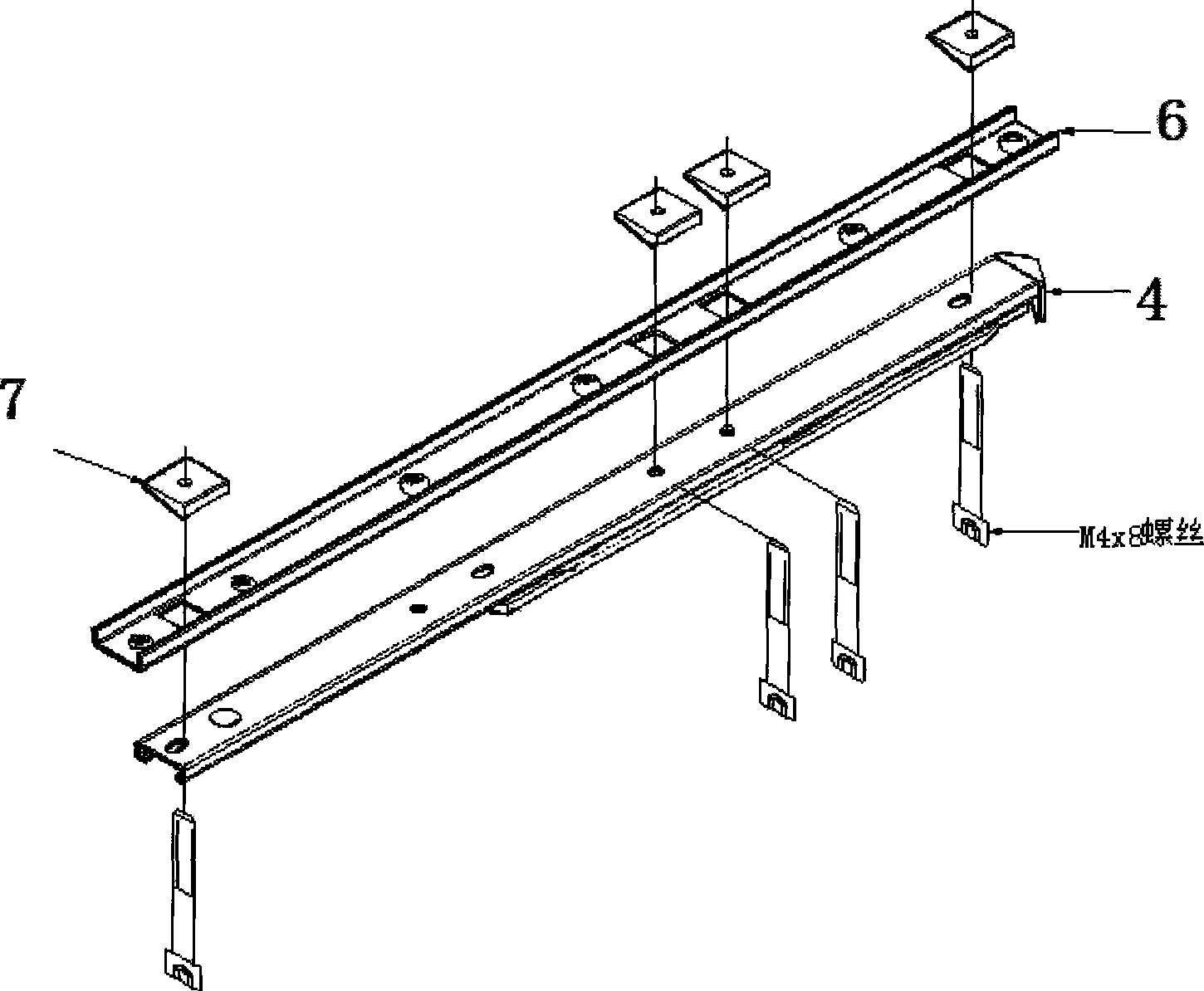

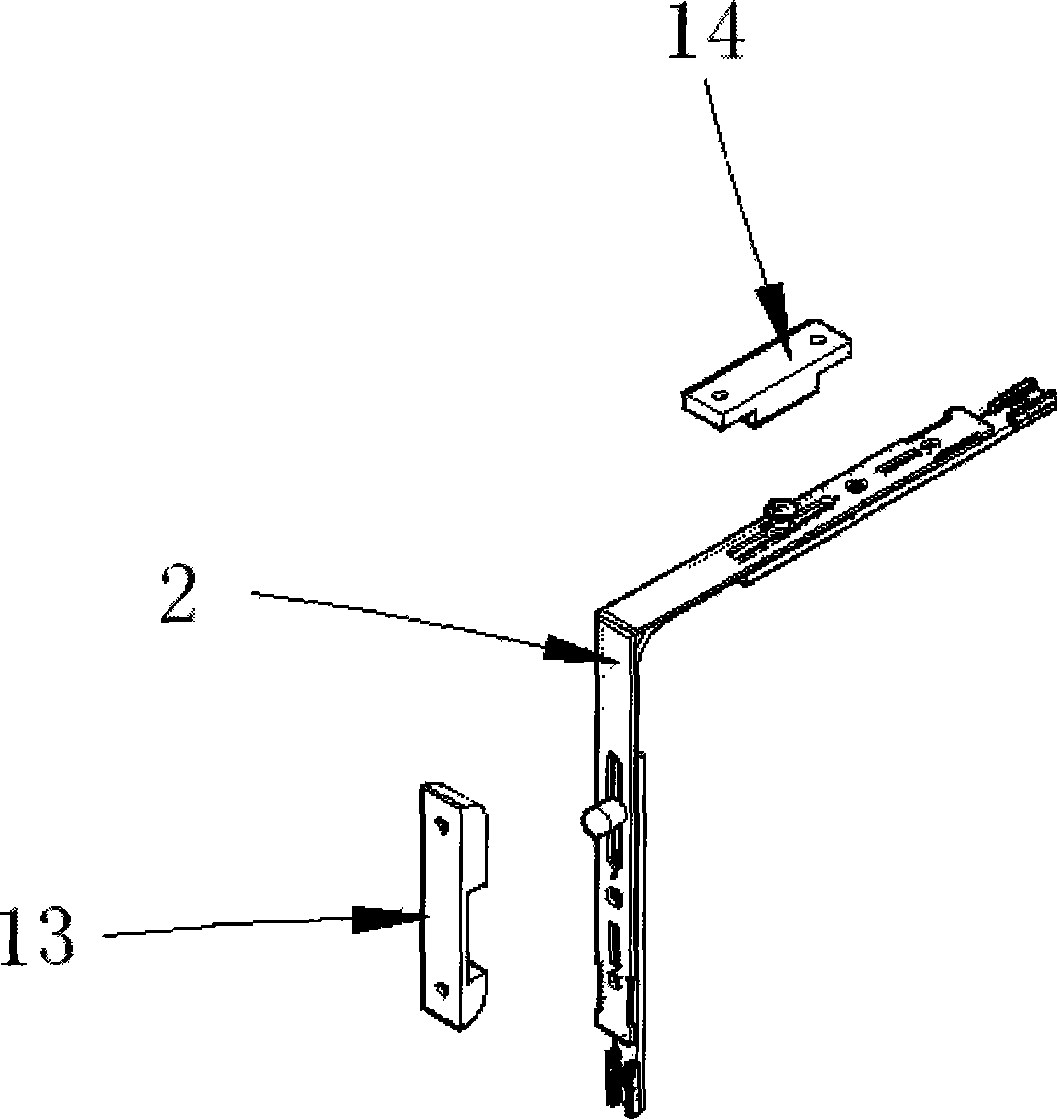

[0047] Such as Figure 1~6 As shown, it is a structural schematic diagram of the hardware mechanism of a casement and bottom-hung window of the present invention. The angle drive type A (2) is installed in the profile notch corresponding to the upper corner of the window sash; in the profile notch corresponding to the vertical side of the sash The transmission rod (1) is installed, and the transmission rod (1) is connected with the angle transmission type A (2) and the height connecting rod (11) using racks, and the gland plate is fixed on the fan at the joint with screws. Angle drive type B (9) is installed on the corner corresponding to the angle drive type A (2) on the upper part of the fan, and a horizontal connecting rod (3) is used between the angle drive type A (2) and the angle drive type B (9). With a rack connection, the gland plate at the joint is fixed on the fan with screws; a five-link sliding brace (4) is installed at the corresponding position on the upper end ...

Embodiment 2

[0049] Such as Figure 7 and 8 As shown, it is a schematic diagram of another hardware structure of a casement bottom-hung window of the present invention, and a schematic diagram of a hardware mechanism of a casement bottom-hung window of the present invention using a guide block. A guide block (21) is installed near the middle of one end, and a "U"-shaped guide groove (22) is installed at one end of the upper pole of the cable-stayed shear bar (8), and the cable-stayed shear bar (8) is installed on the lower edge of the window sash. In the notch of the profile, the five-link sliding brace (4) is installed on the lower edge of the window frame relative to the diagonally-stayed shear bar (8), and is used between the diagonally-stayed shear bar (8) and the five-link sliding brace (4). Riveted and rotatable; the oblique-stayed shear bar (8) is connected with the angle drive type A (2) by a rack, and the gland plate at the joint is fixed on the fan with screws; the guide block (...

Embodiment 3

[0051] Such as Figure 9 and 10 As shown, it is a schematic diagram of another hardware structure of a casement bottom-hung window of the present invention, and a schematic diagram of a hardware mechanism of a casement bottom-hung window of the present invention using corner hinge sleeves. A corner hinge cover (16) is installed, and a corner hinge seat (15) is installed at the position corresponding to the corner hinge cover (16) on the outside of the window frame, and the corner hinge cover (16) and the corner hinge seat (15) Use nut (17) to fasten after mutually assembling; That is, nut (17) can adjust window sash up and down, and corner hinge seat (15) can adjust window sash left and right. A diagonally-stayed shear bar (8) is installed in the profile notch under the window sash; a guide block (21) is installed near the middle of an end of the lower shear bar (8); A "U"-shaped guide groove (22) is installed at one end of the upper layer rod, and one end of the obliquely-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com