Lifting appliance for assembling heavy forklift tire

A technology for forklift tires and reloading is applied in the field of vehicle tire assembly spreaders and spreaders for assembling and reloading forklift tires, which can solve problems such as inability to meet online mass production requirements, non-compliance with assembly operation specifications, and inability to guarantee assembly quality. , to achieve the effect of improving appearance quality, saving manpower and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

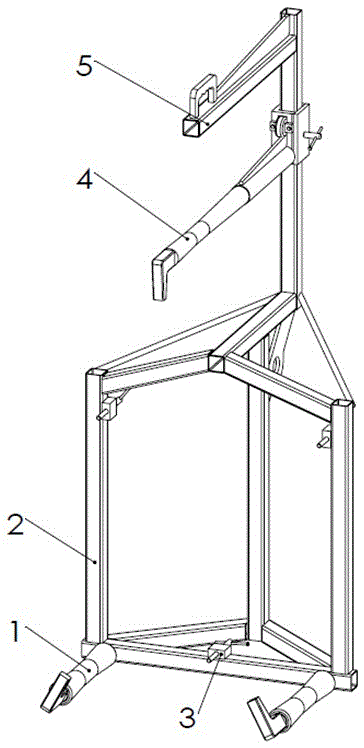

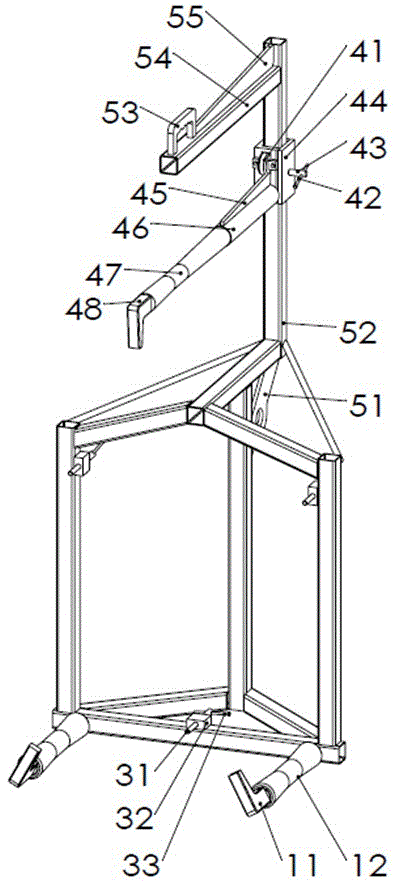

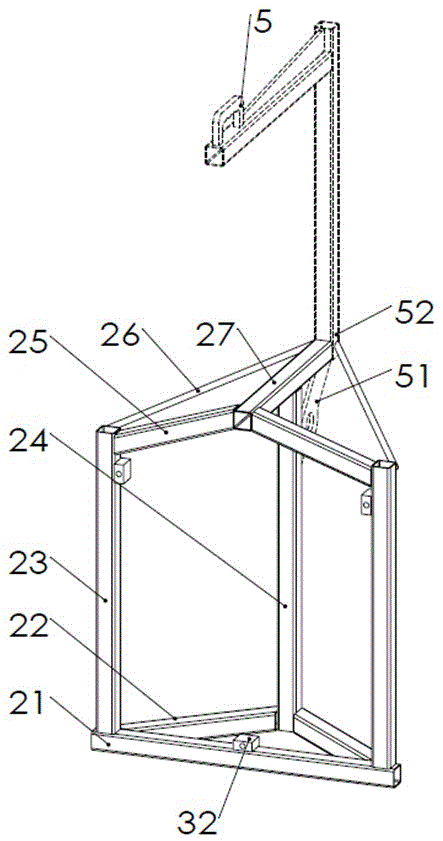

[0037] see figure 1 , figure 2 , image 3 , a spreader for assembling heavy forklift tires, including a pair of idler roller assemblies 1, a main frame 2, three adjustment mechanisms 3, a pressure roller mechanism 4, and a suspension beam mechanism 5; the main frame 2 is three Prismatic; the pair of roller assemblies 1 are symmetrically arranged at the bottom of one side of the main frame 2; the three adjustment mechanisms 3 are respectively arranged on three sides of one side of the main frame 2, and the One side is perpendicular to a pair of idler roller assemblies 1; the suspension beam mechanism 5 is in the shape of an inverted L-shaped rod, one end of its vertical side is fixedly connected to the top of the main frame 2, and its horizontal side is parallel to the top surface of the main frame 2 The pressure roller mechanism 4 is in the shape of a straight rod, one end of which is movably connected to the suspension beam mechanism 5, and the other end is in a cantilever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com