Sheet metal processing device

A processing equipment and sheet metal technology, which is applied in the field of sheet metal processing equipment, can solve problems such as cost-effective workers, reduced steel plate quality, and damaged steel plate surface, and achieve the effects of stable center of gravity, low labor intensity, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

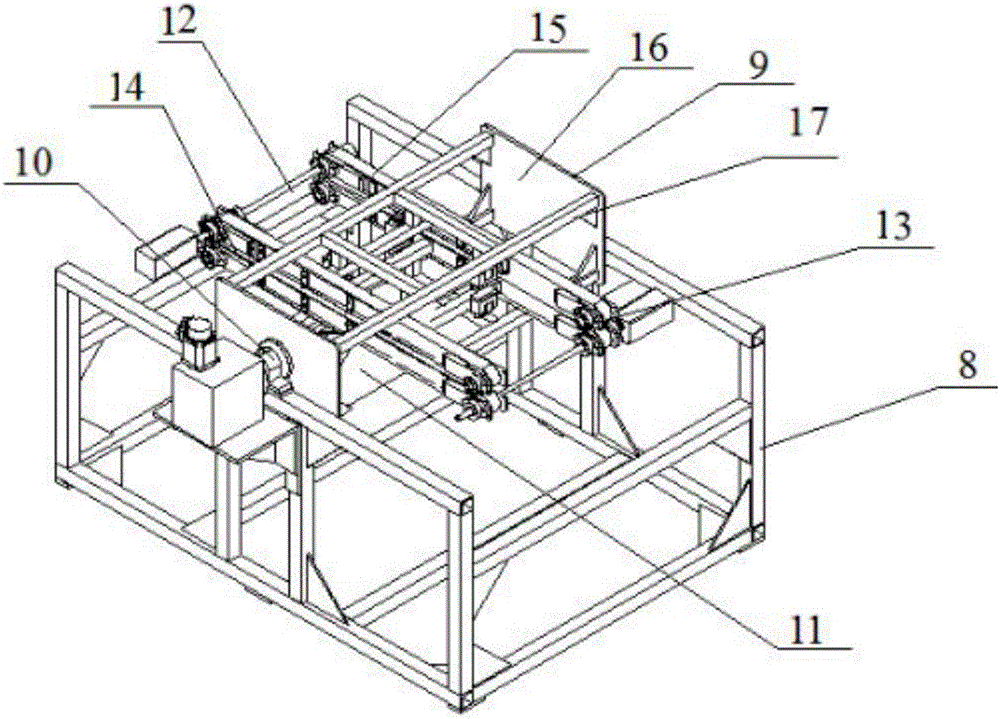

[0024] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

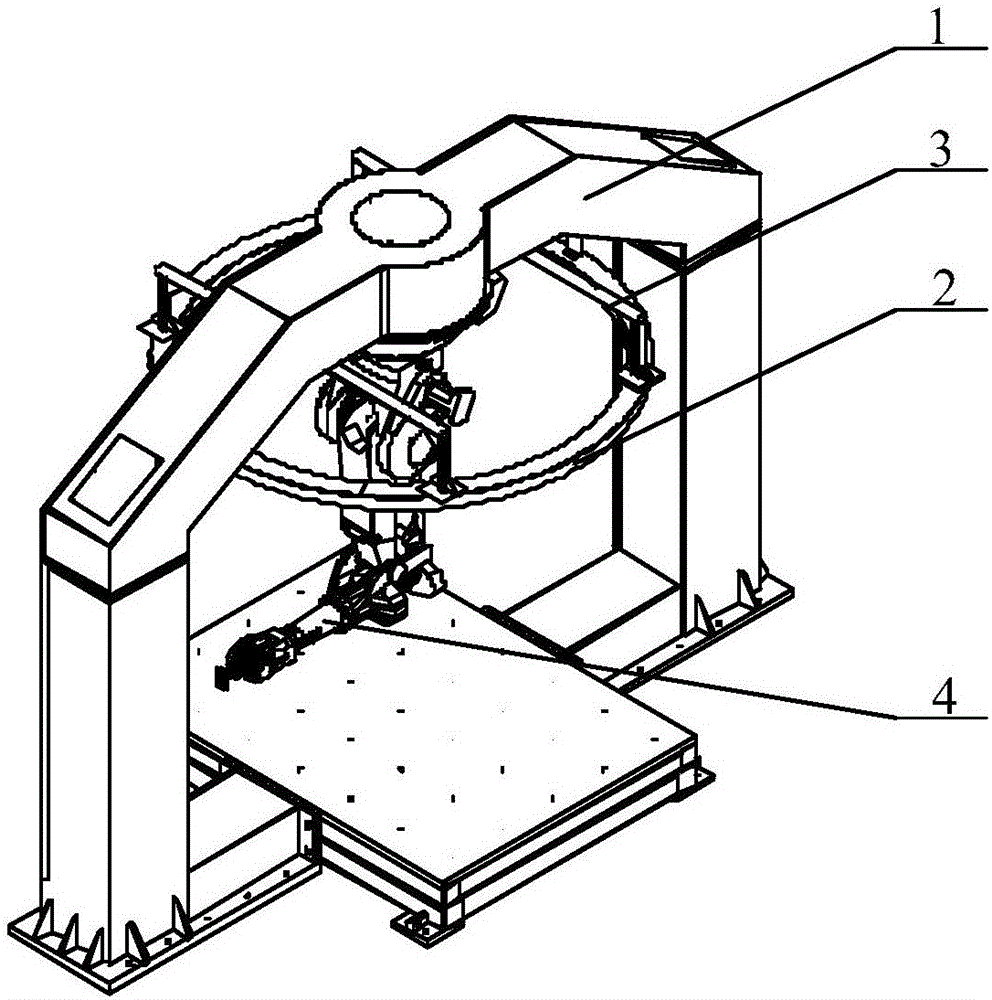

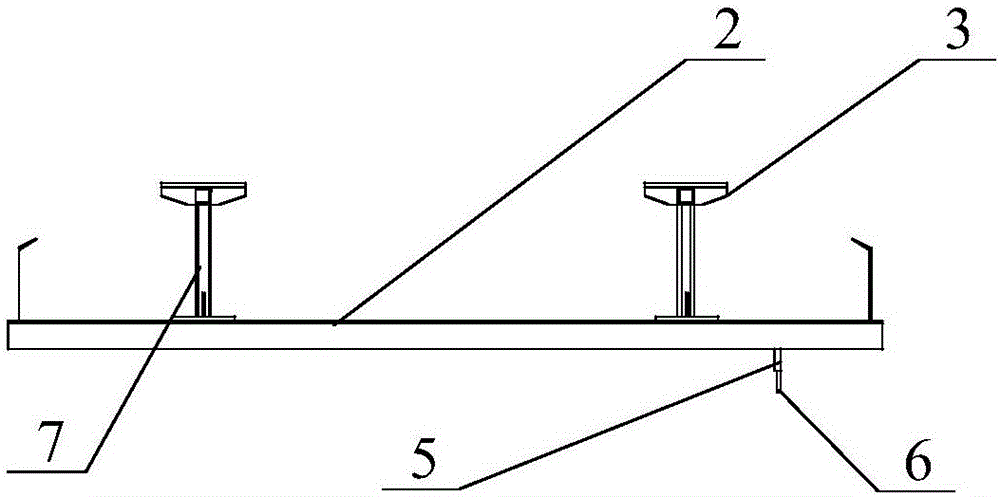

[0025] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a sheet metal processing equipment, including a loading and unloading mechanism, a laser cutting mechanism, a turning mechanism, a grinding mechanism, a conveying mechanism, and a cleaning and drying mechanism connected in sequence. The laser cutting mechanism includes a gantry beam 1 And the robot 4, the robot 4 is fixed on the gantry beam 1, a circular track 2 is arranged under the gantry beam 1, a plurality of sliding assemblies 5 are arranged at the bottom of the circular track 2, and a tension balancer 6 is arranged at the bottom of the sliding assembly 5, The tension balancer 6 includes a telescopic mechanism, and a telescopic cable is arranged inside the telescopic mechanism, and the telescopic cable is connected to the robot 4 .

[0026] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com