Novel automated sand blasting and nickel plating machine

A technology of nickel plating machine and sandblasting, which is applied in the direction of fusion spraying, abrasive spraying machine tools, sputtering plating, etc., can solve the problems of increasing cost and labor, and achieve the effect of material saving, uniform sandblasting and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

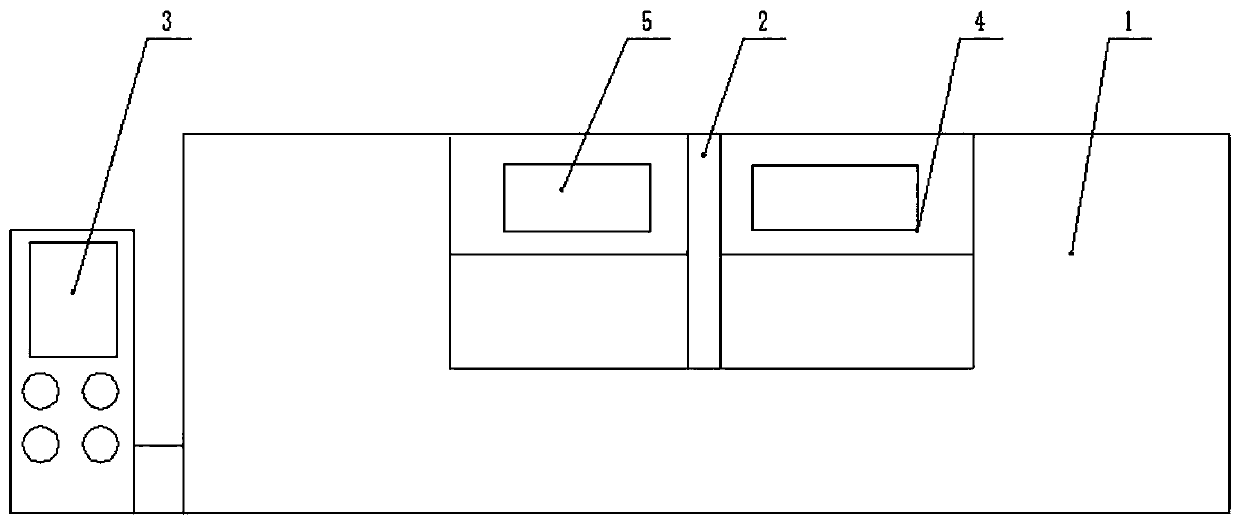

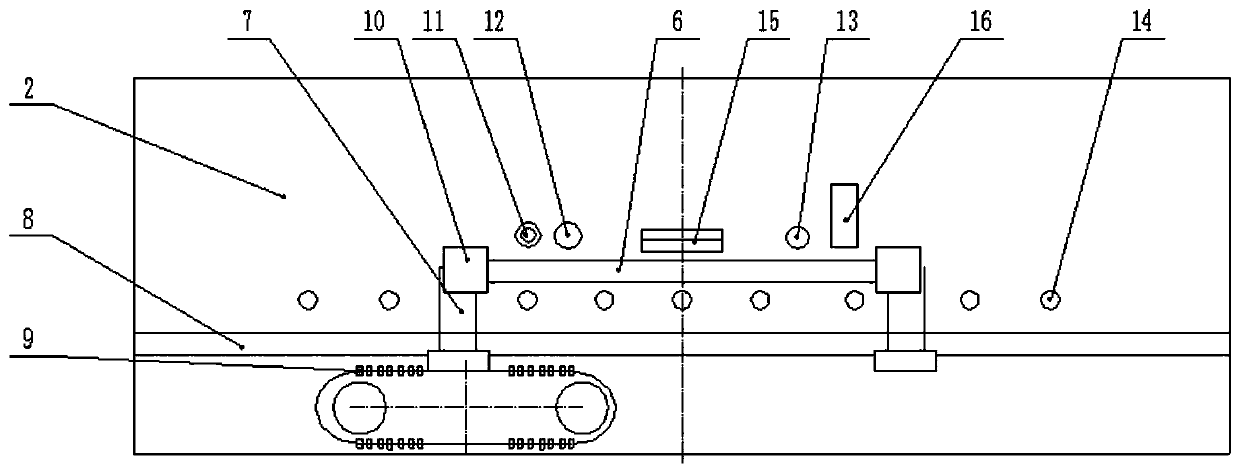

[0013] In the figure: including sand blasting nickel plating machine main body 1, spraying bin 2, control cabinet 3, bin door 4, observation window 5, base pipe 6, base pipe fixing frame 7, running track 8, transmission device 9, rotary joint 10 , sandblasting port 11, purge port 12, nickel-plating arc torch 13, dust removal port 14, grinding device 15, thickness detector 16, described sandblasting and nickel-plating machine main body 1 includes spraying chamber 2 and control cabinet 3, so The surface of the spraying cabin 2 is provided with two doors 4 that can be slid and opened to both sides, and two base pipe fixing frames 7 are arranged in the spraying booth 2, and a base tube is fixed between the two base tube fixing frames 7. 6. A transmission device 9 is provided under the base pipe fixing frame 7. The inner wall of the spraying chamber 2 is provided with a sandblasting port 11, a purge port 12, and a nickel-plated arc gun 13. A dust removal port 14 is also provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com