Ornament prototype surface sandblasting equipment

A surface sandblasting and processing equipment technology, applied in the field of sandblasting, can solve the problems of sandblasting, drop, poor uniformity, etc., to achieve the effect of expanding the support range, improving sandblasting efficiency, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

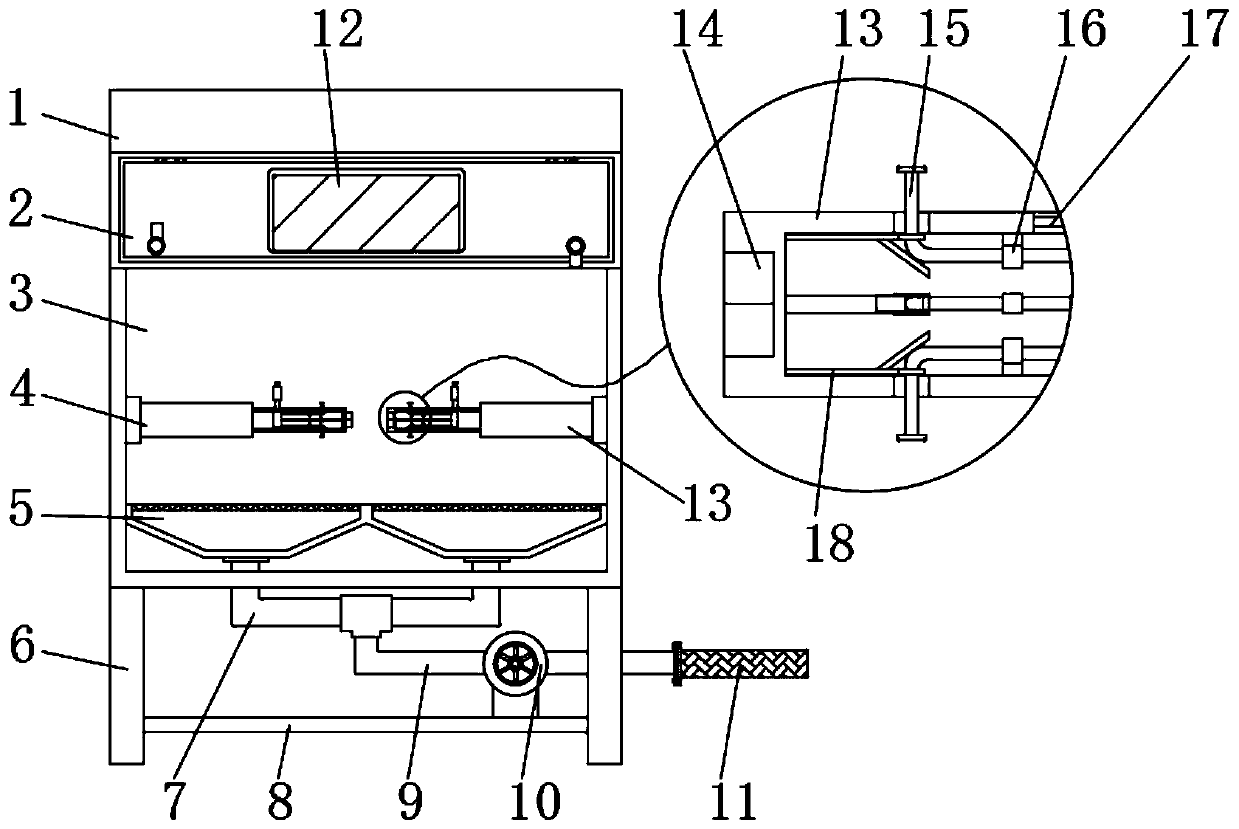

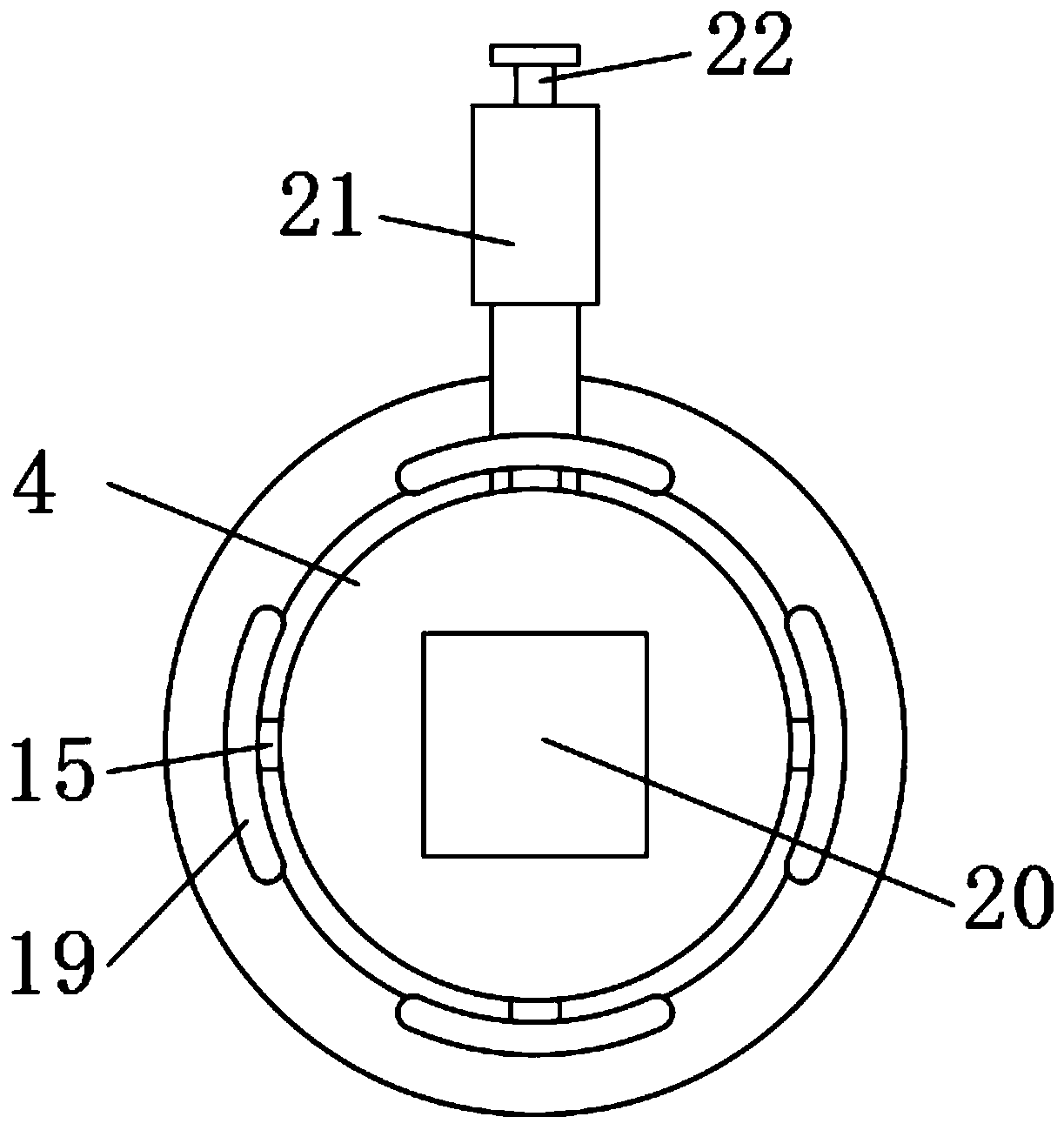

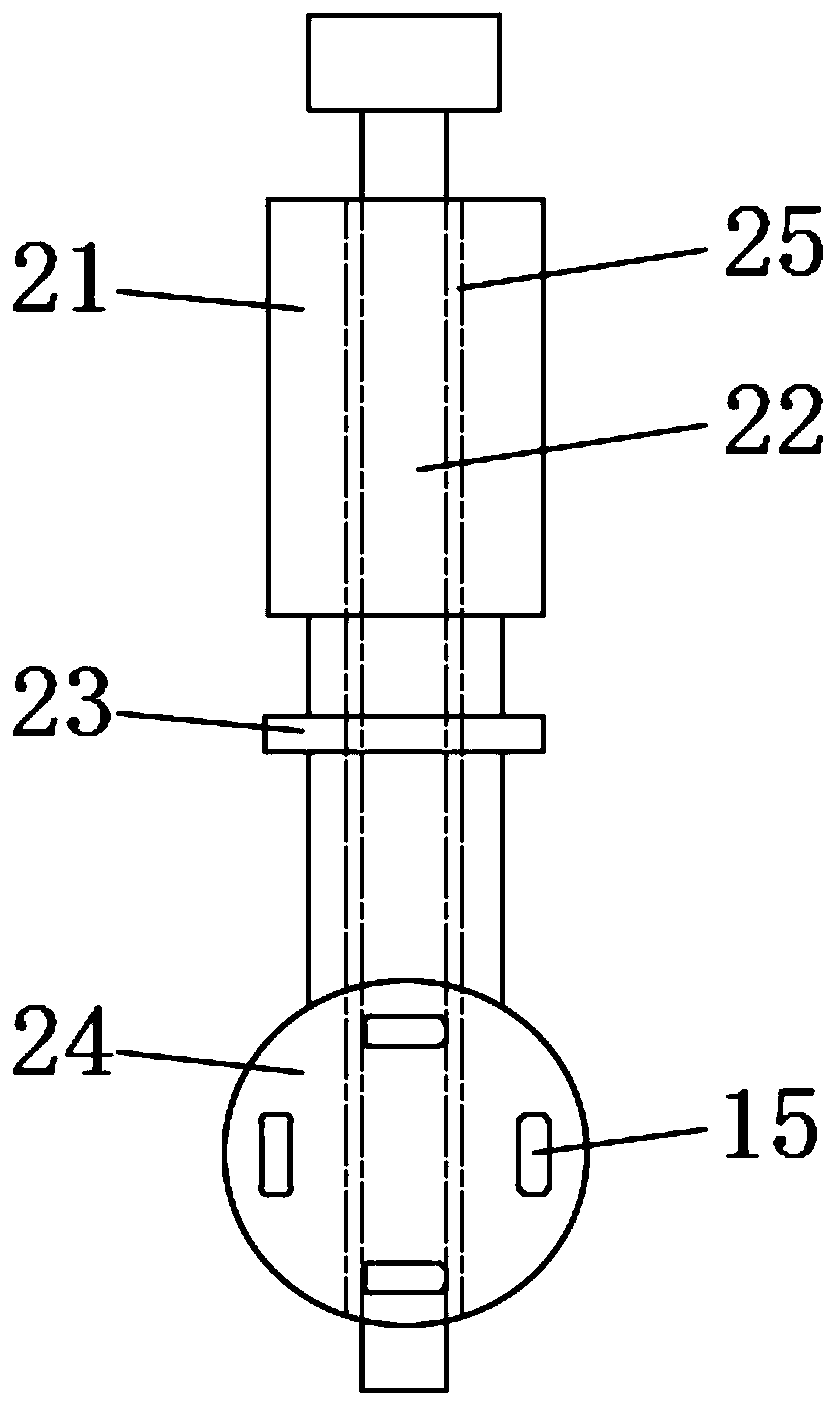

[0029] Embodiment one, with reference to figure 1 , figure 2 , image 3 and Figure 5, a kind of sandblasting treatment equipment for the prototype of jewelry, including a sandblasting machine 1, a sandblasting chamber 3 is opened inside the sandblasting machine 1, and the two sides of the inner wall of the sandblasting chamber 3 are welded with a first telescopic sleeve rod 4 and a second Two telescopic sleeve rods 13, the top surface of the first telescopic sleeve rod 4 and the second telescopic sleeve rod 13 one ends are all provided with chute 17, and the inside of chute 17 is connected with adjusting handle 21 by sliding ring 23, and adjusting handle 21 One end of the first telescopic sleeve rod 4 and the second telescopic sleeve rod 13 are welded with a support plate 24, and a plastic strip 15 is fixedly installed on the surface of the support plate 24, and a fixed sleeve 16 is sleeved on the surface of the plastic strip 15. And one side of the plastic strip 15 is lo...

Embodiment 2

[0030] Embodiment two, refer to figure 1 , the top surface of the sandblasting chamber 3 is located below the first telescopic sleeve rod 4 and the second telescopic sleeve rod 13, and two dust collection covers 5 are fixedly installed, and the top surfaces of the two dust collection covers 5 are welded with hollow mesh, The bottom surface of the sandblasting machine 1 is provided with a connecting pipe 7 of U-shaped structure, and both ends of the connecting pipe 7 run through the sandblasting machine 1 and connect with the bottom surfaces of the two dust collection hoods 5, and the middle position of the connecting pipe 7 passes through a tee Connected with dust suction pipe 9, and dust suction fan 10 is installed on the surface of dust suction pipe 9, and one end flange of dust suction pipe 9 is connected with filter bag 11, and the surface of sand blasting machine 1 is equipped with control panel, and the control panel The output end is electrically connected to the dust s...

Embodiment 3

[0031] Embodiment three, refer to figure 1 and Figure 4 , the top surface of the sandblasting machine 1 is hinged to install the outer door 2, and the edge of the inner surface of the outer door 2 is bonded with a sealing strip 26, and the edge of the outer door 2 is symmetrically welded with two bosses 27, And the surfaces of the two bosses 27 are all ring-connected with a rubber sleeve 28, and one end of the rubber sleeve 28 is provided with an abutment block, and the abutment block abuts against the shell of the sandblasting machine 1, and the middle position on the surface of the outer door 2 is opened. There is a visible window 12, when it is necessary to open the outward opening door 2, by rotating the rubber sleeve 28, one end of the rubber sleeve 28 is forced to break away from the state of abutting against the shell of the sandblasting machine 1, thereby facilitating opening the outward opening door 2 for taking or carrying out jewelry. The maintenance of the sandbl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com