Patents

Literature

37 results about "Jewelry ring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

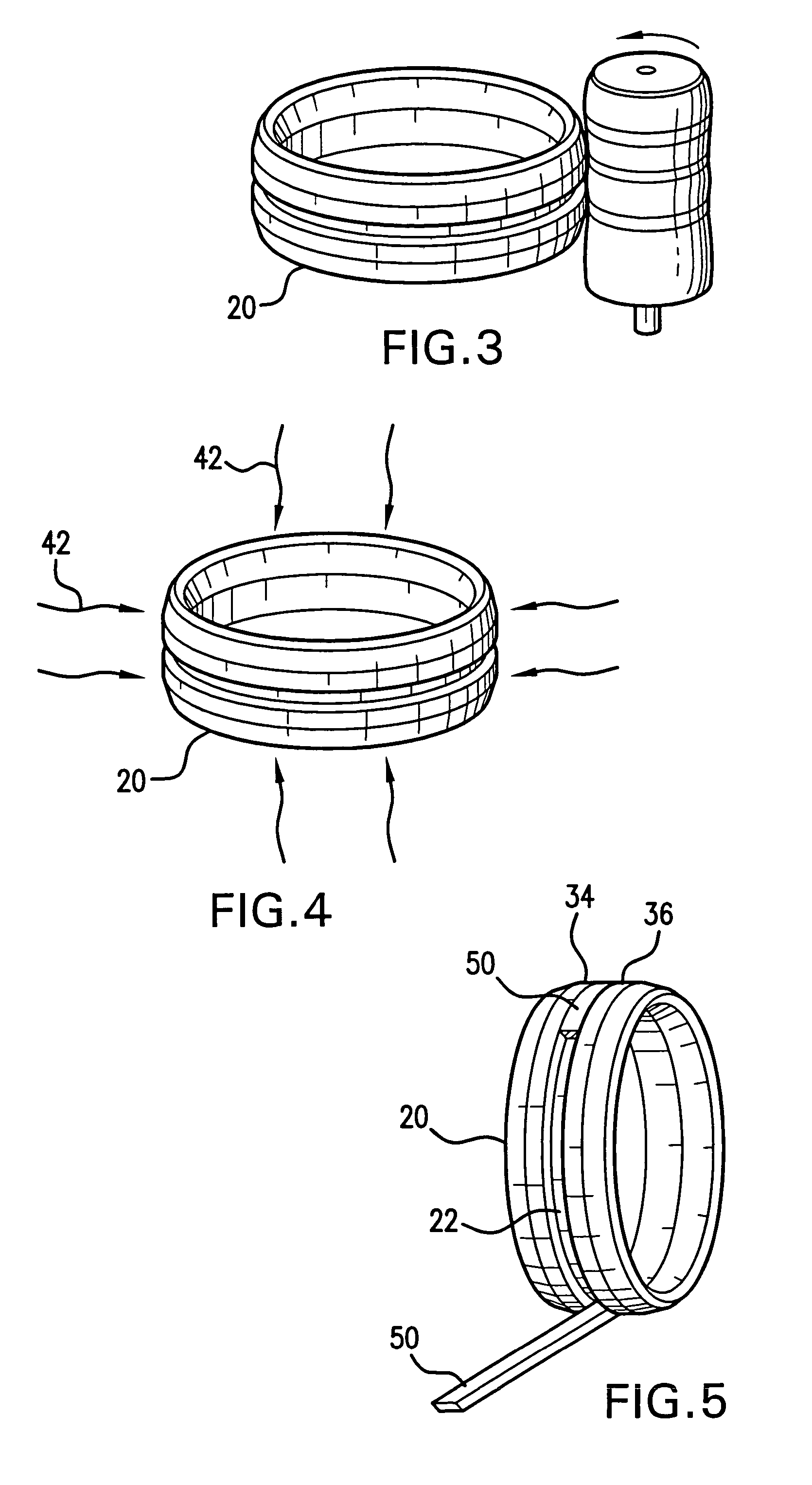

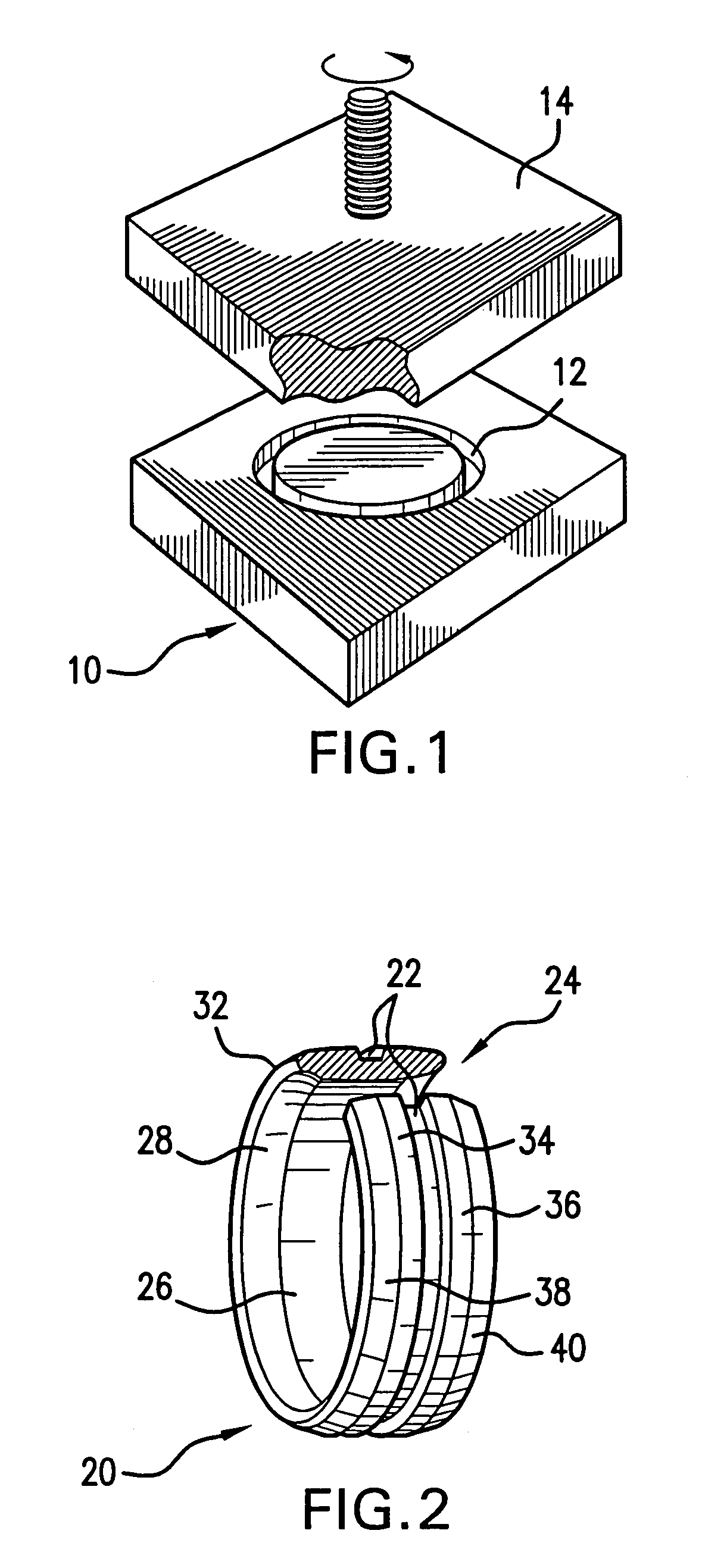

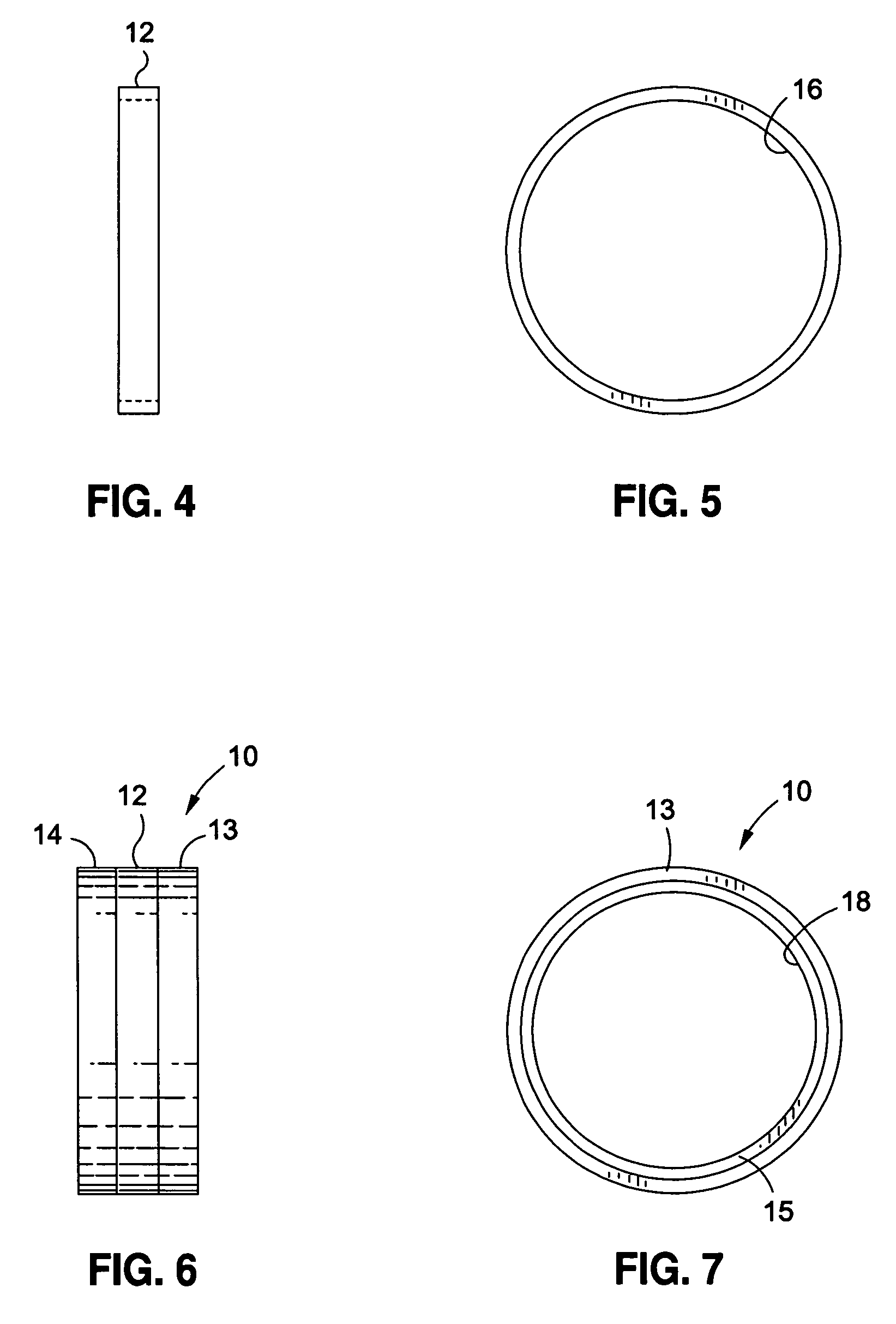

Jewelry ring and method of manufacturing same

Methods are provided of making annular, tungsten-carbide jewelry articles including finger rings, bracelets, earrings, body jewelry, and the like. Advantageously, the methods include providing a tungsten-carbide based annular jewelry article having a desired surface profile and including an annular band that includes providing a mixture of two or more powdered materials of at least 50 weight percent to about 90 weight percent tungsten carbide to form the annular band of the article into a pressure mold having a cavity of predetermined annular configuration and sized formed therein, the size of the mold being greater than the final size of the annular band, compressing the powdered material mixture at a pressure sufficient to form an annular blank, and sintering the annular blank at a temperature sufficient to form the tungsten-carbide based annular jewelry article so as to be long wearing and virtually indestructible during normal use thereof.

Owner:WEST TRENT

Jewelry ring

Owner:NAT CHAIN

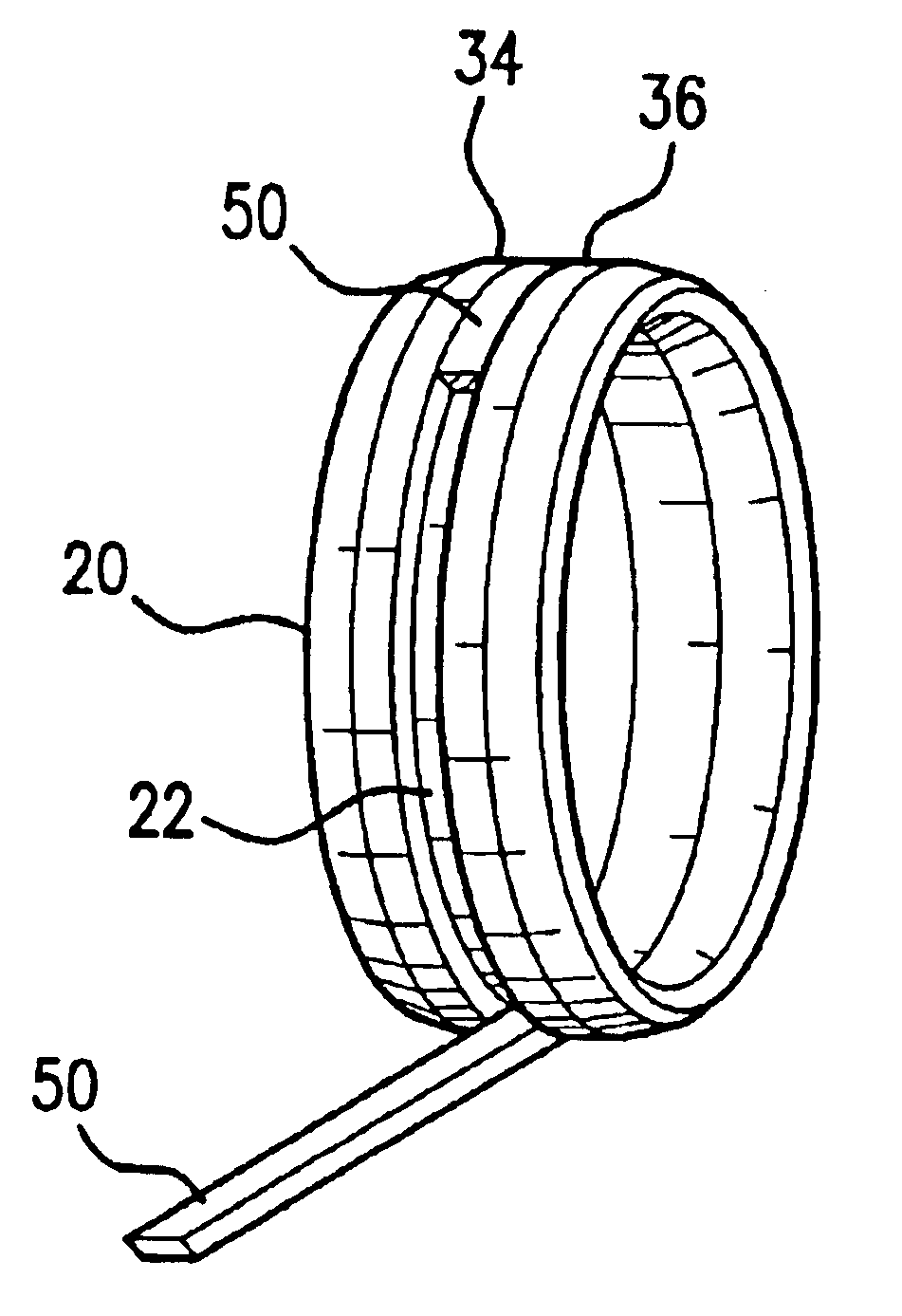

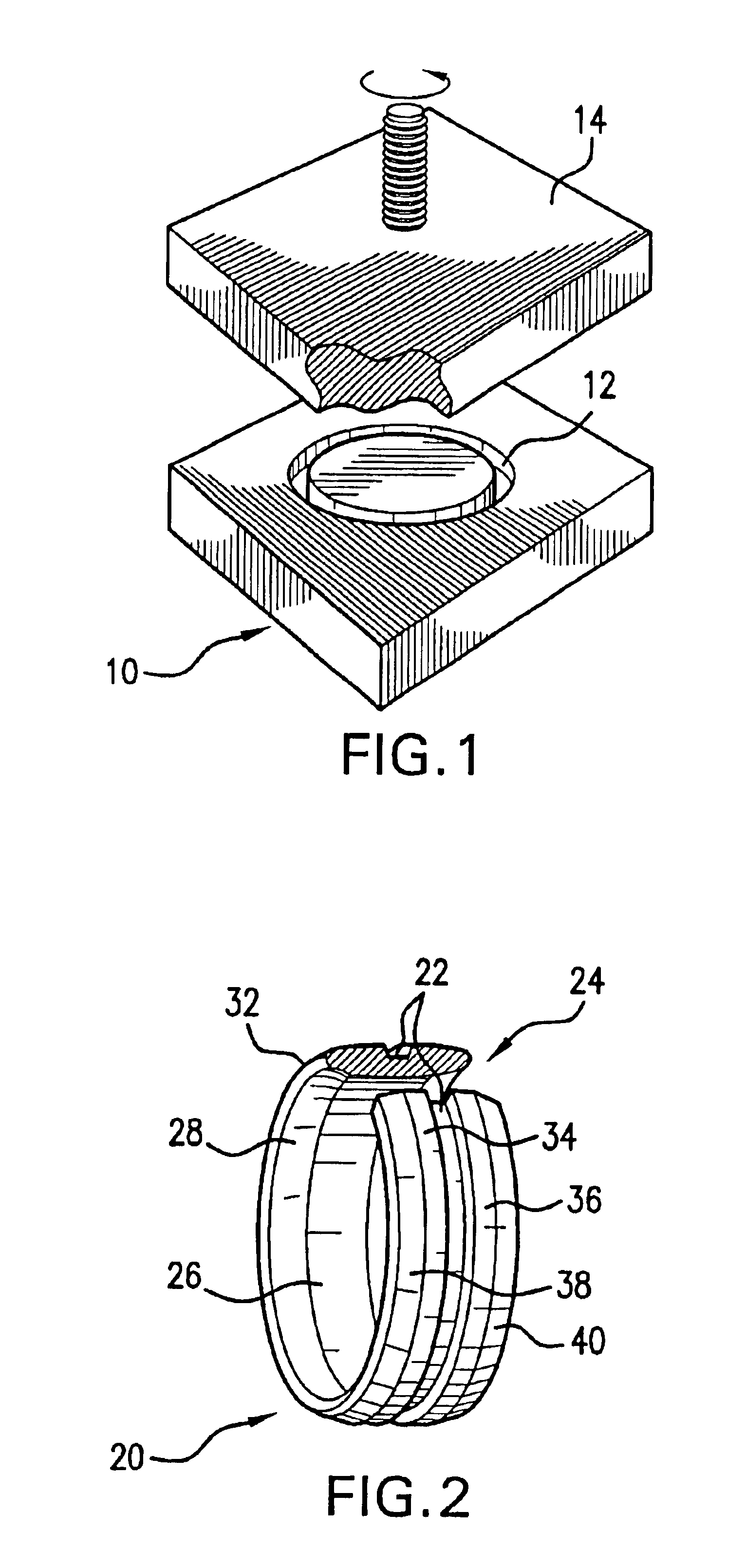

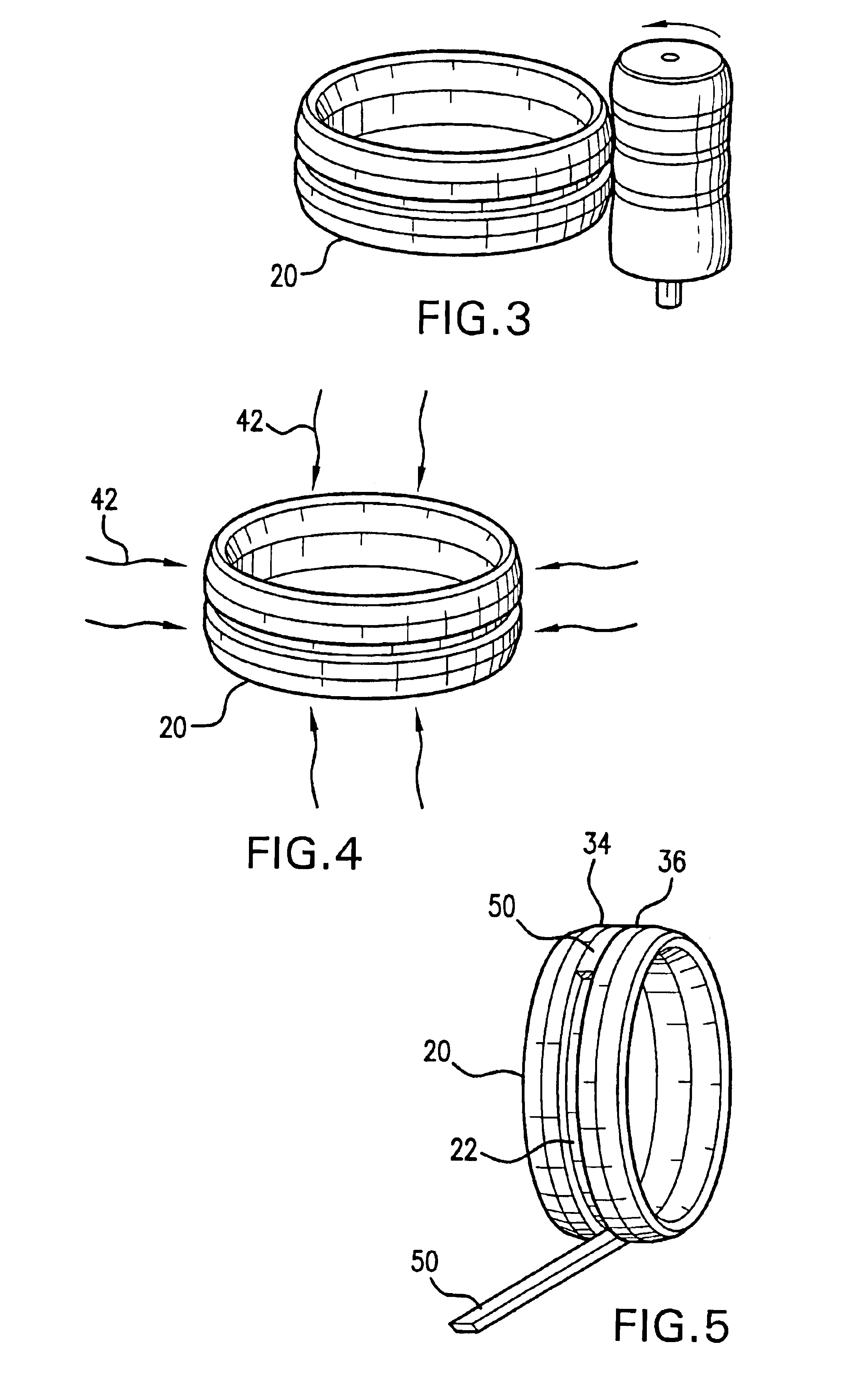

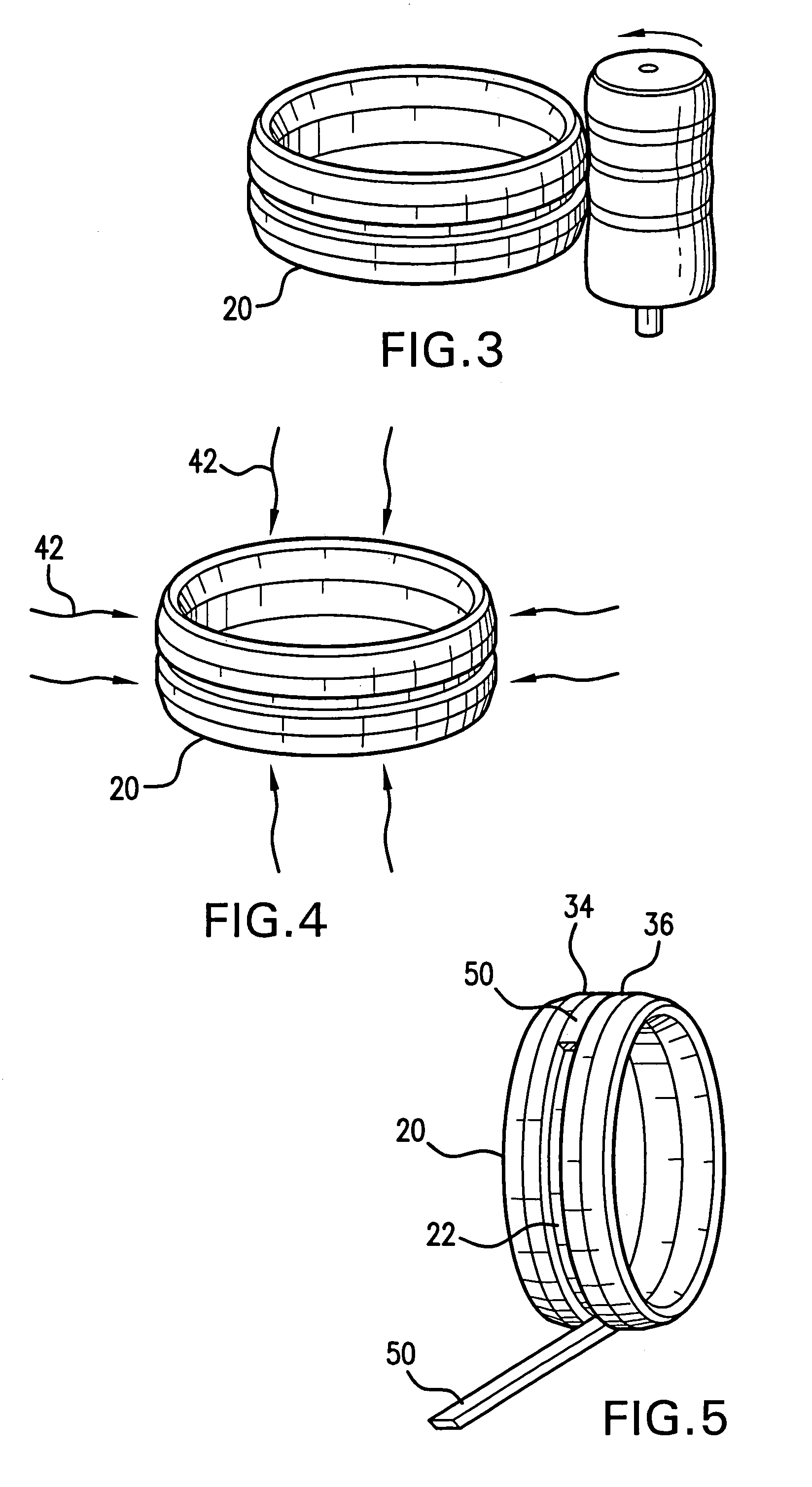

Methods for preparing jewelry articles comprising sintered tungsten carbide

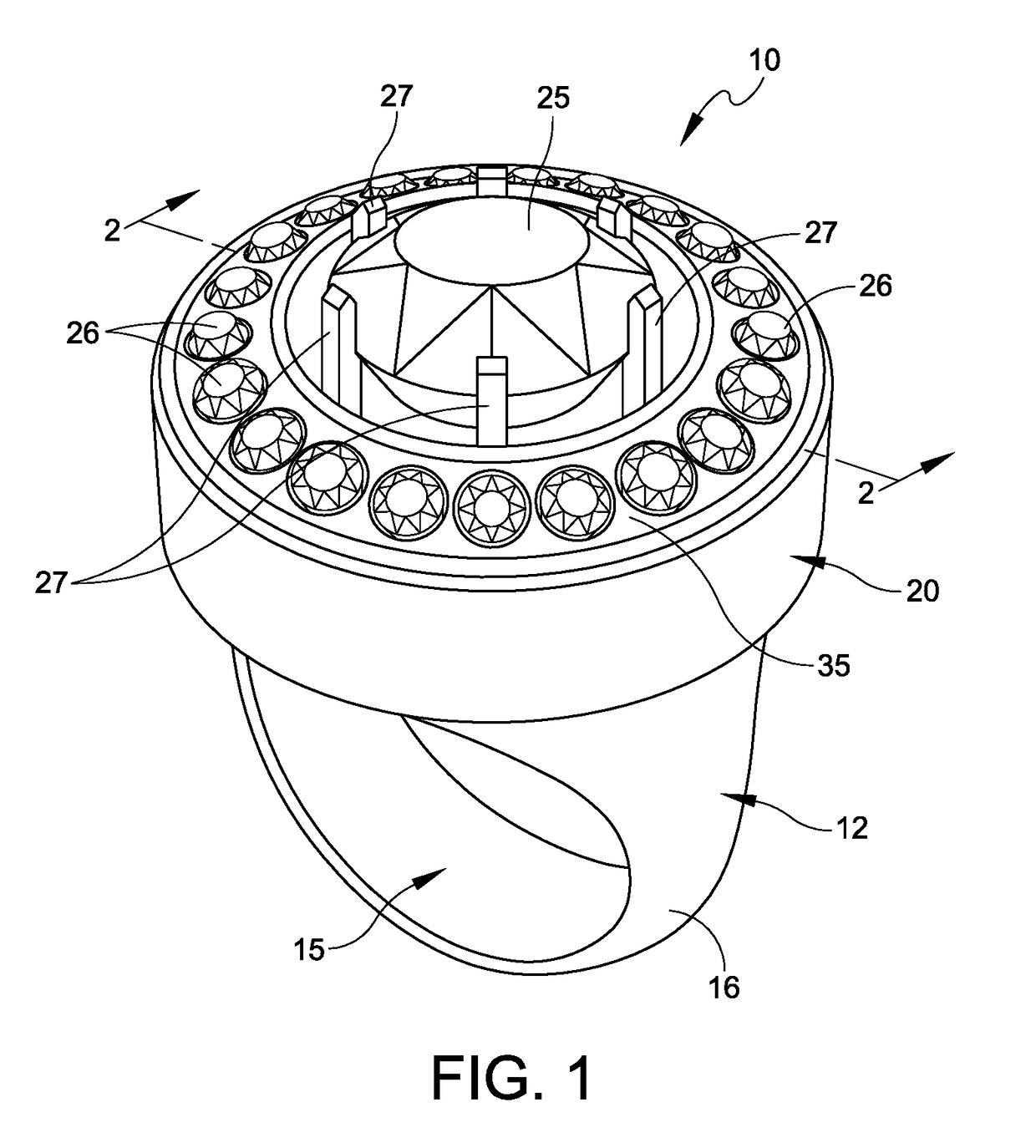

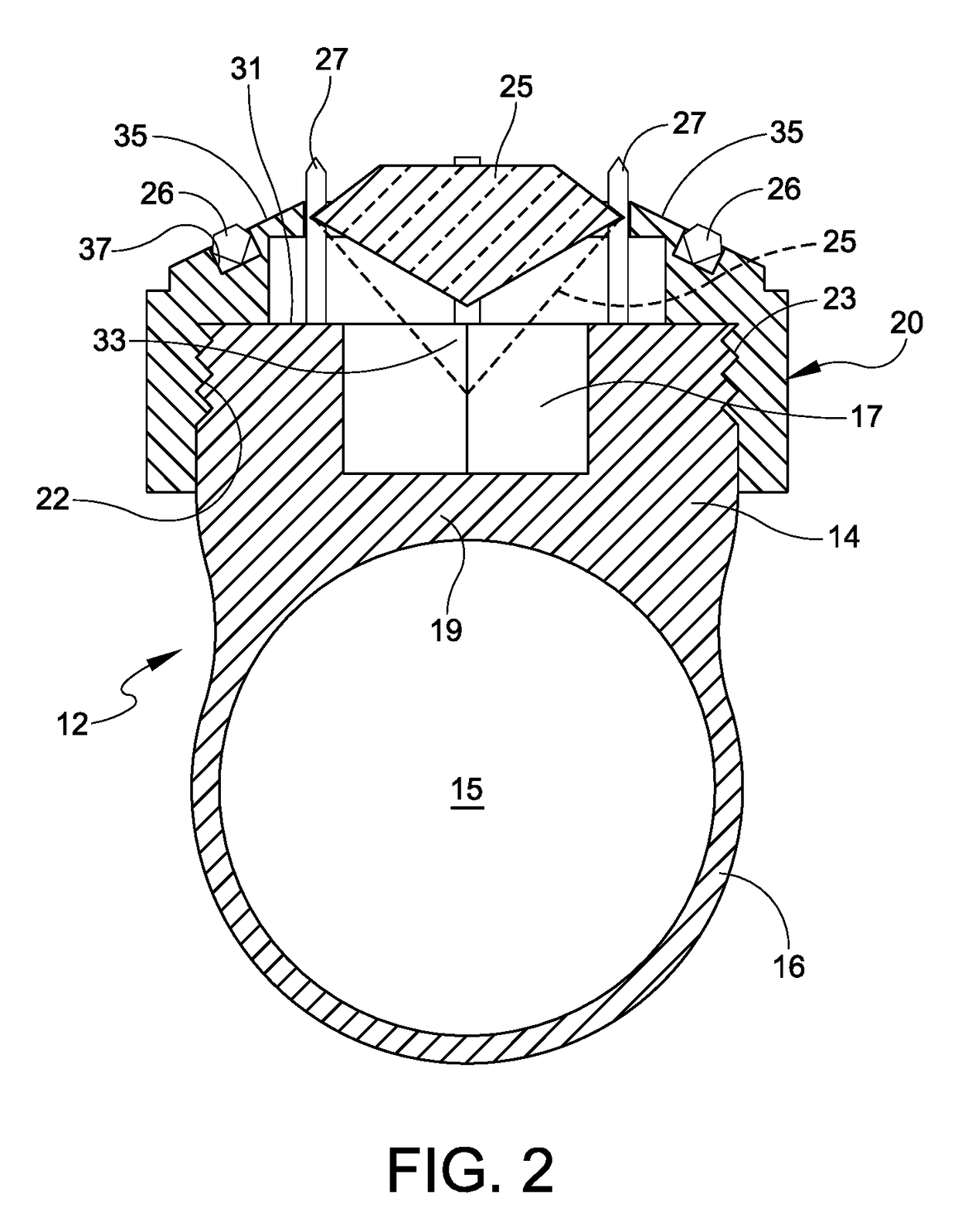

System, apparatus, and method for making composite articles including jewelry rings. Jewelry items such as finger rings, bracelets, earrings, body jewelry, and the like, are examples of such articles. Medical, dental, and industrial devices or components are other examples. Wear resistant jewelry apparatus and method of making same wherein articles of jewelry are made from sinterable metal and / or ceramic powder materials compressed into a predetermined configuration and then sintered to form a blank from which a jewelry item may be made and to which softer precious metals, stones, crystals or other materials suitable for use in jewelry may be affixed. Such items of jewelry may have multiple facets and can be fabricated using various disclosed techniques and various combinations of materials. Method of manufacturing an article including jewelry rings.

Owner:WEST TRENT

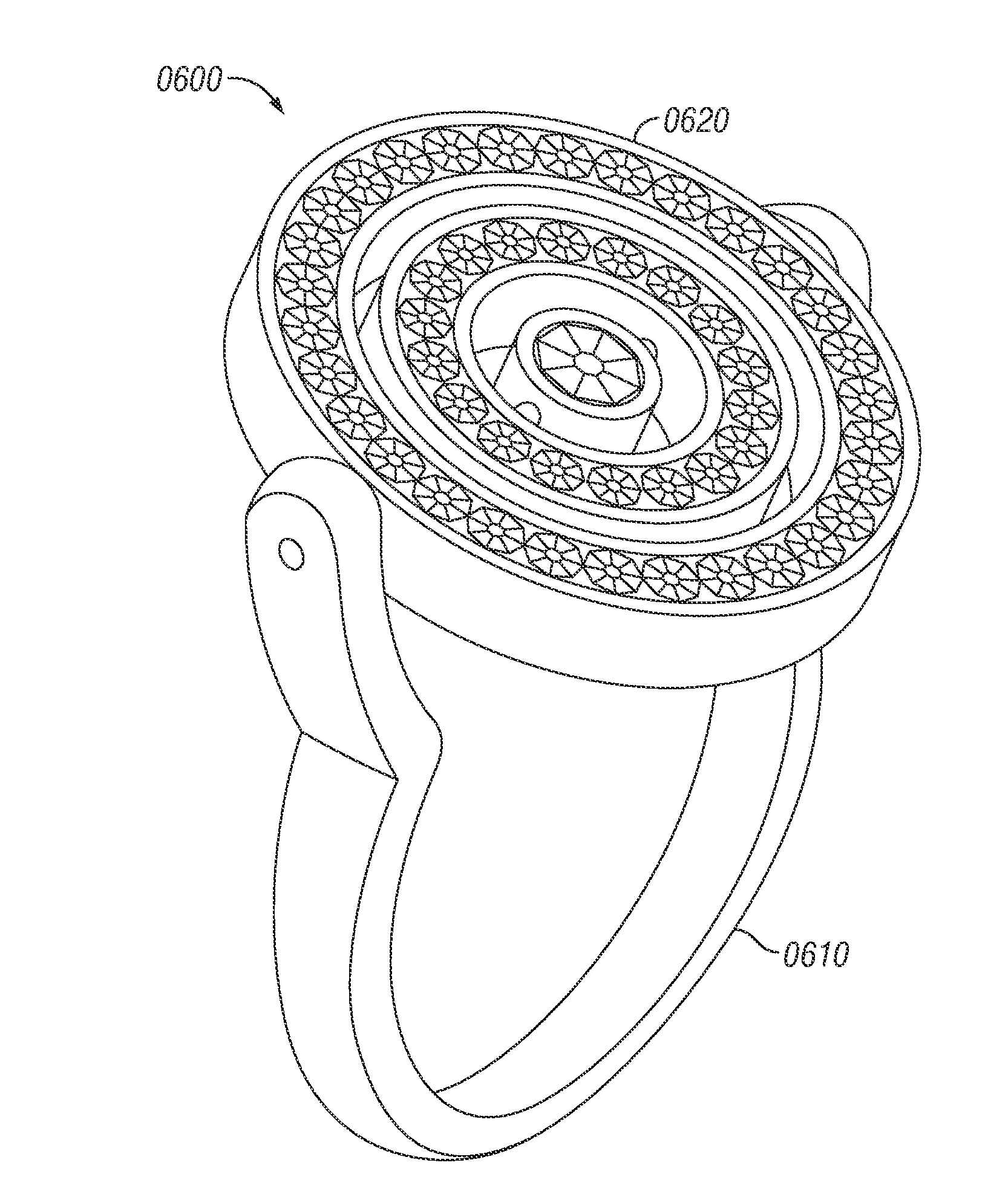

Jewelry ornament system and method

A jewelry ring assembly configured to permit multiple views of a rotatable ornamental inset is disclosed. The system and method utilize a reusable support frame that mechanically constrains a support frame axle. The support frame axle is mechanically coupled to an ornamental element set that is inset within the reusable support frame. The ornamental element set may be rotationally articulated about the support frame axle to enable display presentation of multiple sides of elements with the ornamental element set. The ornamental element set may contain multiple rotatable ornamental insets that individually rotate about the support frame axle and thus permit two or more views of each rotatable ornamental inset to be presented as a multiple number of individual presentation modes within the overall context of the ornamental element set / reusable support frame configuration. Another jewelry assembly includes a necklace that utilizes a reusable suspending string coupled to an ornamental elemental set with the support frame axle.

Owner:NOBLE CYVIA

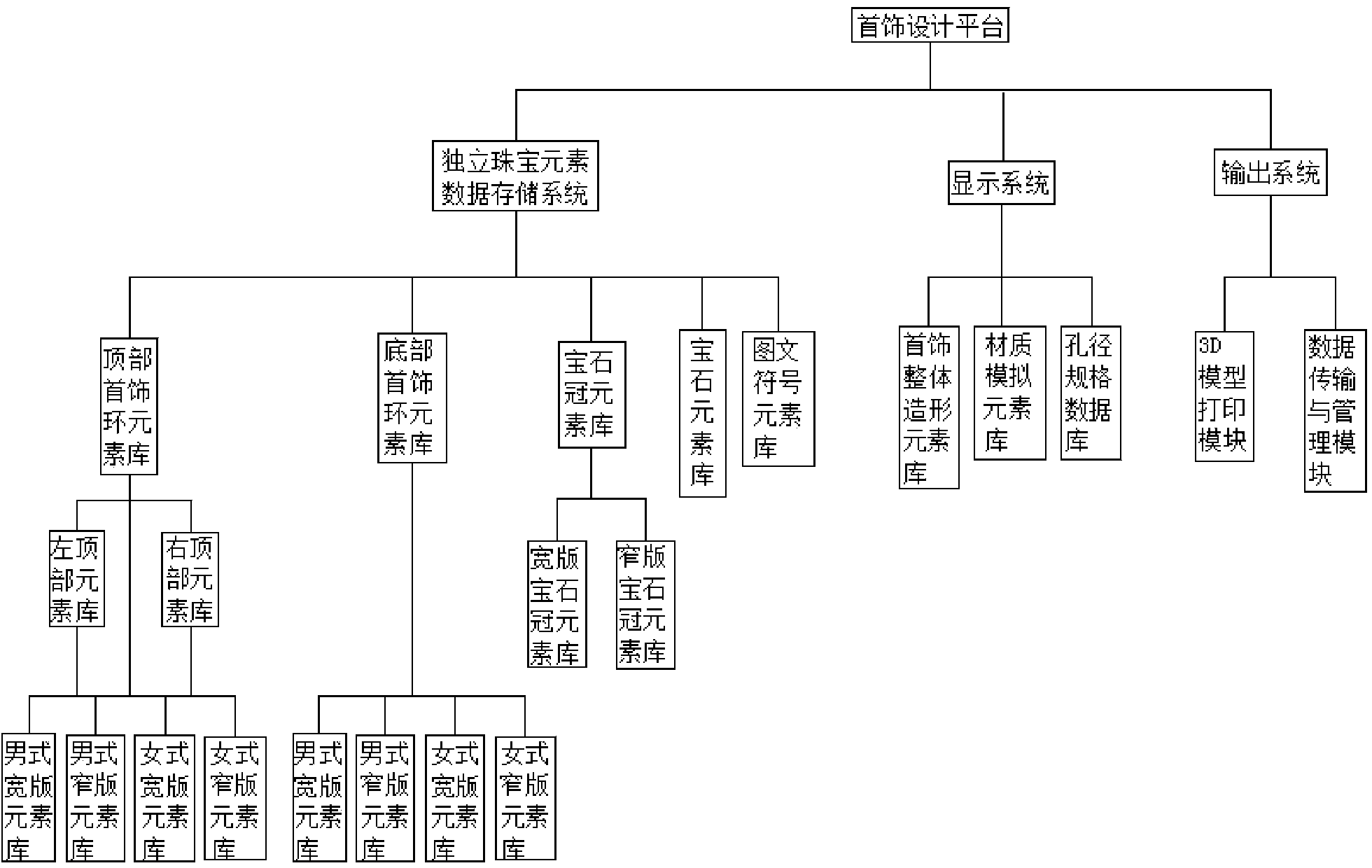

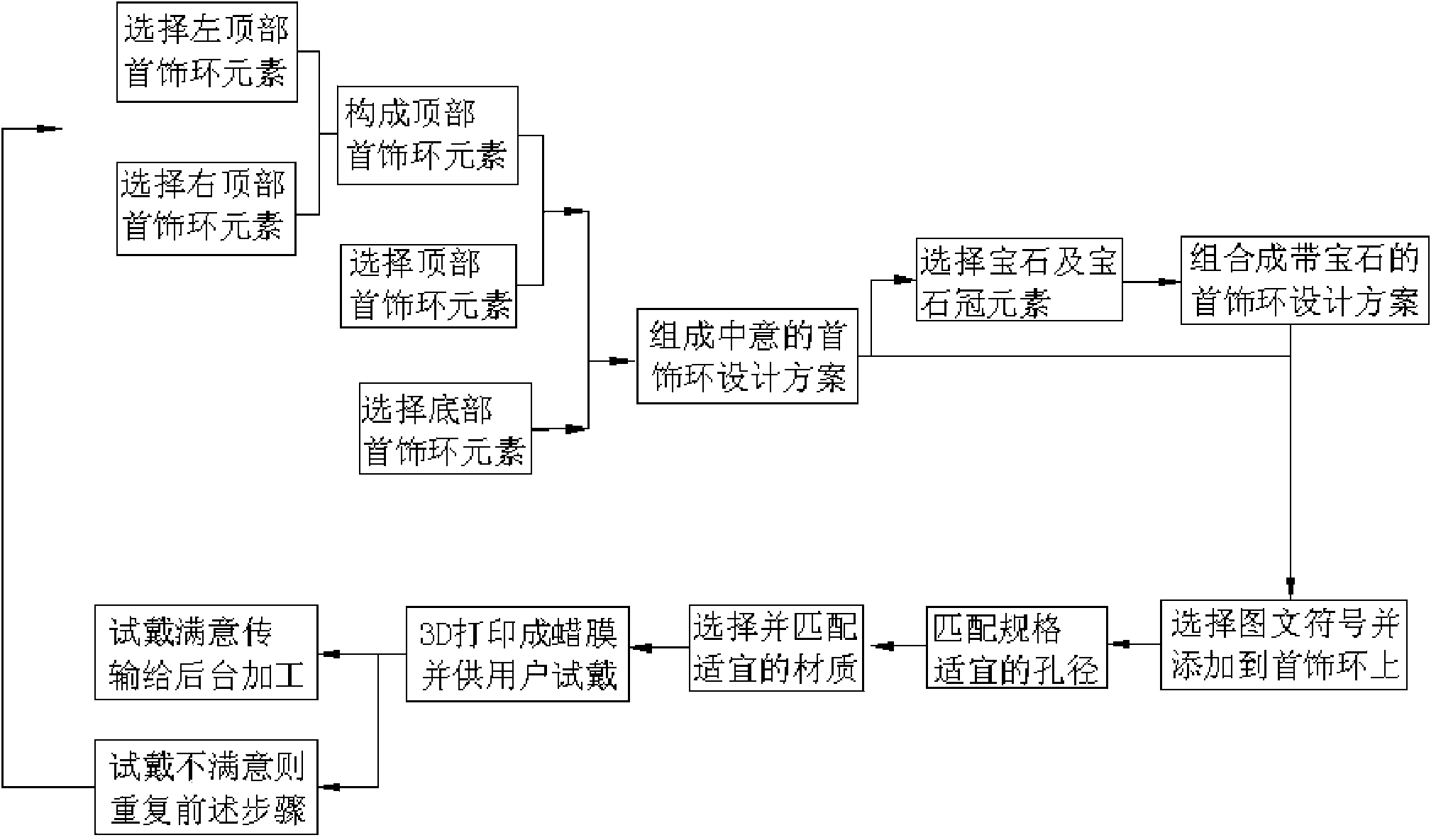

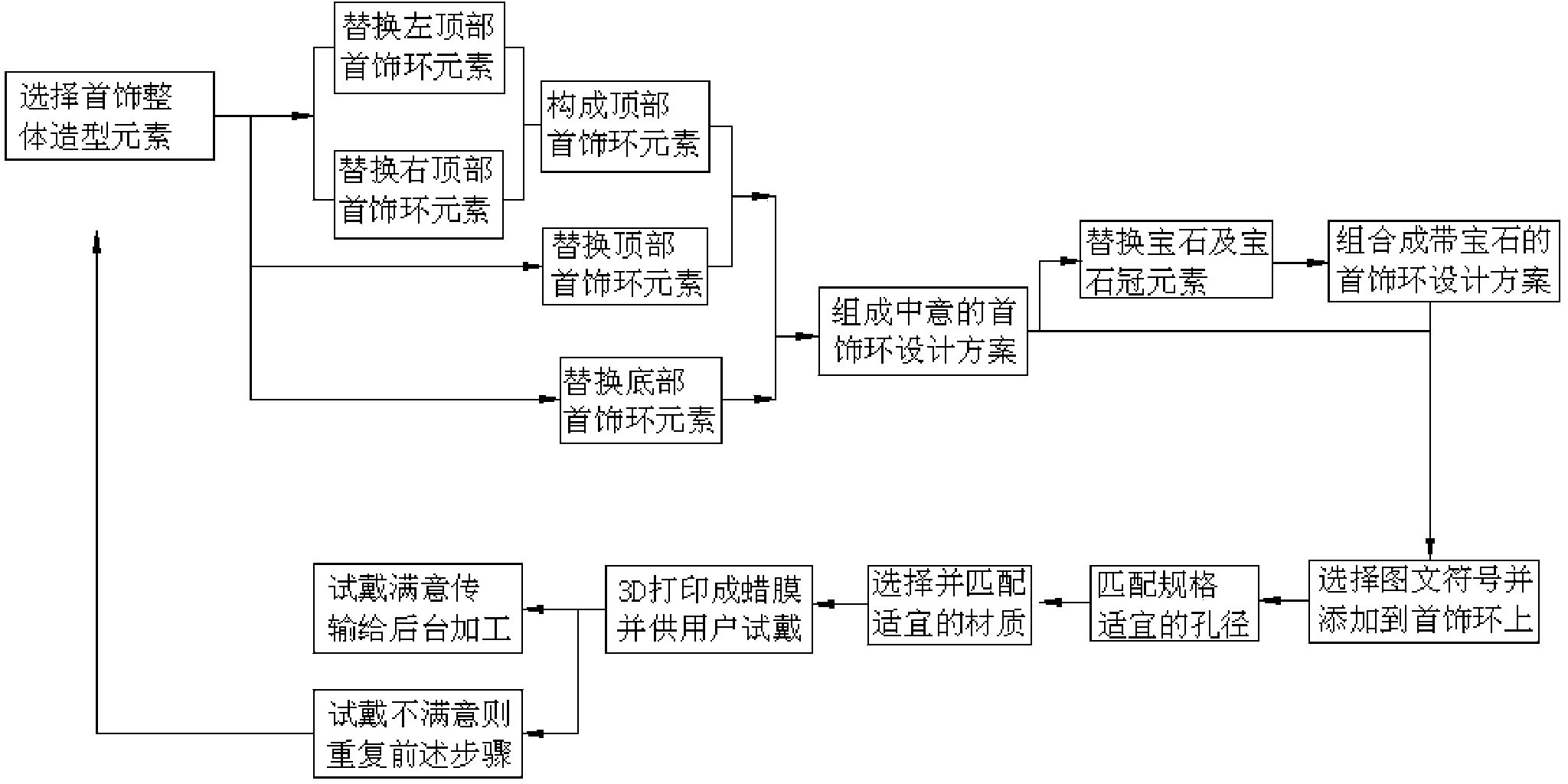

Method for designing jewelry by using jewelry design platform

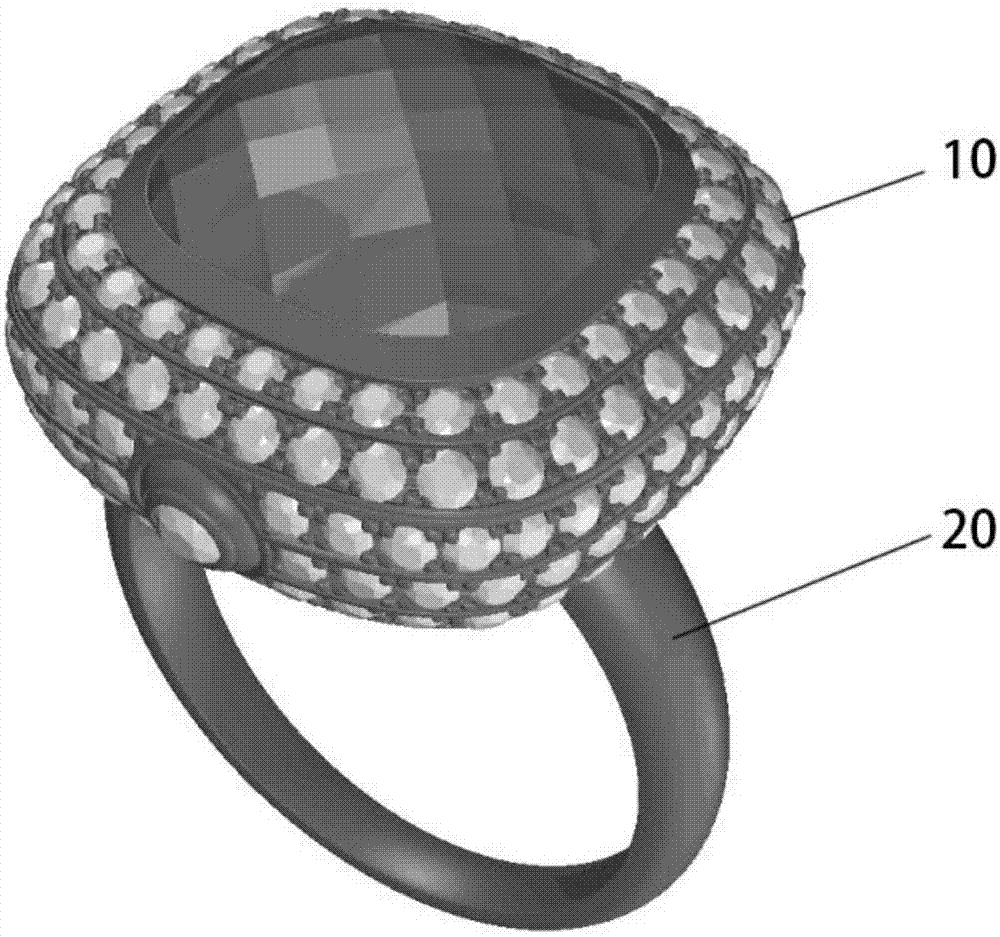

ActiveCN103955589ASimple designImprove design efficiencyJewellerySpecial data processing applicationsPersonalizationGemstone

The invention discloses a method for designing jewelry by using a jewelry design platform. The method comprises the following steps that the jewelry design platform comprising an independent jewelry element data storage system, a display system and an output system is used to divide the jewelry into a jewelry ring, a jeweled tiara and gemstone, and to respectively establish a plurality of element libraries by class according to every part of the jewelry, each element library also comprises thousands of separate elements, the elements are combined and matched by class, interfaces of every classes are matched, consumers select the separate elements of each subdivided part from each element library to randomly match, modify and combine to design the favorite jewelry, images, texts or symbols can be randomly designed on the jewelry, and billions of schemes can be designed.. After satisfaction, the model is three-dimensionally printed by an output system to be tried on by consumers, the personalized and differentiated design of the jewelry can be quickly and independently carried out by the consumers, and a post-industrial platform is built for a C2B model.

Owner:张杜渐

Methods and jewelry articles comprising sintered tungsten carbide

System, apparatus, and method for making composite articles including jewelry rings. Jewelry items such as finger rings, bracelets, earrings, body jewelry, and the like, are examples of such articles. Medical, dental, and industrial devices or components are other examples. Wear resistant jewelry apparatus and method of making same wherein articles of jewelry are made from sinterable metal and / or ceramic powder materials compressed into a predetermined configuration and then sintered to form a blank from which a jewelry item may be made and to which softer precious metals, stones, crystals or other materials suitable for use in jewelry may be affixed. Such items of jewelry may have multiple facets and can be fabricated using various disclosed techniques and various combinations of materials. Method of manufacturing an article including jewelry rings.

Owner:WEST TRENT

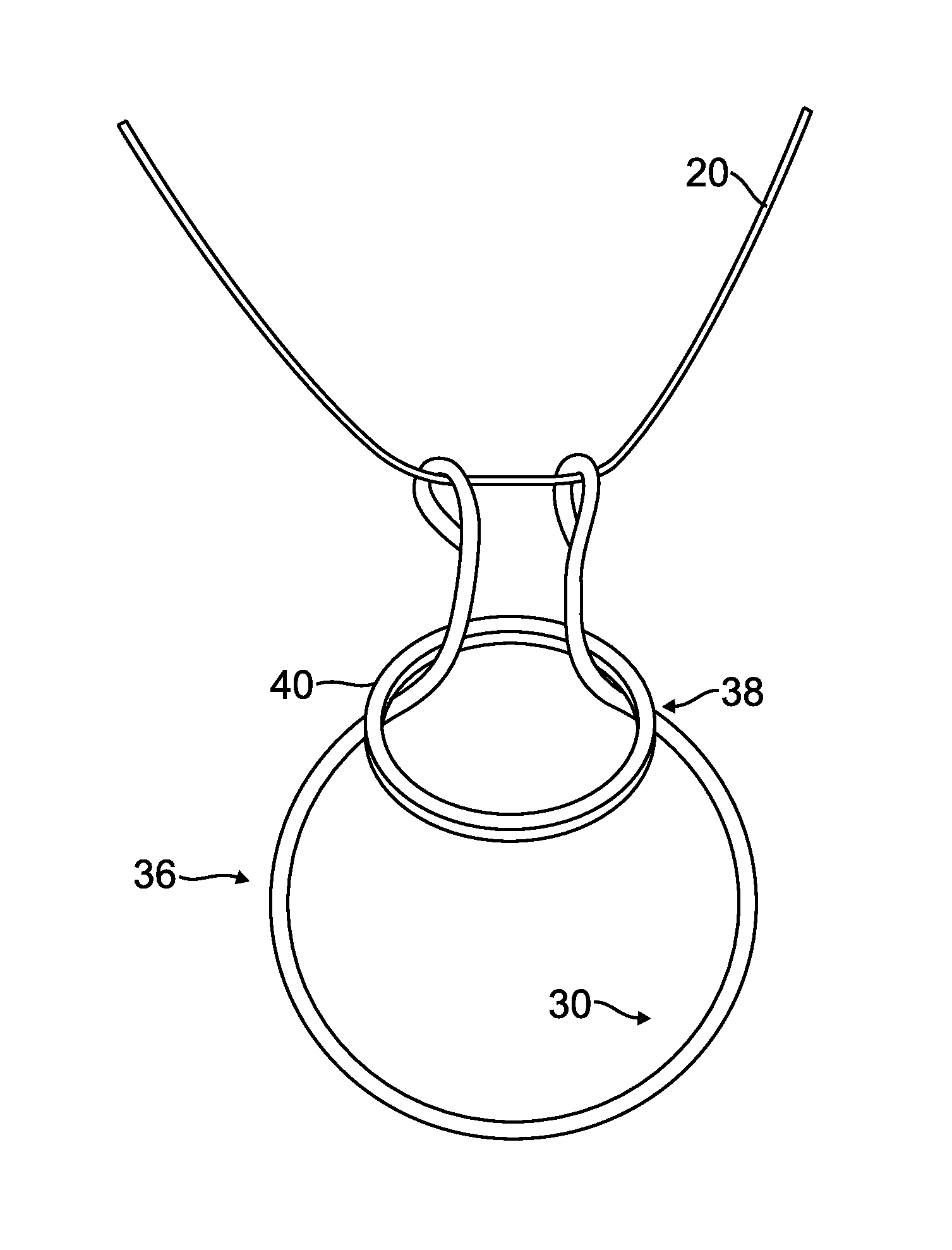

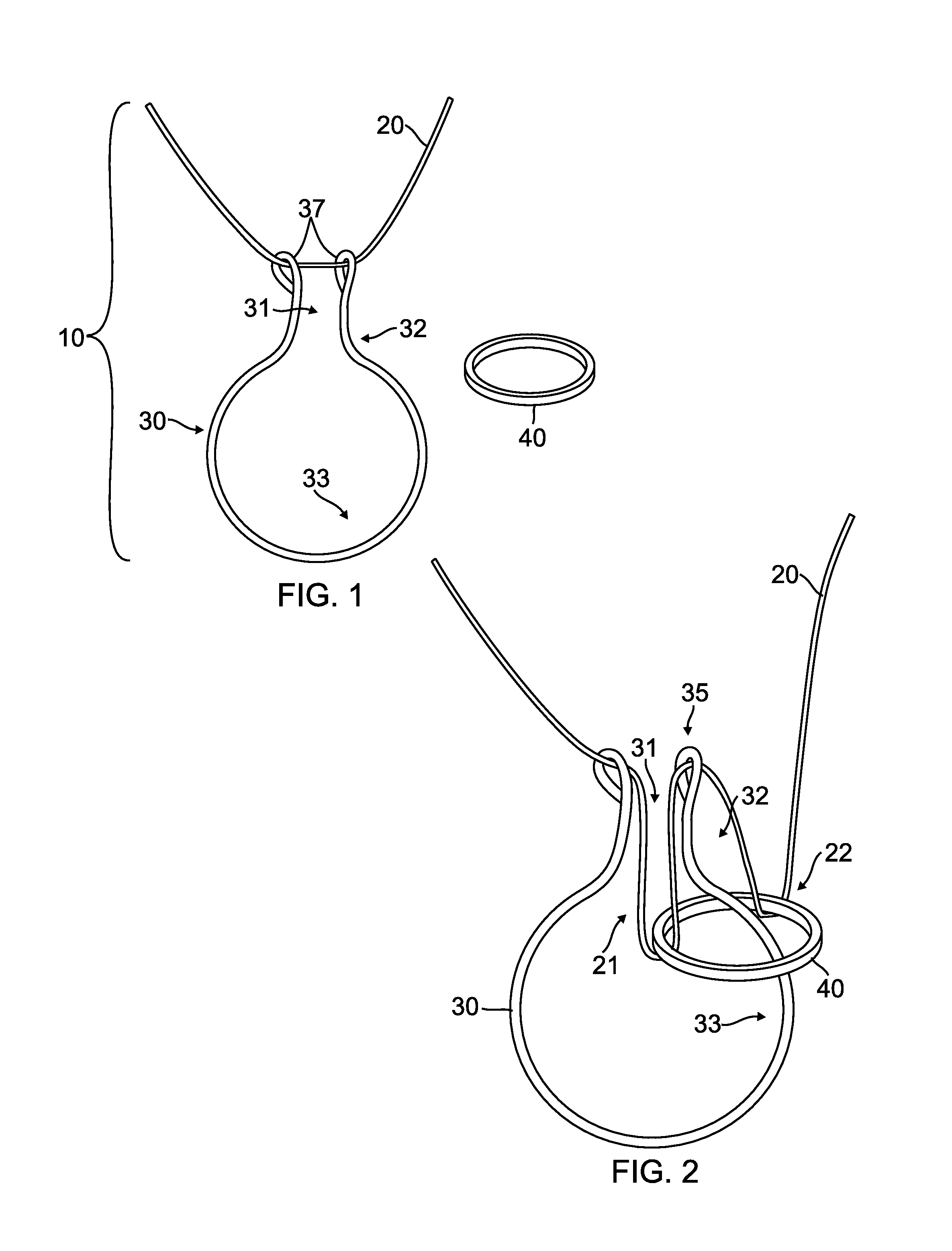

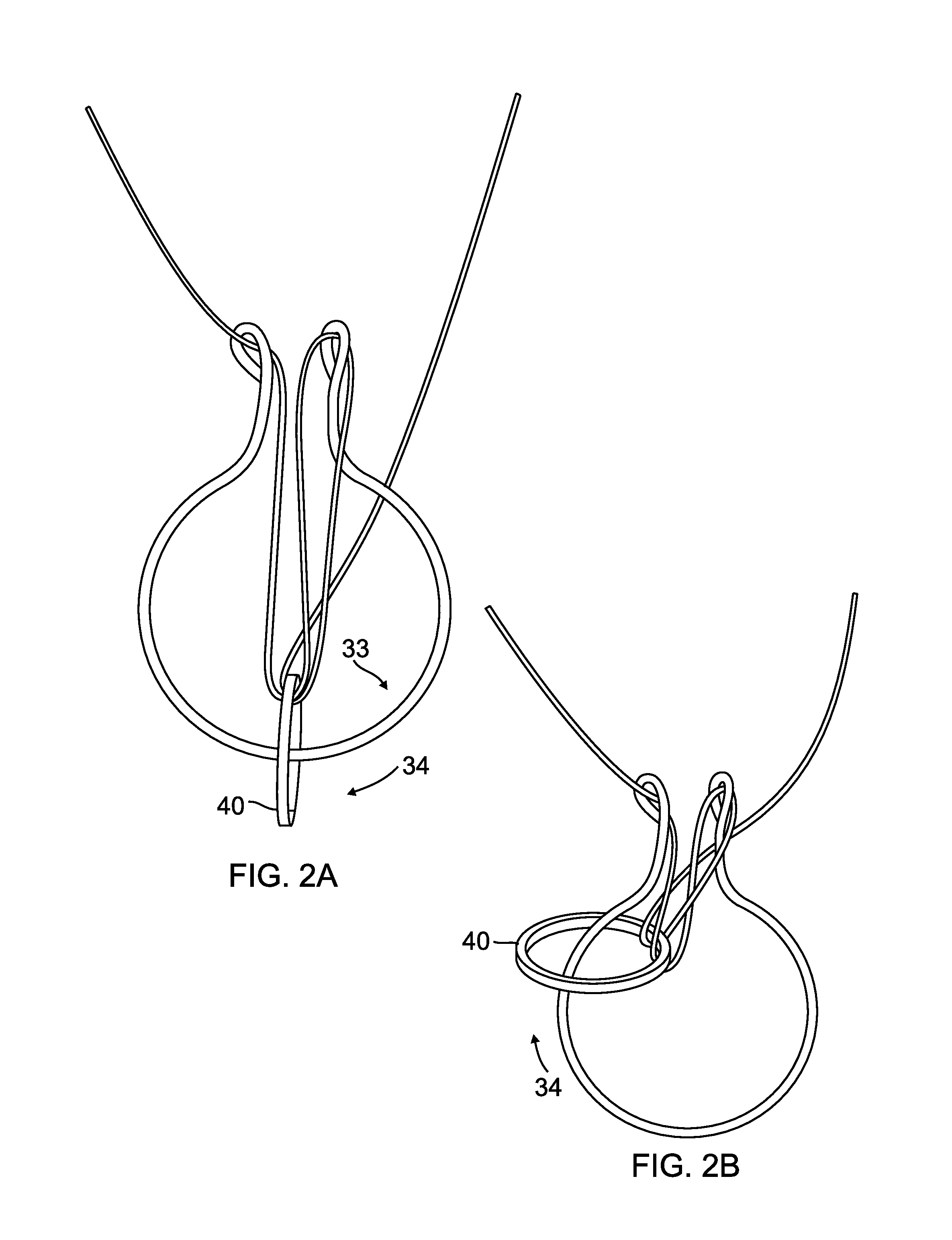

Jewelry ring holding necklace

This invention is a two-part device for suspending a ring around a wearer's neck in the form of a pendant. The two-part device has a cover and an interior ring holding assembly where the interior ring holding assembly is suspended from a neck chain that also supports the cover. The device is structured so that the interior ring holding assembly may be readily removed from the cover and the ring thereby removed at will. Various configurations allow the ring to be either suspended with the stone down or suspended with the stone in an upward position. The device is intended to provide a secure means of transport and displaying a ring from a neck chain.

Owner:CHERRY KENNETH F +1

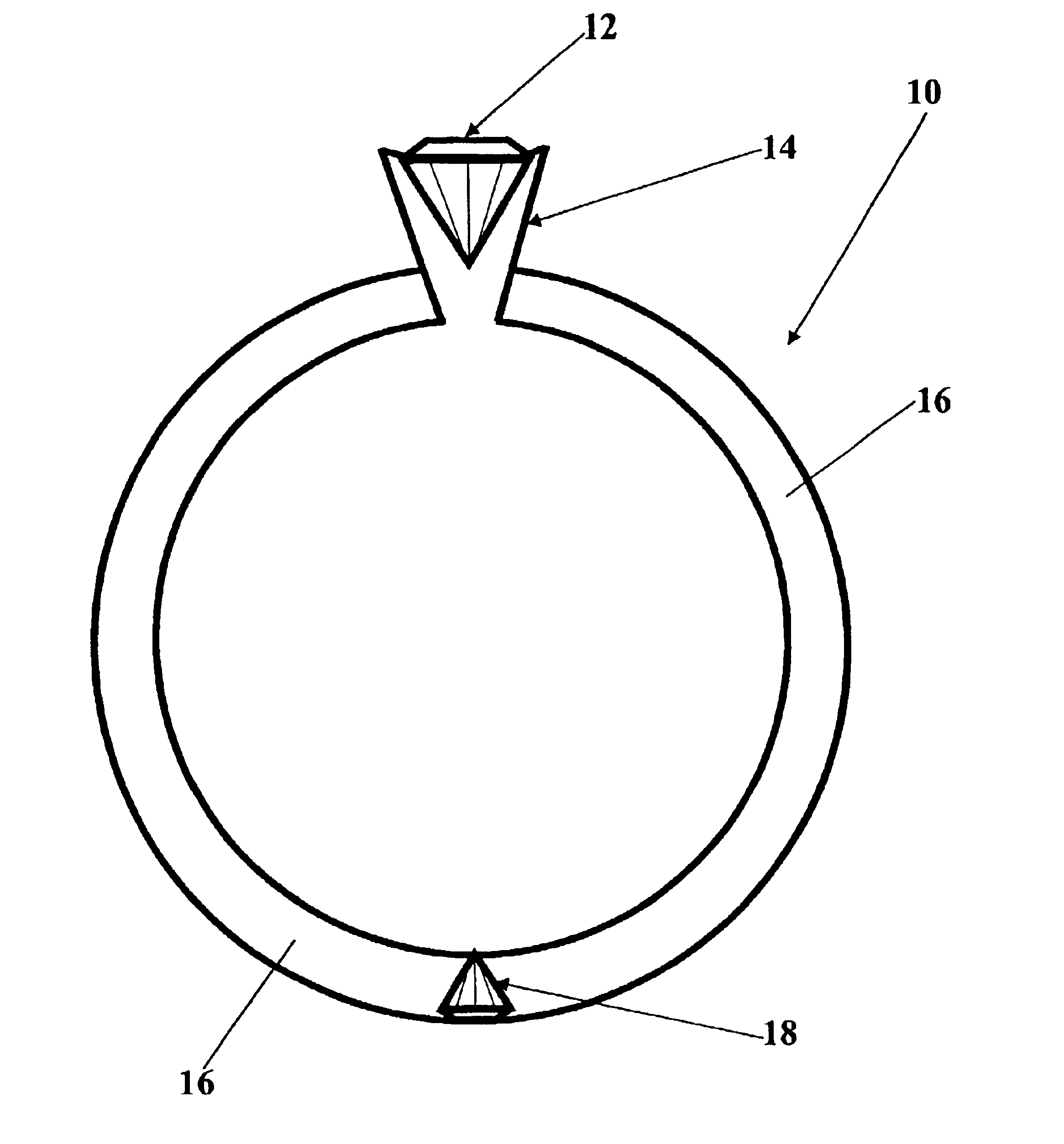

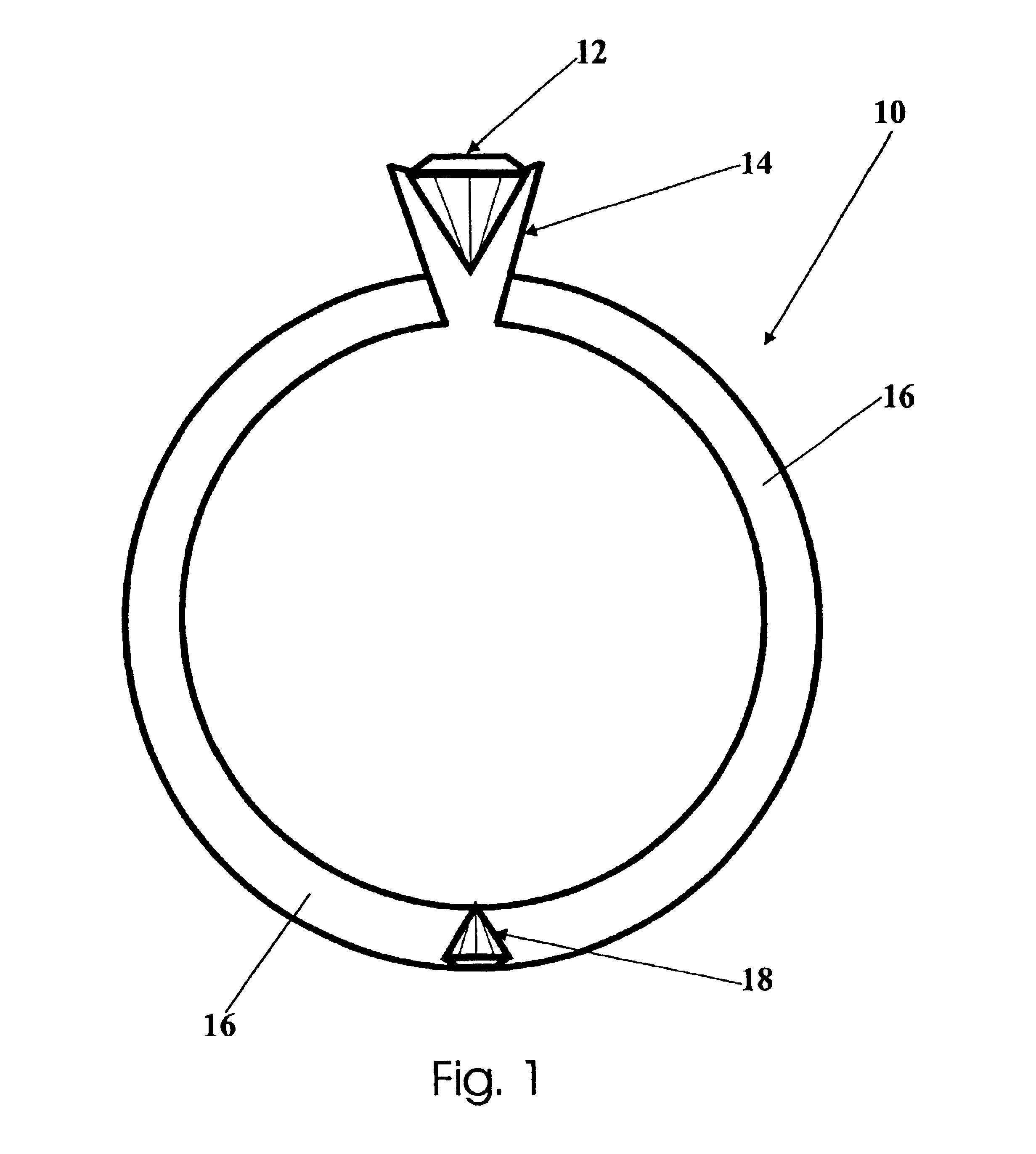

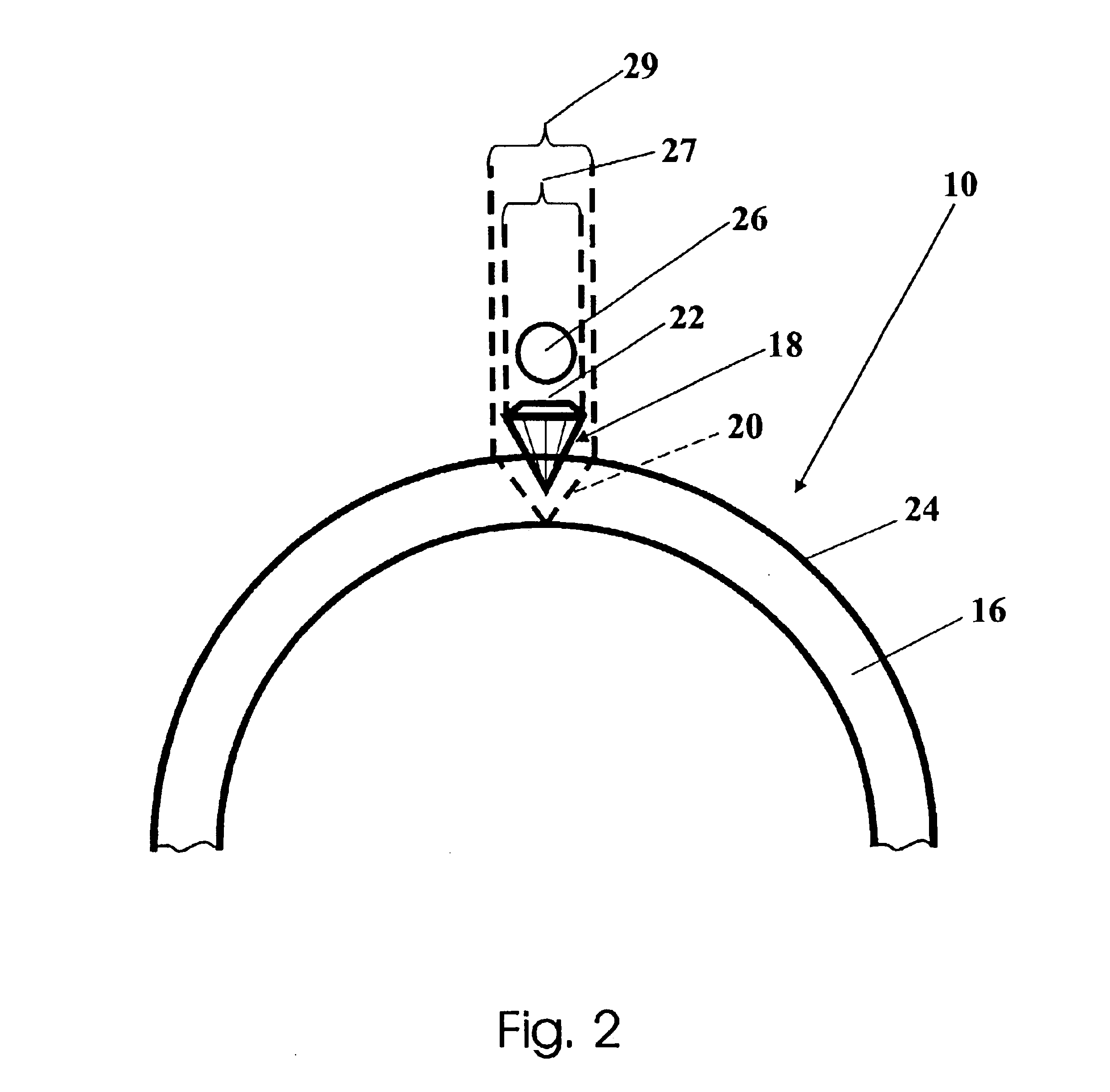

Gemstone encased in ring

InactiveUS6851278B2Sufficient widthAvoid insufficient thicknessFinger-ringsMaterials scienceSmall hole

The invention is a jewelry ring having a small gemstone embedded in the ring shank. The gemstone is embedded by making a small bore in the shank, inserting the gemstone, and covering the top of the gemstone with the same metal that is used to make the ring shank. After laser welding and polishing, the gemstone is invisible until the metal covering the stone eventually wears away.

Owner:KEENAN JERRY

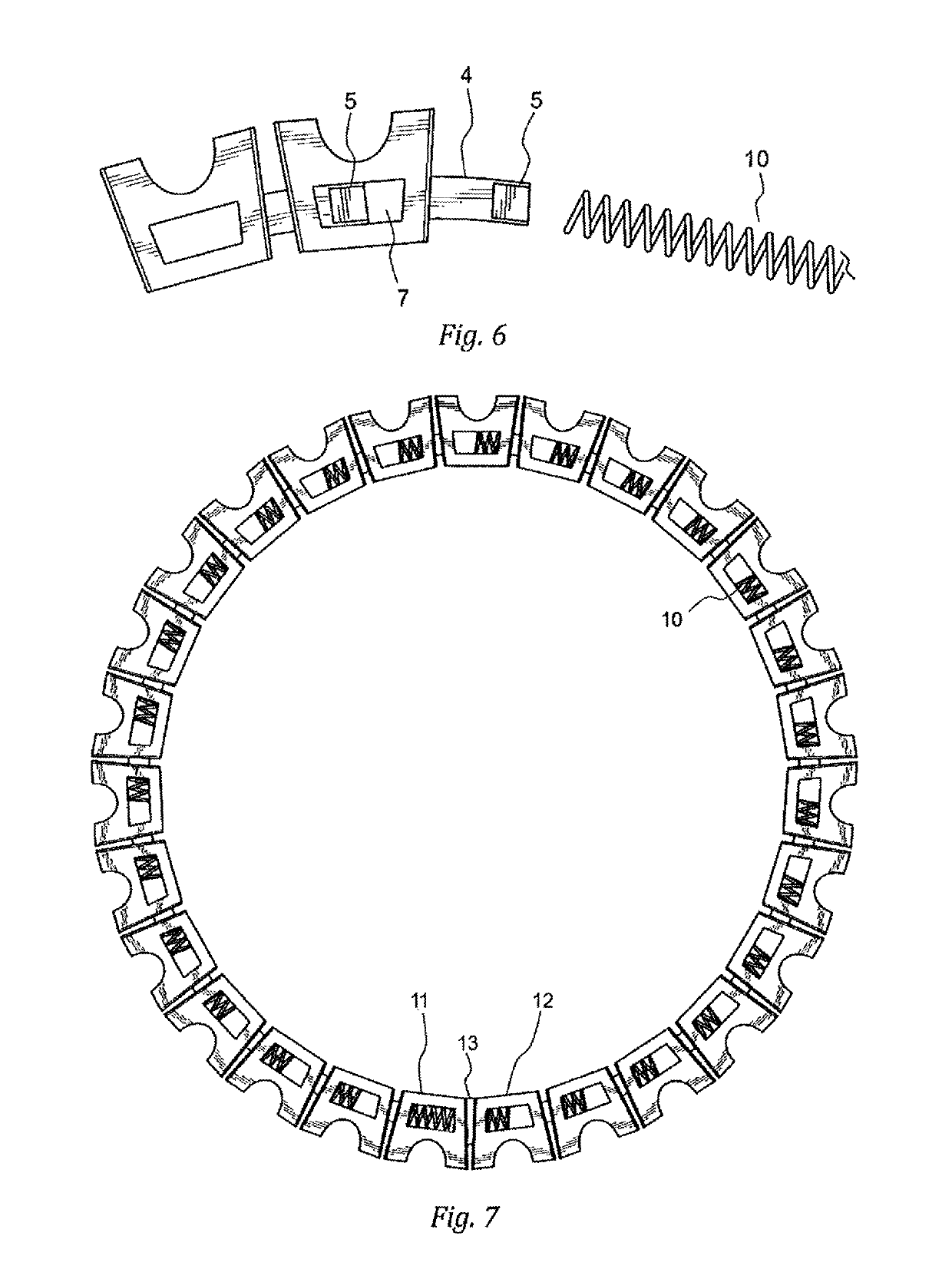

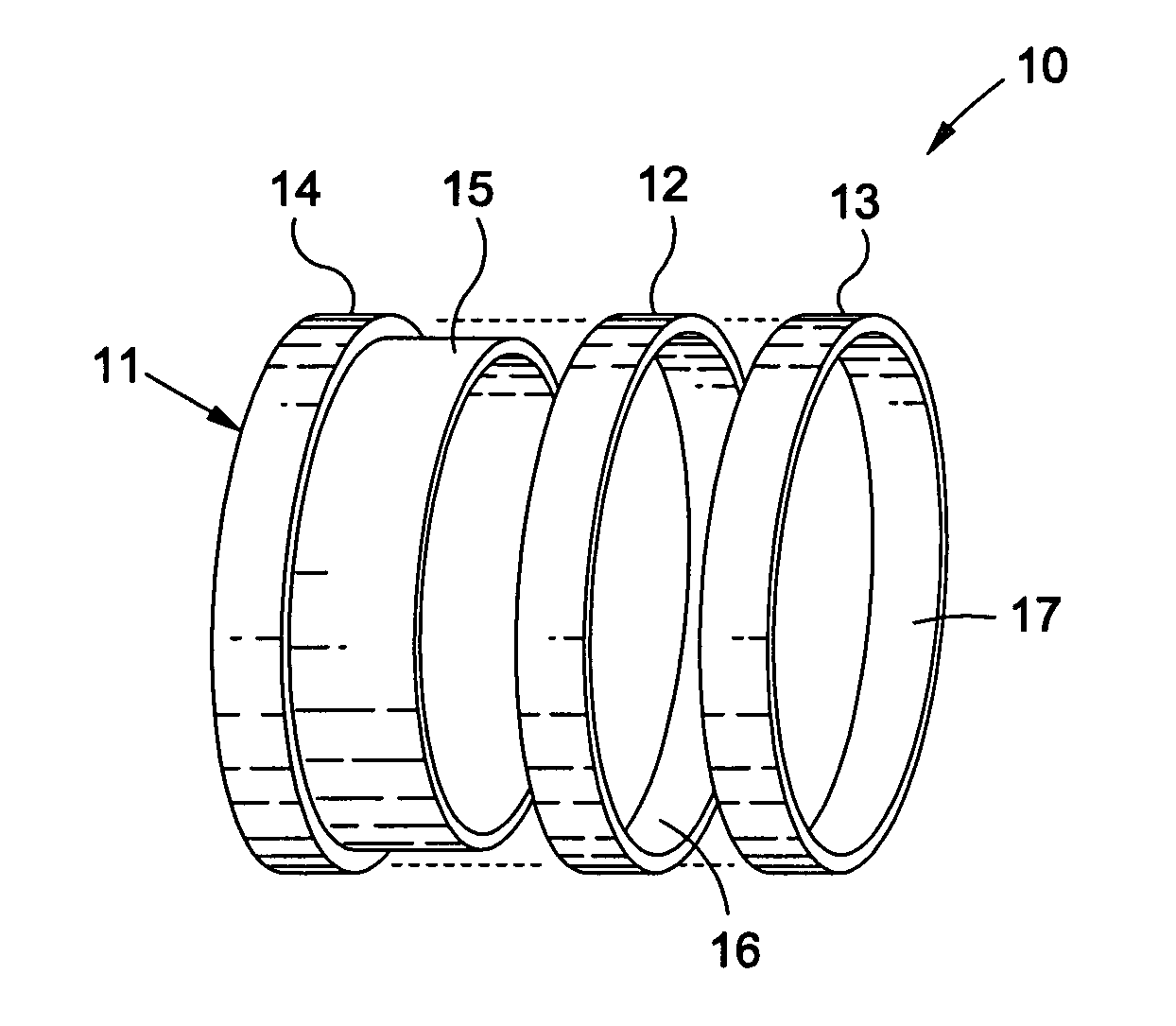

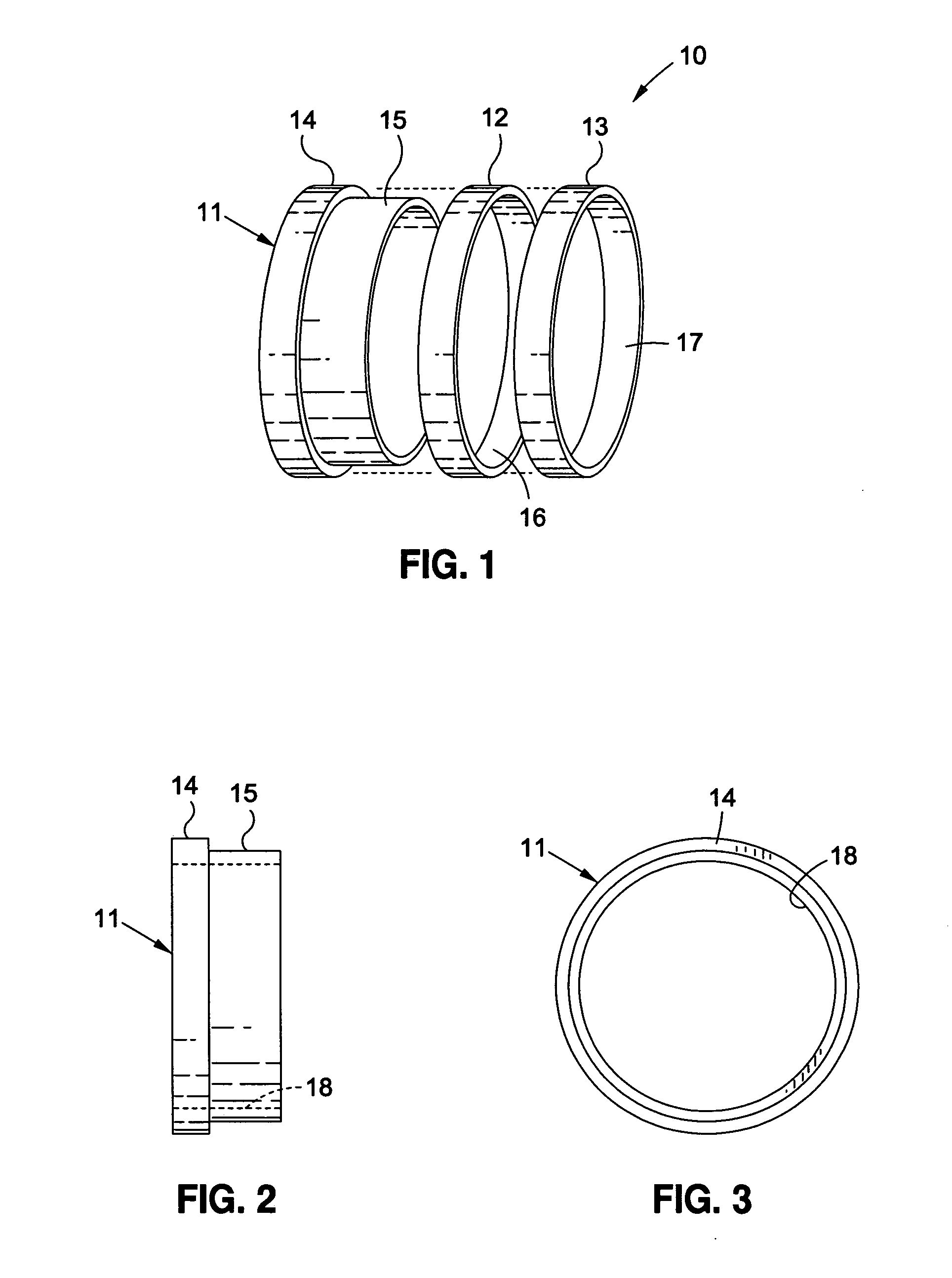

Flexible ring structure for jewelry

The invention provides a flexible ring structure made of loosely-linked prisms, which together define an interior channel. A tensioned spring runs through the length of the channel. The ring, which gives the appearance of a solid and rigid circular structure, can be compressed so as to conform to the cross-section of the finger or hand, and springs back to a circular shape when released. The invention makes it possible to wear an Eternity Ring or a bracelet of smaller diameter than could otherwise be put on the wrist.

Owner:PECK KEVEN

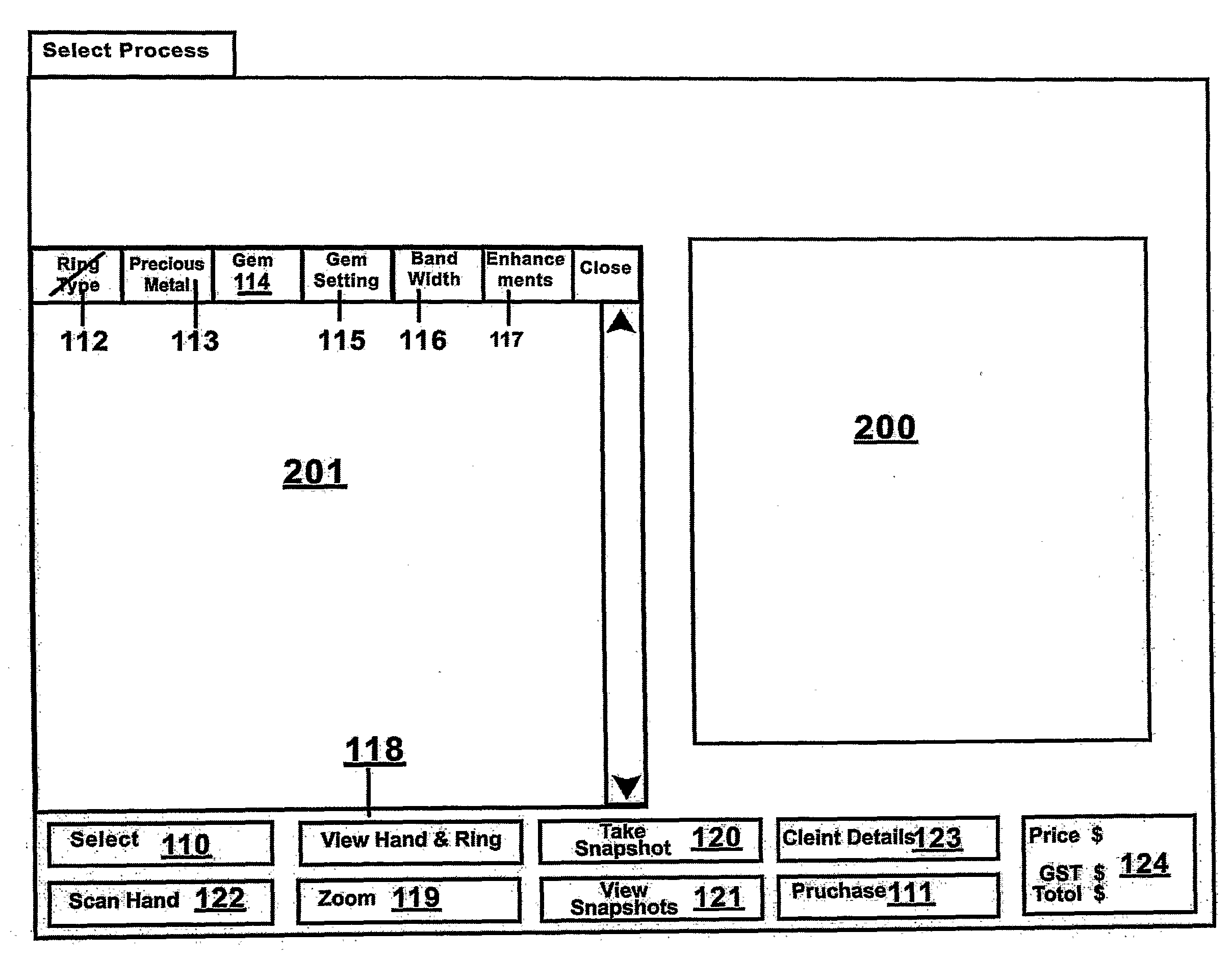

Graphical user interface

InactiveUS20100205568A1Obvious advantagesBuying/selling/leasing transactionsInput/output processes for data processingGraphicsGraphical user interface

This invention provides a graphical user interface which receives a 3-dimensional representation of a first object, provides controls to specify a second object and displays a 3-dimensional representation of the first object in conjunction with the second object. The first object may be a hand of a person and the second object may be a jewellery ring to be made from the specification.

Owner:JEWELSOFT HLDG

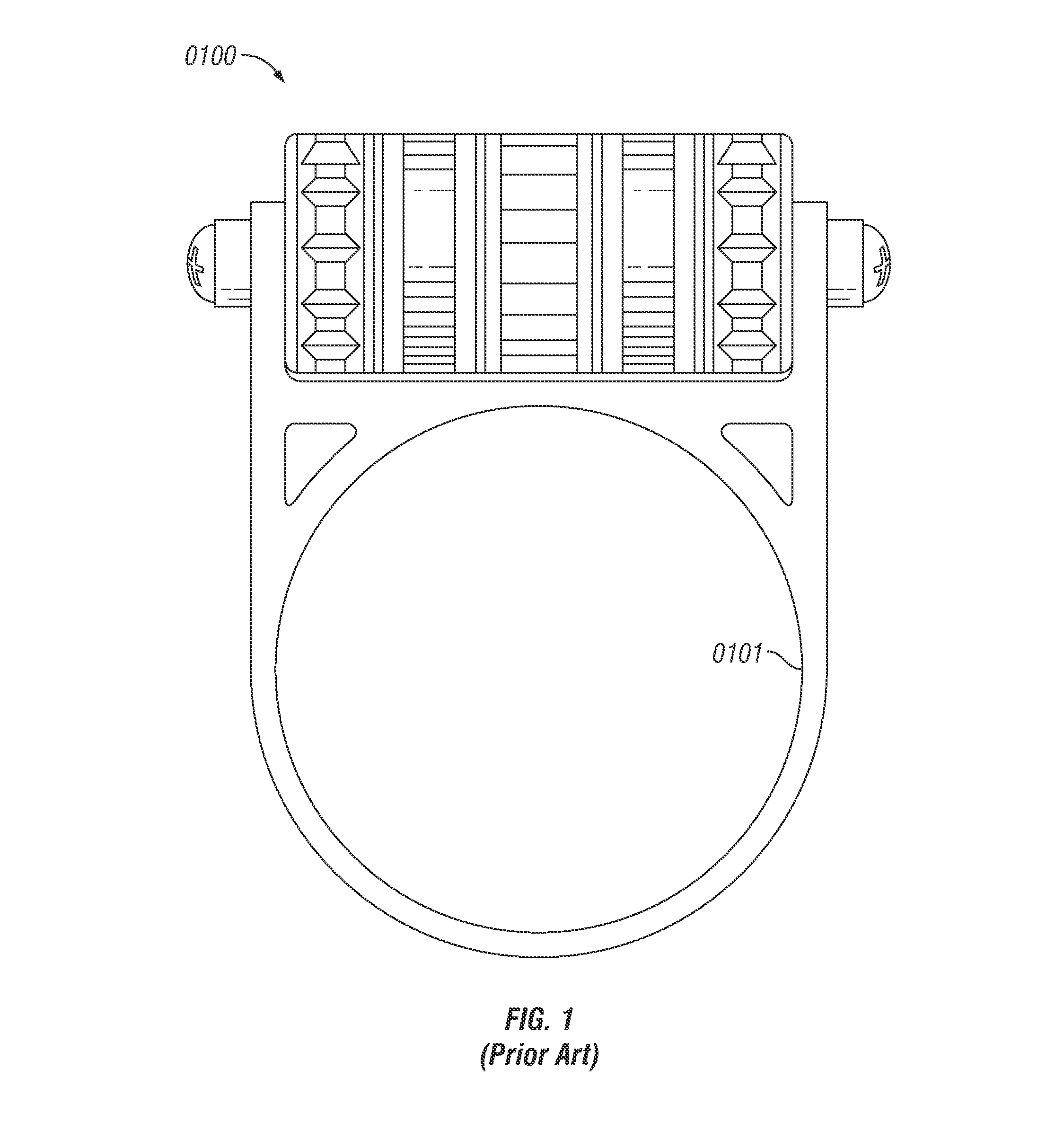

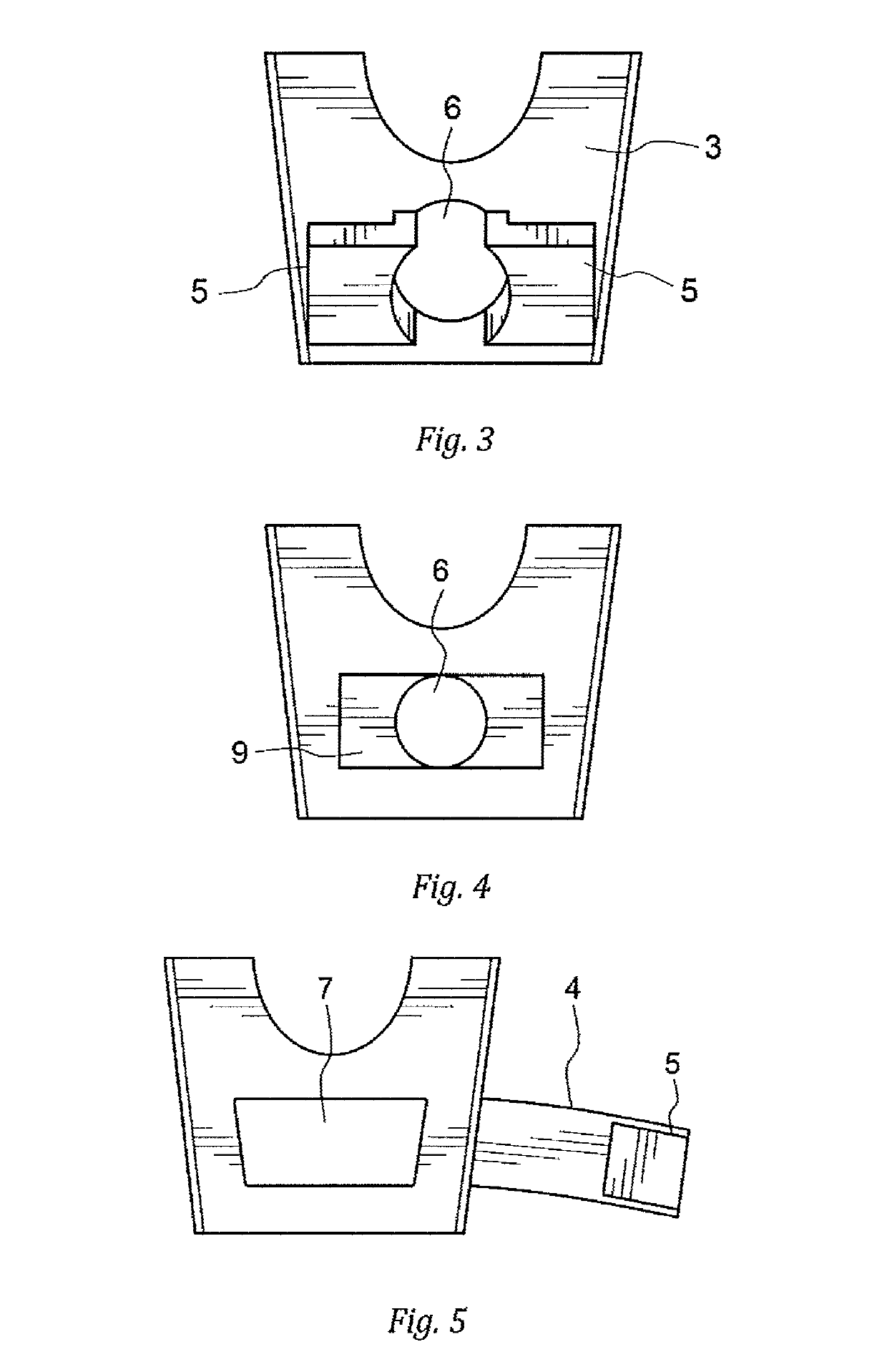

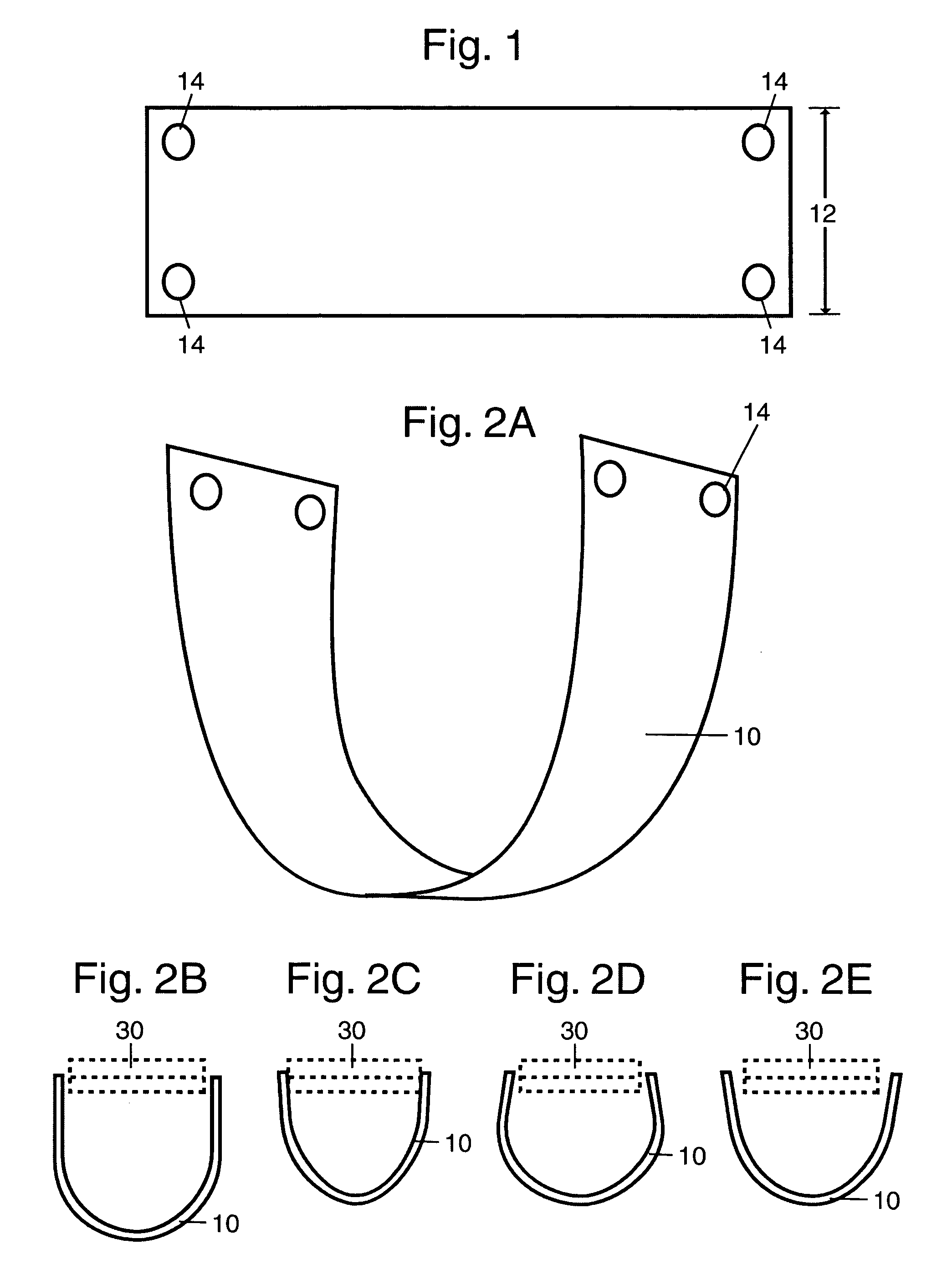

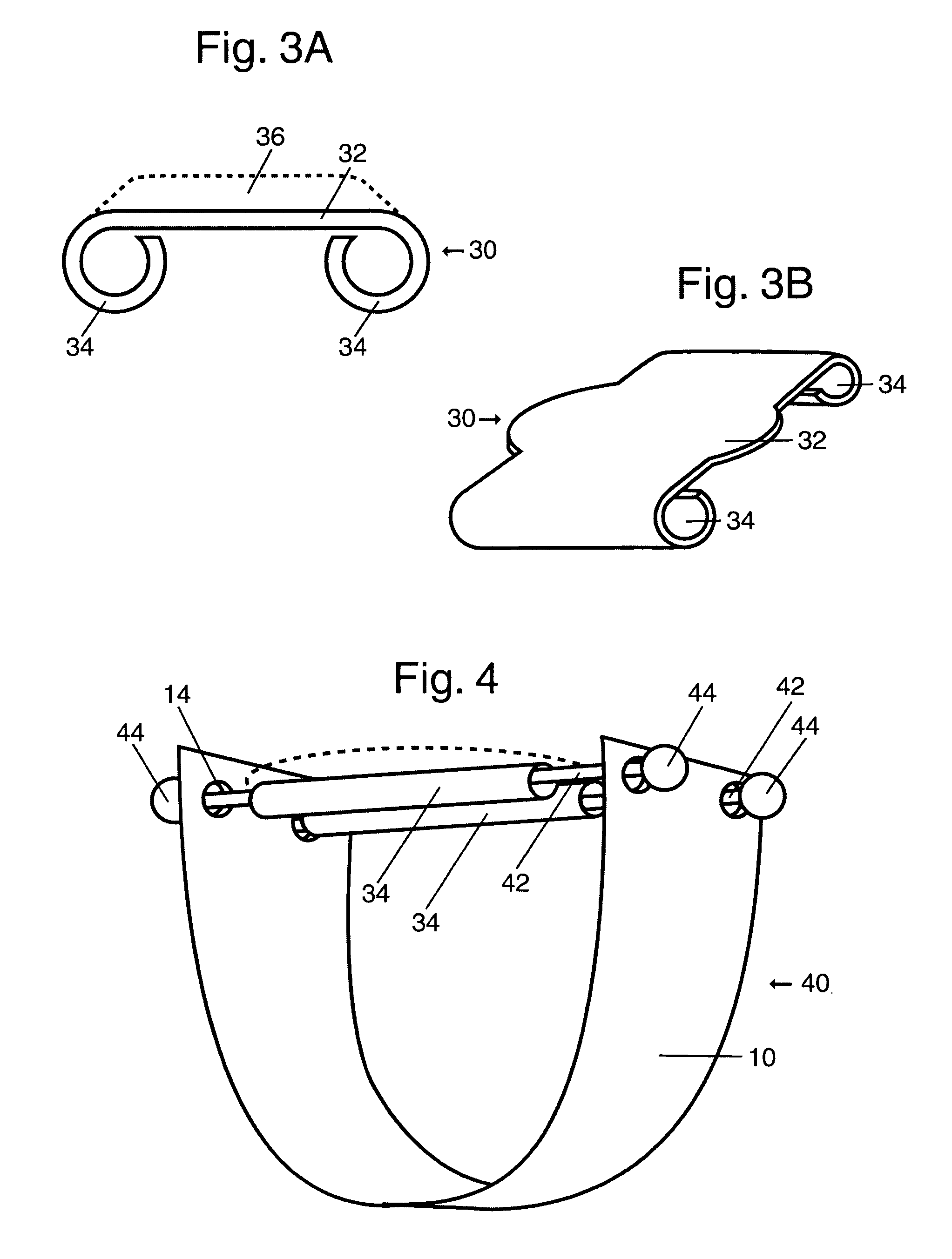

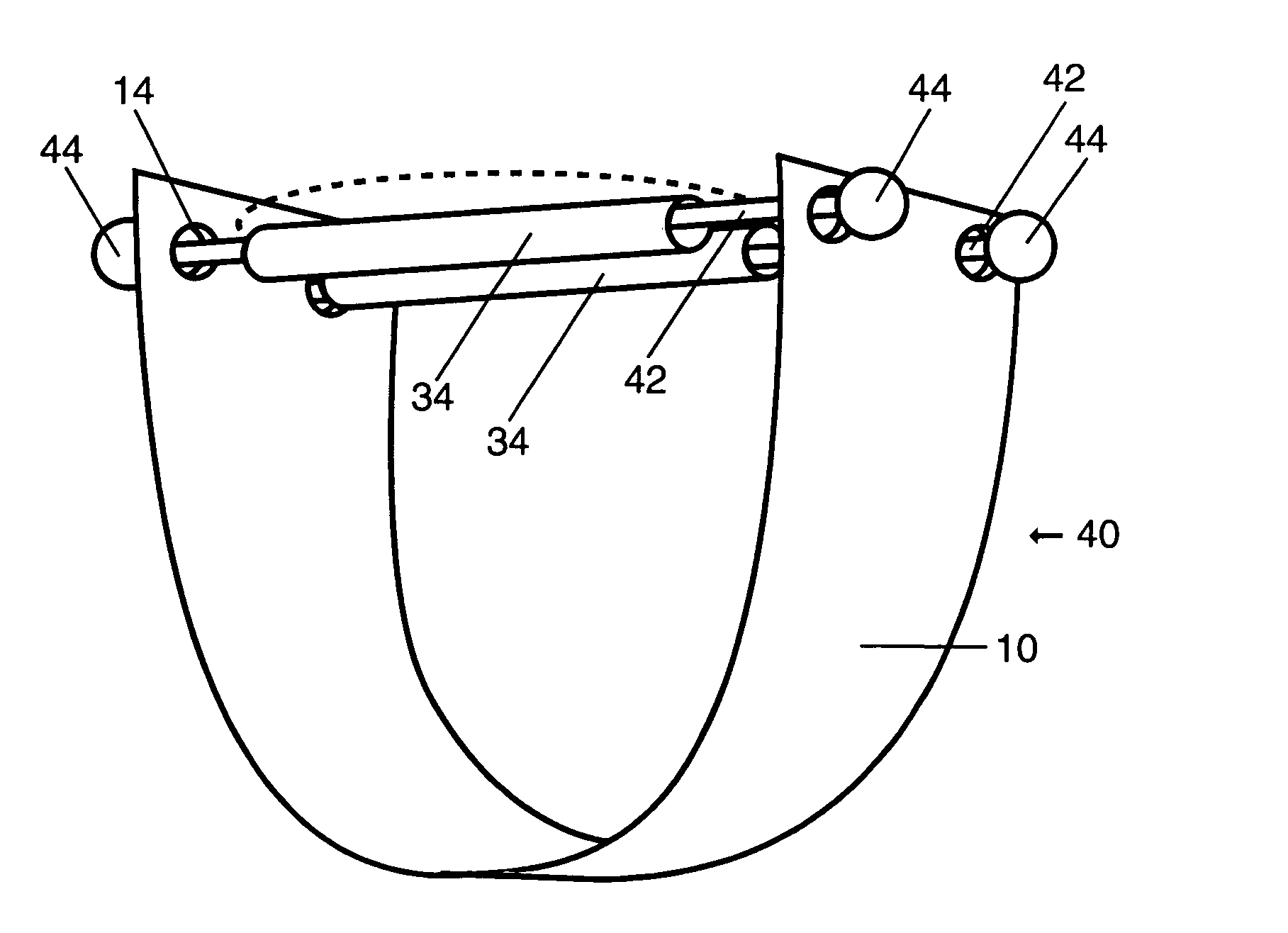

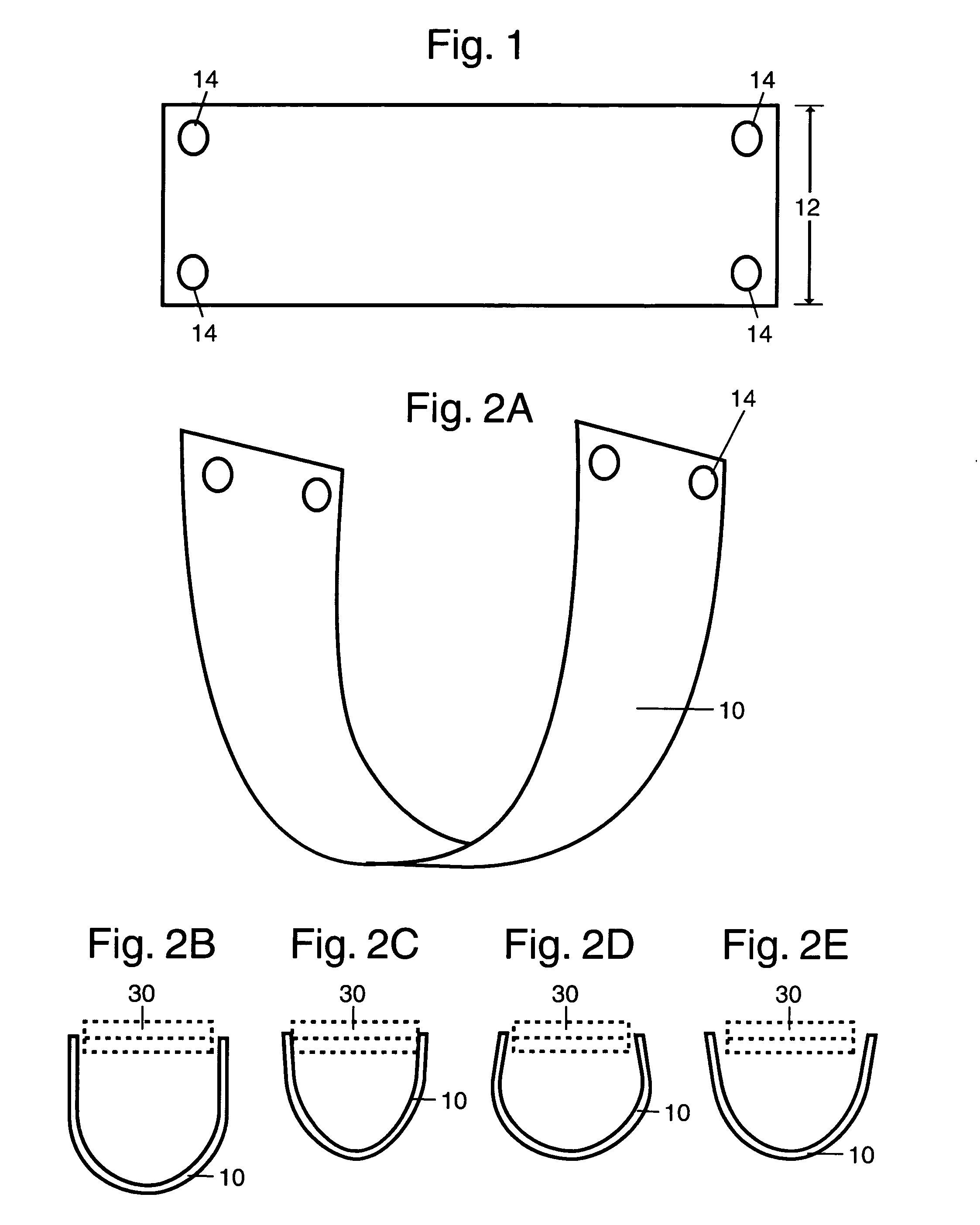

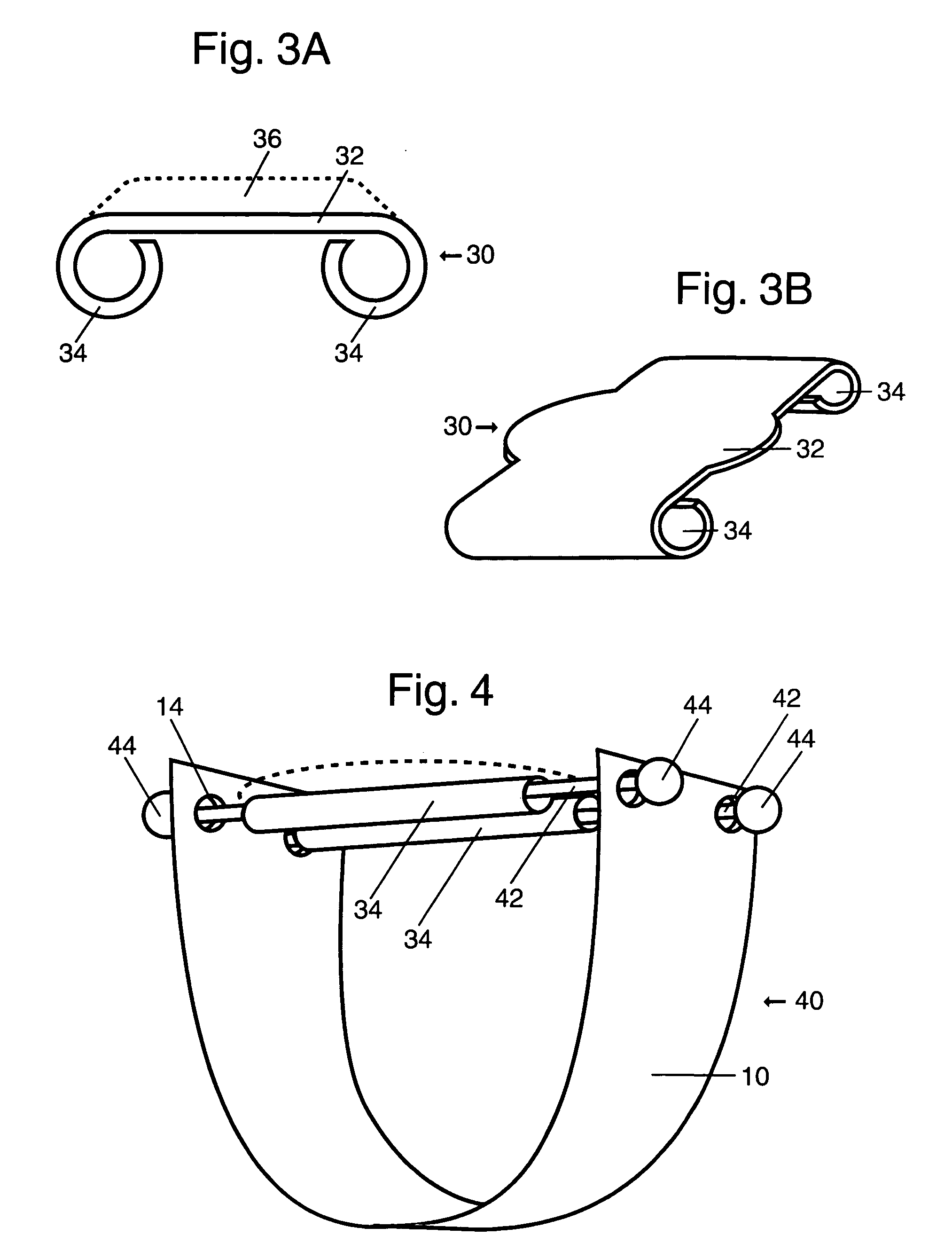

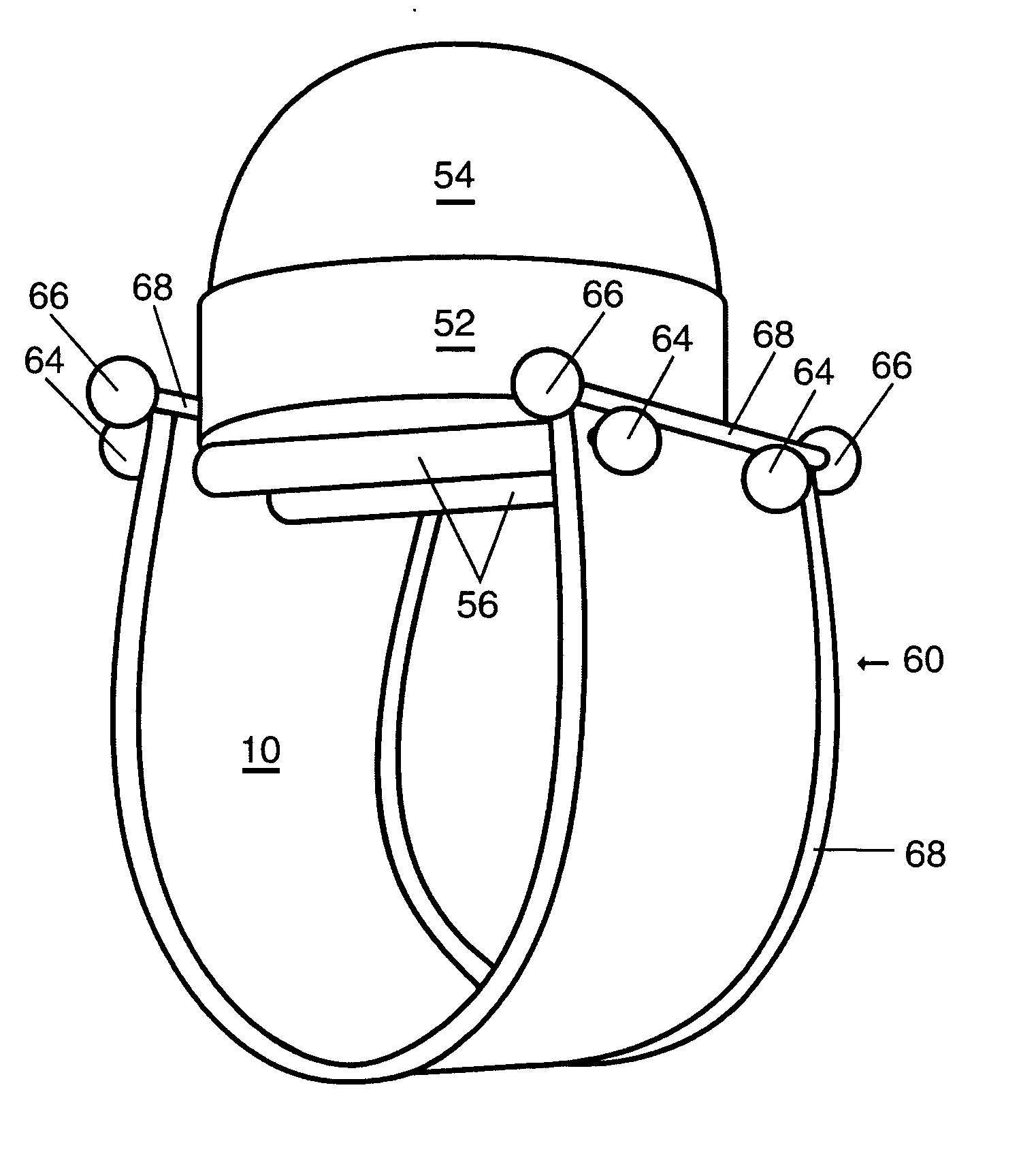

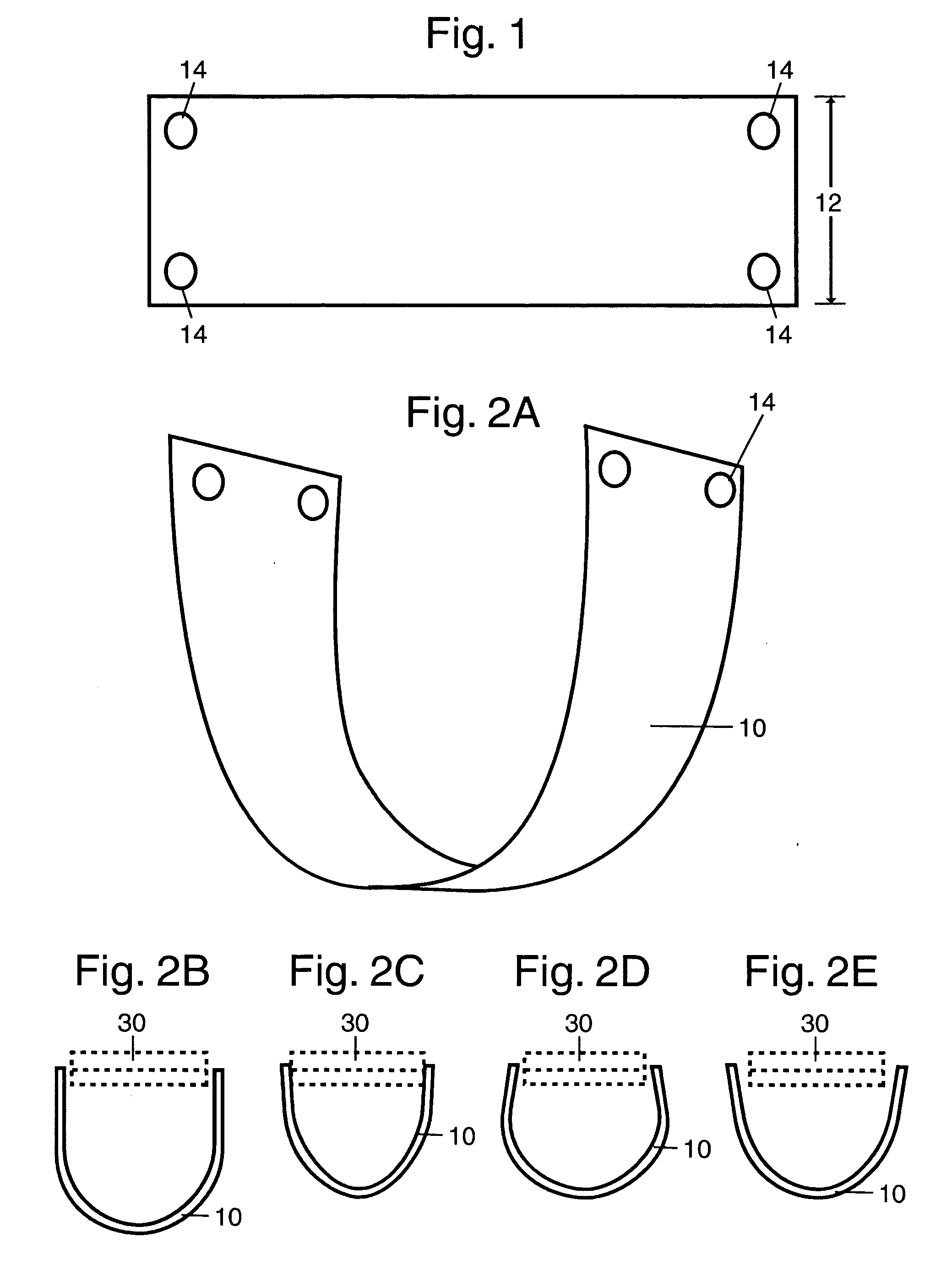

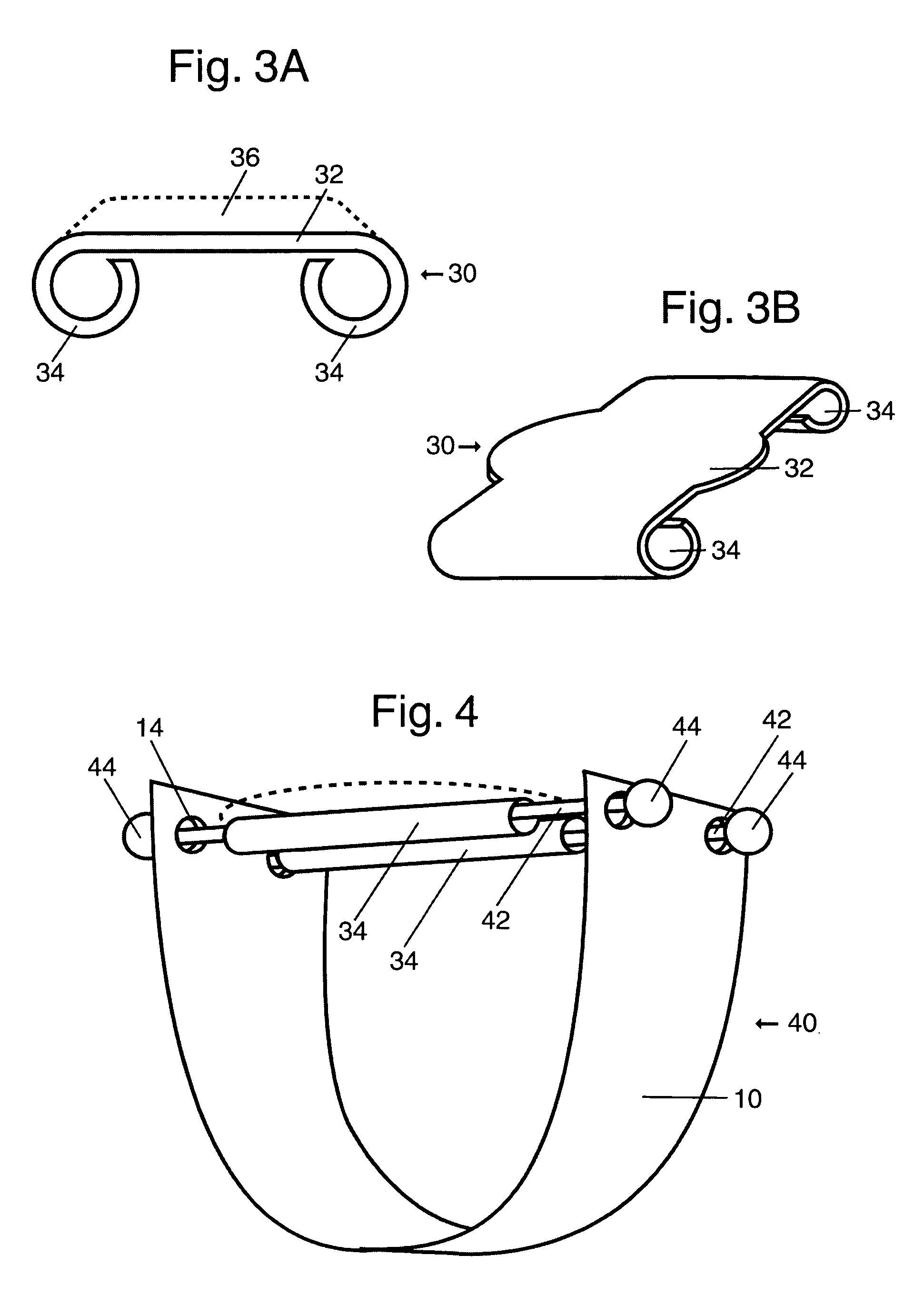

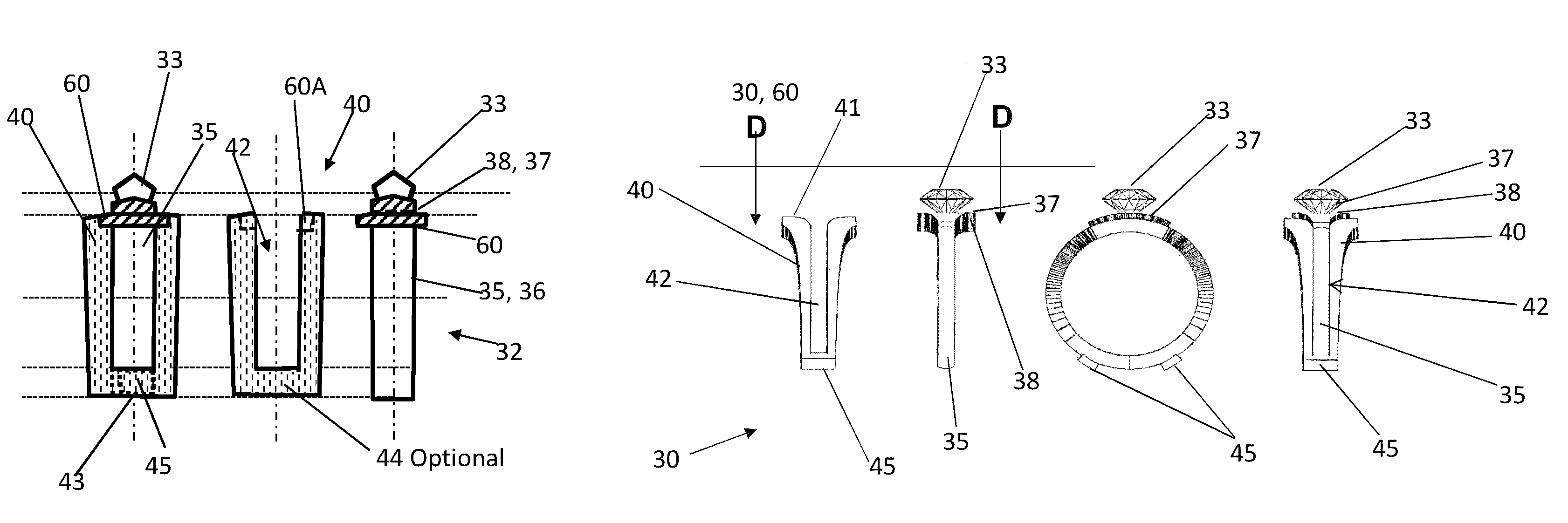

Ornamental ring and assembly method

A jewelry ring and an associated assembly method involves the ring being assembled with a set of easily fabricated components that allow for mass production, easy custom fabrication, and use in hobby kits. The ring employs a U-shaped shank formed of sheet material and a bezel formed of sheet material that are attached to each other in a manner that imparts the ability for the bezel “float.” The bezel has an upper portion formed with sheet material to provide for ornamentation with designs or gemstones. The bezel further includes a lower portion that has a plurality of parallel ferrules. The shank includes a plurality of holes in each end and the bezel is attached to the shank with bars or wires that are inserted through one end of the shank, through the ferrules and through the other end of the shank and secured with retainers.

Owner:ROBERTS SHEA MARTHE

Ornamental ring assembly method

A jewelry ring and an associated assembly method involves the ring being assembled with a set of easily fabricated components that allow for mass production, easy custom fabrication, and use in hobby kits. The ring employs a U-shaped shank formed of sheet material and a bezel formed of sheet material that are attached to each other in a manner that imparts the ability for the bezel “float.” The bezel has an upper portion formed with sheet material to provide for ornamentation with designs or gemstones. The bezel further includes a lower portion that has a plurality of parallel ferrules. The shank includes a plurality of holes in each end and the bezel is attached to the shank with bars or wires that are inserted through one end of the shank, through the ferrules and through the other end of the shank and secured with retainers.

Owner:ROBERTS SHEA MARTHE

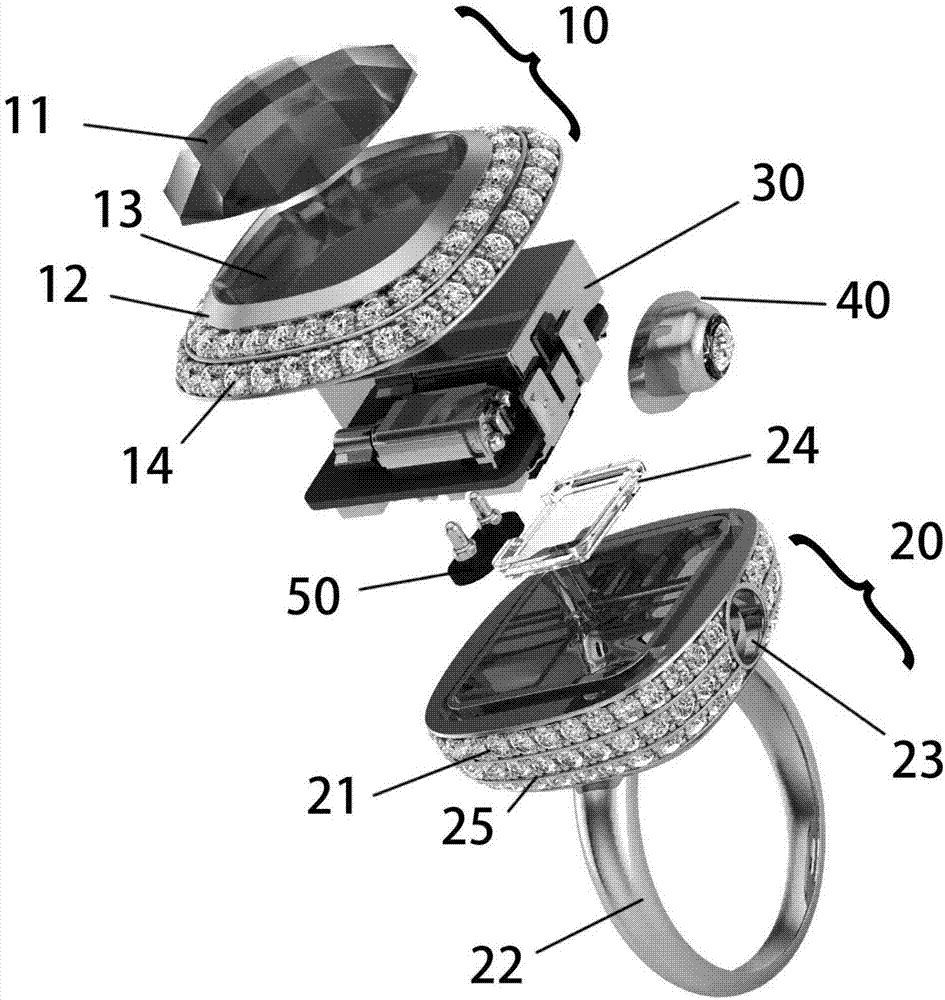

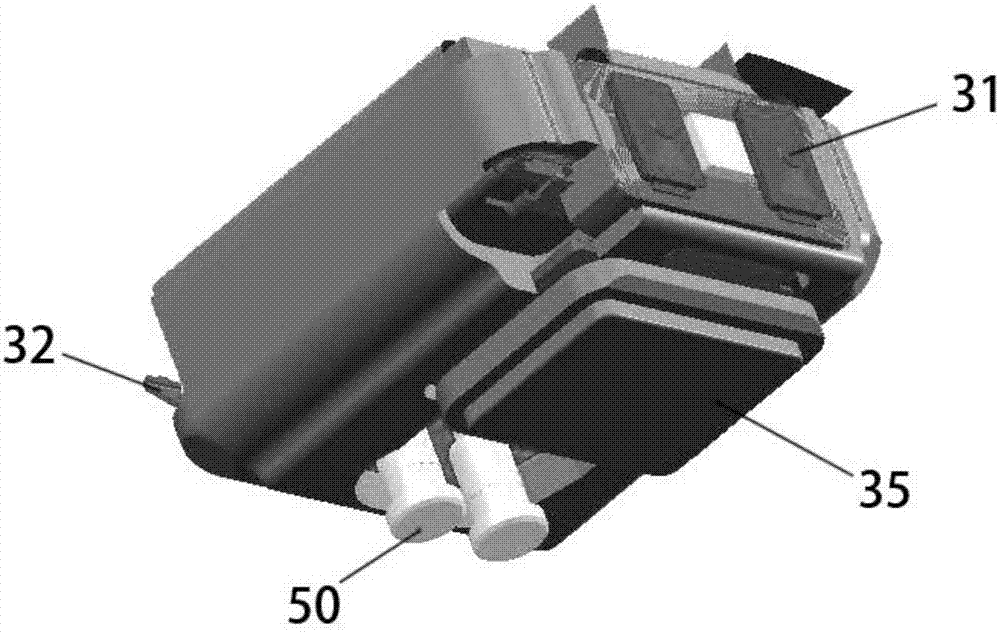

Intelligent jewelry ring

PendingCN107495559ASimple structureNice appearanceSensorsMeasuring/recording heart/pulse rateKey pressingClosed chamber

The embodiment of the invention discloses an intelligent jewelry ring. The intelligent jewelry ring disclosed by the embodiment of the invention comprises an upper intelligent jewelry ring part and a lower intelligent jewelry ring part; a closed chamber is formed after the upper intelligent jewelry ring part and the lower intelligent jewelry ring part are fully combined and coincided with each other; an annular part, into which a finger is inserted, is formed on the lower intelligent jewelry ring part; an intelligent chip module is arranged in the chamber; a button hole is formed in the lateral edge of the lower intelligent jewelry ring part; a button is arranged in the button hole; one end of the button is exposed on the exterior of the intelligent jewelry ring while the other end is inserted into the lower intelligent jewelry ring part, extends into the chamber of an intelligent ring main body and is resisted against a button module arranged on the intelligent chip module. The intelligent jewelry ring disclosed by the embodiment of the invention has a simple structure and beautiful and elegant appearance and meets the basic condition of a decoration function of a ring, and meanwhile, the intelligent chip module is arranged in the ring, is capable of interacting with the other external equipment and is used for delivering and expressing emotion, so that the intelligent function of the ring is realized.

Owner:深圳缪斯智能珠宝有限公司

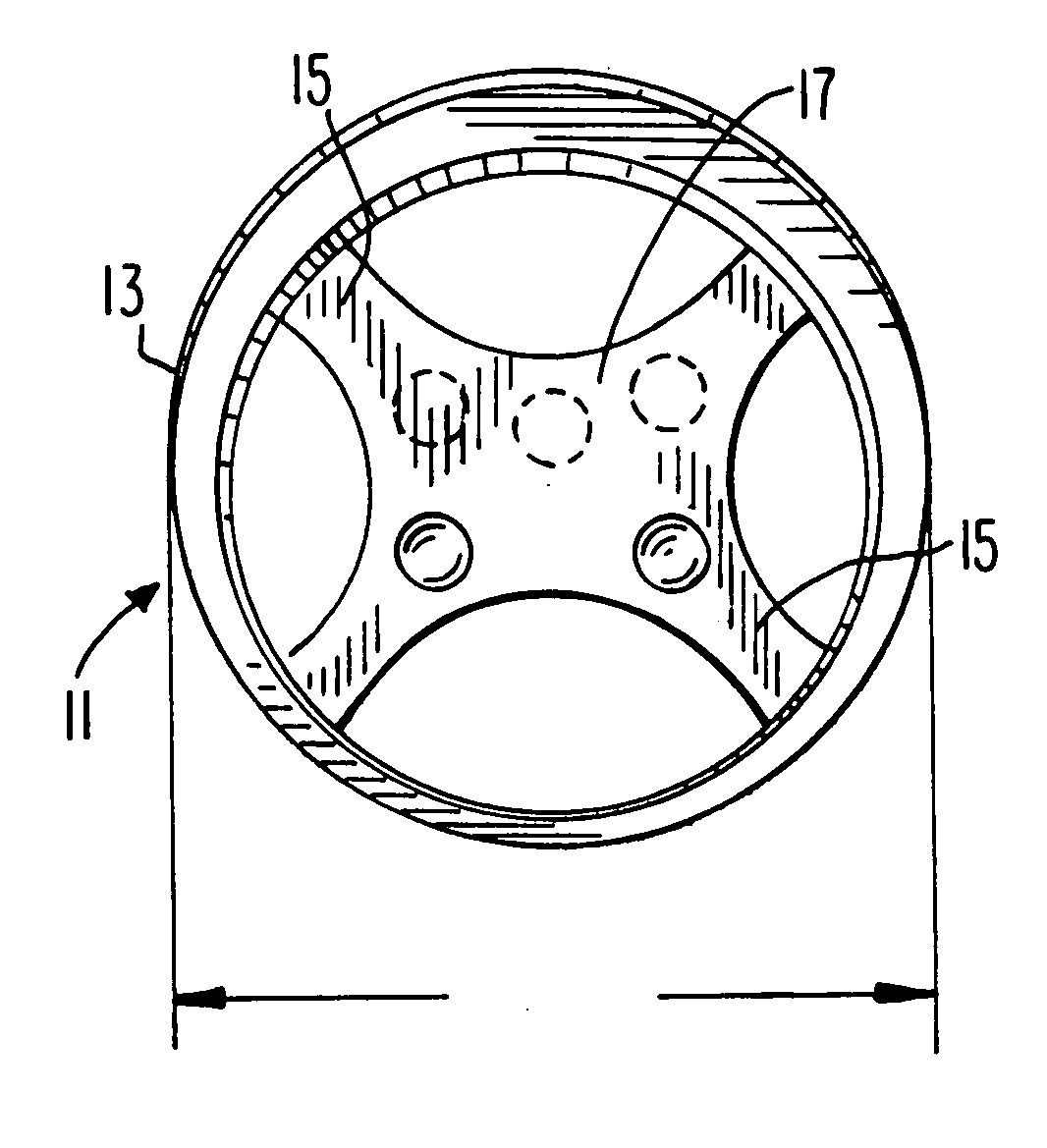

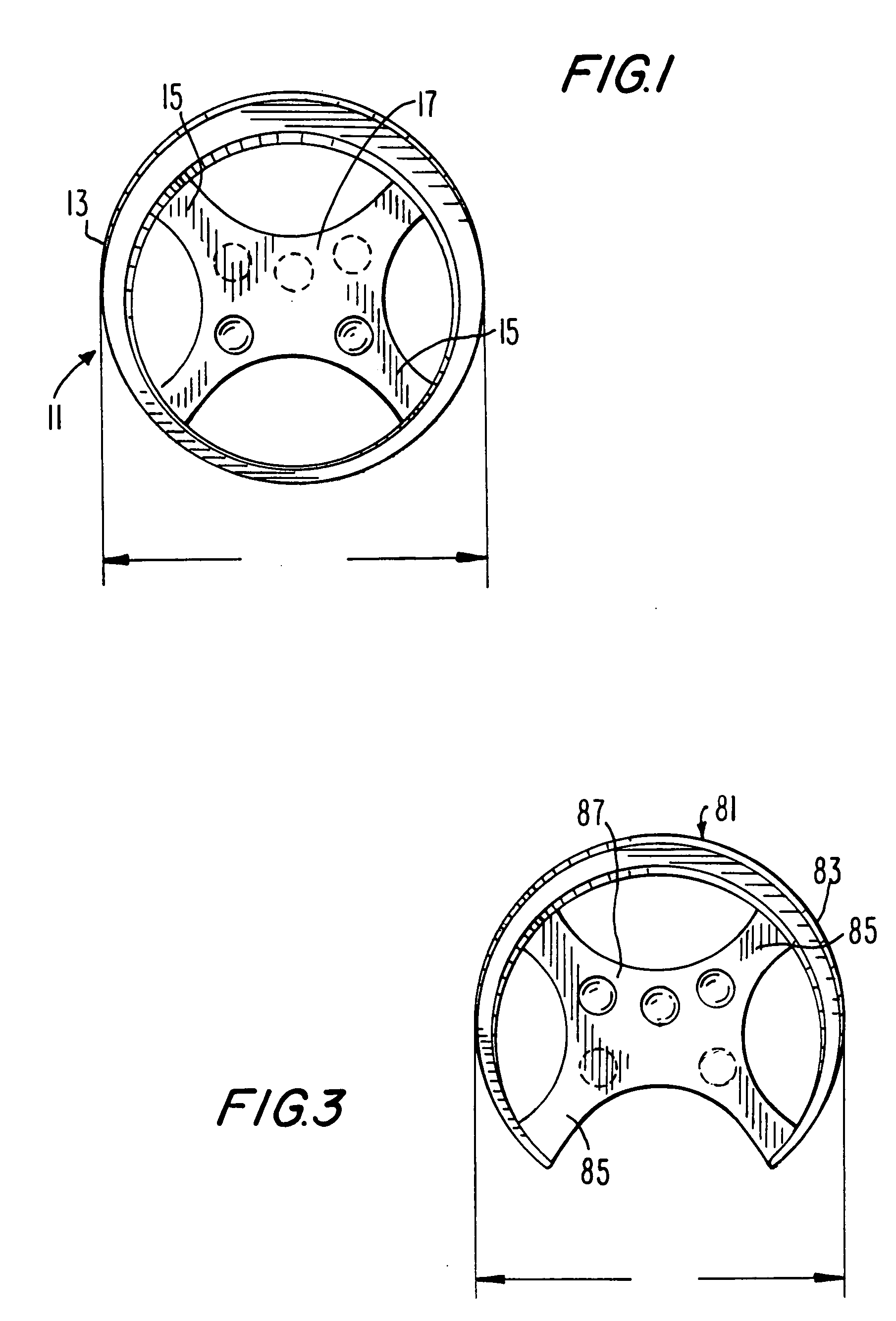

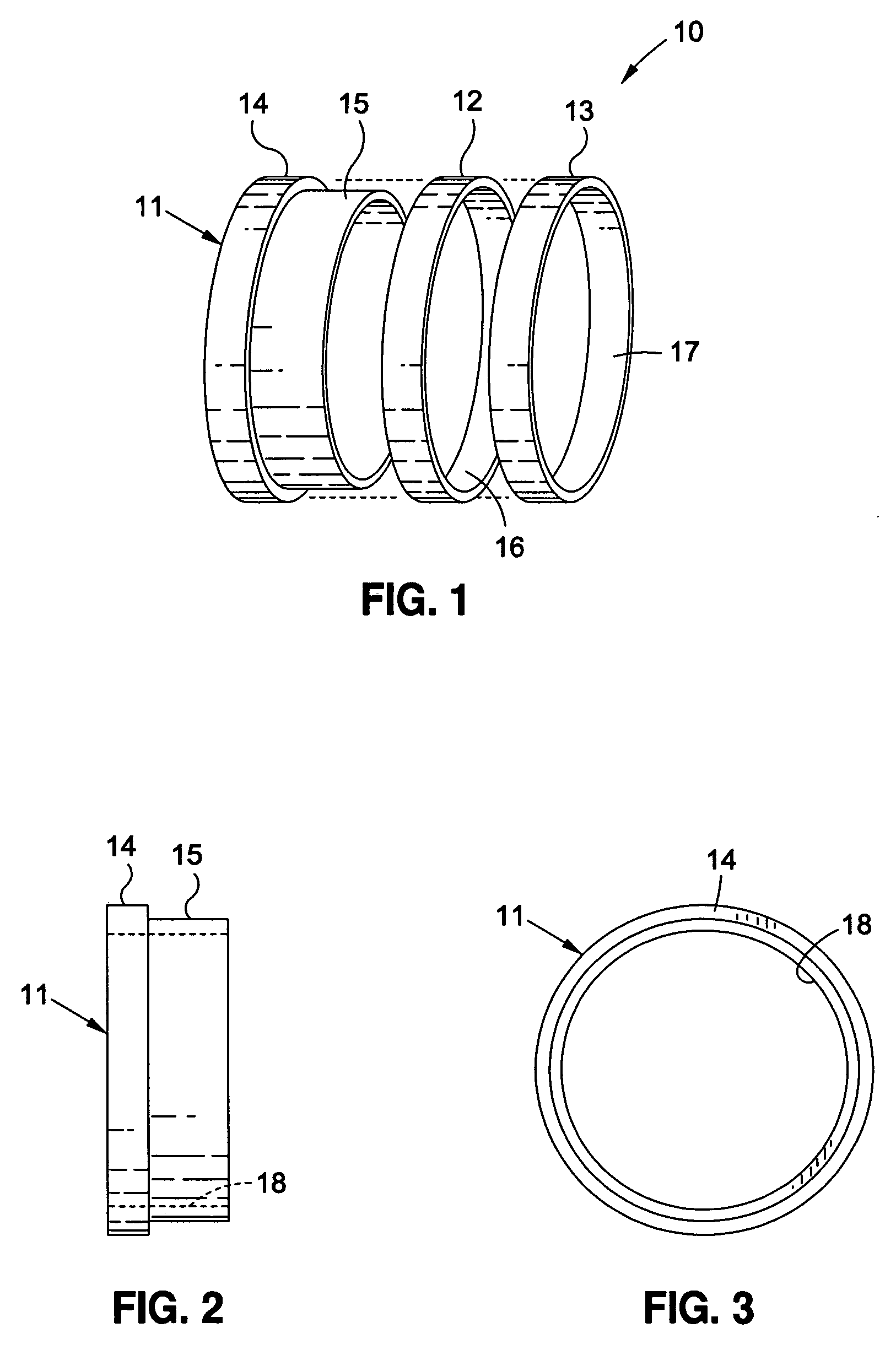

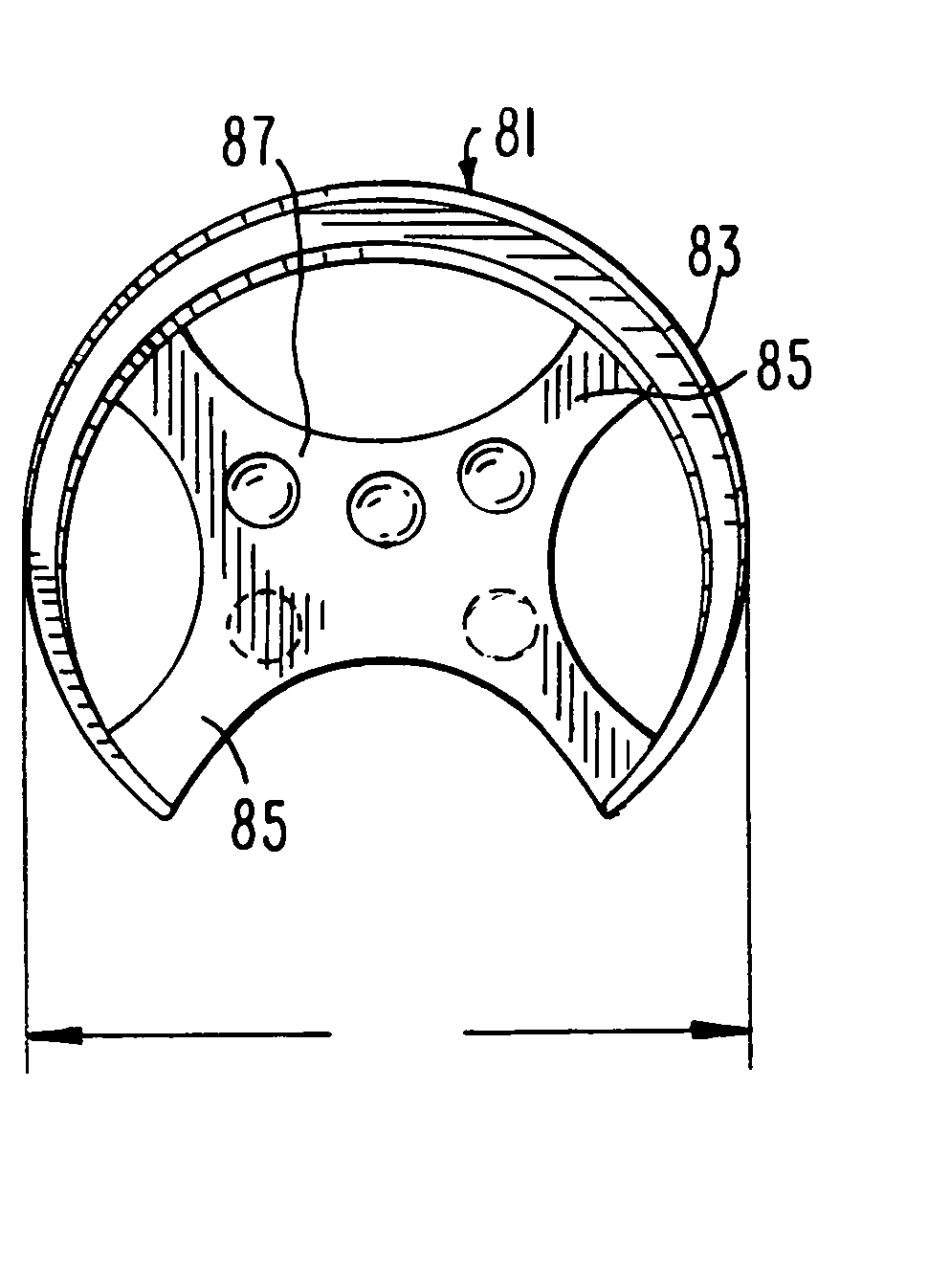

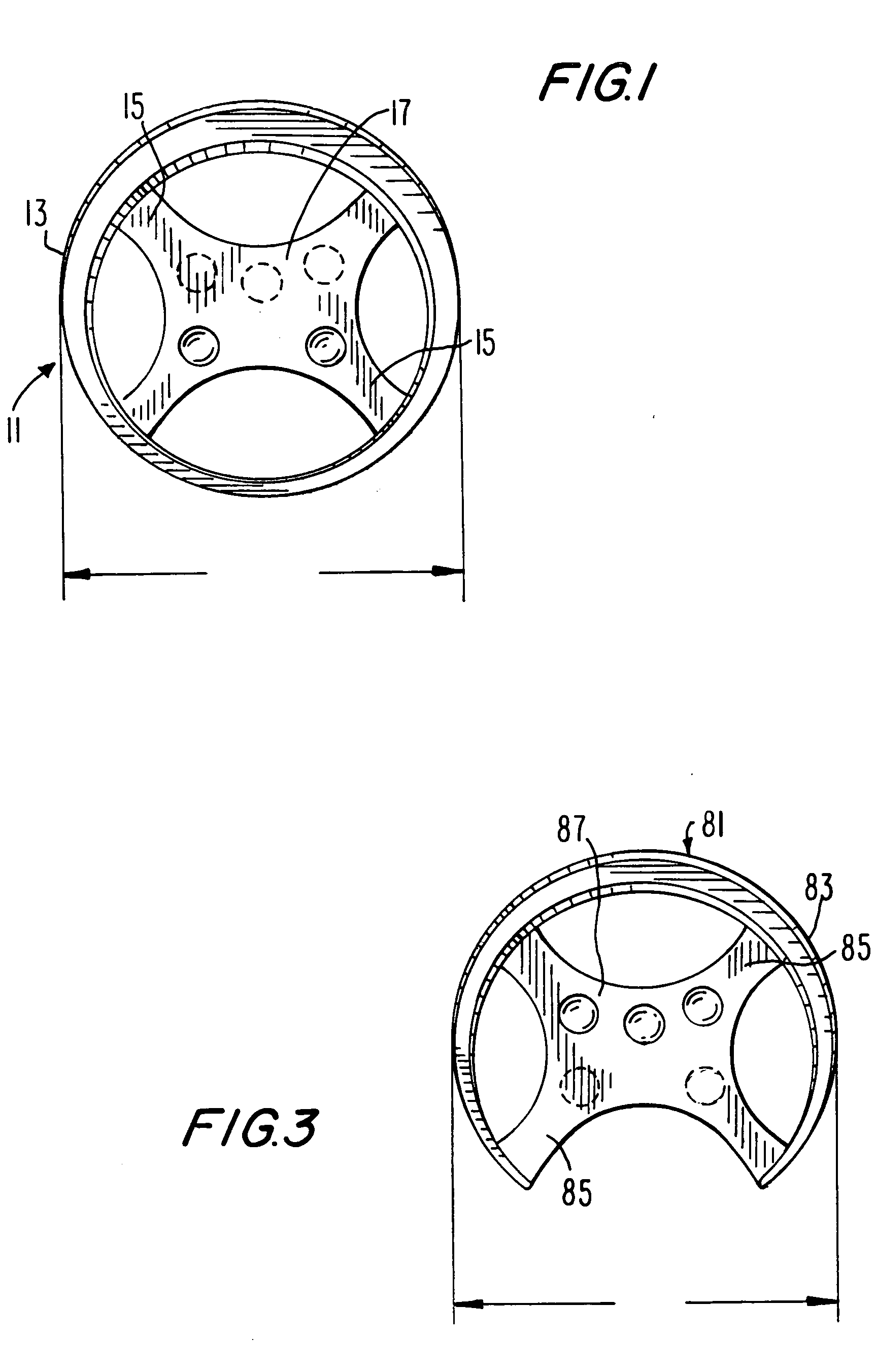

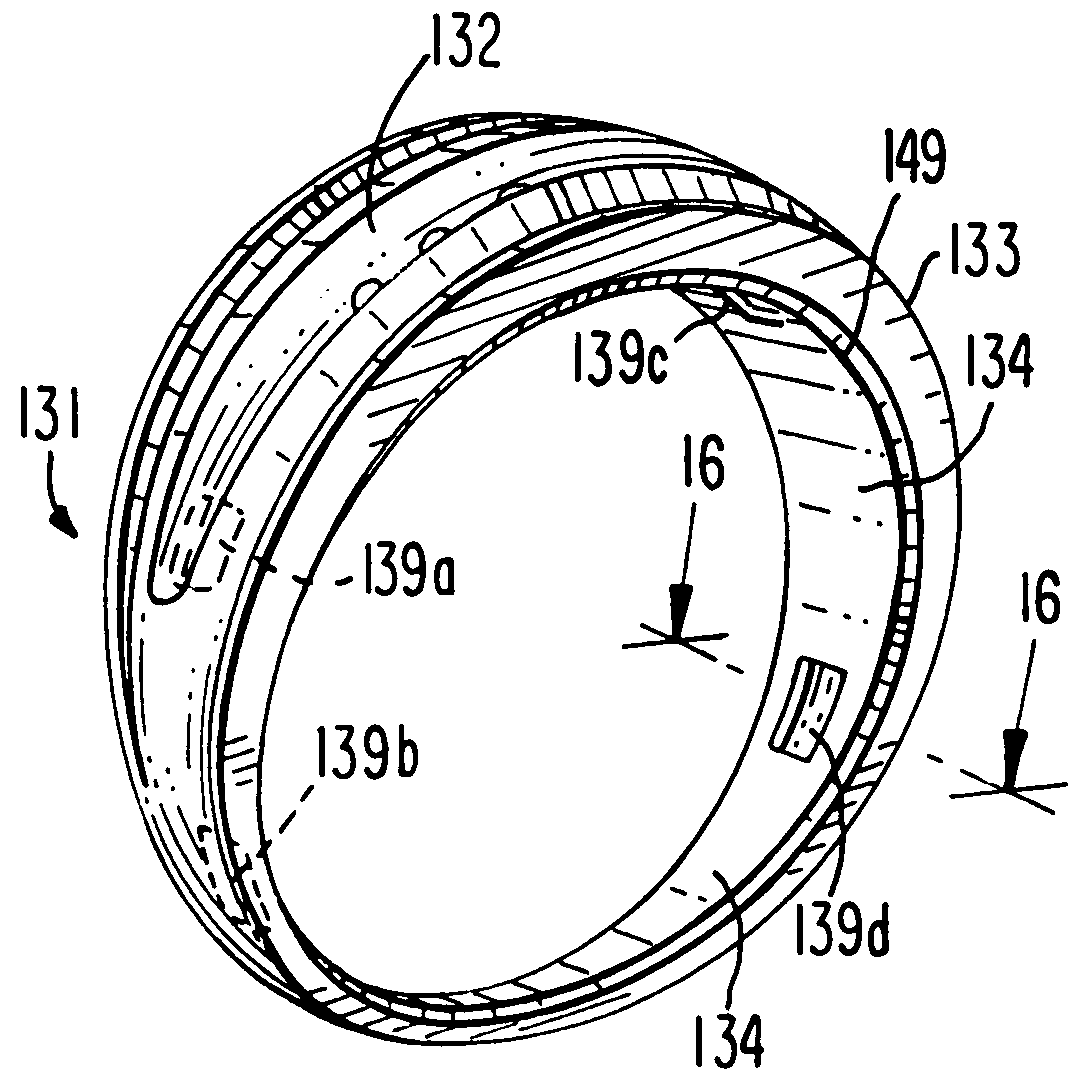

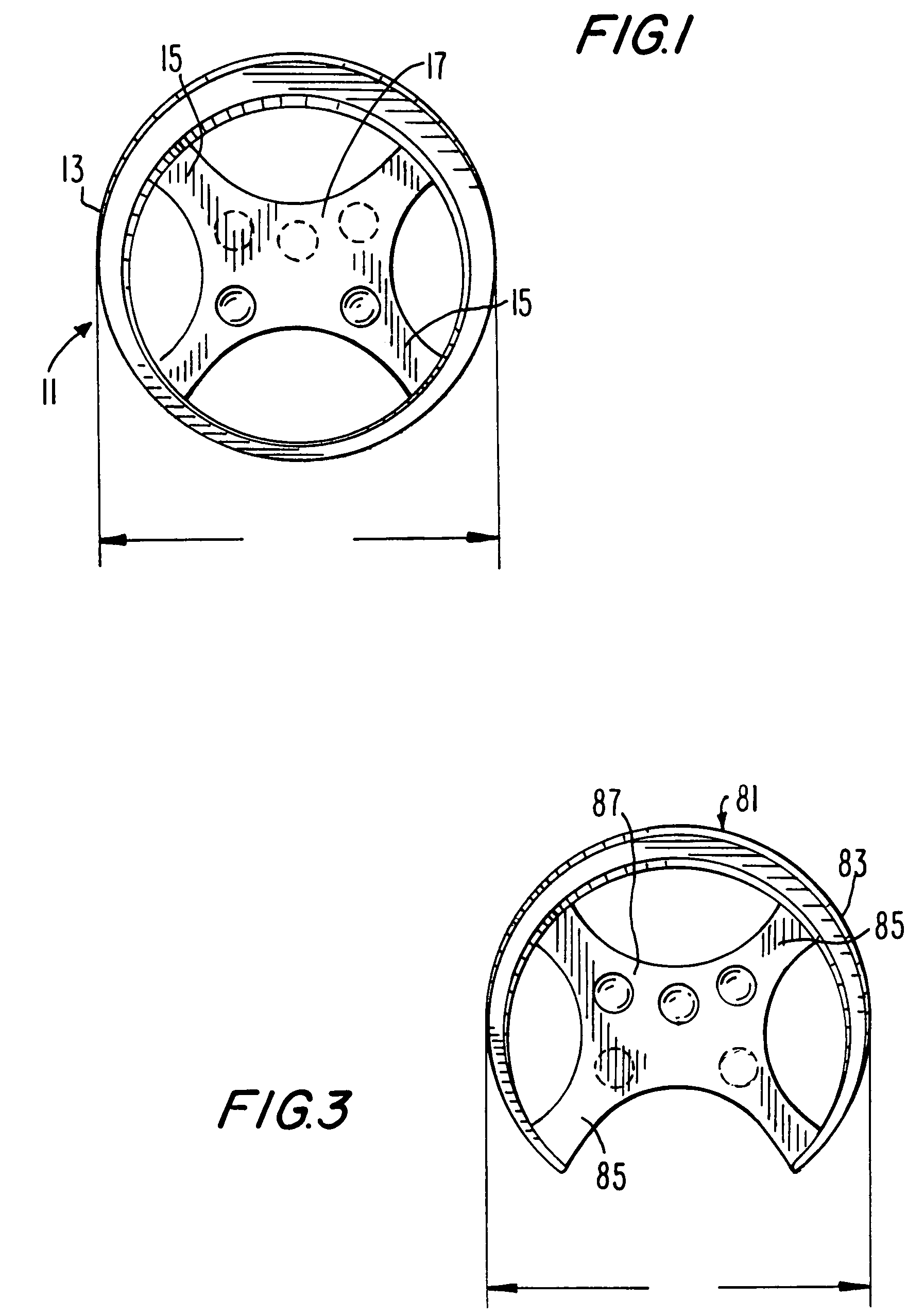

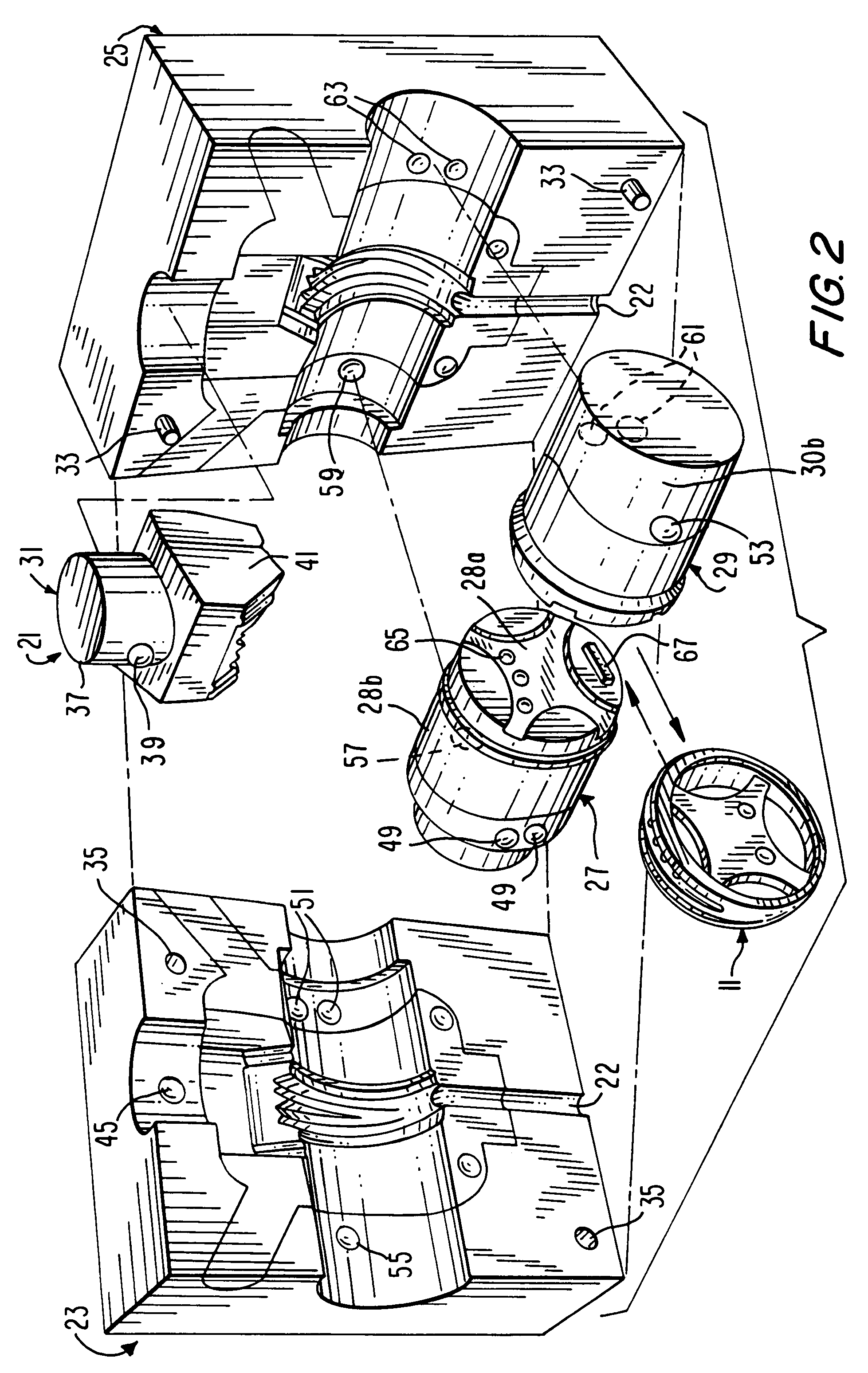

Hollow metal jewelry ring

There is provided a method or process for fabricating a hollow jewelry article which is hollowed or bored out. In accordance with this process, a metal ring model is prepared comprising a solid shank and a metal plate supported along the internal perimeter of the shank by means of a series of spokes extending from the shank. A first metal mold is produced from the metal ring model having the external shape of the jewelry article to be manufactured. From this mold, a wax model of the jewelry article is produced which is first filed down and then cast in order to form a metal model of a core insert; the core insert, like the ring model, has a plate disposed along the perimeter of the shank. This core insert is used to produce a second metal mold. This second mold may then be used repeatedly in order to form a soluble wax core insert model which is then inserted into the cavity of the first mold in order to define the hollow region of the article. A non-soluble wax is then introduced into the first mold for completely surrounding the soluble wax core insert. The non-soluble wax then hardens and the entire unit is removed from the first mold, including the soluble wax core. The core is then removed by a suitable water soluble or chemical mechanism. The remaining wax model contains a hollow core running along a substantial portion of the arcuate length of the shank; the shank has a finger facing surface formed with a plurality of openings which lead to said core. The wax model is then cast in order to form the inventive ring design.

Owner:QUALITY CASTING

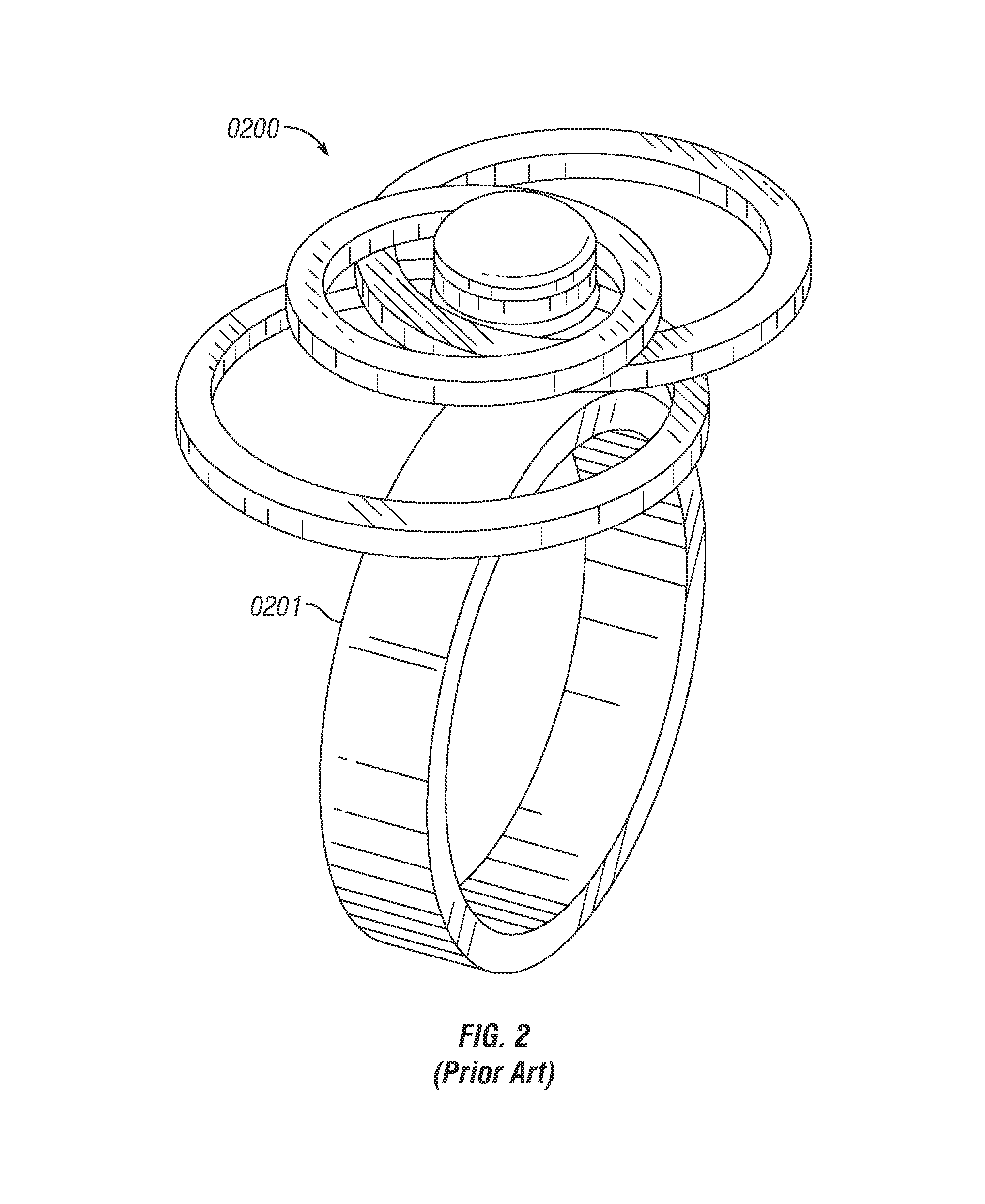

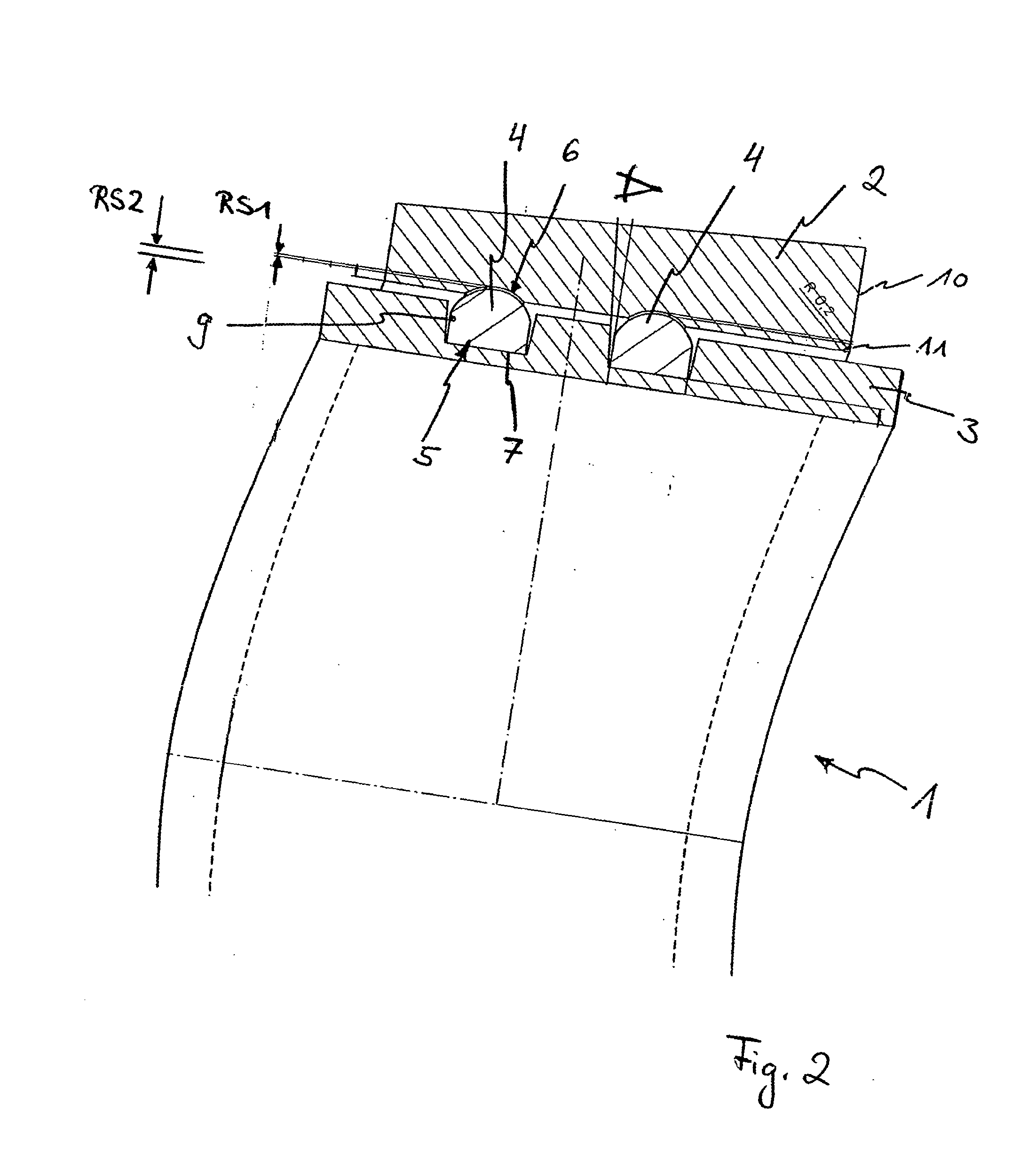

Jewelry ring and method for the production thereof

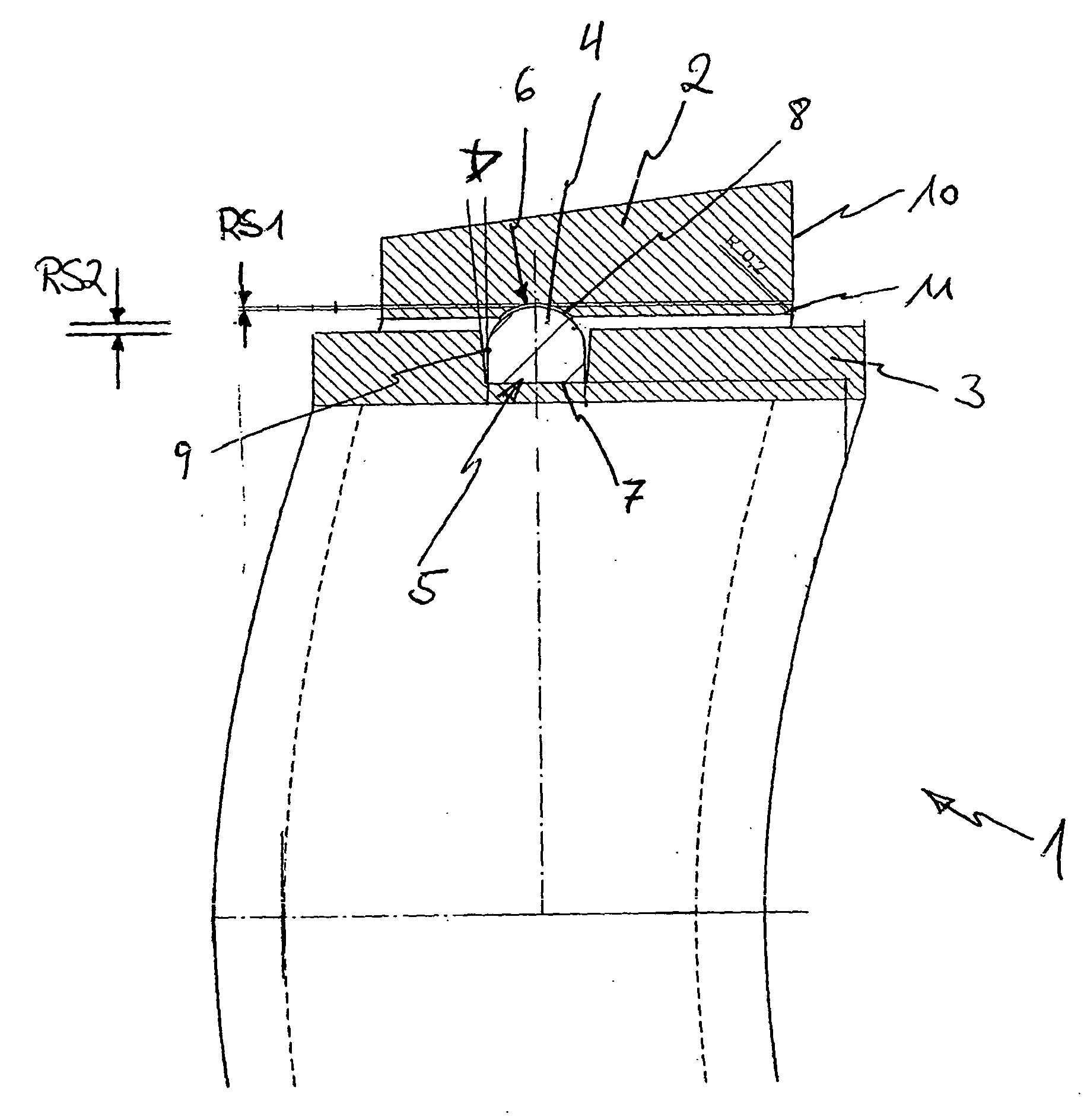

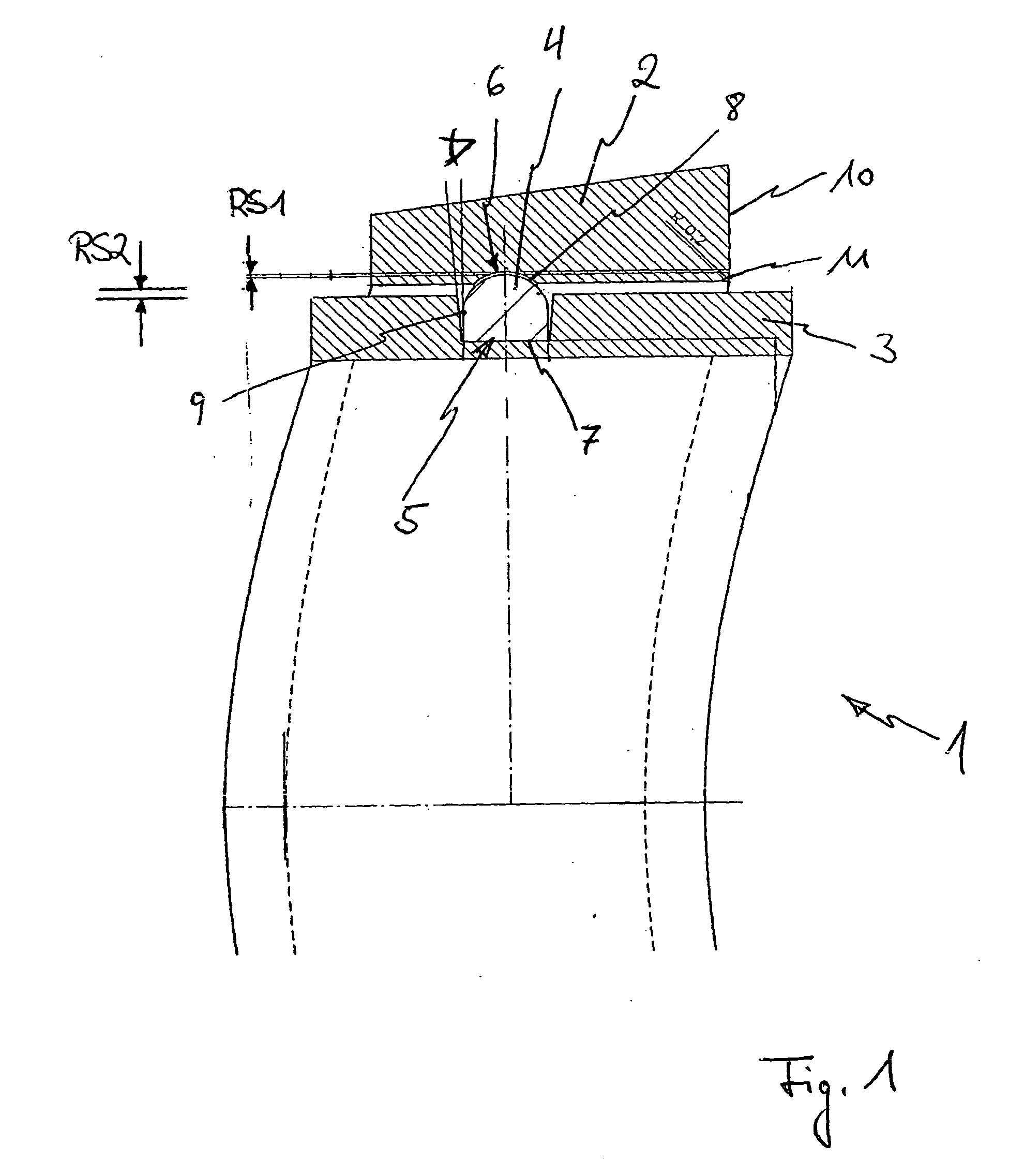

InactiveUS7937965B2Avoid it happening againEliminate relative motionFinger-ringsEngineeringSlip ring

Owner:MONTBLANC SIMPLO

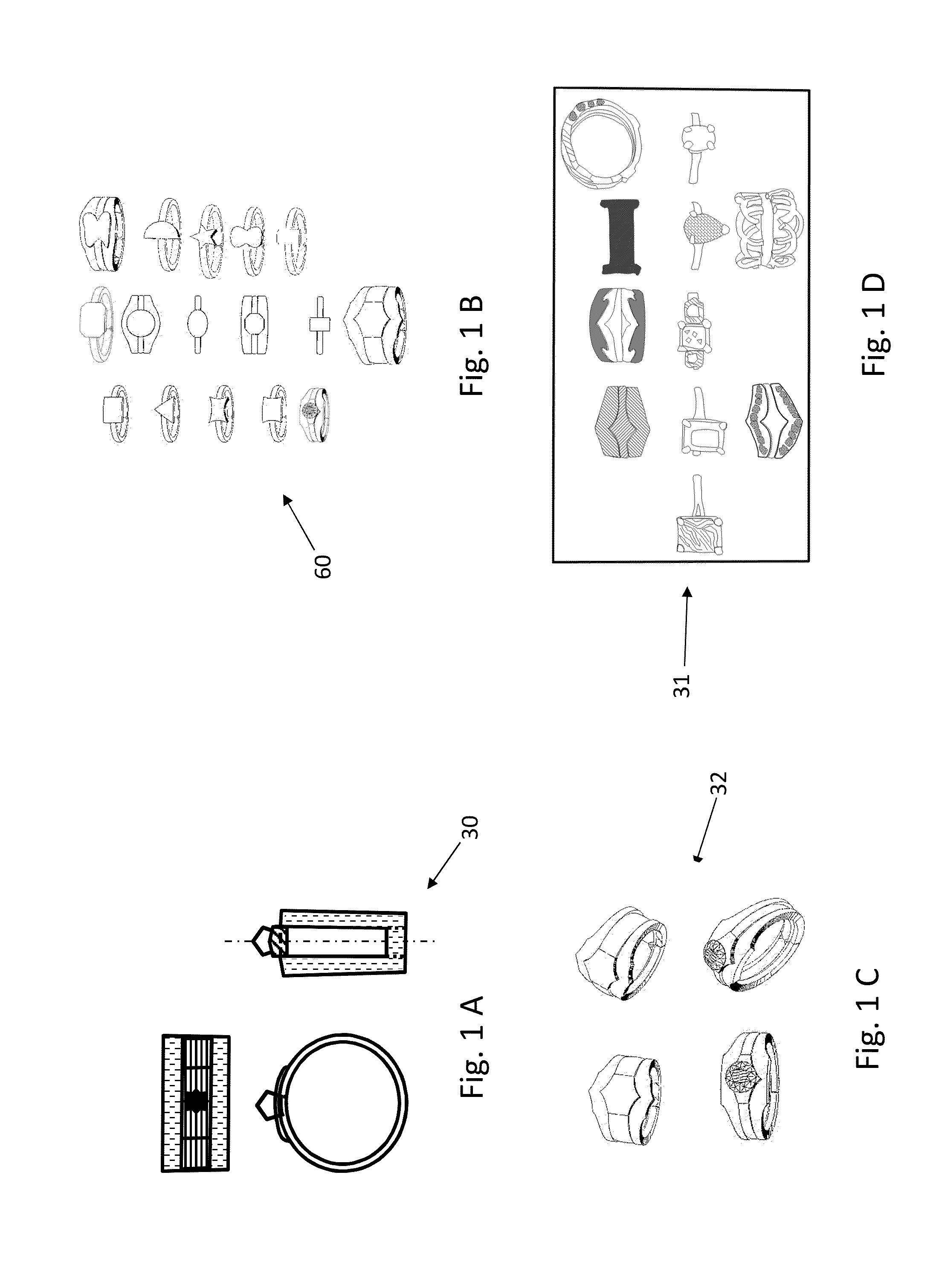

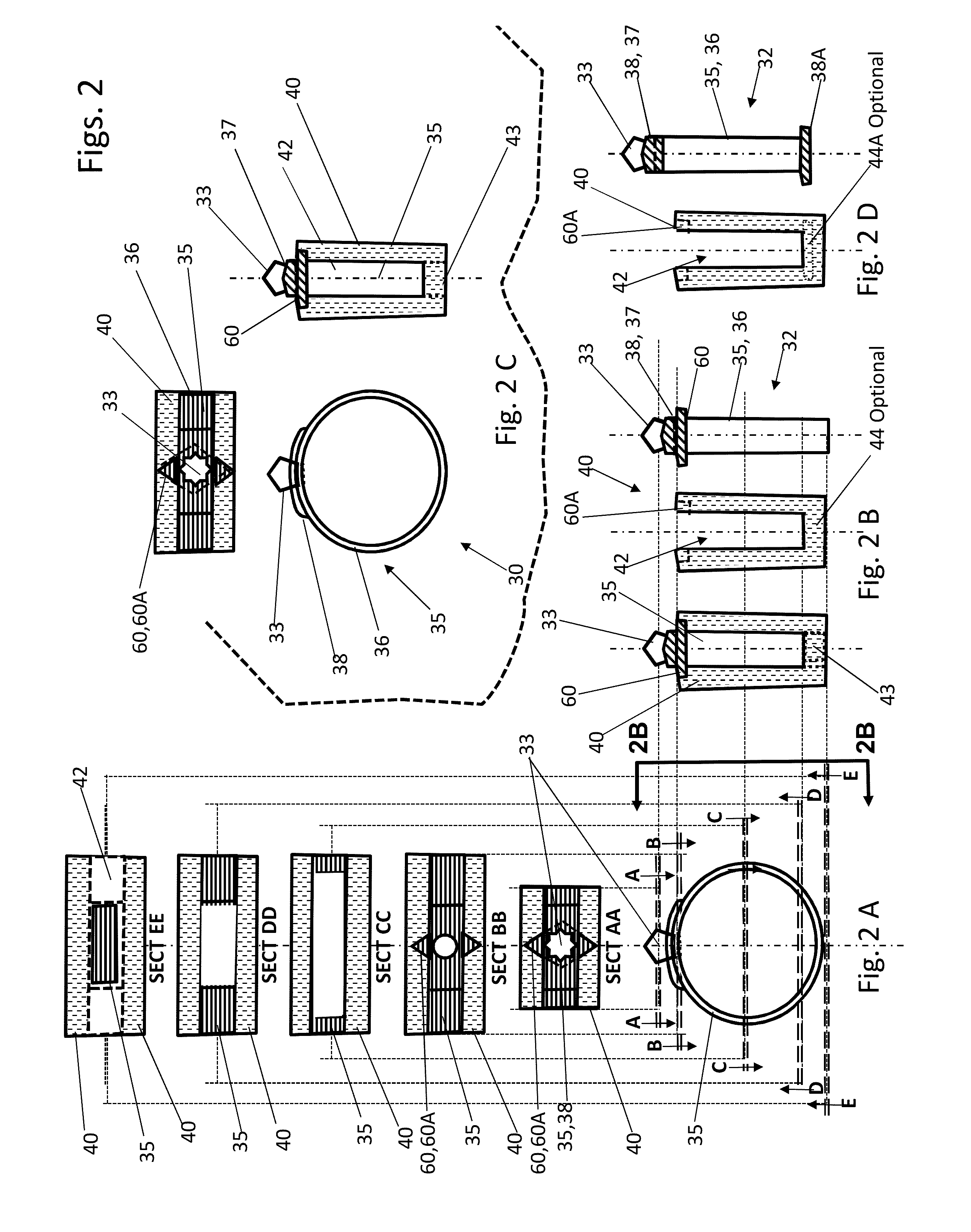

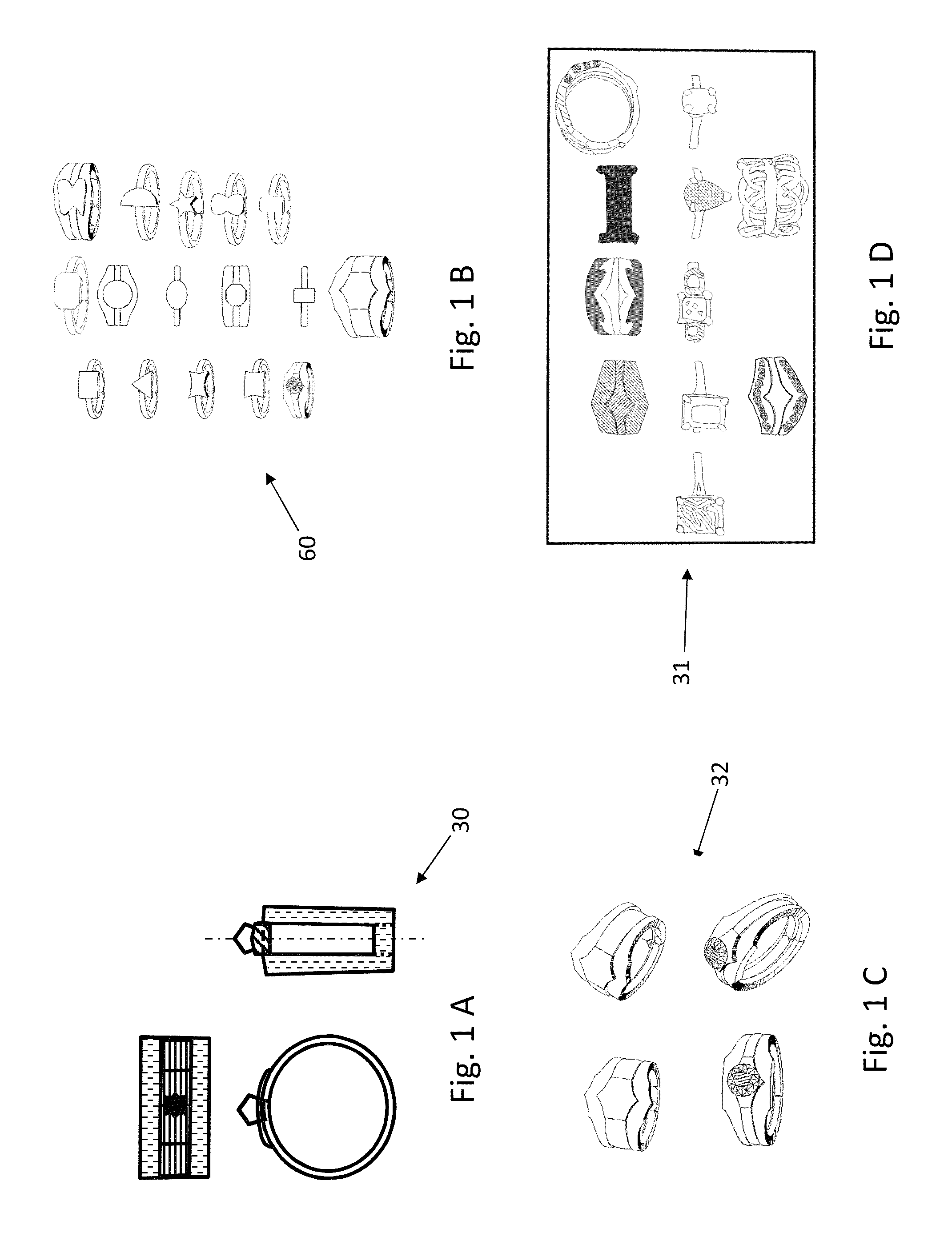

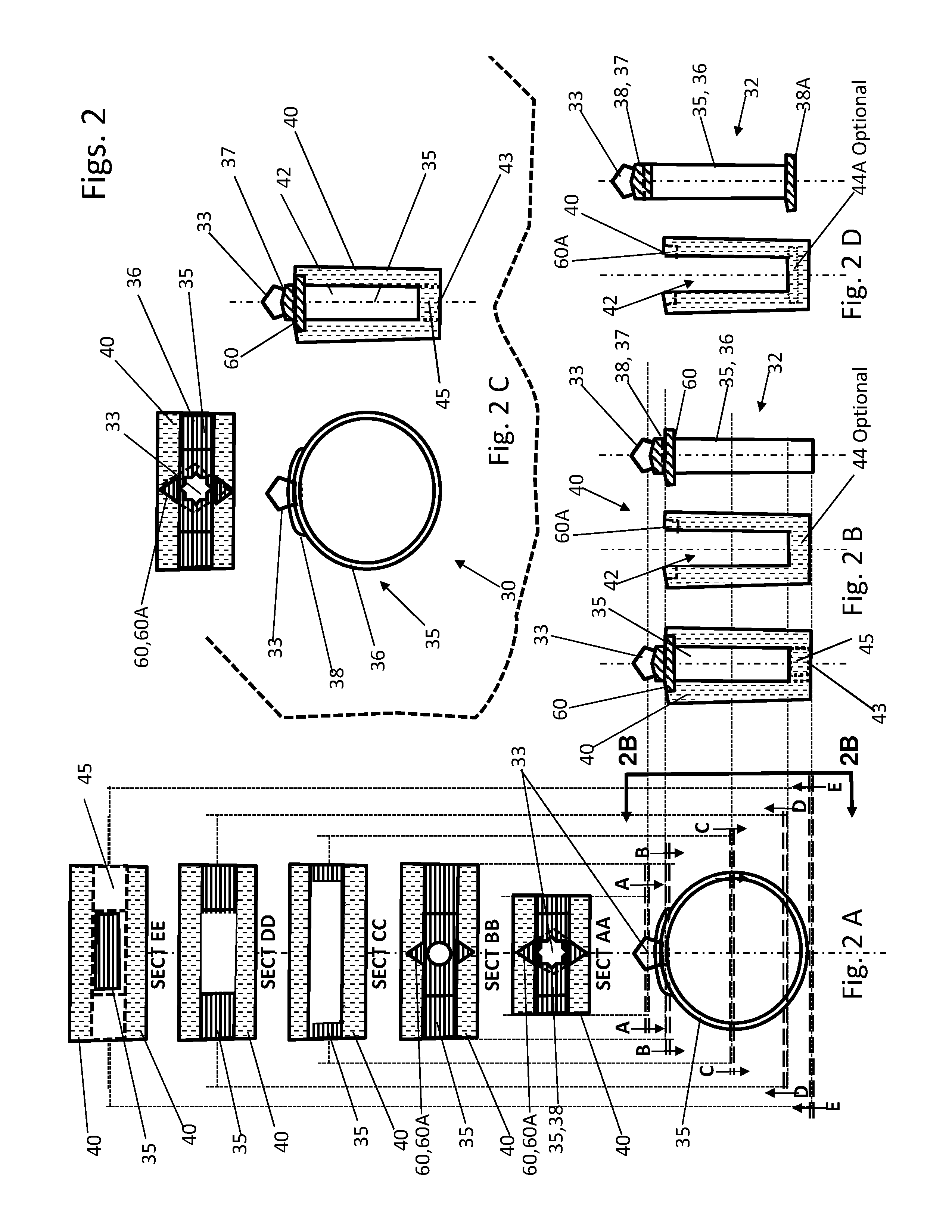

Interlocking Ring System and device with Interchangeable Outer Jackets and Center Rings called a TULIP.

A jewelry ring configuration having interchangeable elements and especially jewelry rings which have a decorative feature mounted on a center ring. This new device / process may be simply described as a device for an interlocking ring system and device with interchangeable outer jackets and center rings comprised with a center ring, ornate and decorative or smooth and with or without gemstones, the center ring in various mounting styles such as prong, bezel, pave etc.; and a jacket as an outer band, held together by one or more straps, the jacket being ornate and with or without gemstones and made of the same, complimentary or contrasting materials as the center ring wherein the interchangeable outer jackets and center rings provide an interchangeable, stylish combination of interlocking jackets and center rings.

Owner:MURRAY TODD E +1

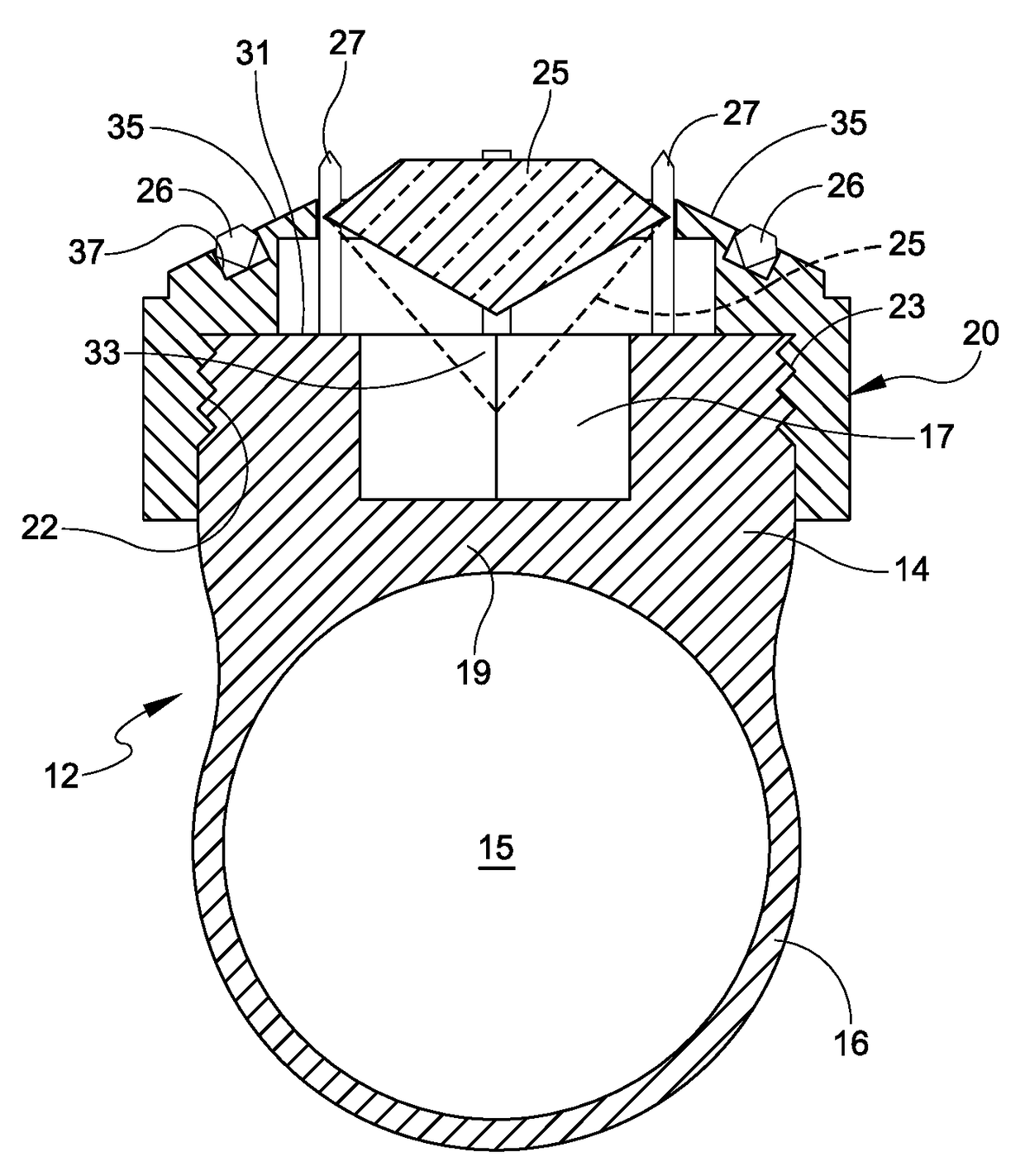

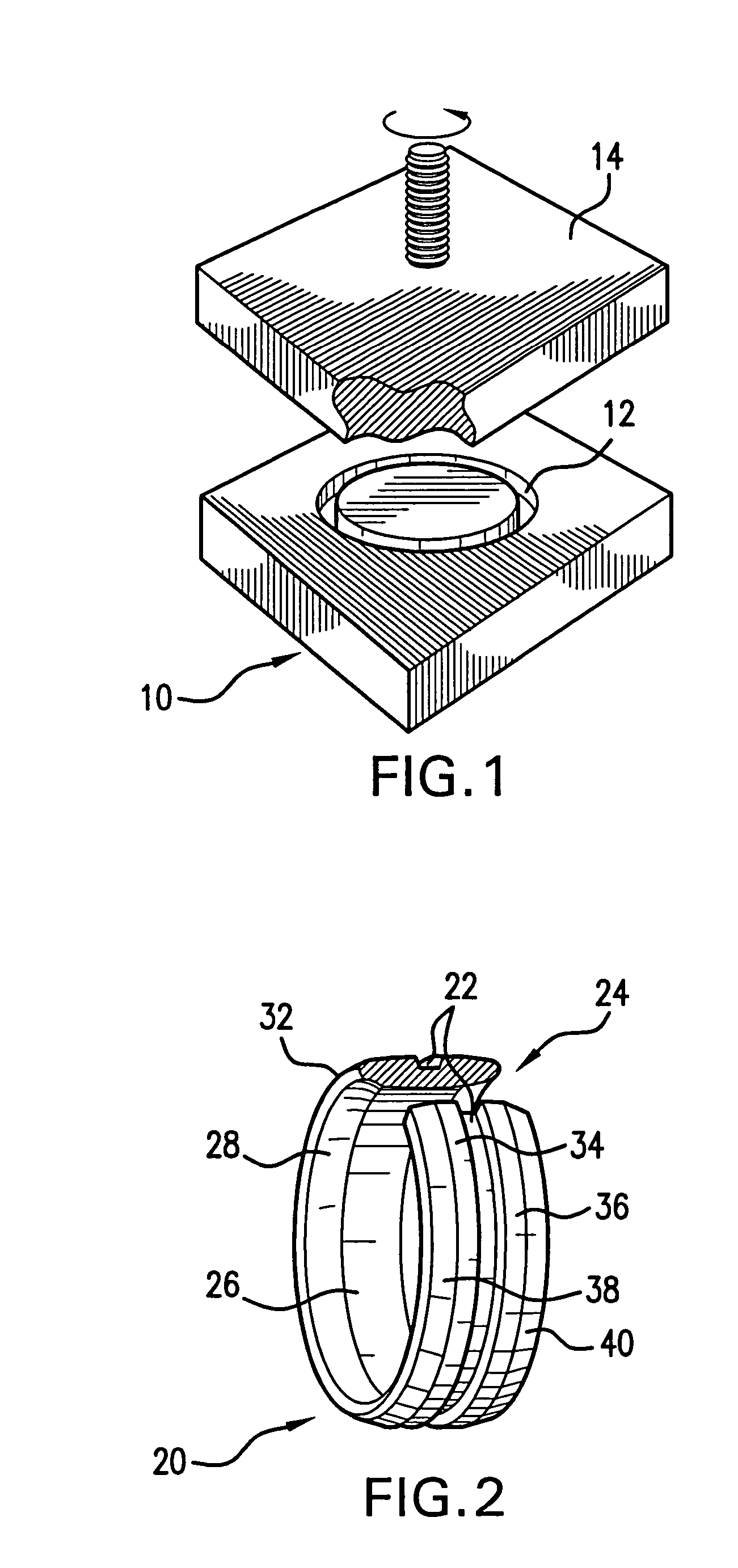

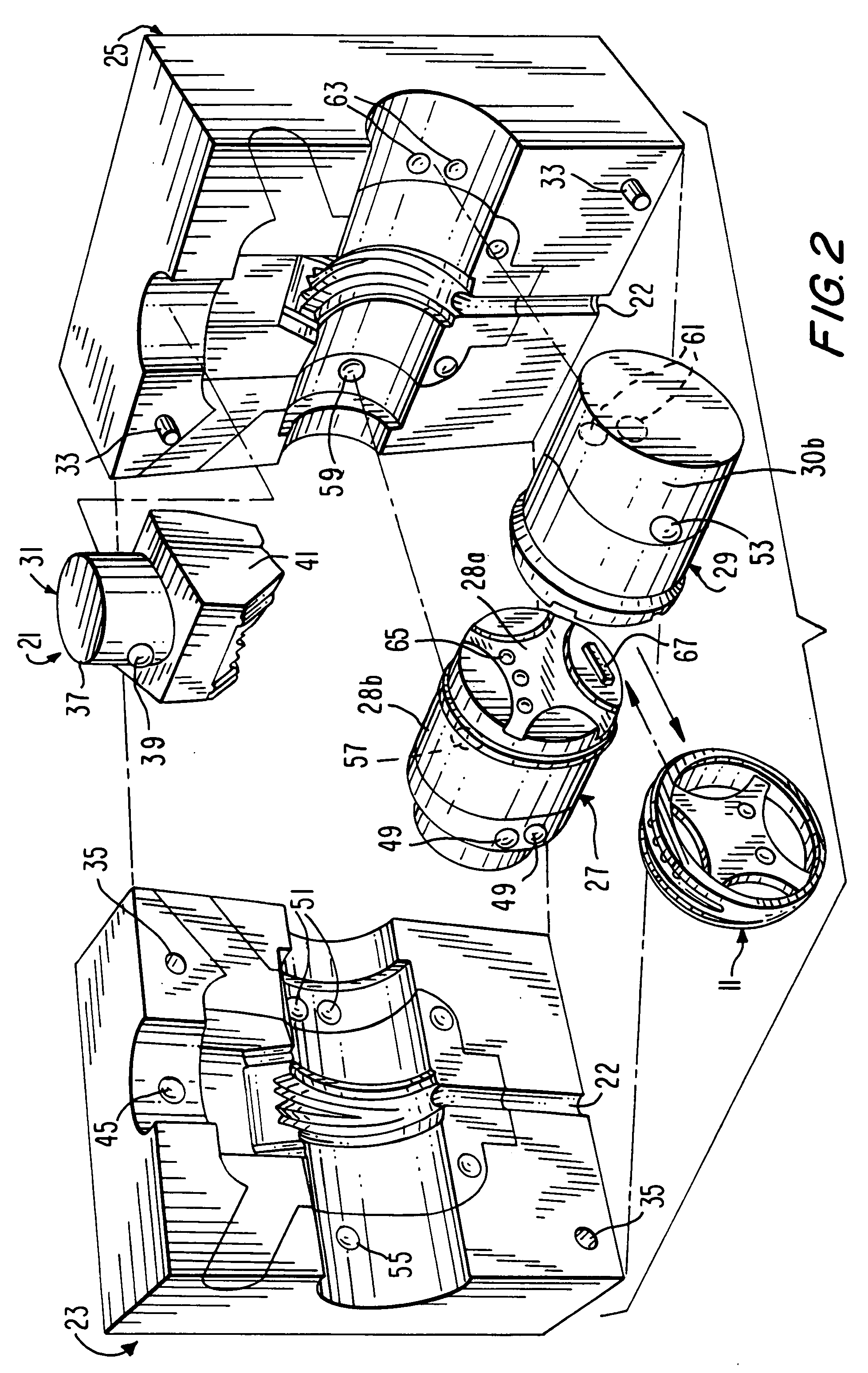

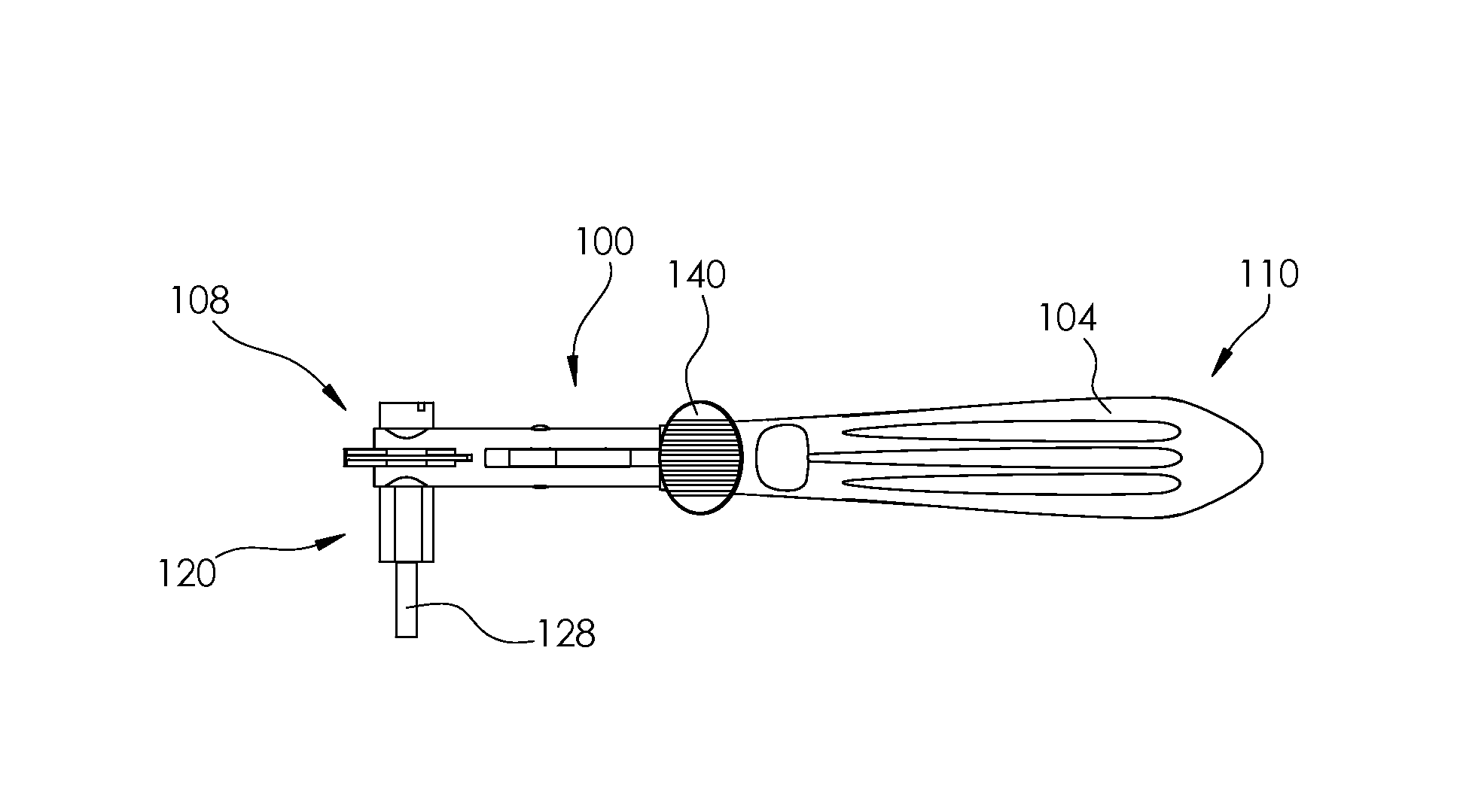

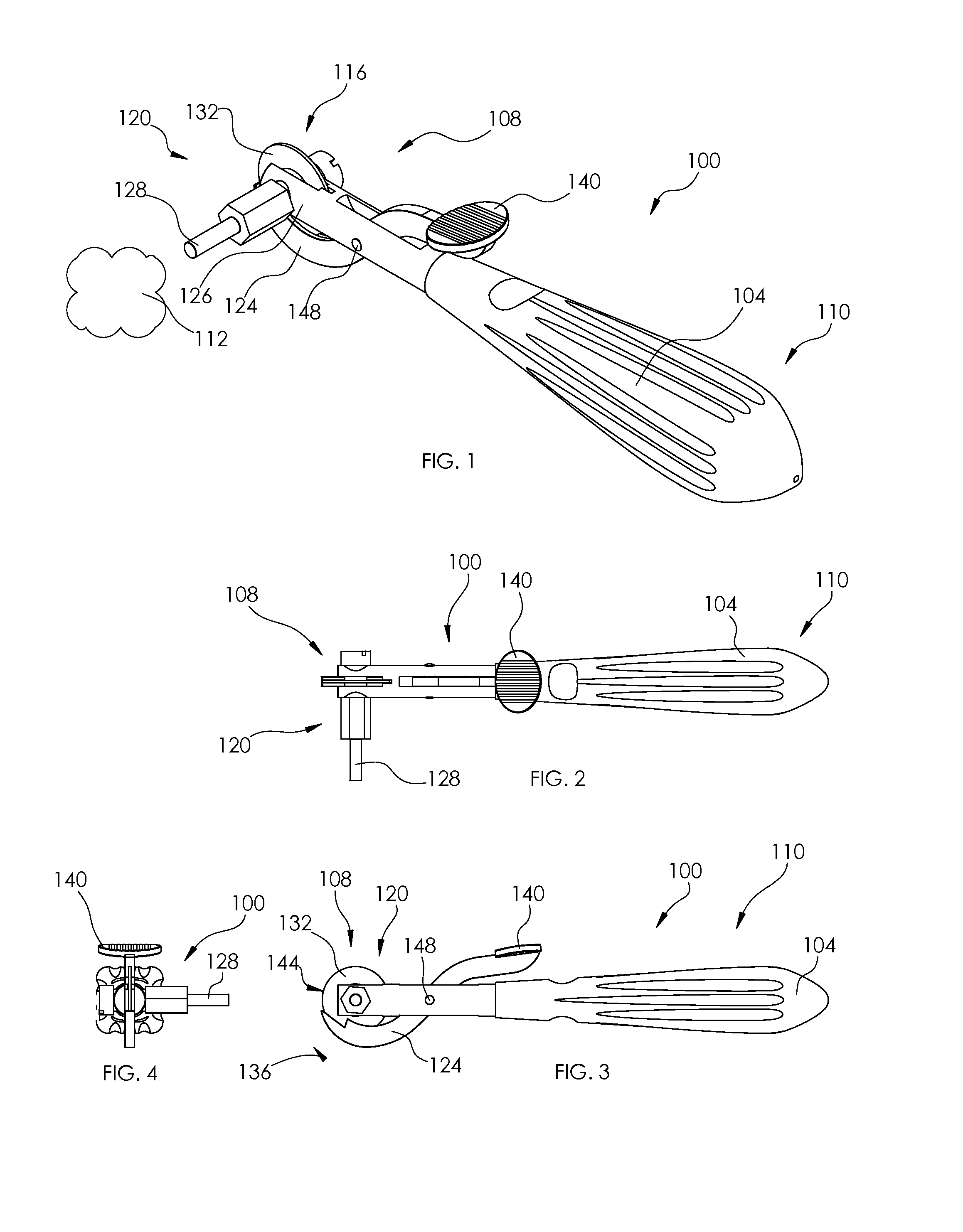

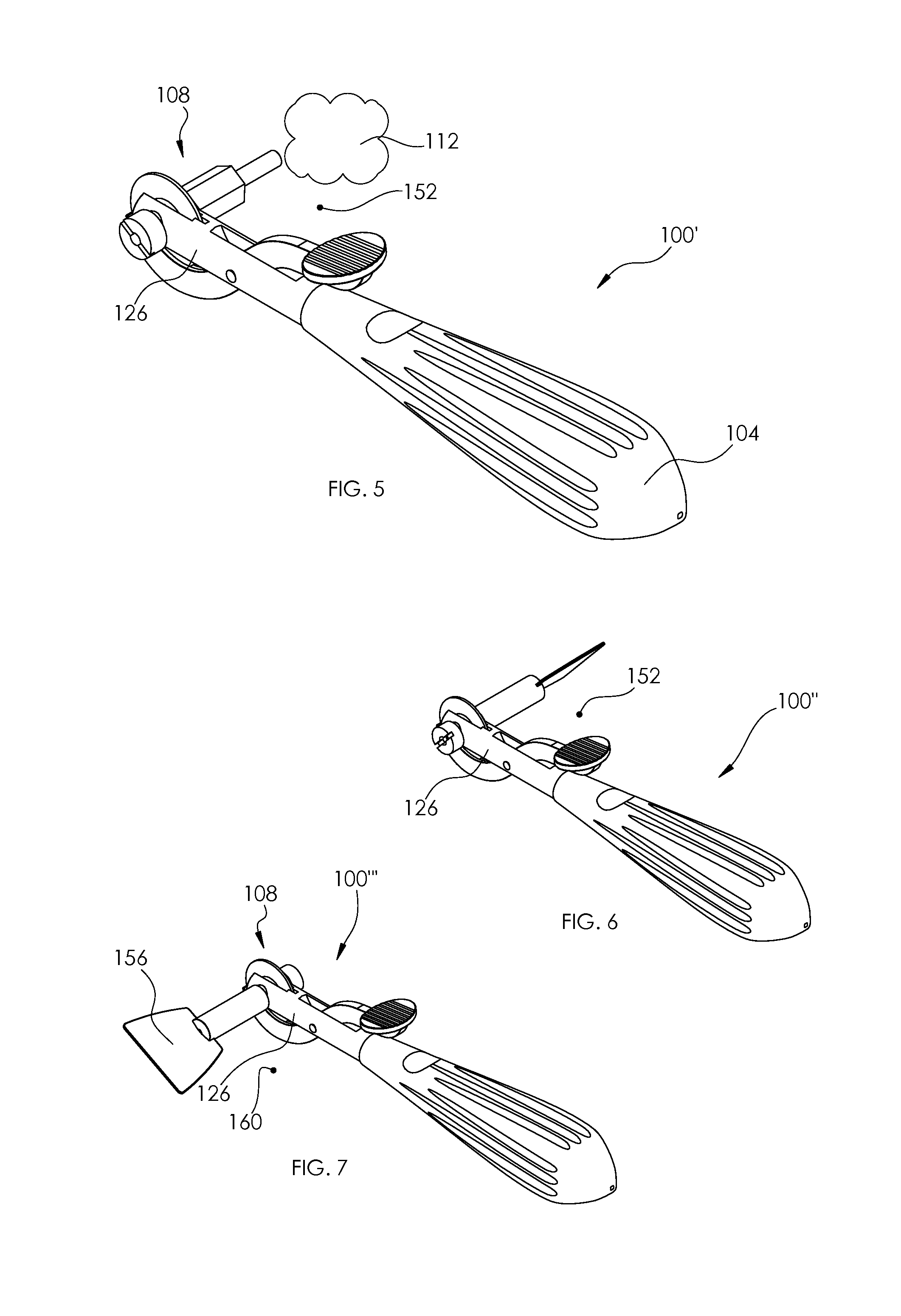

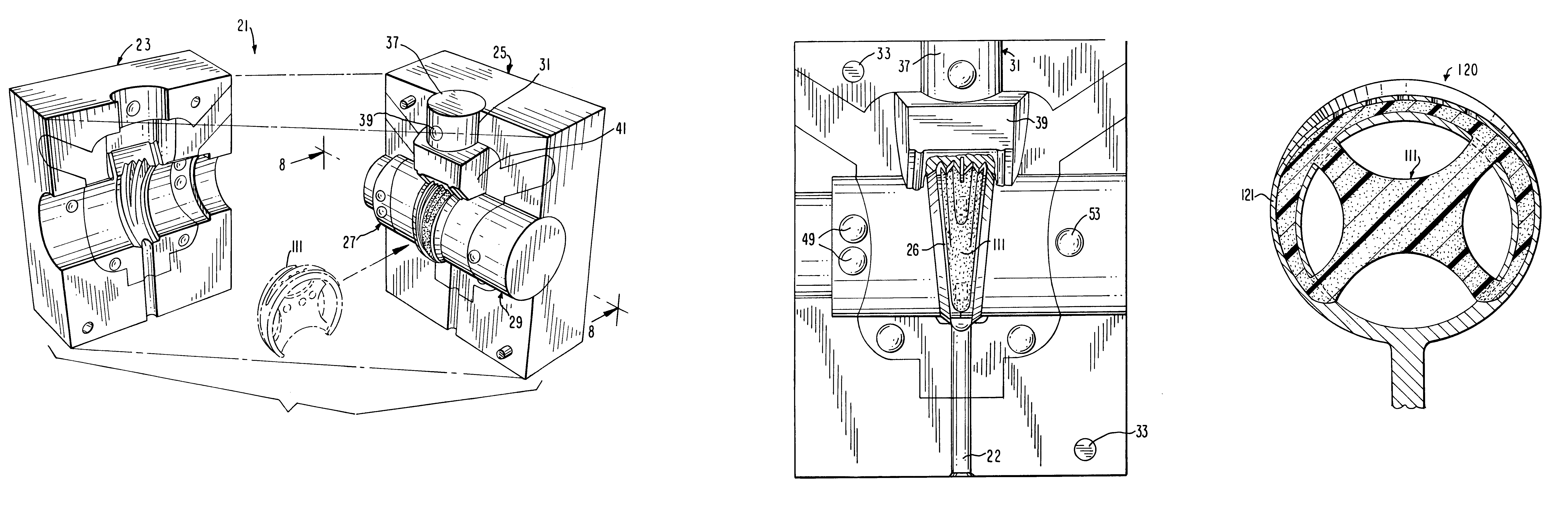

Ring cutting device and method

A specialized cutter adapted to remove a jewelry ring from a finger of a human hand. The cutter may include a diamond covered wheel having diamond grit sized between about 100-grit and about 170-grit. Preferably, the cutter can be assembled to permit either of a left-hand, or a right-hand mode of operation. Certain embodiments are structured to preclude relative motion between a cutting blade and the drive shaft on which it is mounted.

Owner:MORTON STEVEN D

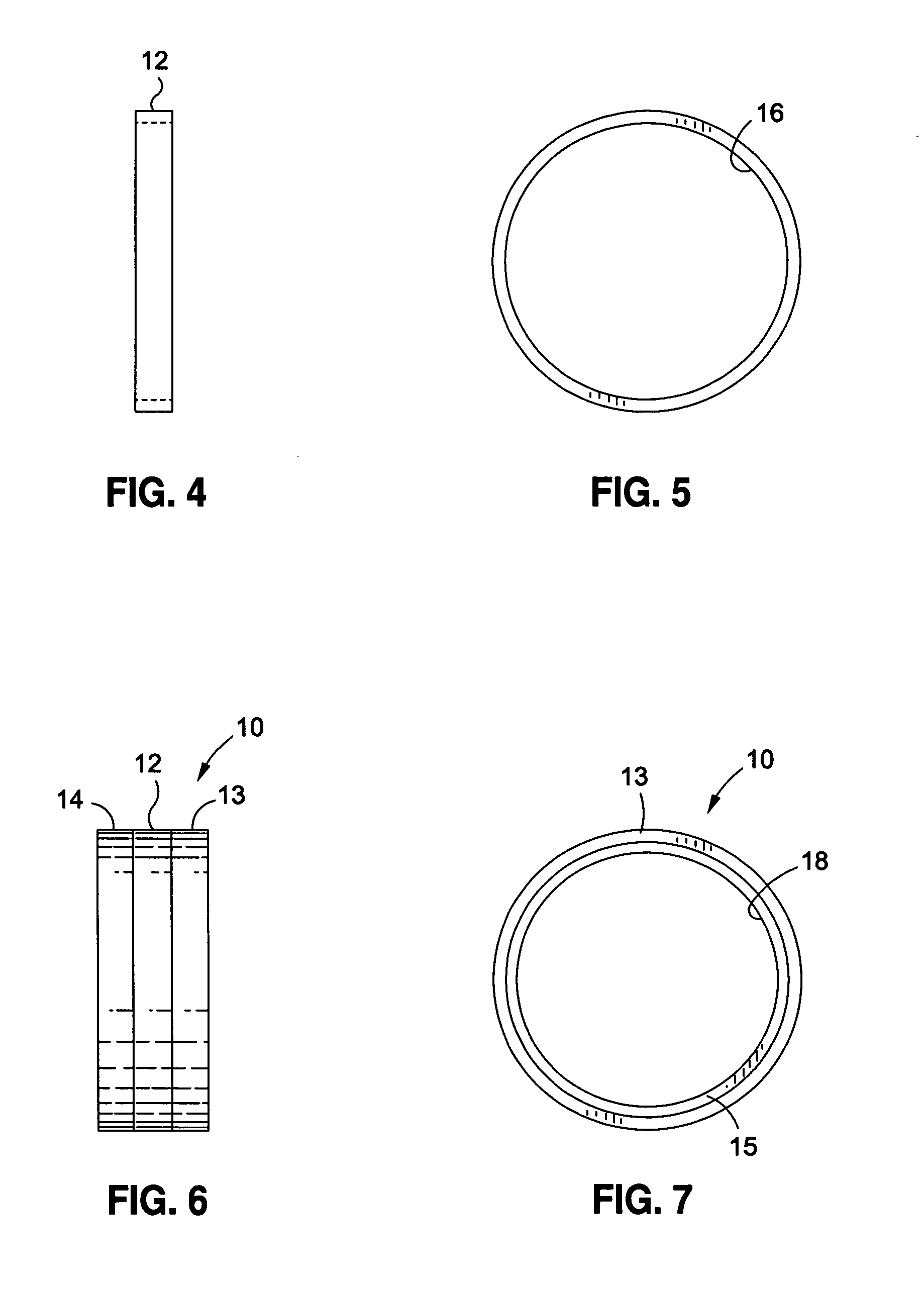

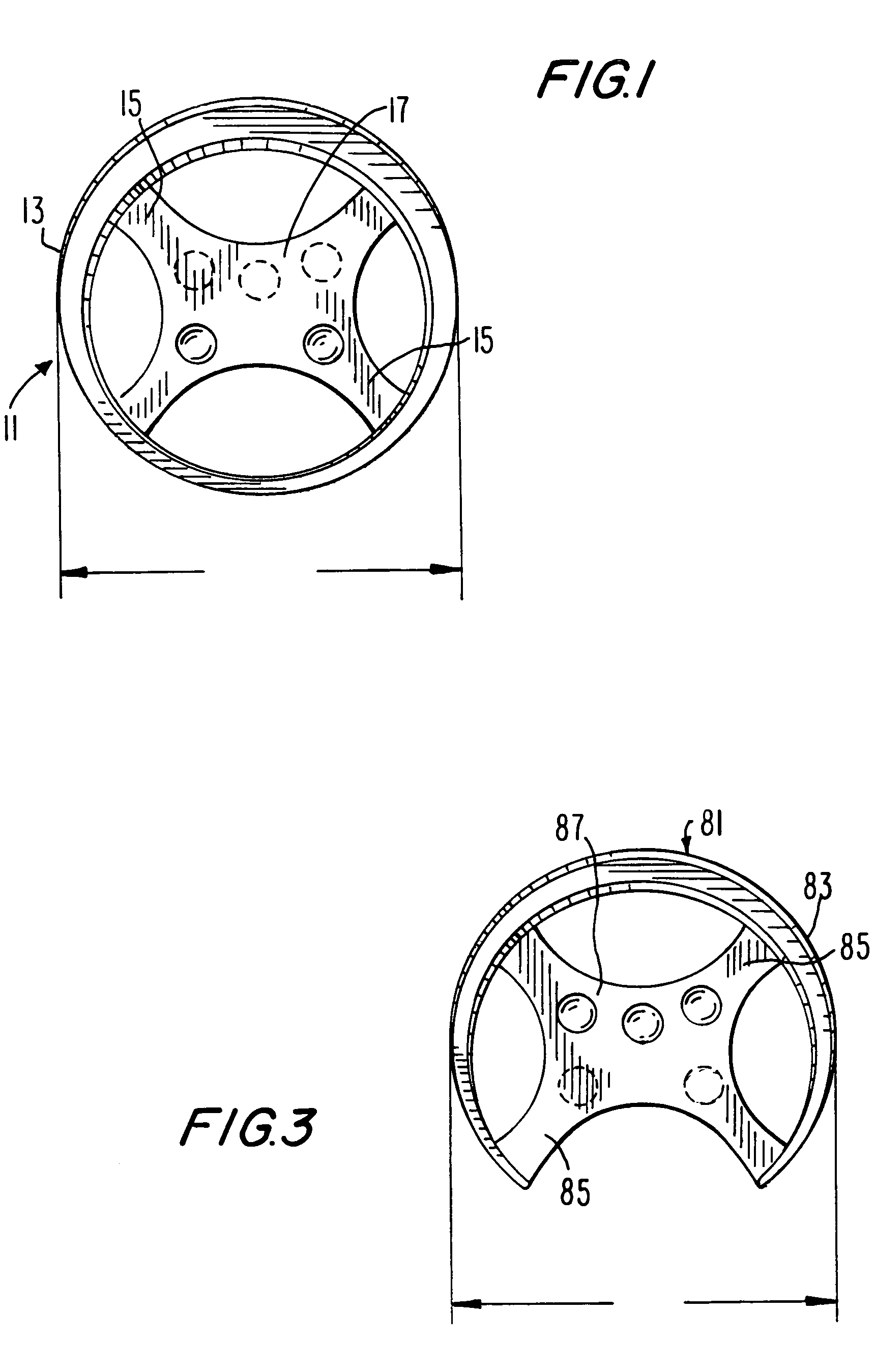

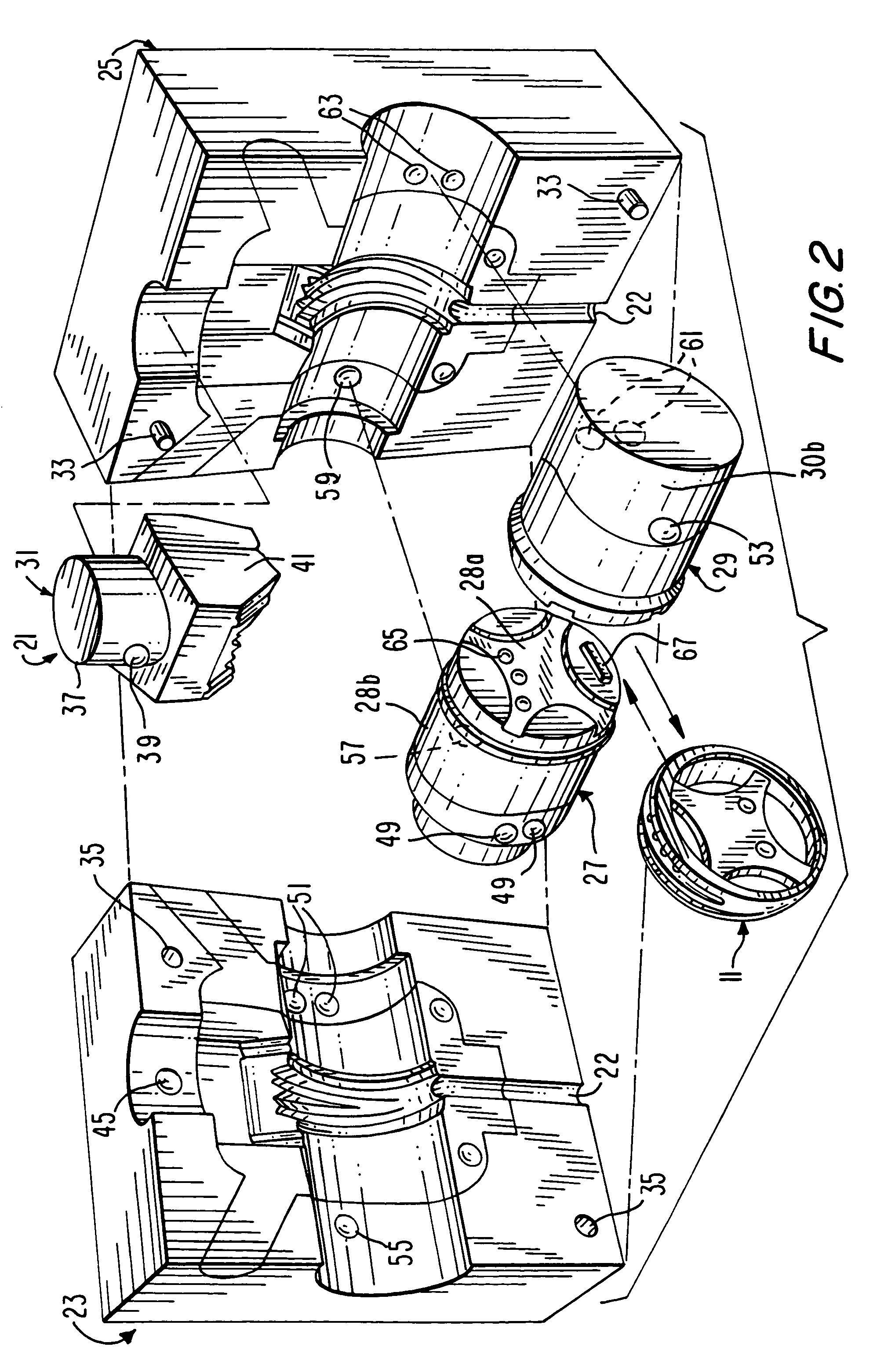

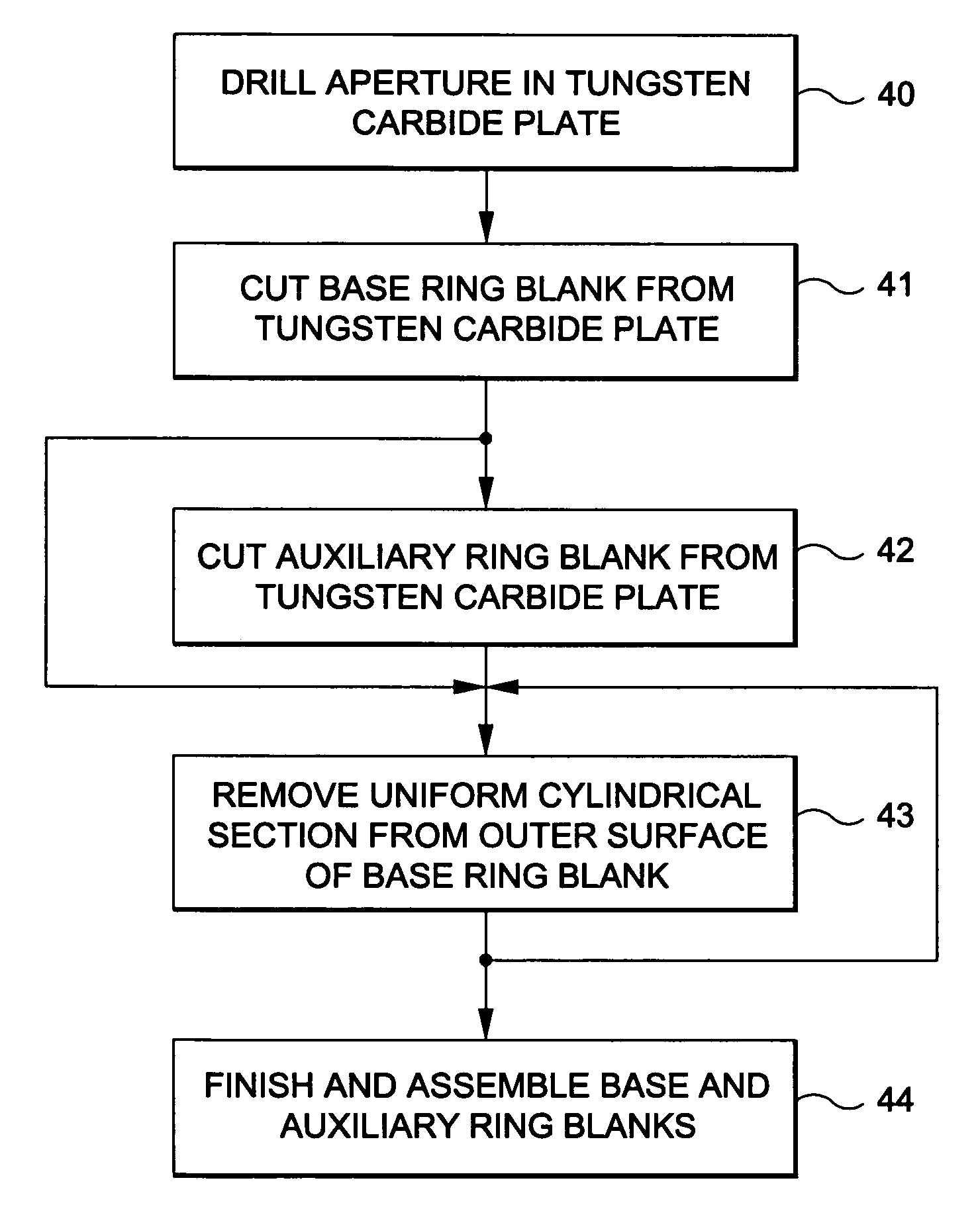

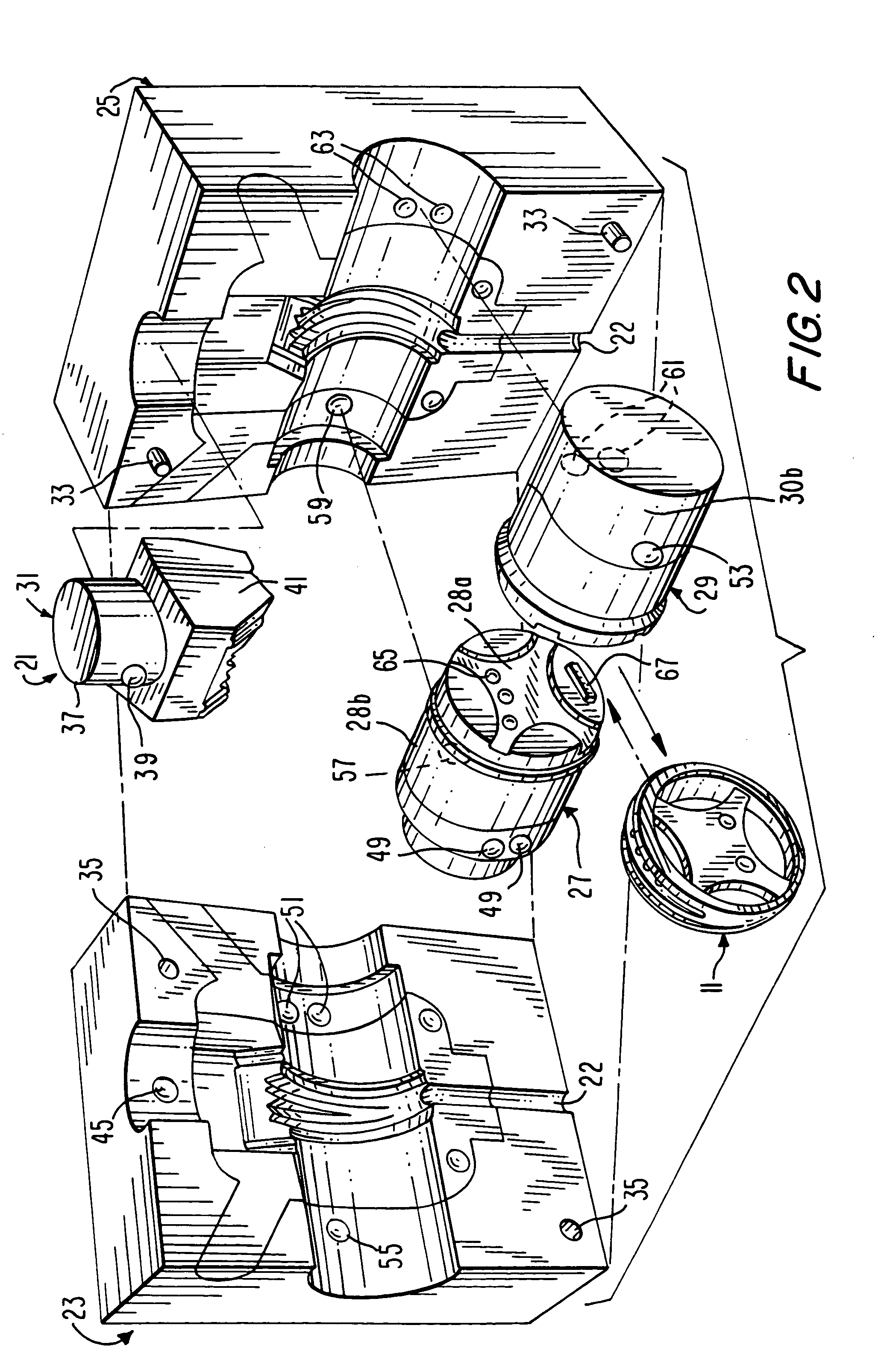

Method of manufacturing multi-element tungsten carbide jewelry rings

A method for manufacturing annular jewelry rings employing multiple annular elements, at least one of which is composed of tungsten carbide. All annular ring elements composed of tungsten carbide are produced directly from tungsten carbide plate. Using an electrical discharge machining apparatus employing a preformed cylindrical electrode, an aperture of predetermined diameter is drilled through a planar, tungsten carbide plate. Using a wire electric discharge machining apparatus, annular blanks are cut from the planar tungsten carbide plate, the outer surface of the annular blank being cylindrical and concentric with the inner, drilled surface of the annular blank. The inner and outer surfaces of the tungsten carbide annular blanks are cooperatively machined to allow additional annular elements composed of tungsten carbide and other materials to be integrally coupled to one another to form jewelry in the form of rings.

Owner:DDLNYC LLC

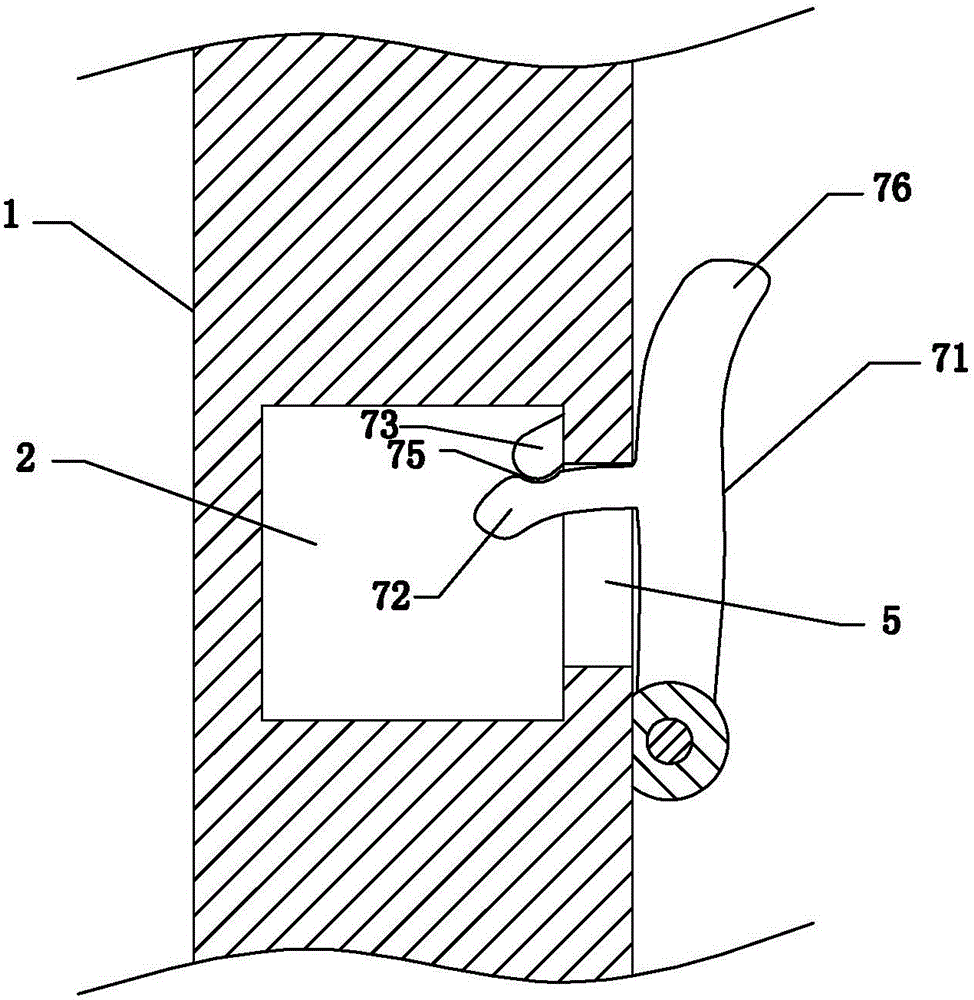

Ring

The invention belongs to the technical field of jewelry, and particularly relates to a ring. The ring comprises an annular ring body. An installing hole is formed in the ring body, a jewelry-ring-surface buckling base is inserted into the installing hole, a jewelry ring surface is installed on the jewelry-ring-surface buckling base, a first through hole is formed in one side wall of the installing hole, a second through hole corresponding to the first through hole in position is formed in the jewelry-ring-surface buckling base, and a buckle structure is installed in the first through hole and the second through hole. According to the ring, different-type jewelry ring surfaces can be replaced according to requirements, the problem that when rings with different-type jewelry ring surfaces are required, new rings need to be bought is solved, money is saved, and resources are saved; the ring is simple in structure and convenient to process, manufacture and use.

Owner:山东蓝天首饰有限公司

Ornamental ring and assembly method

A jewelry ring and an associated assembly method involves the ring being assembled with a set of easily fabricated components that allow for mass production, easy custom fabrication, and use in hobby kits. The ring employs a U-shaped shank formed of sheet material and a bezel formed of sheet material that are attached to each other in a manner that imparts the ability for the bezel “float.” The bezel has an upper portion formed with sheet material to provide for ornamentation with designs or gemstones. The bezel further includes a lower portion that has a plurality of parallel ferrules. The shank includes a plurality of holes in each end and the bezel is attached to the shank with bars or wires that are inserted through one end of the shank, through the ferrules and through the other end of the shank and secured with retainers.

Owner:ROBERTS SHEA MARTHE

Hollow jewelry ring design

There is provided a method or process for fabricating a hollow jewelry article which is hollowed or bored out. In accordance with this process, a metal ring model is prepared comprising a solid shank and a metal plate supported along the internal perimeter of the shank by means of a series of spokes extending from the shank. A first metal mold is produced from the metal ring model having the external shape of the jewelry article to be manufactured. From this mold, a wax model of the jewelry article is produced which is first filed down and then cast in order to form a metal model of a core insert; the core insert, like the ring model, has a plate disposed along the perimeter of the shank. This core insert is used to produce a second metal mold. This second mold may then be used repeatedly in order to form a soluble wax core insert model which is then inserted into the cavity of the first mold in order to define the hollow region of the article. A non-soluble wax is then introduced into the first mold for completely surrounding the soluble wax core insert. The non-soluble wax then hardens and the entire unit is removed from the first mold, including the soluble wax core. The core is then removed by a suitable water soluble or chemical mechanism. The remaining wax model contains a hollow core running along a substantial portion of the arcuate length of the shank; the shank has a finger facing surface formed with a plurality of openings which lead to said core. The wax model is then cast in order to form the inventive ring design.

Owner:QUALITY CASTING

Method of manufacturing multi-element tungsten carbide jewelry rings

A method for manufacturing annular jewelry rings employing multiple annular elements, at least one of which is composed of tungsten carbide. All annular ring elements composed of tungsten carbide are produced directly from tungsten carbide plate. Using an electrical discharge machining apparatus employing a preformed cylindrical electrode, an aperture of predetermined diameter is drilled through a planar, tungsten carbide plate. Using a wire electric discharge machining apparatus, annular blanks are cut from the planar tungsten carbide plate, the outer surface of the annular blank being cylindrical and concentric with the inner, drilled surface of the annular blank. The inner and outer surfaces of the tungsten carbide annular blanks are cooperatively machined to allow additional annular elements composed of tungsten carbide and other materials to be integrally coupled to one another to form jewelry in the form of rings.

Owner:DDLNYC LLC

Hollow jewelry ring design

There is provided a method or process for fabricating a hollow jewelry article which is hollowed or bored out. In accordance with this process, a metal ring model is prepared comprising a solid shank and a metal plate supported along the internal perimeter of the shank by means of a series of spokes extending from the shank. A first metal mold is produced from the metal ring model having the external shape of the jewelry article to be manufactured. From this mold, a wax model of the jewelry article is produced which is first filed down and then cast in order to form a metal model of a core insert; the core insert, like the ring model, has a plate disposed along the perimeter of the shank. This core insert is used to produce a second metal mold. This second mold may then be used repeatedly in order to form a soluble wax core insert model which is then inserted into the cavity of the first mold in order to define the hollow region of the article. A non-soluble wax is then introduced into the first mold for completely surrounding the soluble wax core insert. The non-soluble wax then hardens and the entire unit is removed from the first mold, including the soluble wax core. The core is then removed by a suitable water soluble or chemical mechanism. The remaining wax model contains a hollow core running along a substantial portion of the arcuate length of the shank; the shank has a finger facing surface formed with a plurality of openings which lead to said core. The wax model is then cast in order to form the inventive ring design.

Owner:QUALITY CASTING

Hollow metal jewelry ring

There is provided a method or process for fabricating a hollow jewelry article which is hollowed or bored out. In accordance with this process, a metal ring model is prepared comprising a solid shank and a metal plate supported along the internal perimeter of the shank by means of a series of spokes extending from the shank. A first metal mold is produced from the metal ring model having the external shape of the jewelry article to be manufactured. From this mold, a wax model of the jewelry article is produced which is first filed down and then cast in order to form a metal model of a core insert; the core insert, like the ring model, has a plate disposed along the perimeter of the shank. This core insert is used to produce a second metal mold. This second mold may then be used repeatedly in order to form a soluble wax core insert model which is then inserted into the cavity of the first mold in order to define the hollow region of the article. A non-soluble wax is then introduced into the first mold for completely surrounding the soluble wax core insert. The non-soluble wax then hardens and the entire unit is removed from the first mold, including the soluble wax core. The core is then removed by a suitable water soluble or chemical mechanism. The remaining wax model contains a hollow core running along a substantial portion of the arcuate length of the shank; the shank has a finger facing surface formed with a plurality of openings which lead to said core. The wax model is then cast in order to form the inventive ring design.

Owner:QUALITY CASTING

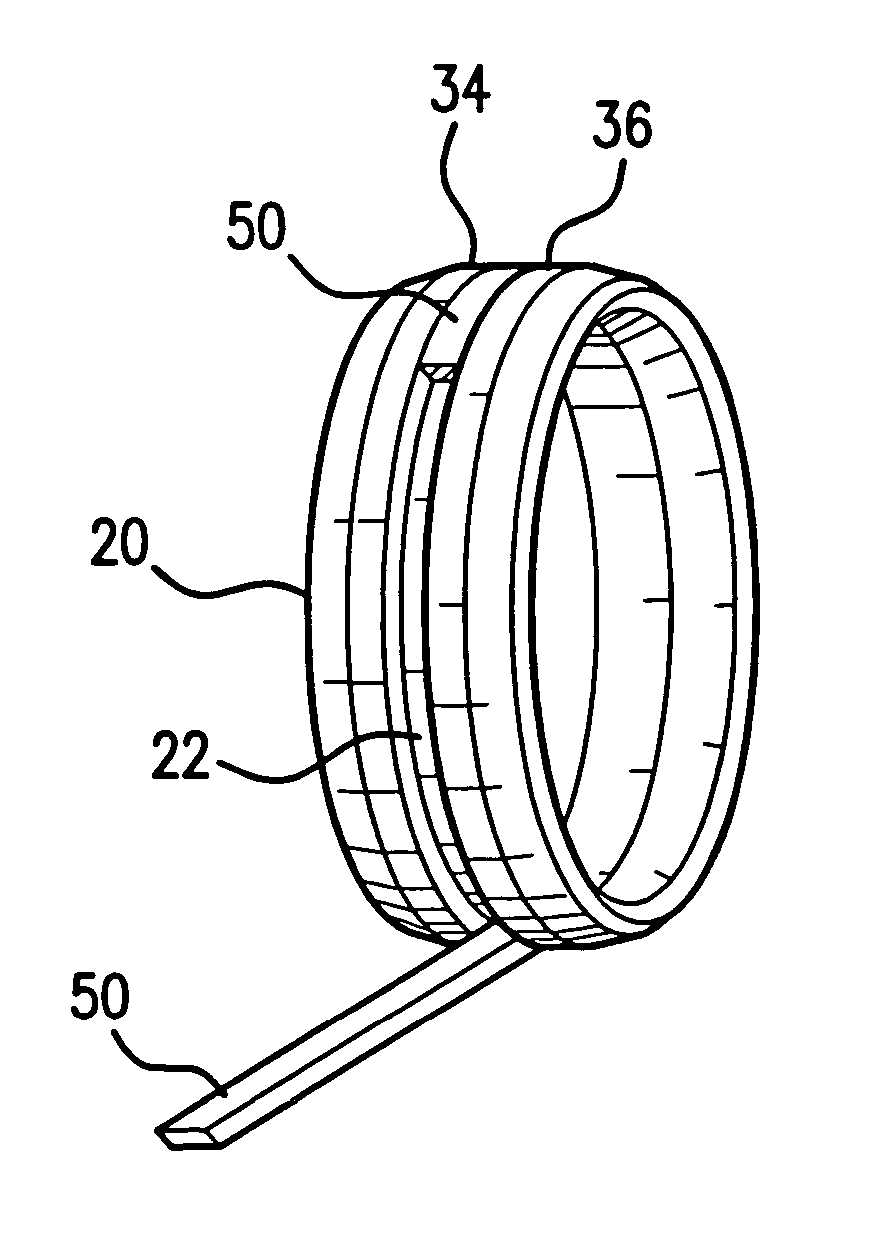

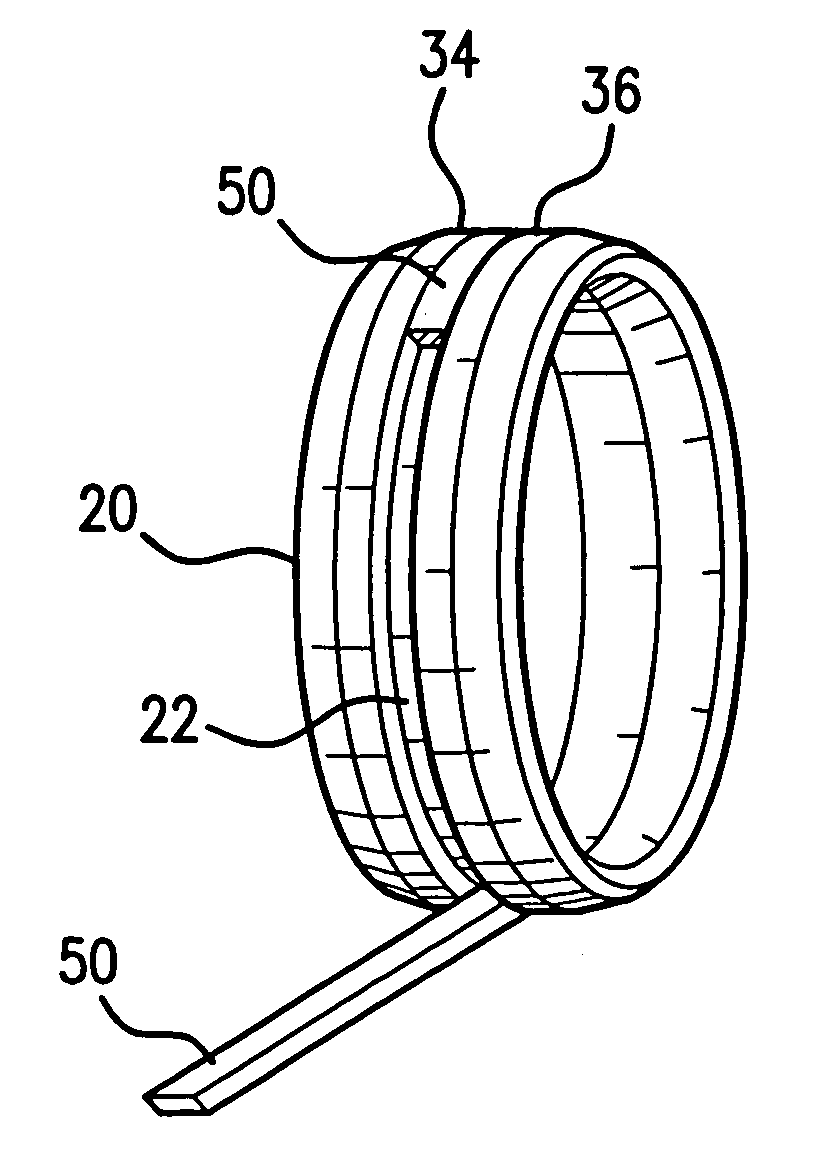

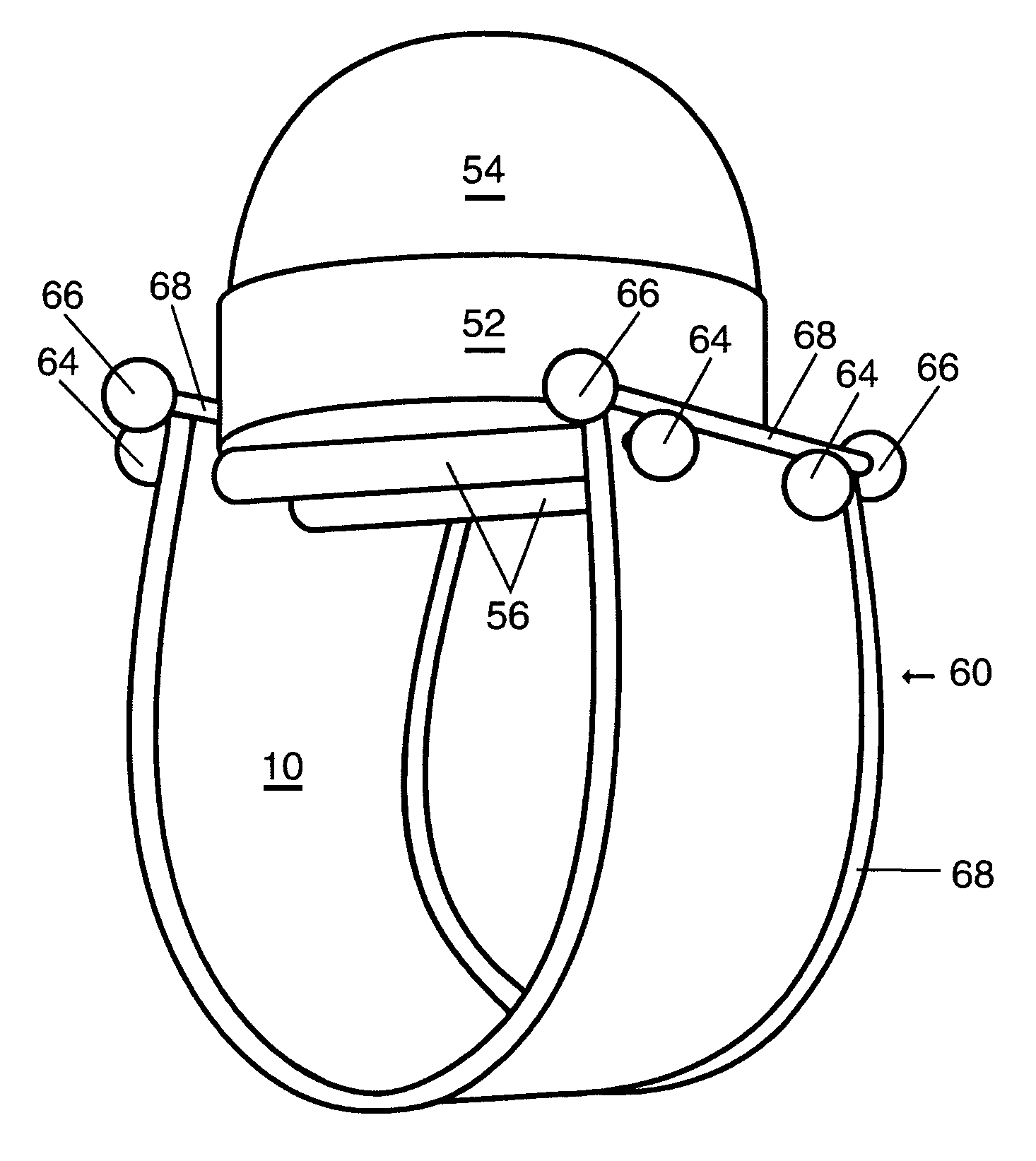

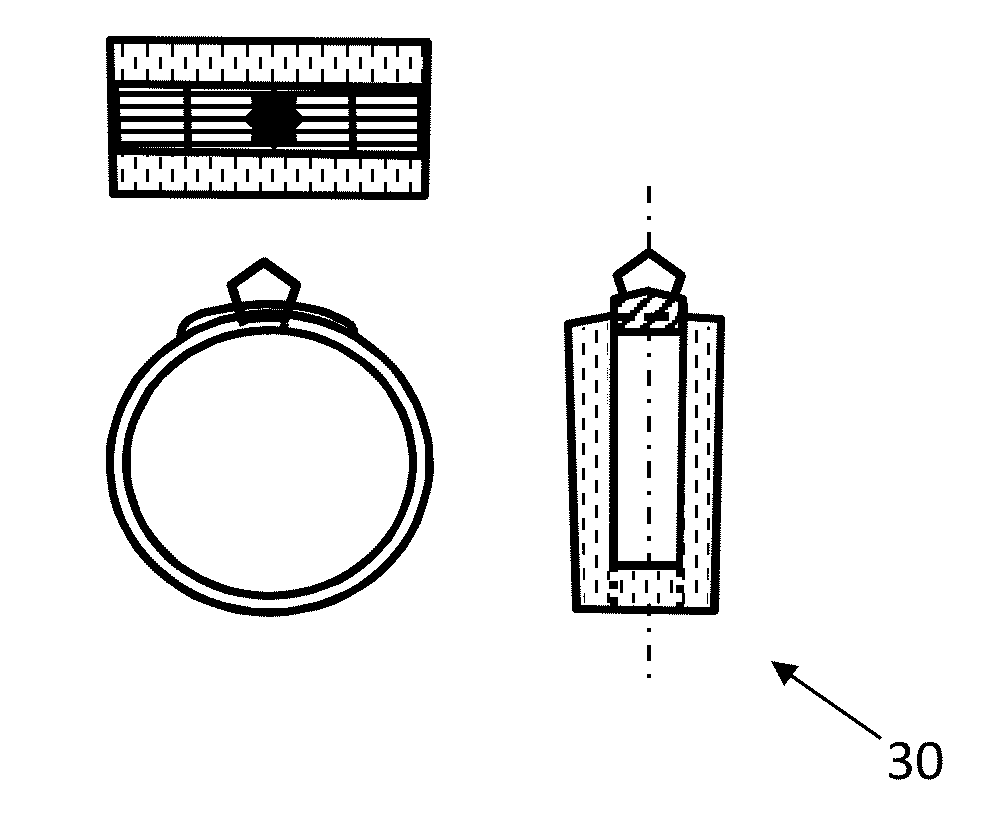

Wearable device for jewelry ring storage

The present invention relates to a mobile device and method for a secure jewelry ring holder. The improved jewelry ring holder provides a wearable storage device for displaying the jewelry ring from a chain while suspending a jewelry ring in a secure fashion. For securing, the jewelry ring is threaded onto the improved wearable storage device rather than requiring that the wearer remove or unfasten a chain, or open or unlock a clasp. The chain holds in place a wearable storage pendant. When threaded onto the wearable storage pendant the jewelry ring is stored as it rests securely on the wearable storage pendant. Curvatures located on the wearable storage pendant allow the jewelry ring to lie substantially flat against the wearer's body.

Owner:GRAVES CRITTENDEN EMILY

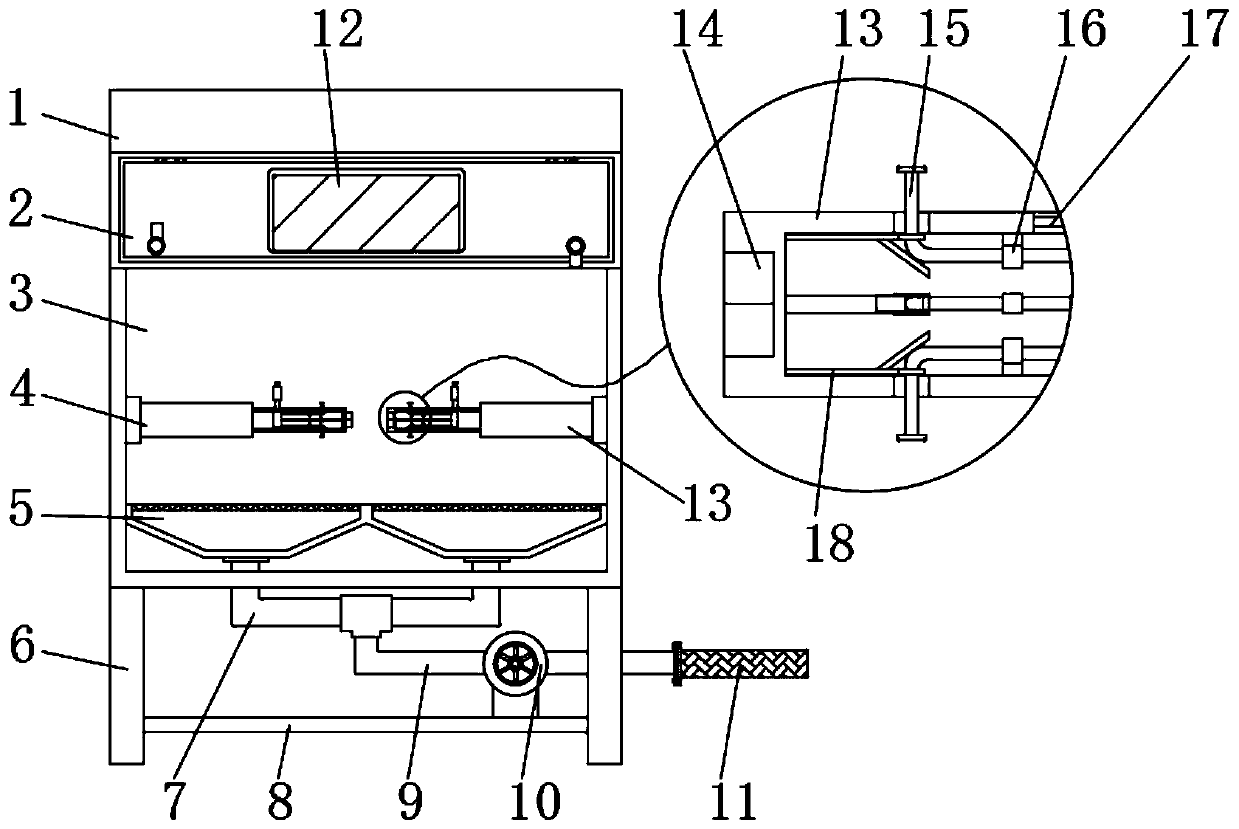

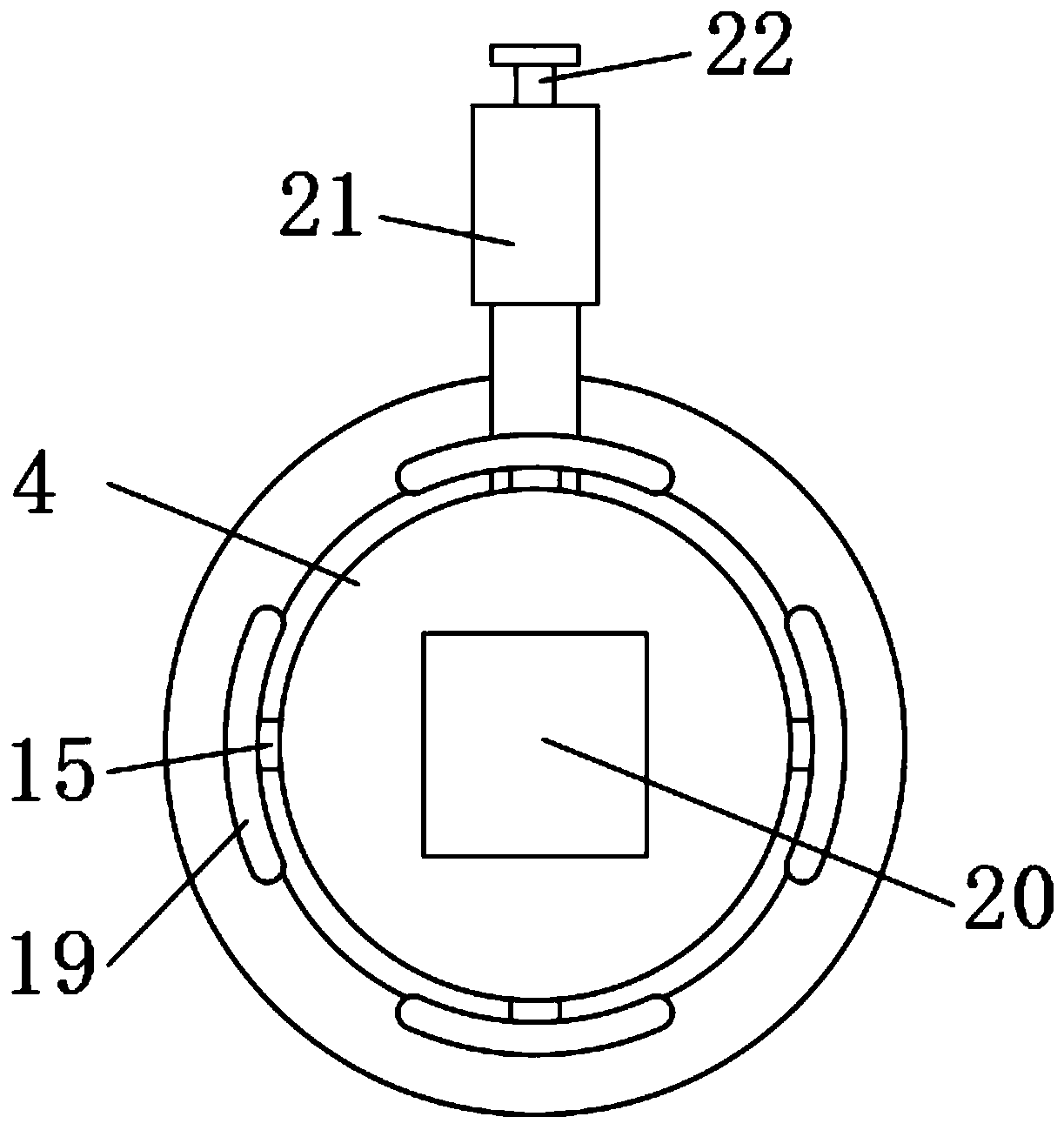

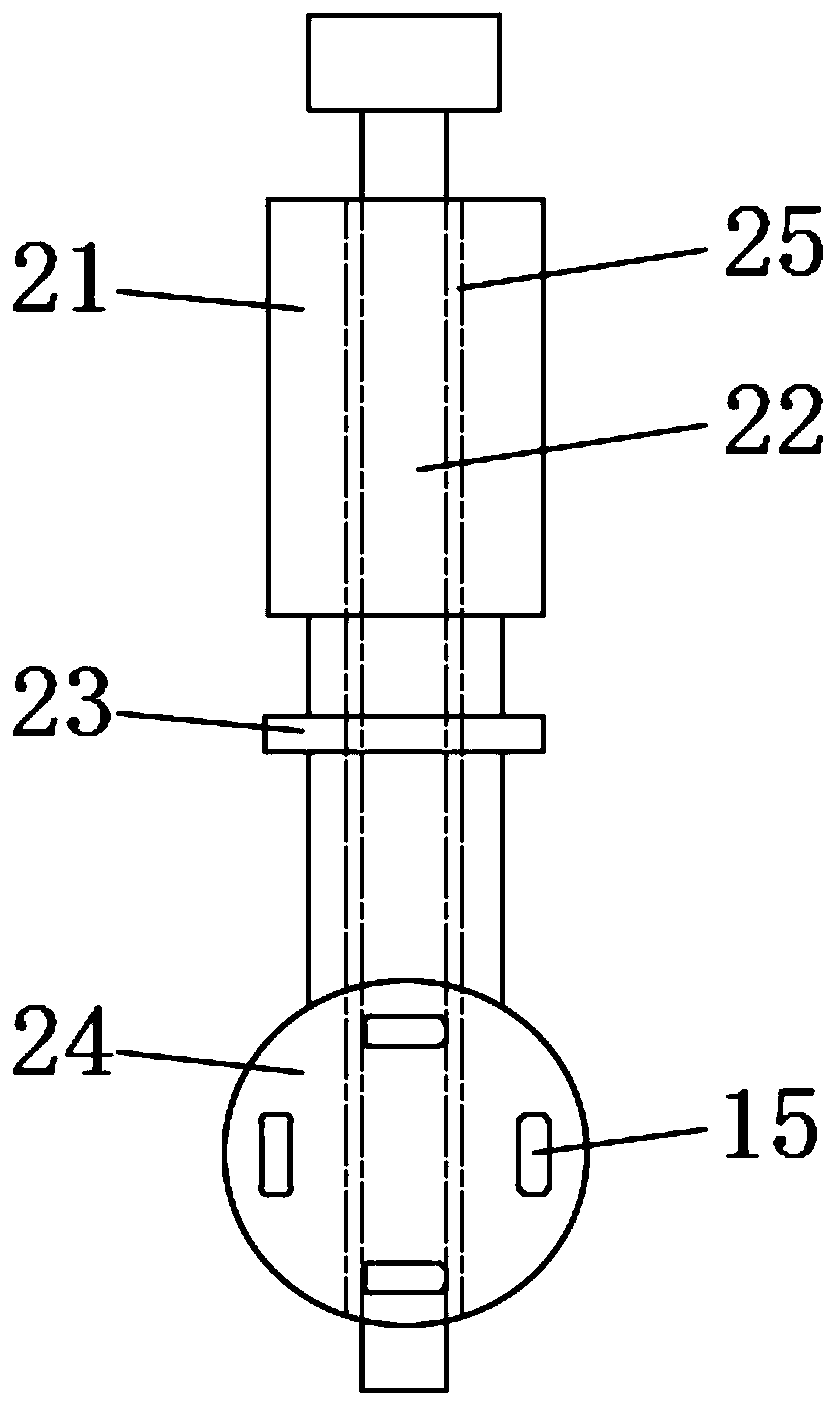

Ornament prototype surface sandblasting equipment

InactiveCN110788761AImprove stabilityEven sandblastingAbrasive machine appurtenancesAbrasive blasting machinesStructural engineeringMechanical engineering

The invention discloses ornament prototype surface sandblasting equipment which comprises a sandblasting machine, and a sandblasting cavity is arranged in the sandblasting machine. According to the ornament prototype surface sandblasting equipment, a jewelry ring to be subjected to sandblasting is arranged on object loading blocks of a first telescopic sleeve rod and a second telescopic sleeve rodin a sleeve manner, then the first telescopic sleeve rod and the second telescopic sleeve rod are stretched in opposite directions, connecting columns of quadrangular structures and connecting grooves are in butt joint, adjusting handles on the surfaces of the first telescopic sleeve rod and the second telescopic sleeve rod slide to promote supporting discs at the bottom ends of the adjusting handles to push multiple plastic strips to move under the sleeving, connecting and supporting actions of a fixed sleeve, and therefore the plastic strips penetrate through avoiding holes of the first telescopic sleeve rod and the second telescopic sleeve rod and through grooves in a support plate to outwards extend, in cooperation with the guide effect of guide strips, the supporting scope of the object loading blocks of the multiple arc-shaped structures is enlarged, the multiple object loading blocks are promoted to support and carry an inner ring of the jewelry ring to be processed, and the ornament prototype surface sandblasting equipment is suitable for fixing and supporting jewelry rings with different diameters.

Owner:义乌市傅宝仙饰品有限公司

Interlocking ring system and device with interchangeable outer jackets and center rings called a TULIP

A jewelry ring configuration having interchangeable elements and especially jewelry rings which have a decorative feature mounted on a center ring. This new device / process may be simply described as a device for an interlocking ring system and device with interchangeable outer jackets and center rings comprised with a center ring, ornate and decorative or smooth and with or without gemstones, the center ring in various mounting styles such as prong, bezel, pave etc.; and a jacket as an outer band, held together by one or more straps, the jacket being ornate and with or without gemstones and made of the same, complimentary or contrasting materials as the center ring wherein the interchangeable outer jackets and center rings provide an interchangeable, stylish combination of interlocking jackets and center rings.

Owner:MURRAY TODD E +1

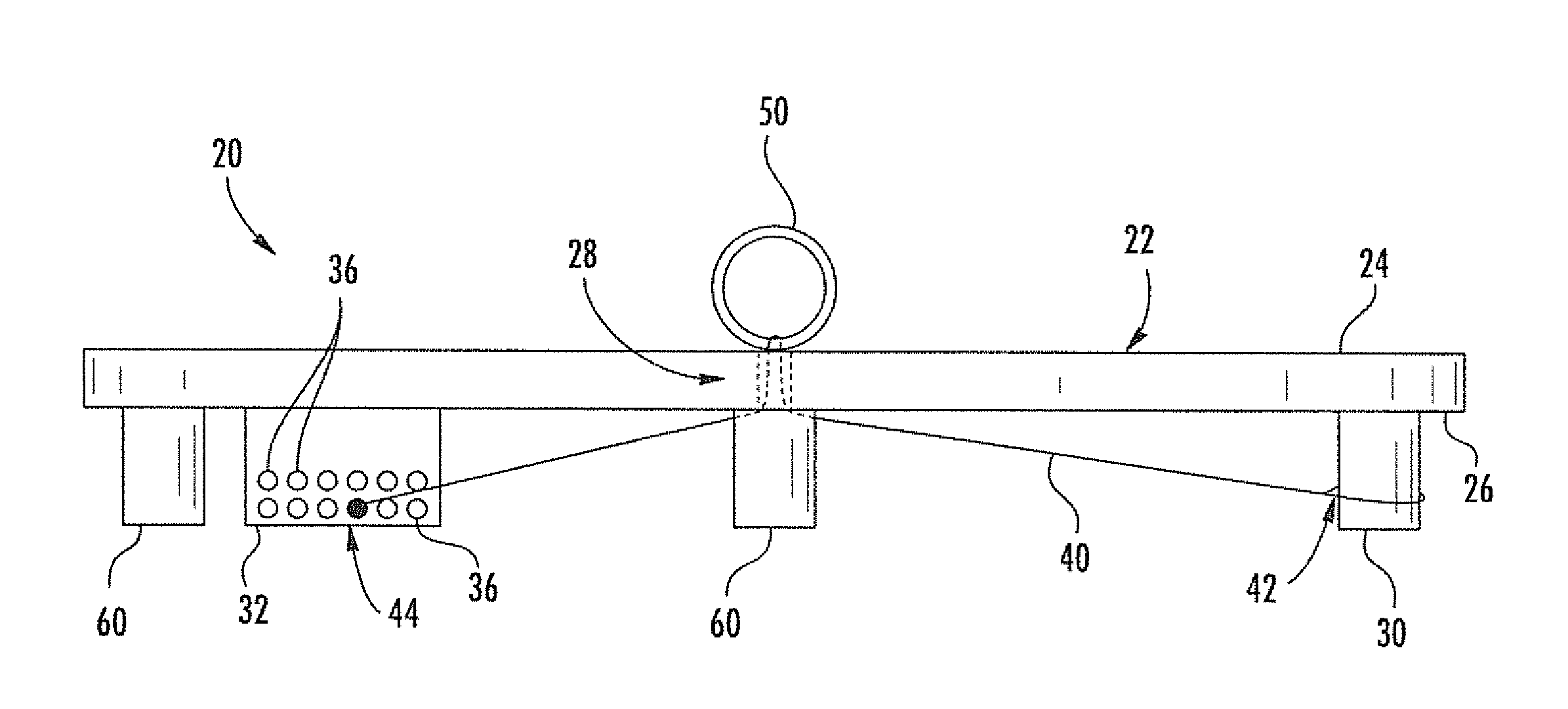

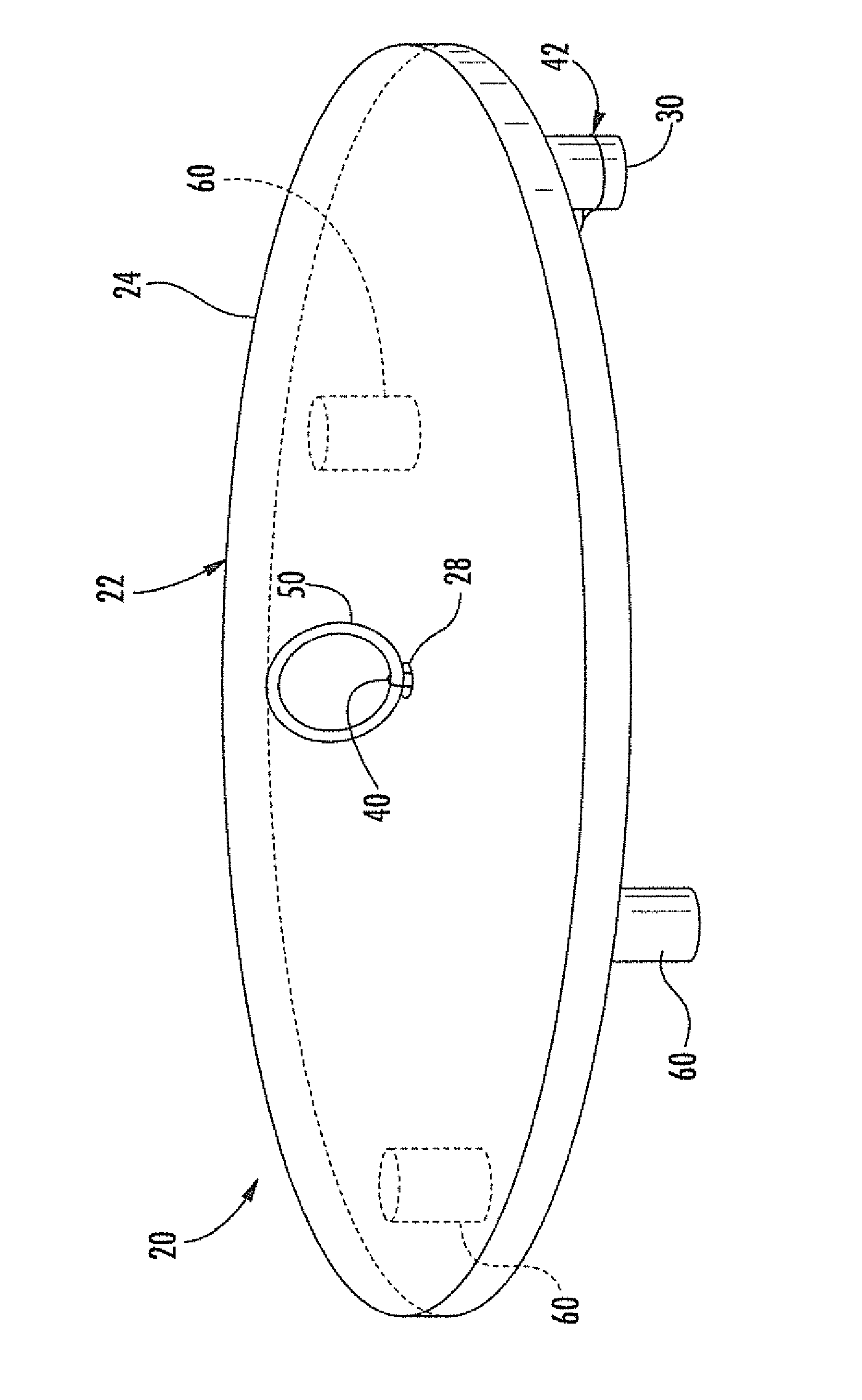

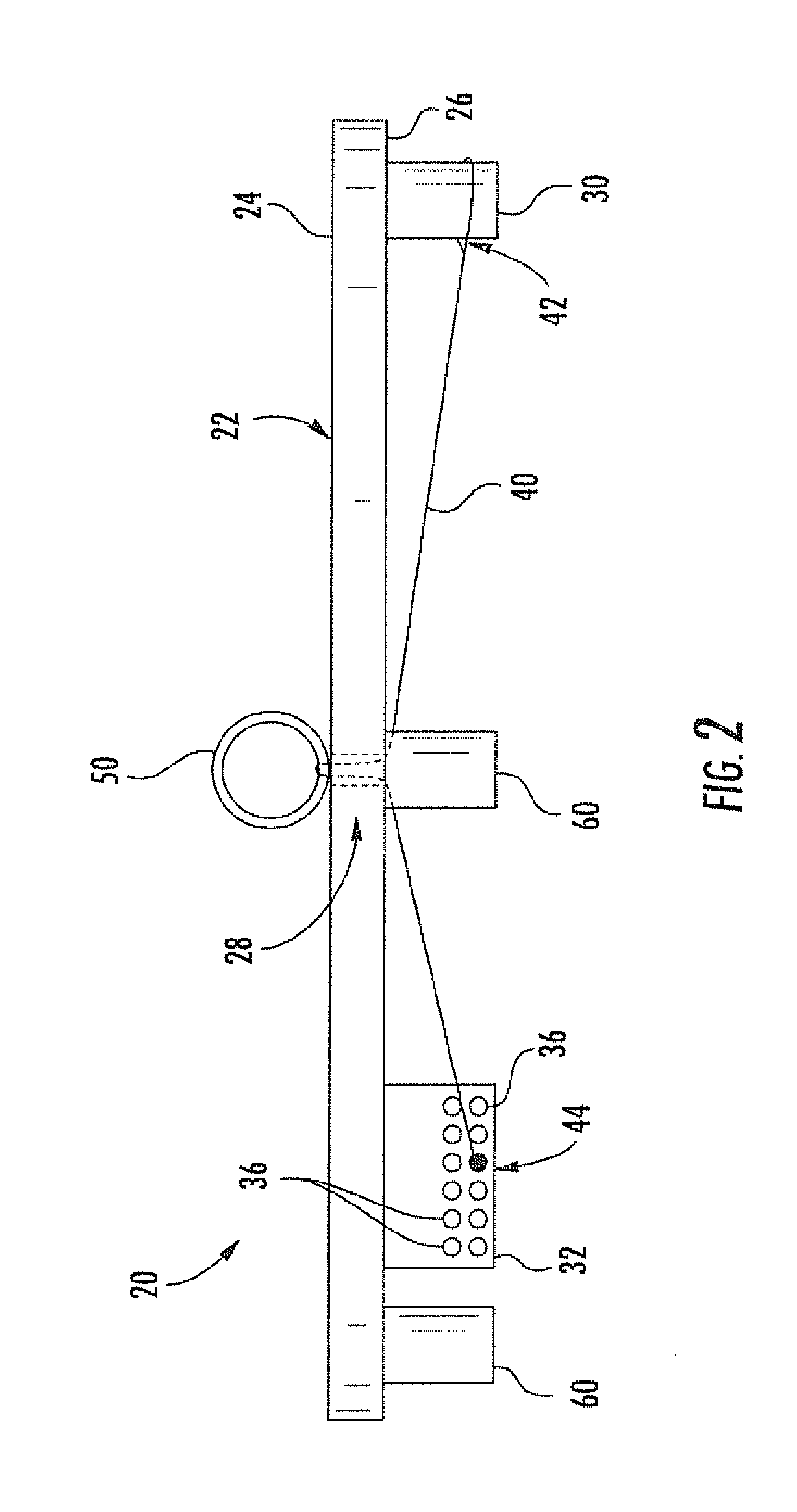

Jewelry ring display apparatus and associated methods

InactiveUS20150265010A1Precise positioningStands/trestlesKitchen equipmentEngineeringMechanical engineering

A jewelry ring display apparatus includes a platform having upper and lower surfaces with an opening extending therebetween. A first end line attachment is on the lower surface, and a second end line attachment is on the lower surface and positioned so that the opening is between the first and second end line attachments. A line has a first end to be held by the first end line attachment, and a second end to be passed through the opening and inserted through and around a ring to be displayed on the upper surface. The second end of the line is to be passed back through the opening and is to be held by the second end line attachment. The line is under tension when extending between the first and second end line attachments so that the ring can be held in a stationary position with respect to the upper surface of the platform.

Owner:CLOUD DISPLAY

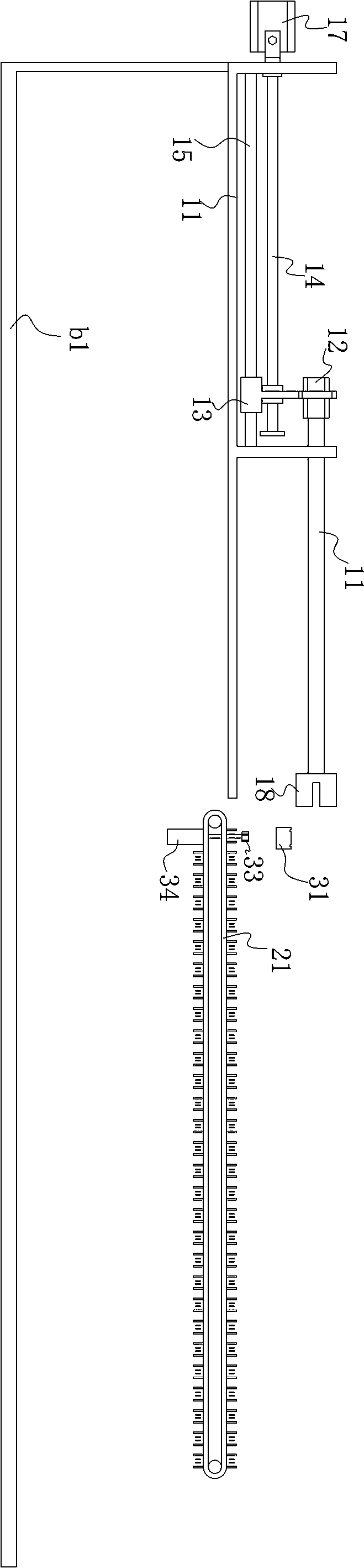

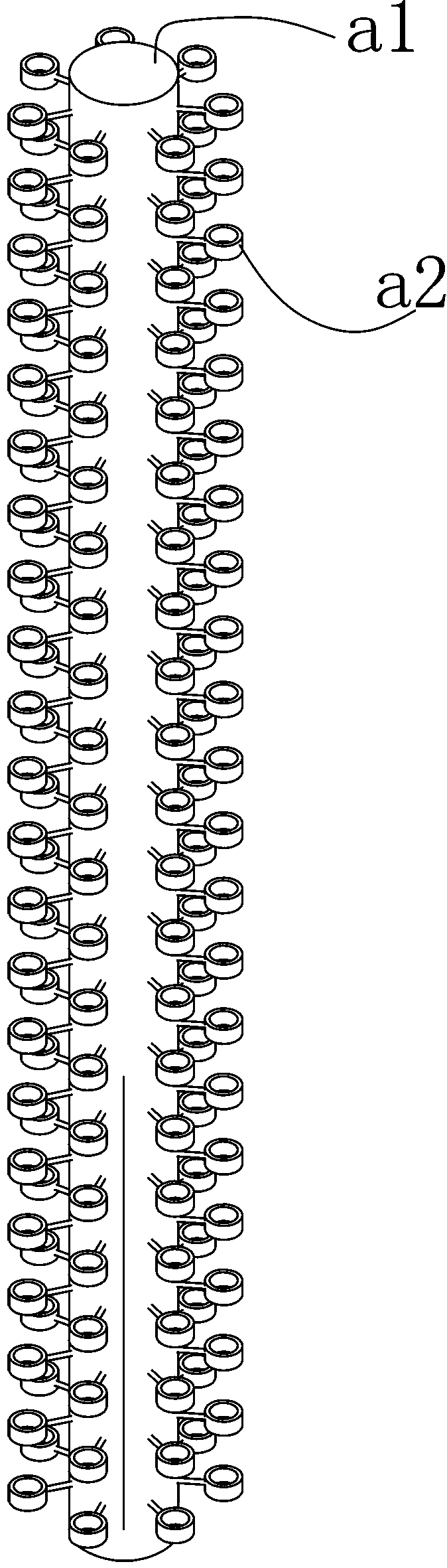

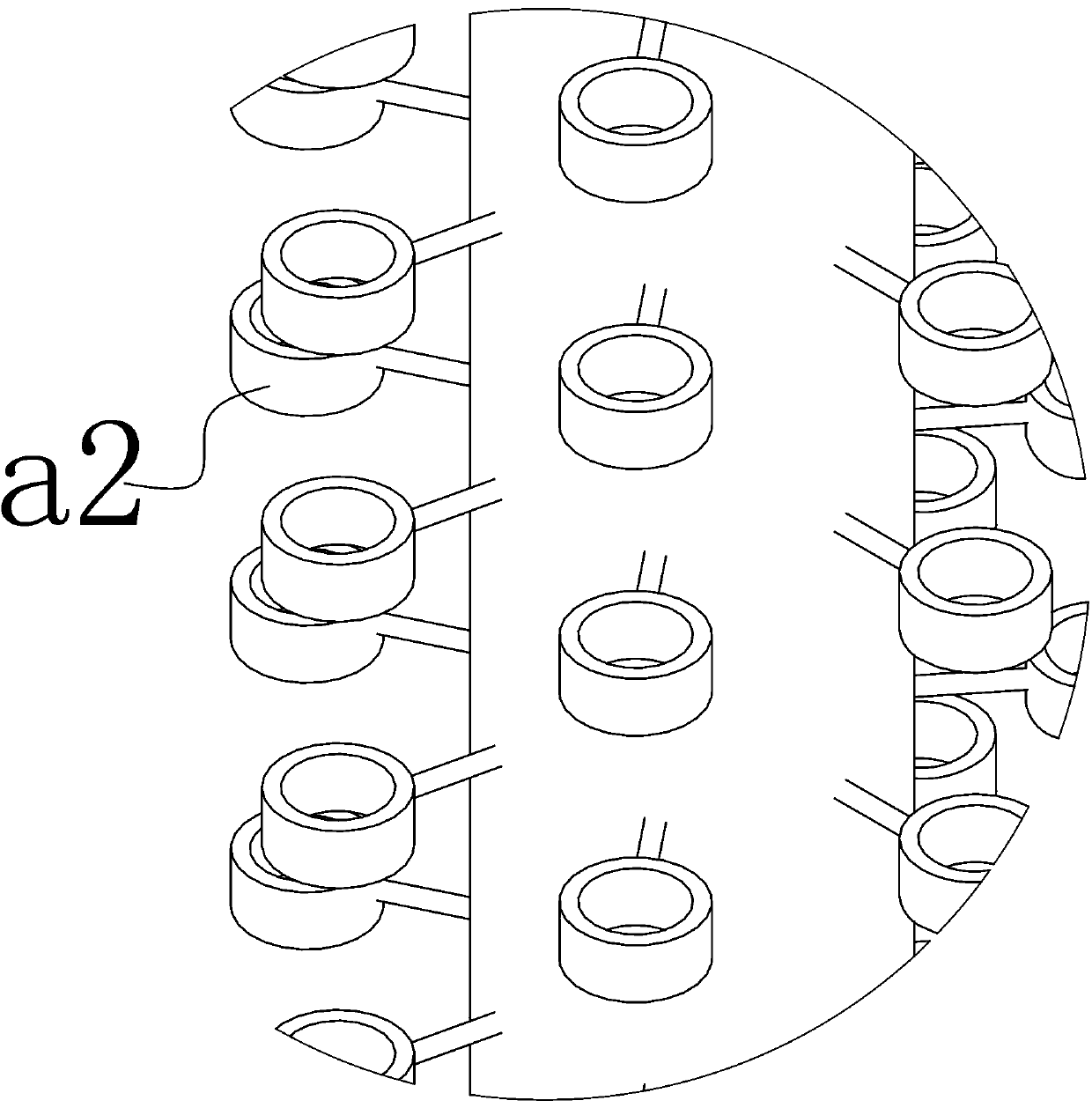

Ring jewelry wax machine

A jewelry ring wax welding machine, comprising a main frame (b1), and a wax welding mechanism fixed on the main frame (b1) and used for welding wax. The wax welding mechanism comprises an extension rod (11) and a first motor (12) driving the extension rod (11) to rotate. The free end of the extension rod (11) is used for fixing a wax rod (a1). The jewelry ring wax welding machine further comprises a moving mechanism for moving the extension rod (11) along the axial direction of the extension rod (11). The jewelry ring wax welding machine further comprises a conveying mechanism for conveying ring wax (a2) to a wax welding region. The jewelry ring wax welding machine further comprises a welding structure for melting the bottoms of the ring wax (a2) and pasting the wax onto the wax rod (a1). By means of the design of a mechanical structure, a manual wax welding operation is changed into a mechanical wax welding operation, so that the wax welding efficiency is improved, the pollution is reduced, and the human body injury is prevented.

Owner:SHENZHEN XINWANFU JEWELRY

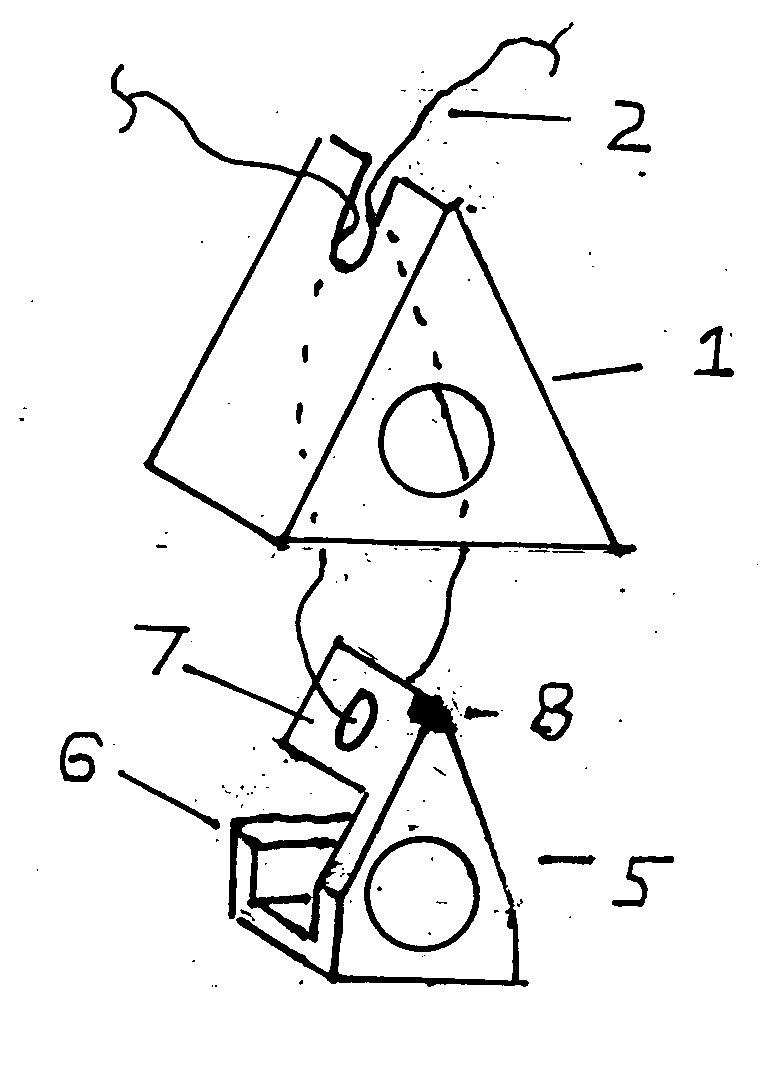

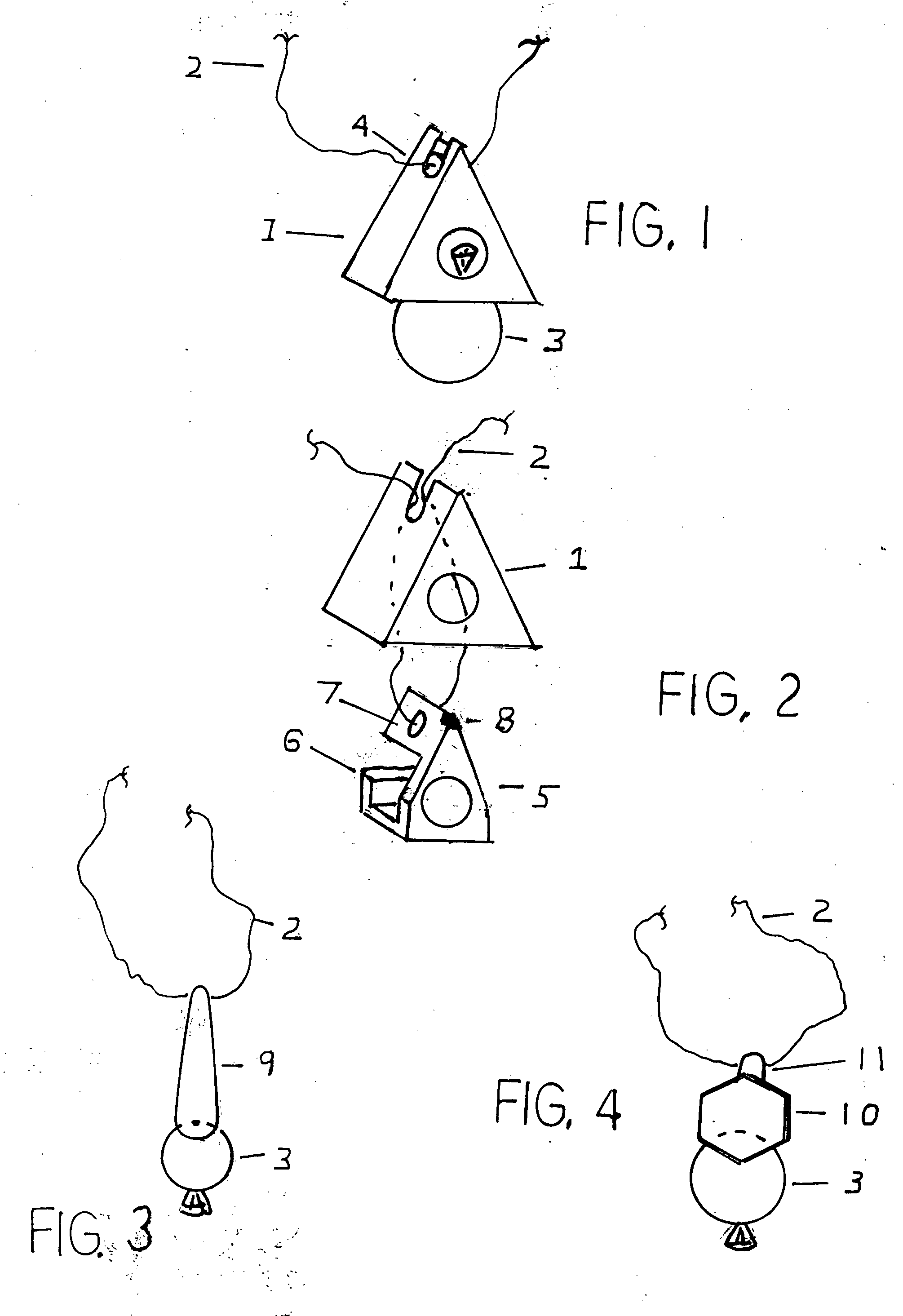

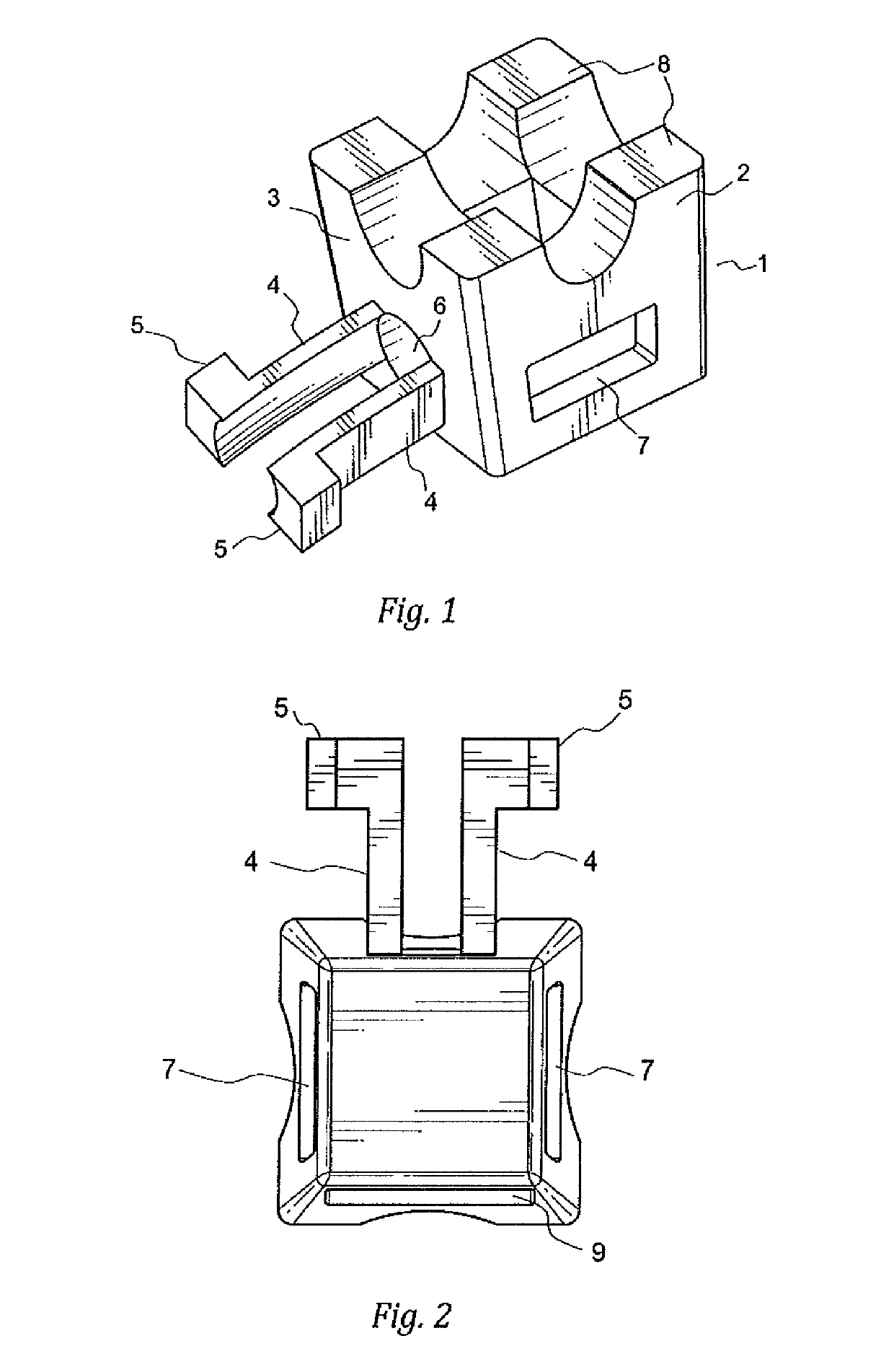

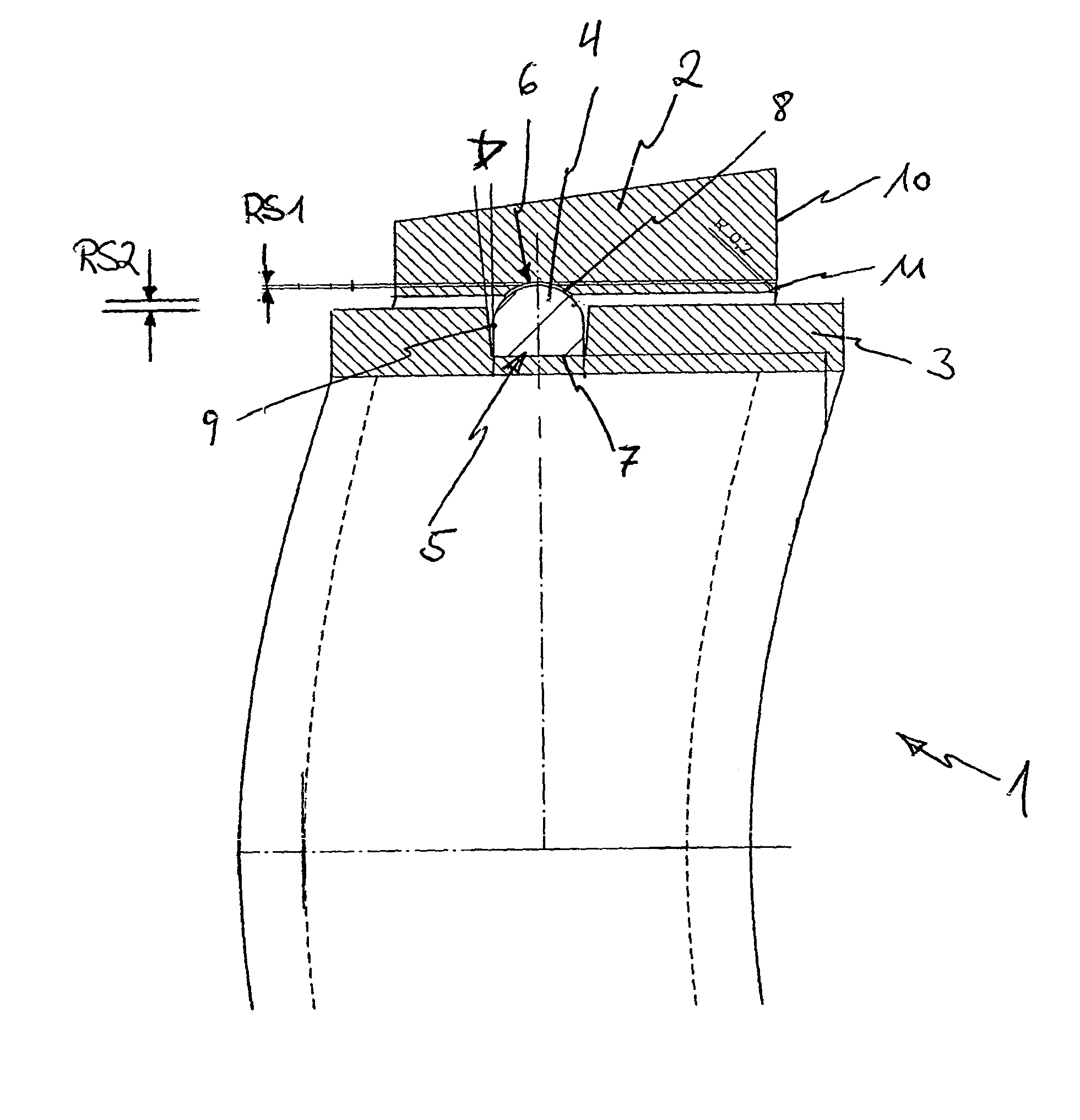

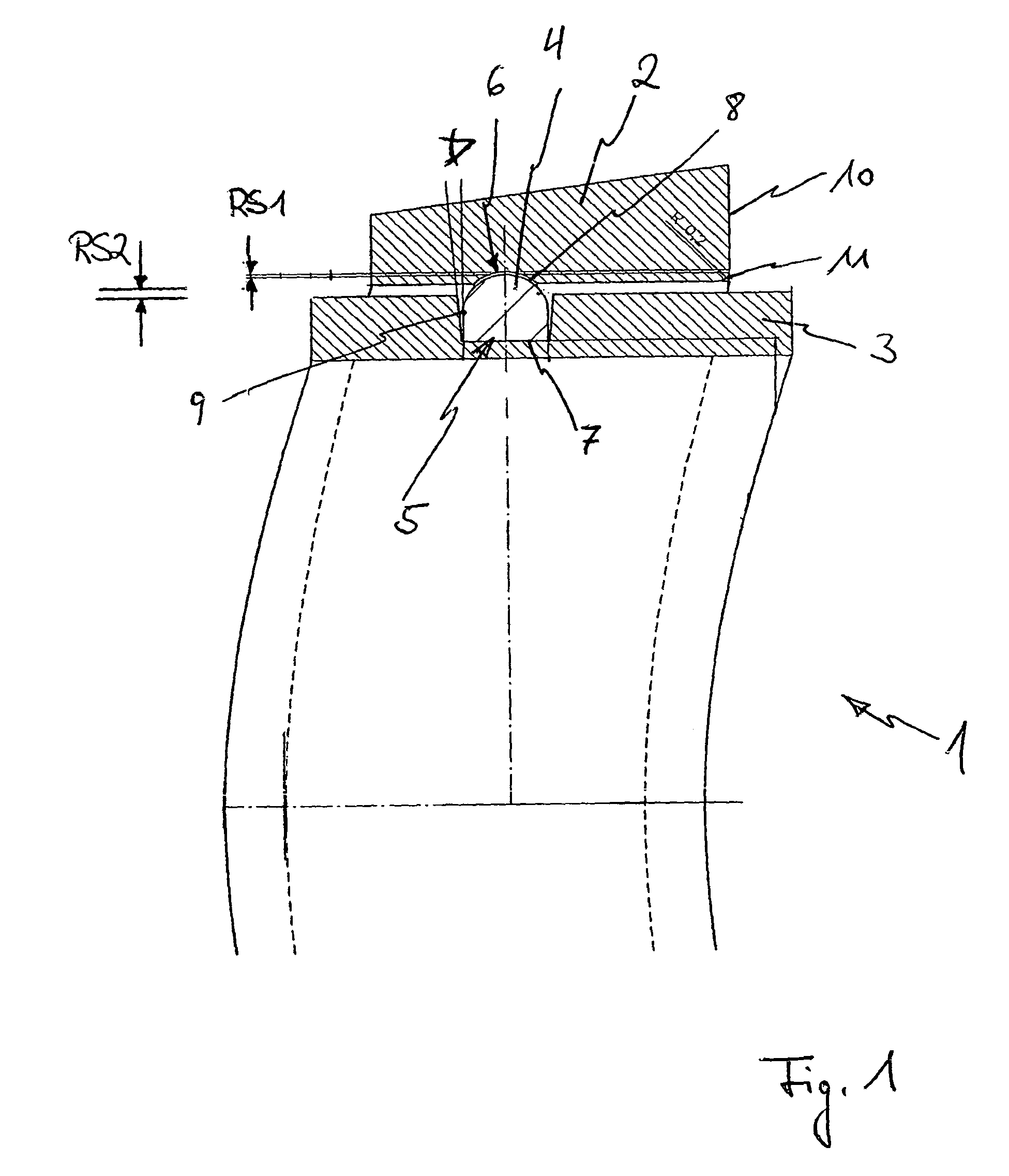

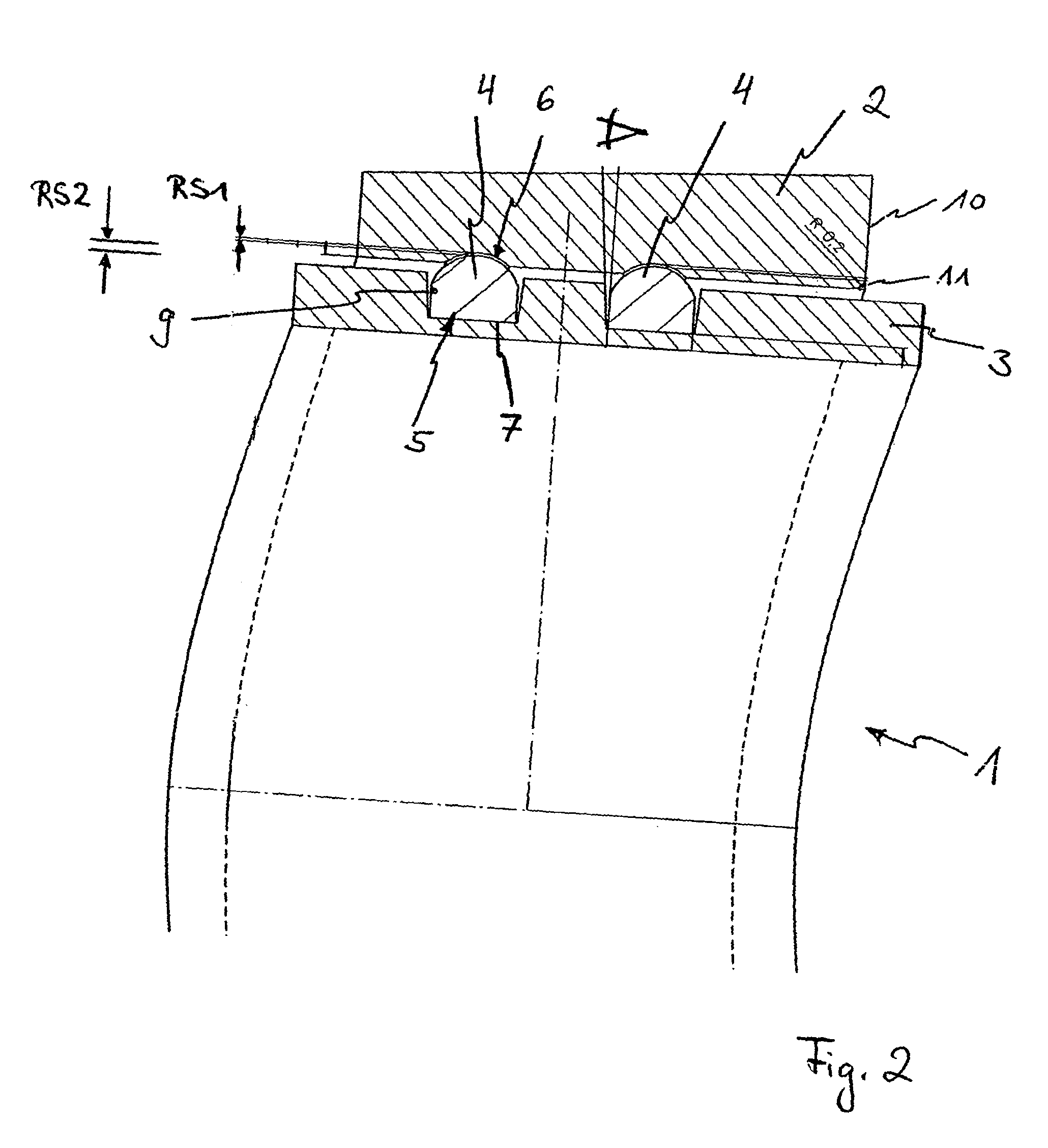

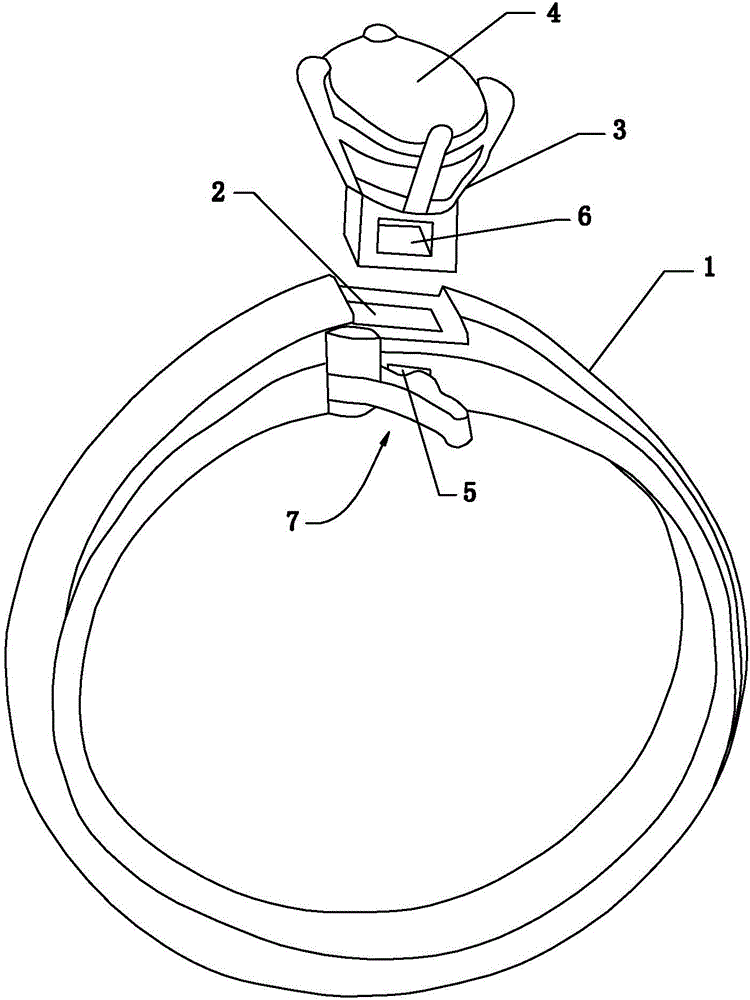

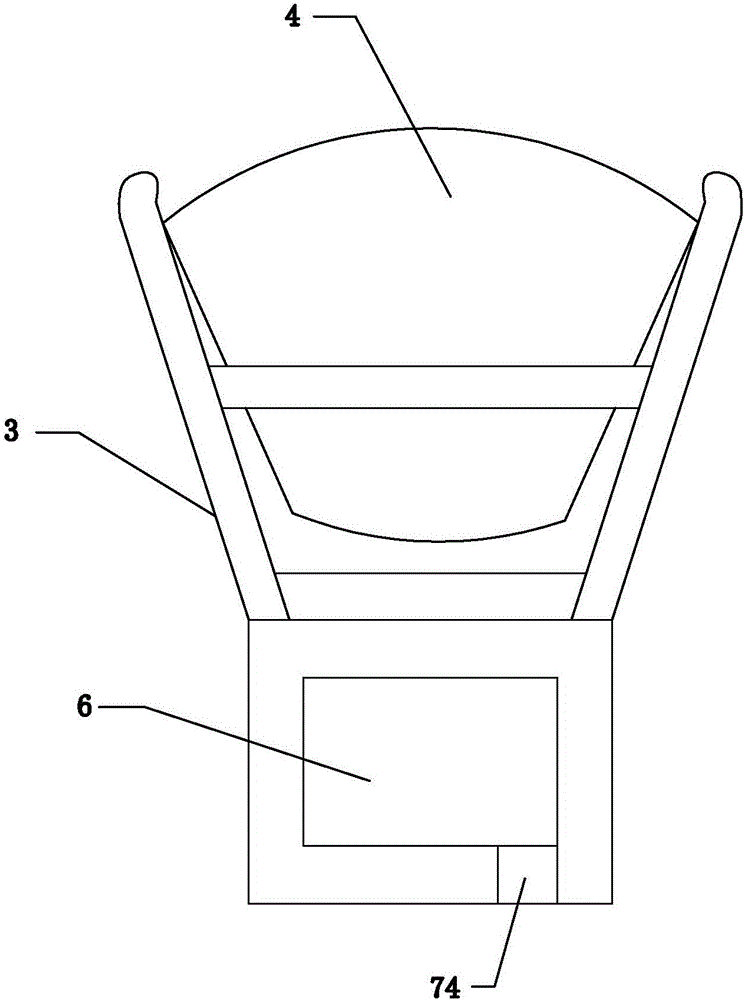

Jewelry ring and method for the production thereof

InactiveUS20090084134A1Avoid it happening againEliminate relative motionFinger-ringsEngineeringJewelry ring

The present invention generally relates to a jewelry ring (1) and a method for the production of such a jewelry ring (1). The jewelry ring consists of a first ring (2) having an inner surface area, a second ring (3) and a sliding ring (4), the latter is located between the first ring (2) and the second ring (3) to ease a preferably frictionless twistability of the two rings to each other.

Owner:MONTBLANC SIMPLO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com