Machining device and method for sharpness of antenna target plate

The technology of a processing device and a processing method is applied in the field of processing devices for the sharpness of an antenna target plate, which can solve the problems of the antenna unable to stably receive and release microwave signals, the antenna unable to achieve stable signal transmission, and the increase of production costs, and to reduce mechanical strength. , The effect of stable transmission and reduction of production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

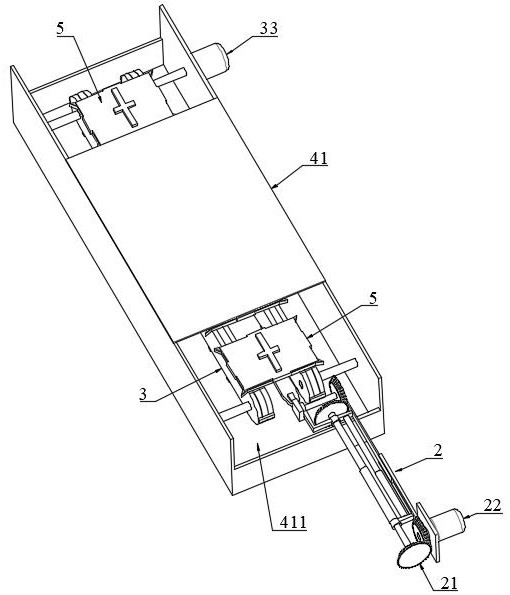

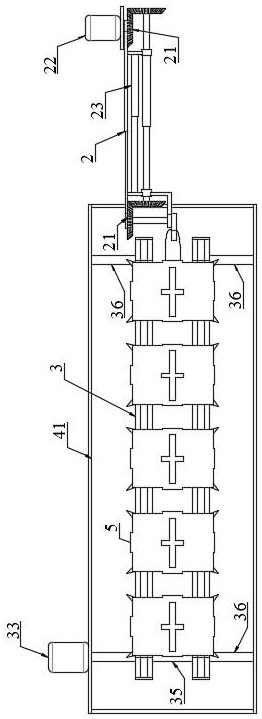

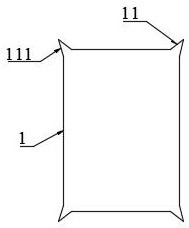

[0049] Such as figure 1 As shown, the present embodiment provides a processing device for the sharpness of the antenna target plate, such as image 3 As shown, the four corners of the target board 1 are PAD positions 11, and the PAD position 11 is provided with a protrusion 111, and the protrusion 111 is triangular, circular or square, and the processing device includes a target board transfer mechanism 2, a conveying mechanism 3, a sandblasting Mechanism 4 and protective shell 5.

[0050] Specifically, such as Figure 4As shown, the protective case 5 includes a target board bottom bracket 51 and a target board cover 52. The target board cover 52 is fastened to the target board bottom bracket 51. The inside of the protective case 5 is used to place the target board 1, and the target board bottom The four corners of holder 51 are provided with special-shaped convex plate 511, and the shape and size of special-shaped convex plate 511 are identical with protrusion 111, and prot...

Embodiment 2

[0060] Such as Figure 10 As shown, the present embodiment provides a method for processing the sharpness of the antenna target plate, using the processing device for the sharpness of the antenna target plate in Embodiment 1, the processing method includes the following steps:

[0061] S1. Place the target board 1 on the target board bottom support 51, the protrusion 111 is located on the special-shaped convex plate 511, and then fasten the target board cover 52 to the target board bottom support 51, and the protrusion 111 is exposed on the target board cover 52 outside;

[0062] S2. At this time, the guide column 231 and the telescopic rod 23 are all in a vertical state, and the clamping plate 24 is in a horizontal state;

[0063] Place the target board bottom bracket 51 on the clamping plate 24, match the slot 241 of the clamping plate 24 with one of the branches of the cross 53, use the first motor 22 to turn the steering plate 221 counterclockwise, and make the clamping p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com