Abrasion blasting head as well as abrasion blasting unit and abrasive blaster thereof

A blasting head and blasting chamber technology, applied in abrasive jet machine tools, spray guns, used abrasive treatment devices, etc. Disassembly and maintenance, avoid dealing with dead corners, and uniform sandblasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with the preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

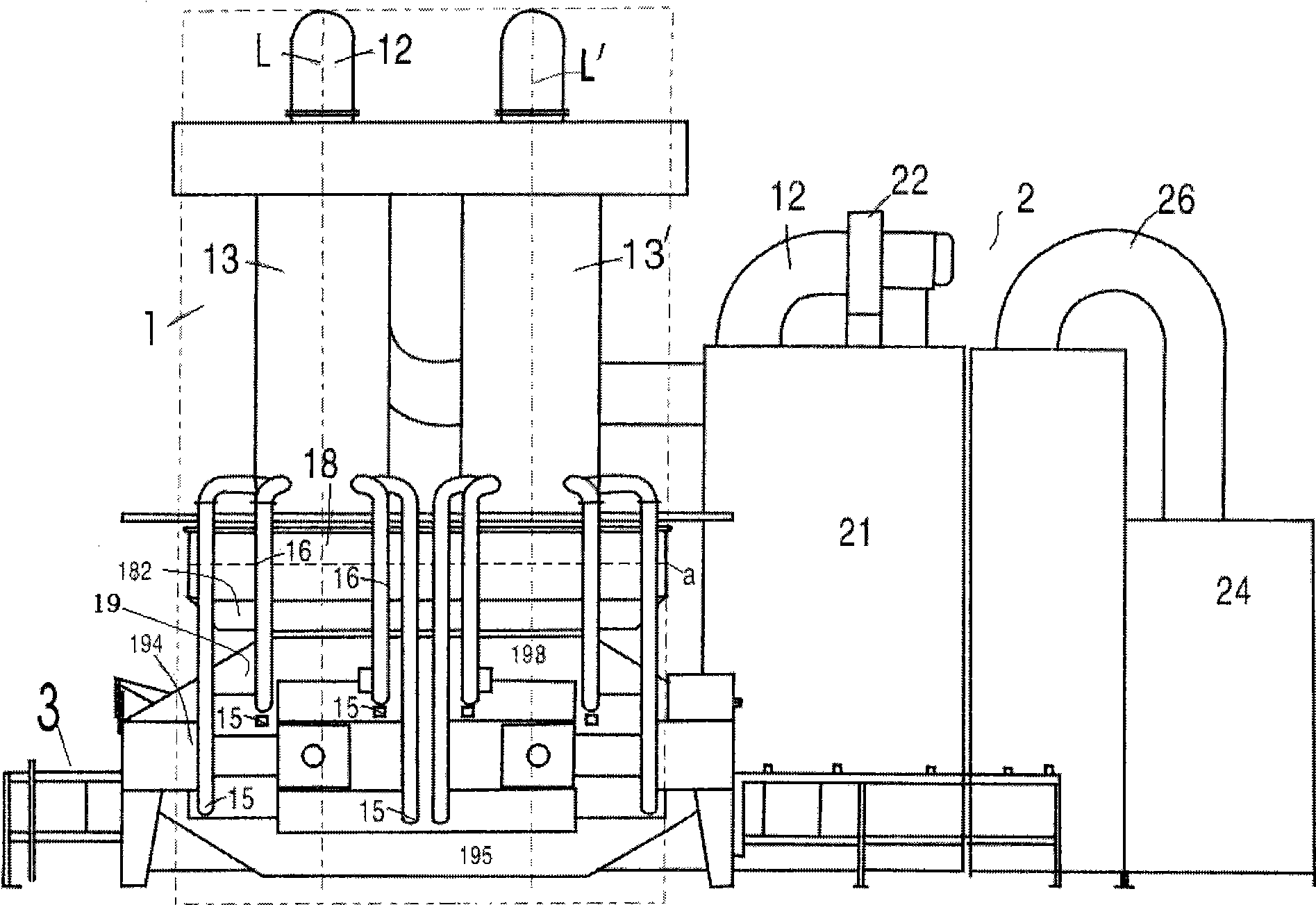

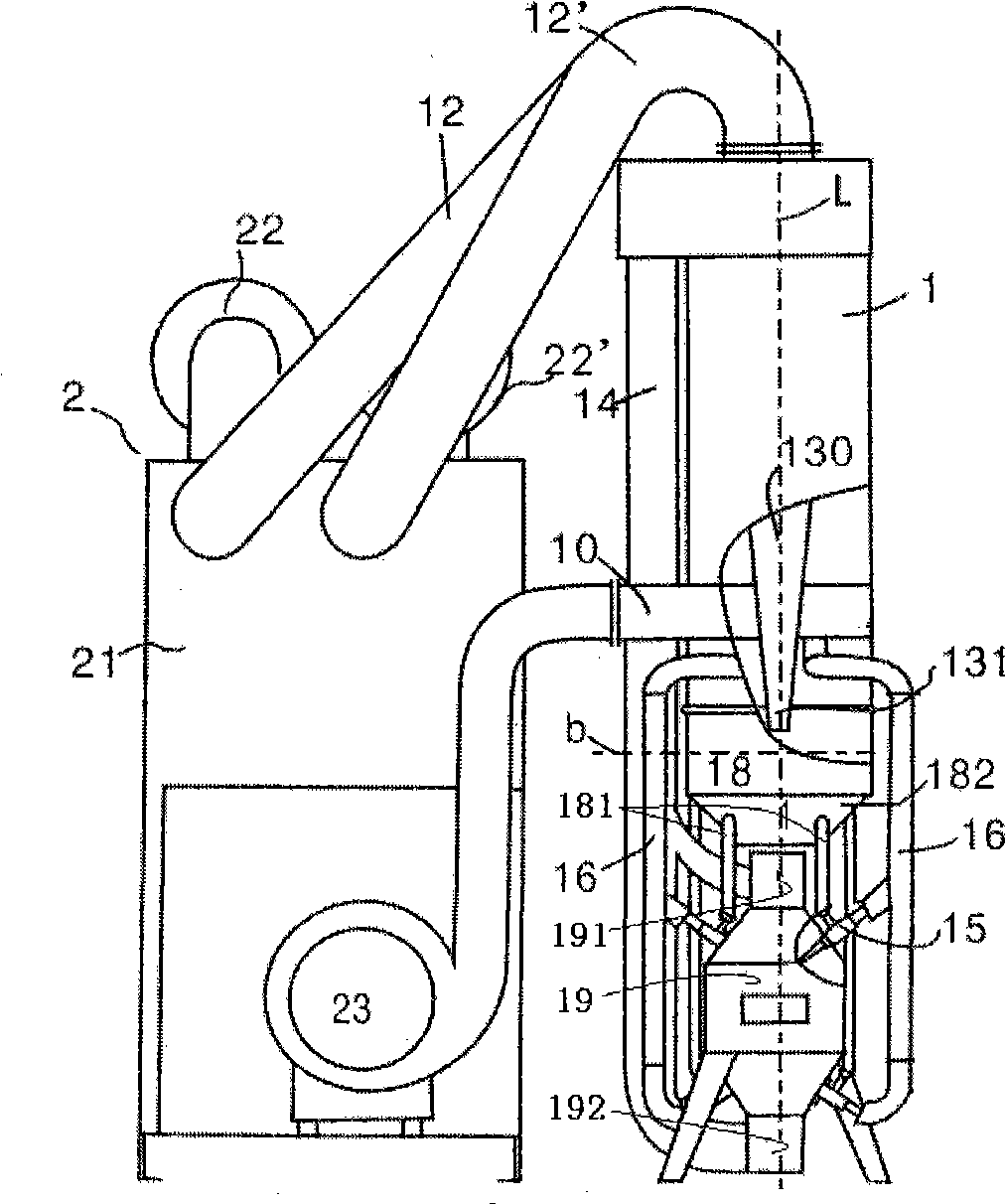

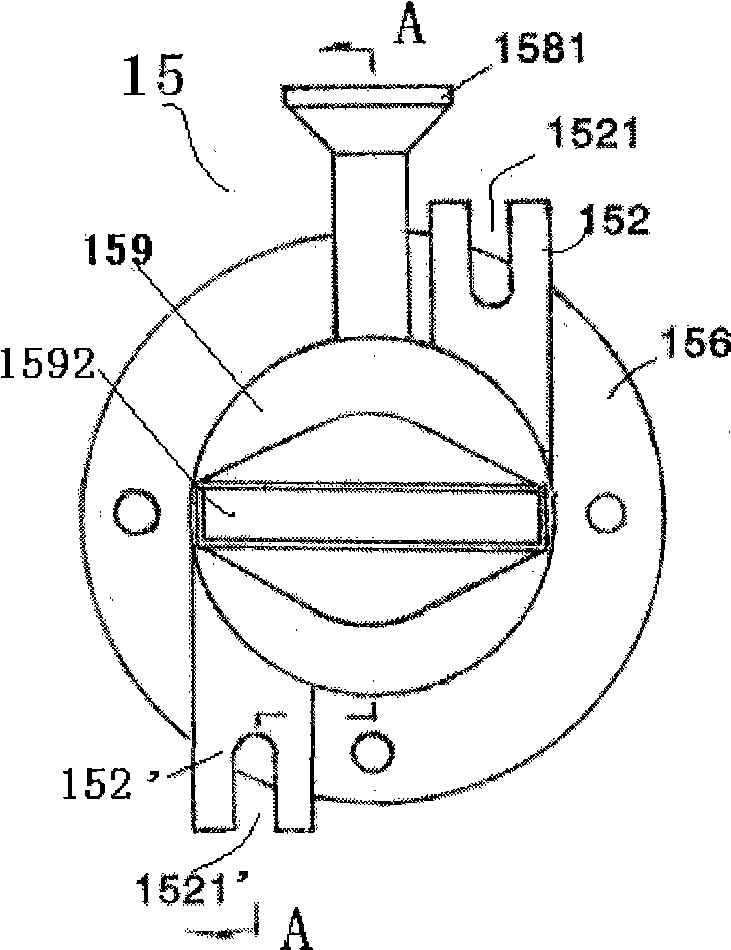

[0042] like Figure 1-3 As shown, a sandblasting machine includes a sandblasting unit 1 and a dust removal mechanism 2 with a sandblasting head 15, wherein,

[0043] The sandblasting unit 1 has a sand storage chamber 18, which has a rectangular inner cavity; the same first tower body 13 and second tower body 13' are installed above the sand storage chamber to form a double tower structure;

[0044]The tower body is equipped with a separator 130, and the inverted cone port 131 of the separator extends into the upper part of the sand storage chamber;

[0045] The installation position of the first tower body i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com