Sanding and grinding process of wood product

A technology for wood products and sanding, which is used in the manufacture of tools, grinders, abrasives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with specific examples.

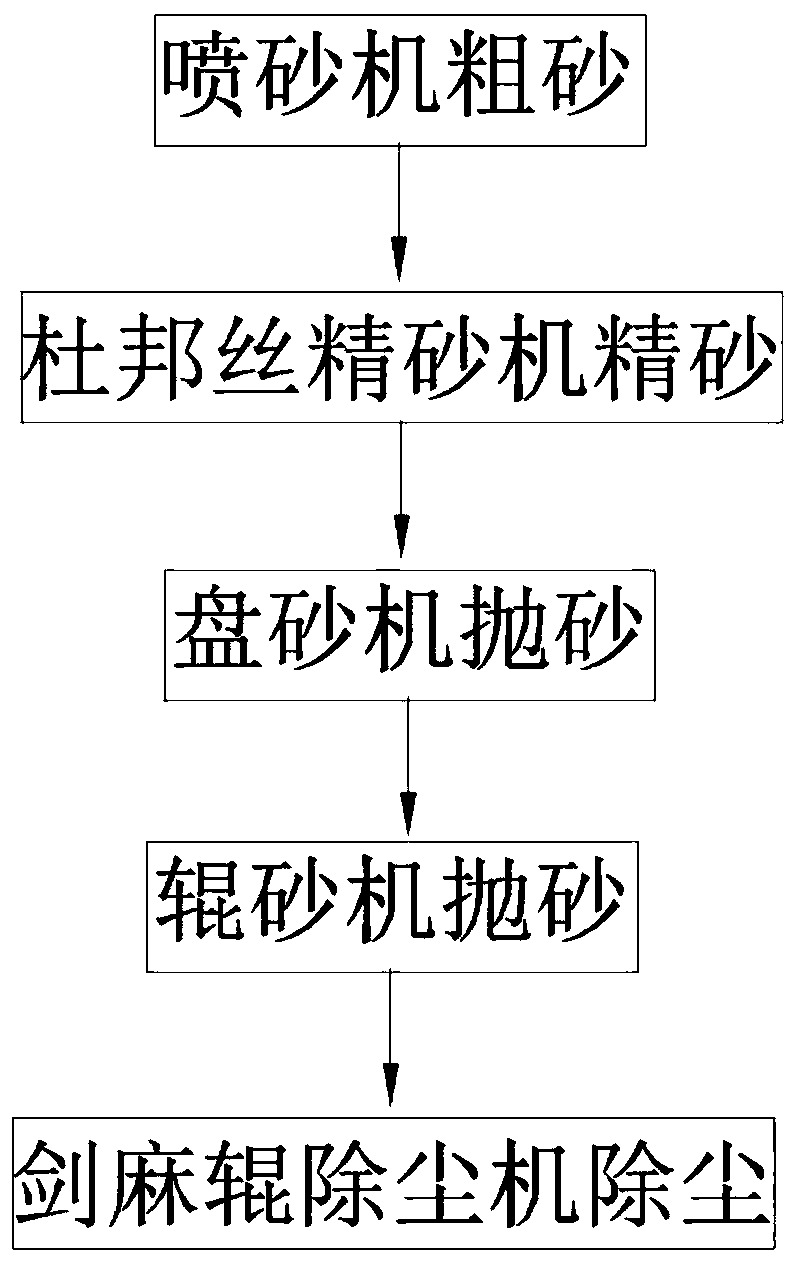

[0052] see figure 1 : A wood product sanding process, the wood product undergoes the following steps in sequence:

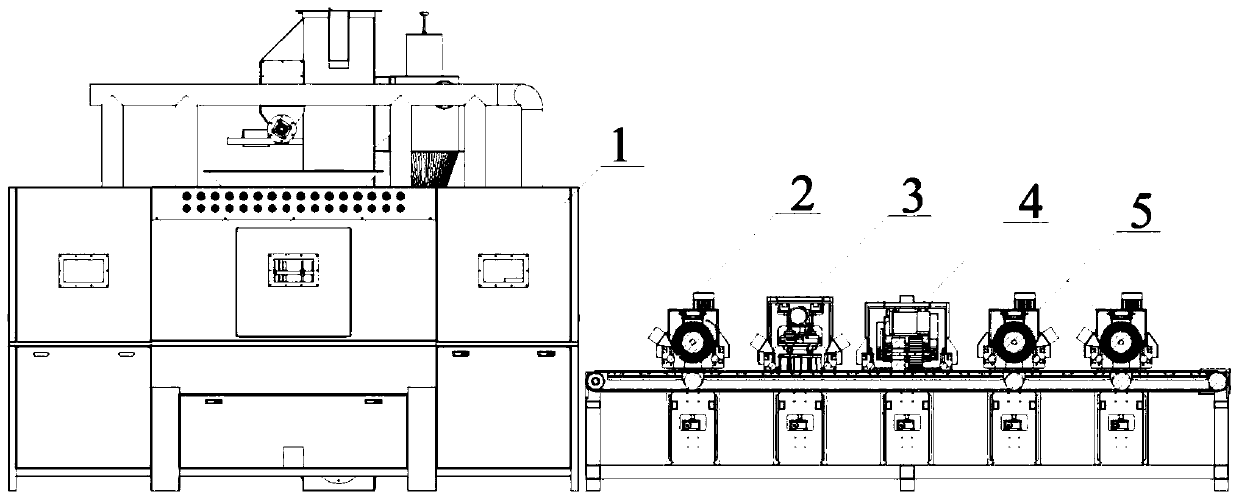

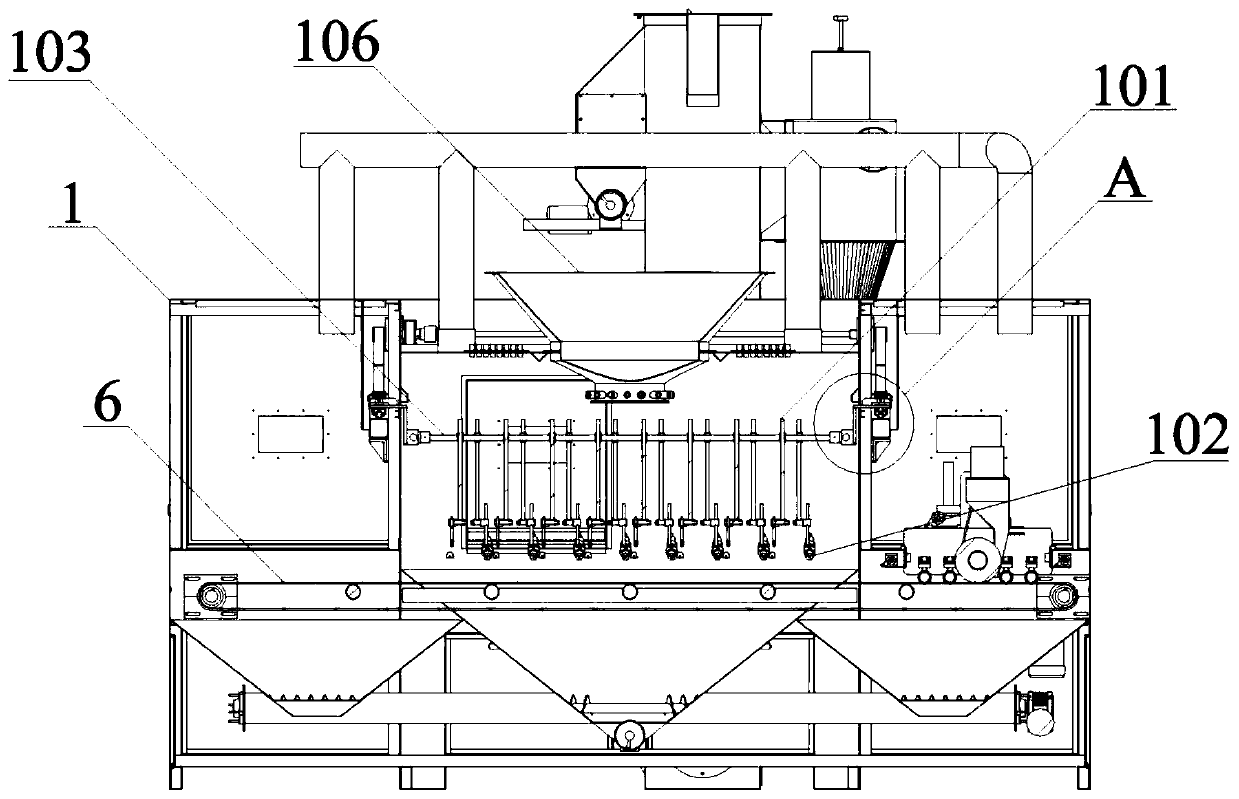

[0053](1) Sand blasting machine 1 coarse sand, so that the surface of wood products can achieve a matte effect;

[0054] (2) DuPont silk fine sand machine 2 fine sand, remove the sand left over from sandblasting and cover the sand marks left over from sandblasting;

[0055] (3) Disc sand machine 3 and roller sand machine 4 blast sand to cover the sand marks of DuPont silk;

[0056] (4) Sisal roller dust collector 5 for dust removal.

[0057] During the sanding process, the wood products are transported on conveyor belts. Conveyor belt can be whole, also can segment, as being divided into two sections: the first conveyer belt 61 and the second conveyer belt 62, first conveyer belt 61 is arranged on sandblasting machine 1 in the present embodiment, and second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com