Patents

Literature

33 results about "Slip (ceramics)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A slip is a liquid mixture or slurry of clay and/or other materials suspended in water. It has many uses in the production of pottery, and other ceramic wares. In pottery the two most important uses of slip are: firstly, to form the basic shape by slipcasting with moulds; this has been extremely important for several centuries, and secondly, to protect or decorate the pottery, which is discussed below.

Method for coloring ceramics via colloidal dispersion

ActiveUS9365459B2Maintain colloidal stabilityFacilitate homogenous solutionImpression capsDentistry preparationsOrganic solventSlurry

Coloring in a slip casting process by which a ceramic slurry is cast into green state bodies. It is during this slip casting that a coloring solution consisting of metallic salts is introduced to the slurry and subsequently slip-cast. A coloring solution may comprise for example a metallic salt, a solvent, an organic solvent such as derivatives of propylene oxides, and an acid can be introduced to the slip casting process. Such a coloring solution can be added to the slip casting process. The solution is thoroughly mixed with the ceramic slurry, after which the ceramic body is cast, dried and finally subjected to a sintering process. After final sinter, the resulting ceramic body possesses an innate color that is homogenous throughout its composition. The method is especially useful for coloring zirconia dental restorations.

Owner:JAMES R GLIDEWELL DENTAL CERAMICS

Slip casting preparation method for high-whiteness earthenware

The invention relates to the field of ceramics, in particular to a slip casting preparation method for high-whiteness earthenware. The method comprises the following steps: selecting mineral raw minerals, namely selecting the following ceramic mineral sources with high purity in parts: 38 to 42 parts of Suzhou kaolin clay, 26 to 30 parts of Pingjiang feldspar, 24 to 33 parts of Jiangxi porcelain stone and 3 to 5 parts of Haicheng talc, performing washing and preparation, treating mud after ball milling by virtue of an additional pressure filtration procedure, performing slip casting to obtain a blank and firing the blank. According to the method, a process flow of sequentially performing high-temperature biscuit firing and low-temperature glaze firing is adopted, the apparent quality of a burnt matrix is similar to that of ceramic whiteware, the section is substantially sintered to be compacted, the whiteness reaches 70 percent, and the water absorption is lower than 0.5 percent; the product has practical value, and is as white and pleasant as cream.

Owner:江苏省宜兴彩陶工艺厂

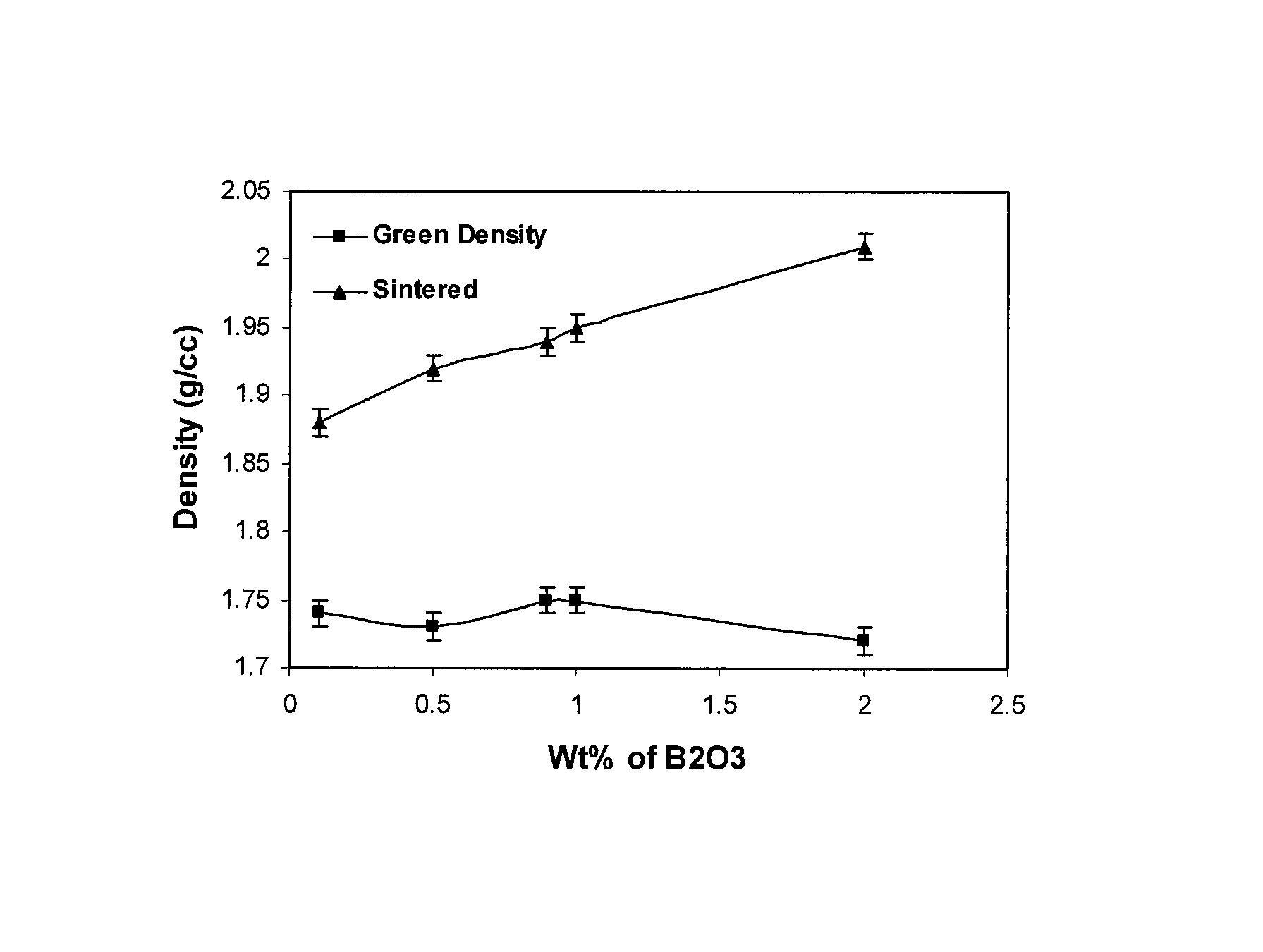

Process for manufacturing high density slip-cast fused silica bodies

ActiveUS20120098169A1Simple and cost-effectiveDrawback can be obviatedGlass shaping apparatusCeramic shaping apparatusVitrificationHigh density

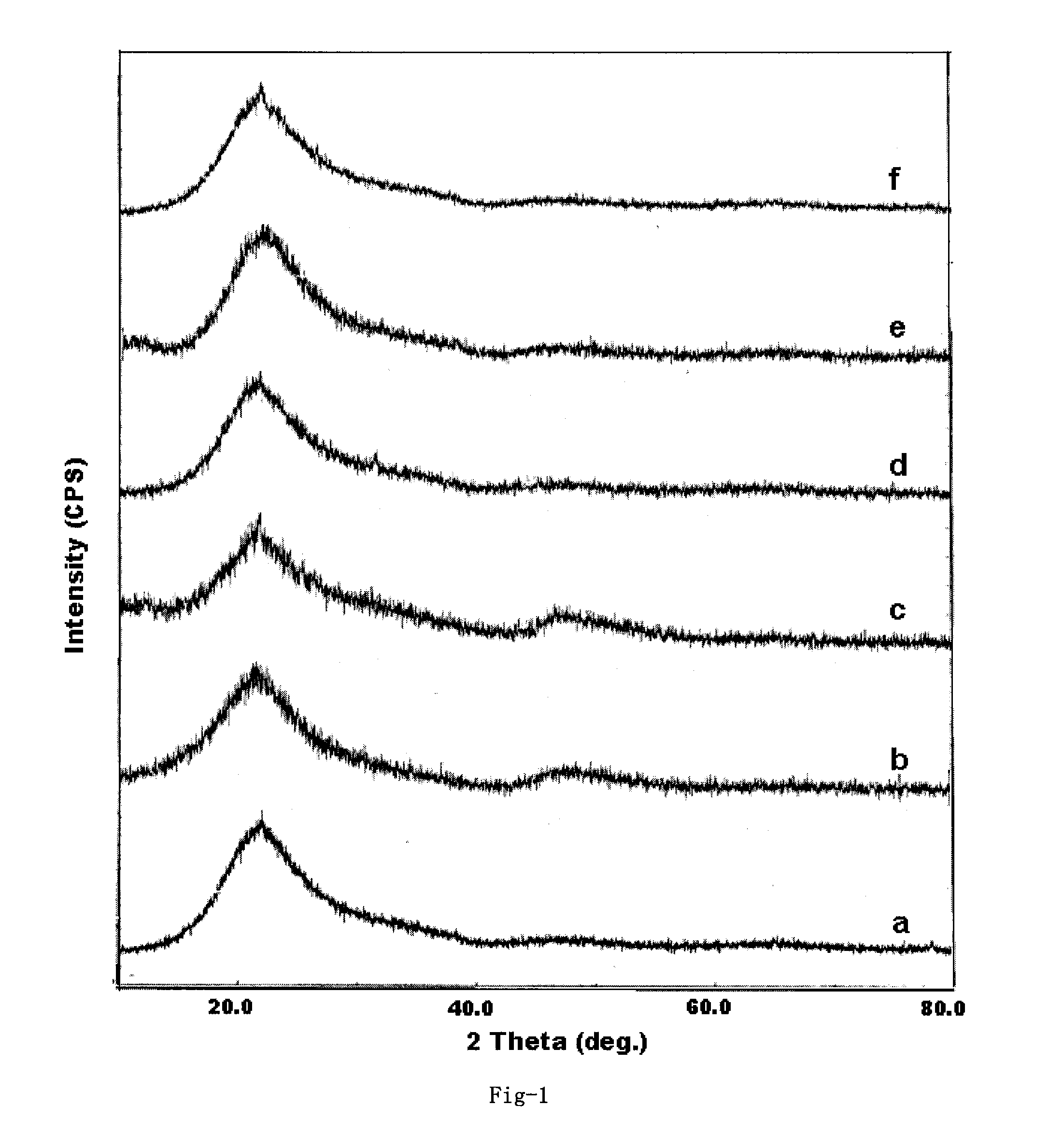

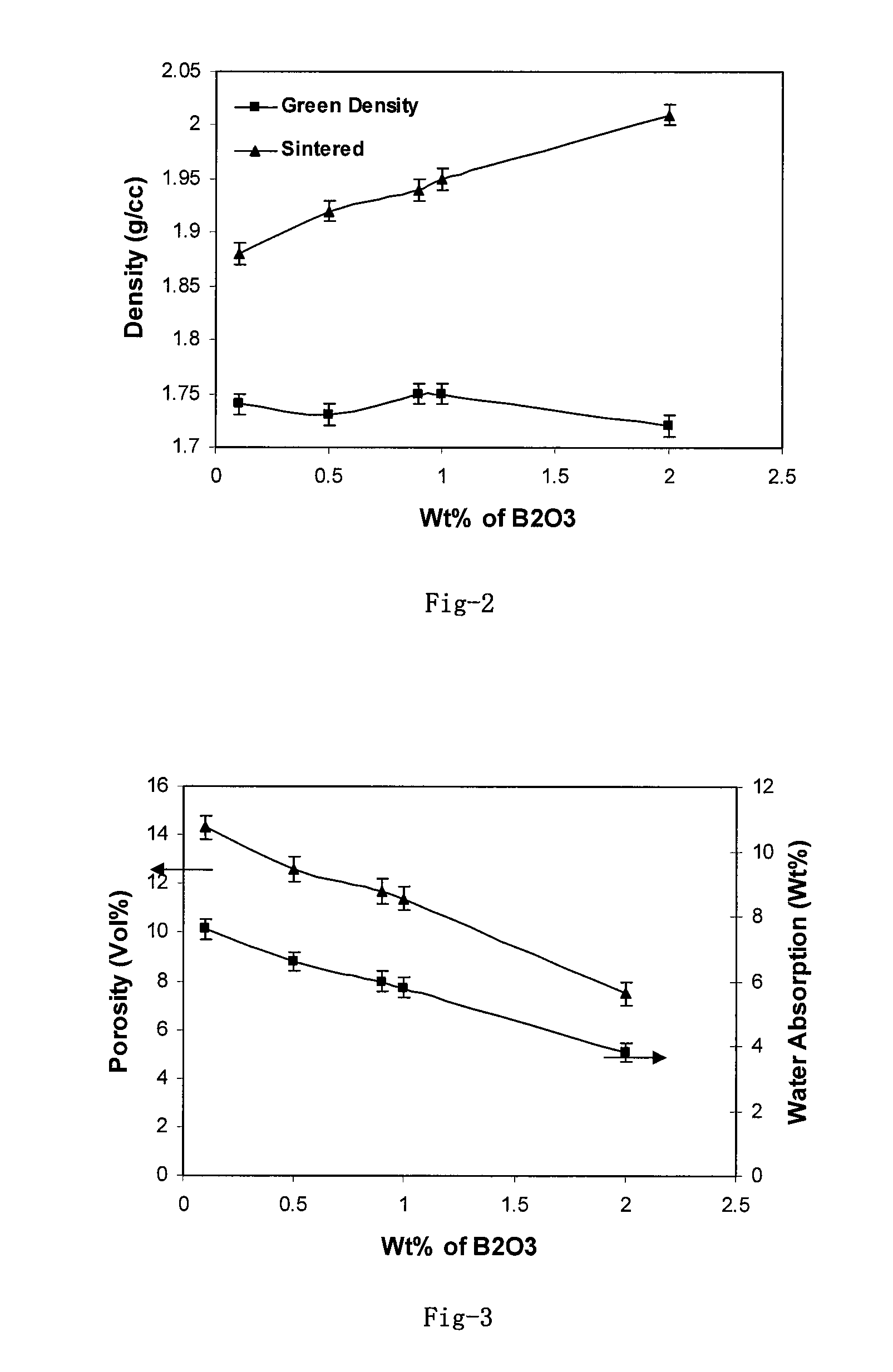

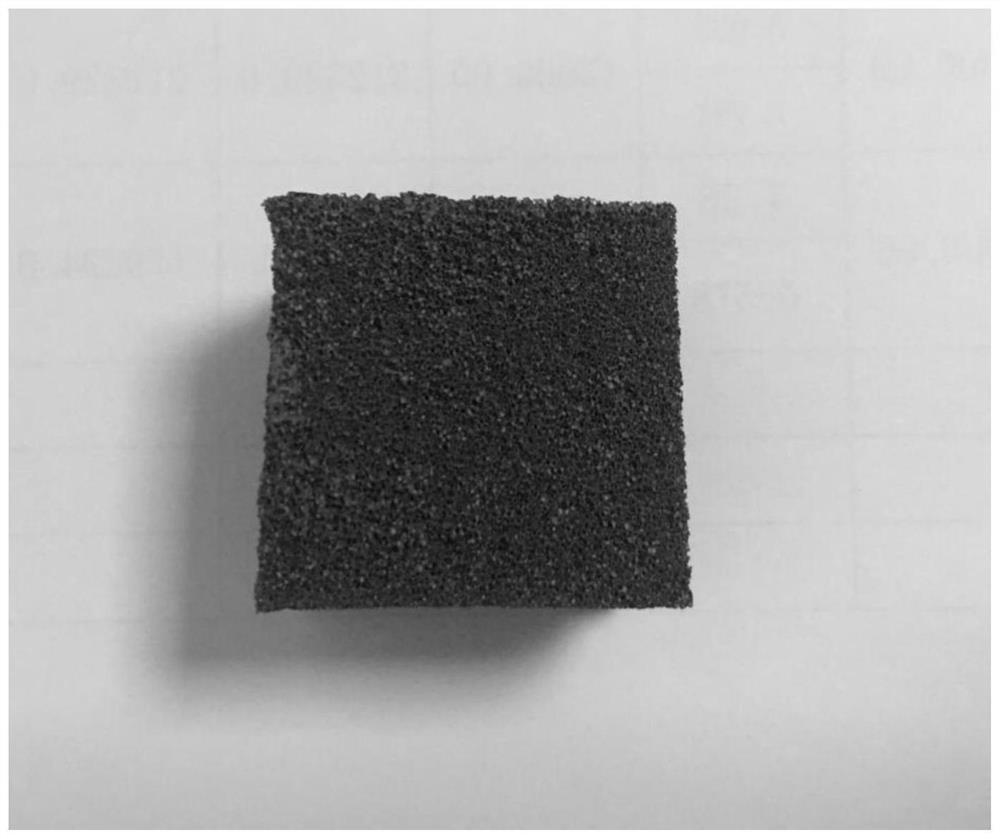

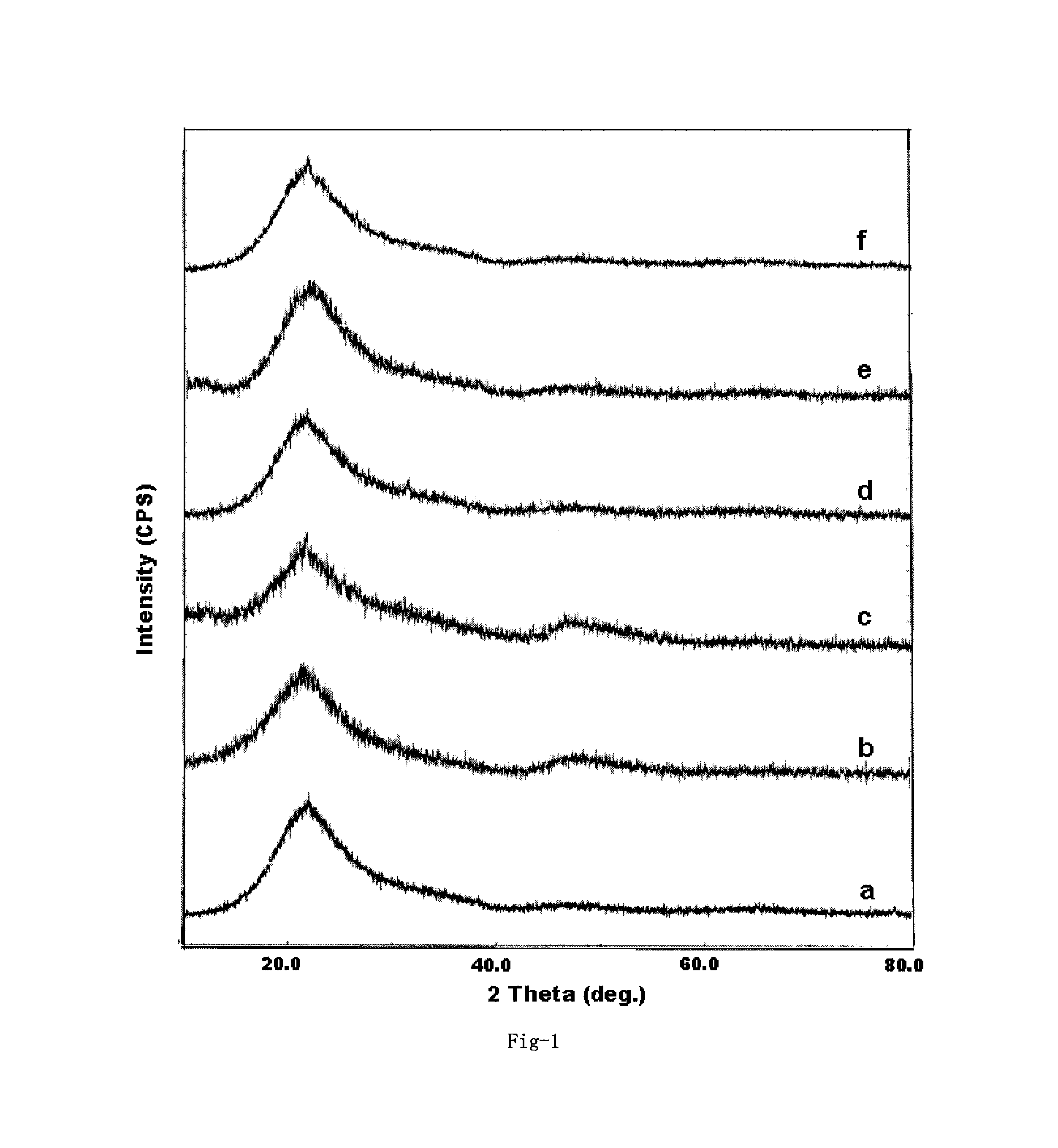

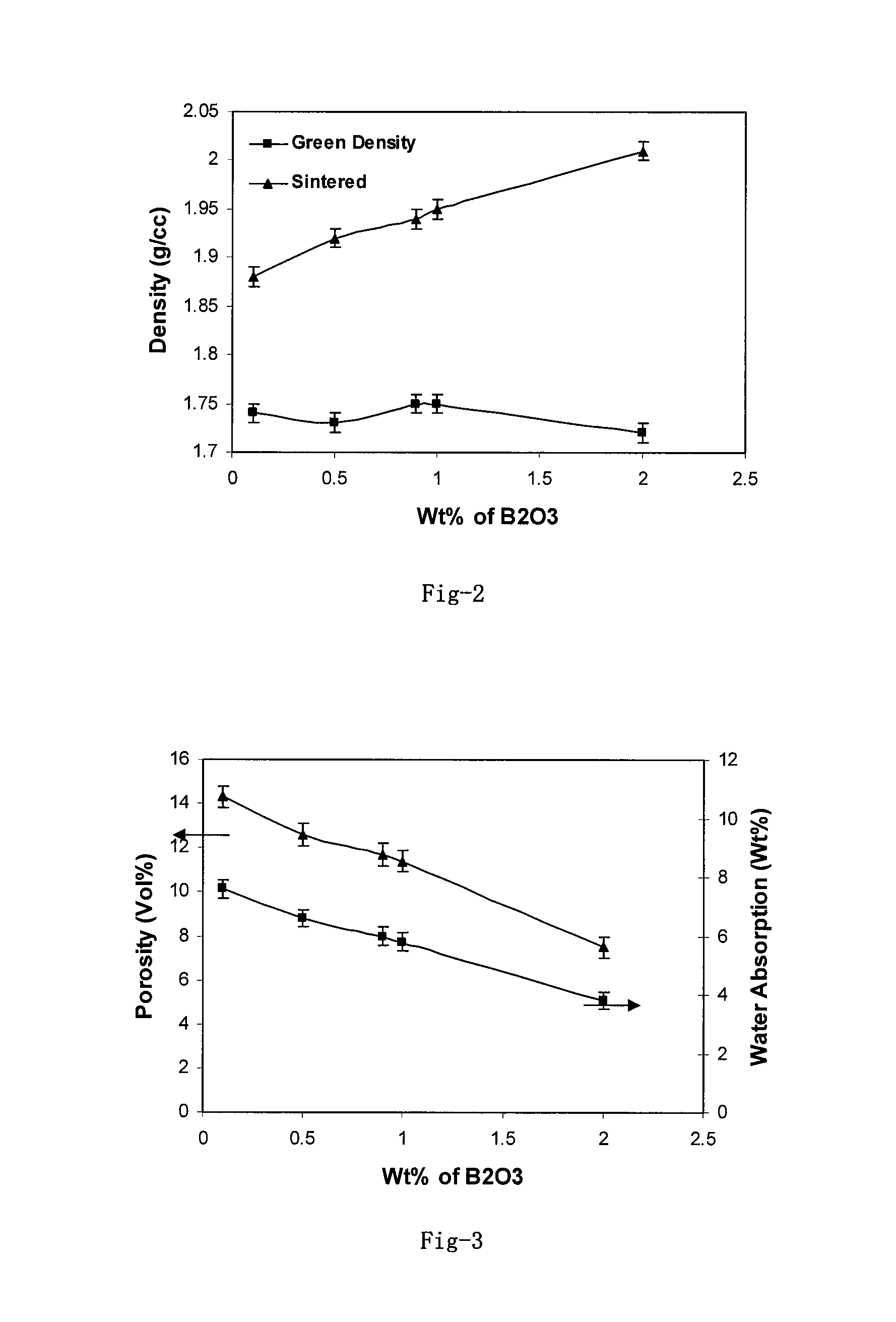

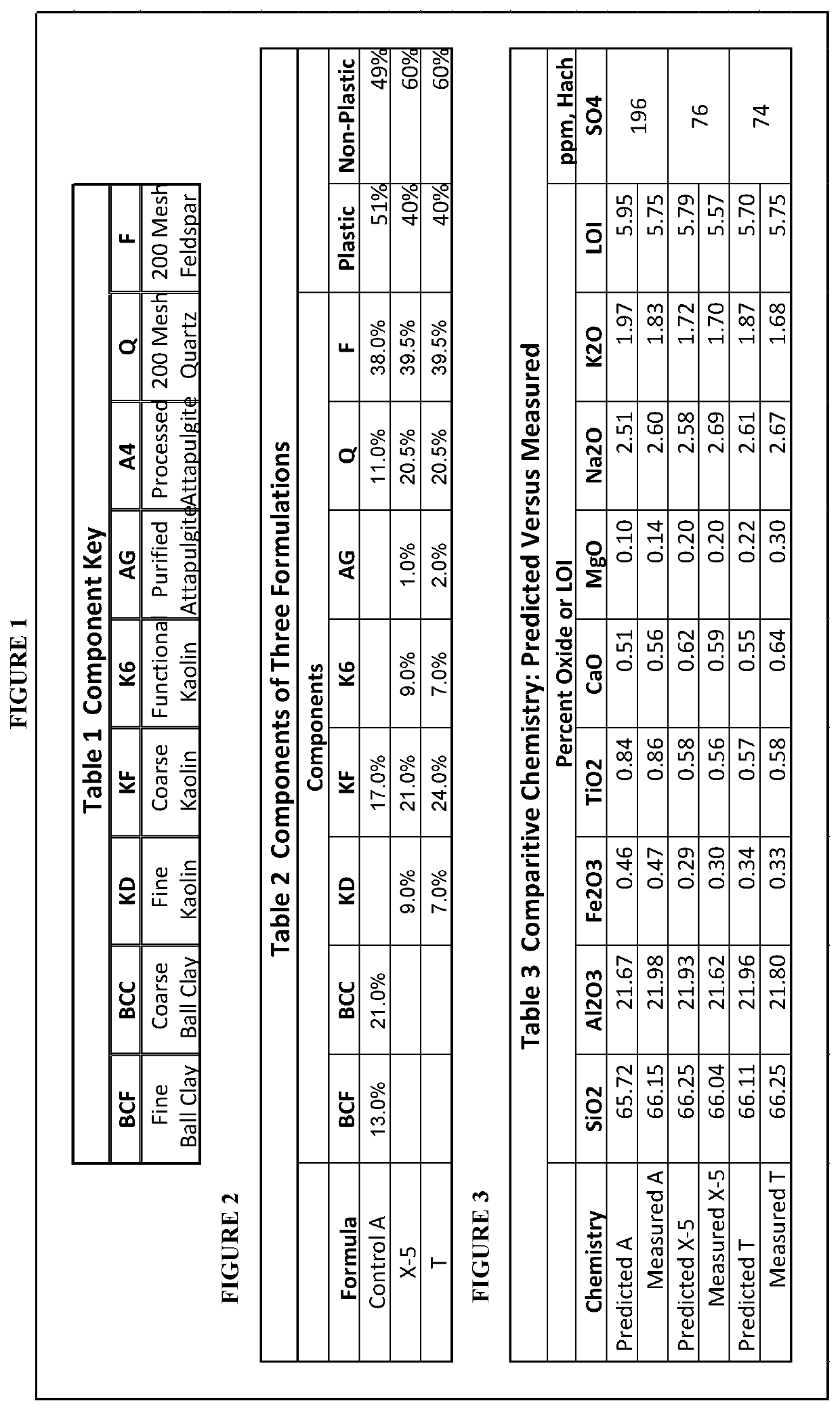

Fused silica ceramics plays demanding role in high velocity missile / aircraft'radome development. Slip casting is the most common and commercially viable process utilized for radome production. Unfortunately slip casting cannot afford high density due to its poor green packing density which in turn results in poor rain erosion resistance. Present invention discloses process for preparing high density fused silica bodies by adding boron oxide (B2O3) with the commercially available high purity fused silica as sintering aid cum de-vitrification inhibitor. Various concentrations of B2O3 were added to high purity fused silica. Thus formed compositions were made into slip-castable slurries in aqueous medium without any addition of dispersing agents. The reheological properties like mild shear thinning and low thixotropic behaviour of the slurries were established. These slurries were then slip-casted in plaster of parries mold. The green and sintered properties of the casted samples were studied. The sintered sample with density higher than 2 g / cc (90-95% of the theoretical density) was achieved without de-vitrification. XRD studies on sintered samples showed the amorphous nature of the sample. The improved properties of fused silica system can favor its utilization in radome applications.

Owner:COUNCIL OF SCI & IND RES

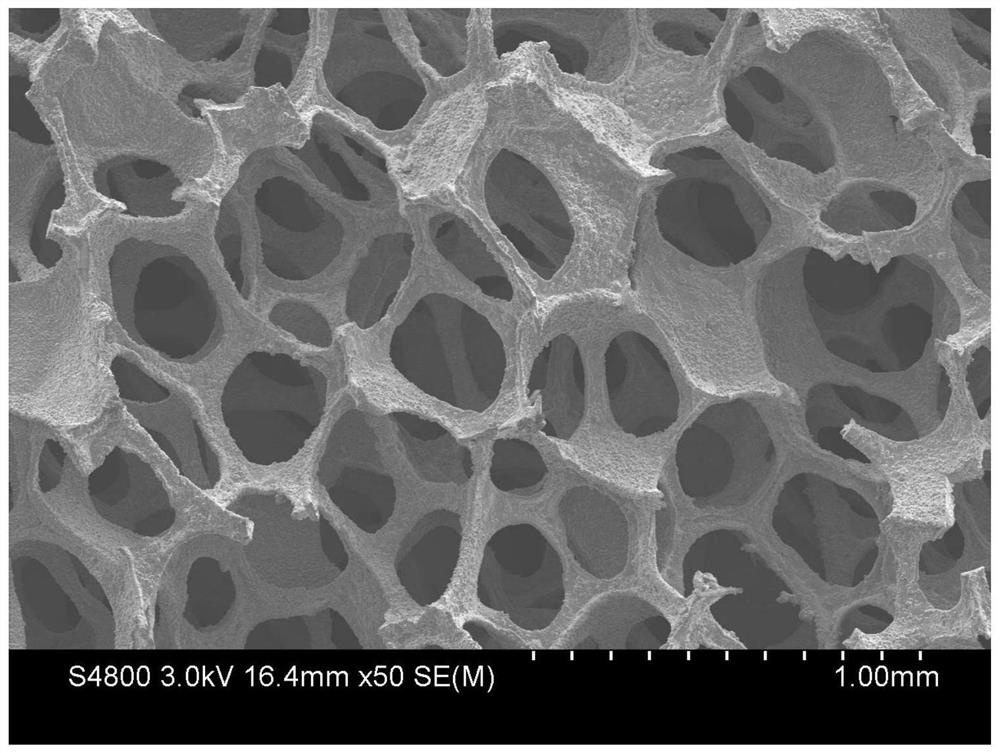

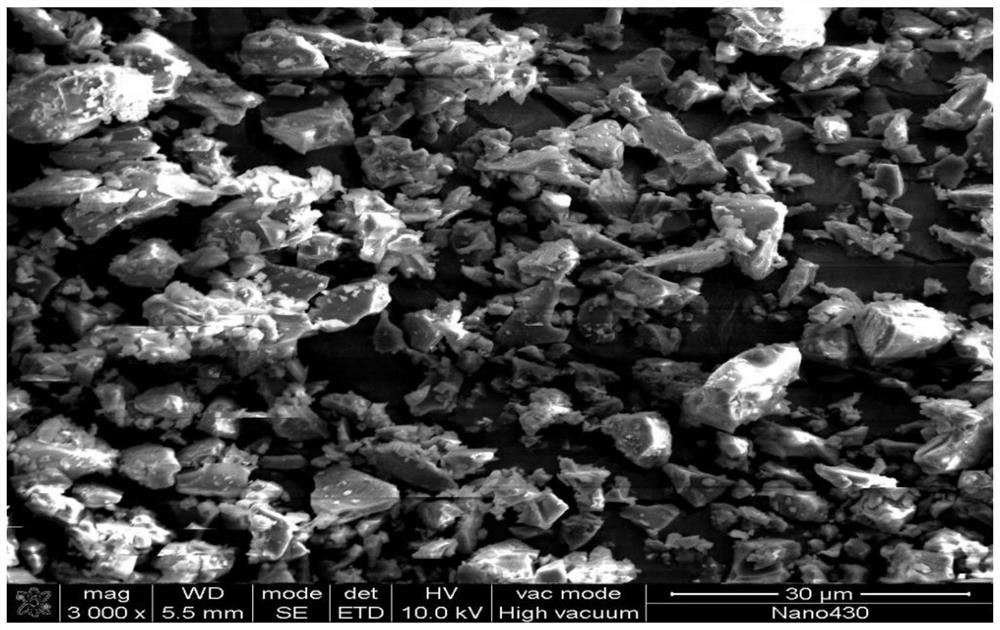

Method for preparing high-performance foamed ceramic by combining template method with chemical vapor infiltration method

PendingCN111925229ARealize the combination designAchieve preparationCeramicwareSlip (ceramics)Slurry

The invention relates to a method for preparing high-performance foamed ceramic by combining a template method with a chemical vapor infiltration method. A template method and a chemical vapor infiltration method are combined, no sintering aid needs to be added, a foamed ceramic skeleton is obtained by preparing high-purity ceramic powder slurry and based on the template method through slurry hanging, drying and template removal (optional), then the foamed ceramic skeleton is densified by combining the chemical vapor infiltration method, and finally the high-performance foamed ceramic is obtained. Compared with a traditional foamed ceramic preparation method, preparation of various ultrahigh-temperature foamed ceramics can be achieved without limitation of the preparation temperature. Compared with a traditional foamed ceramic preparation method, the method can also realize combined design and preparation of multiple components of the foamed ceramic based on different slurries and CVIprecursor materials, so that the prepared foamed ceramic has designability and compatibility of multiple functions of structure, bearing, electromagnetism and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

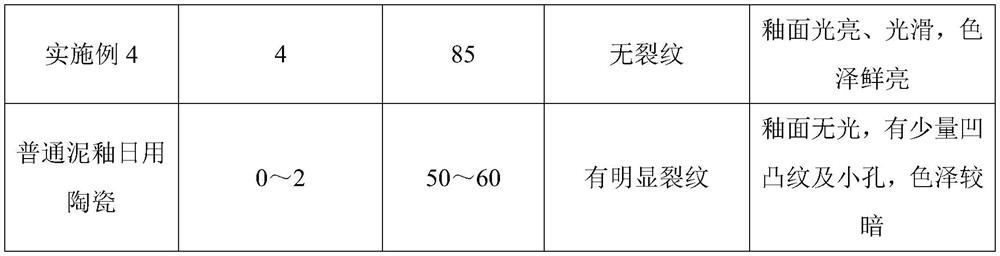

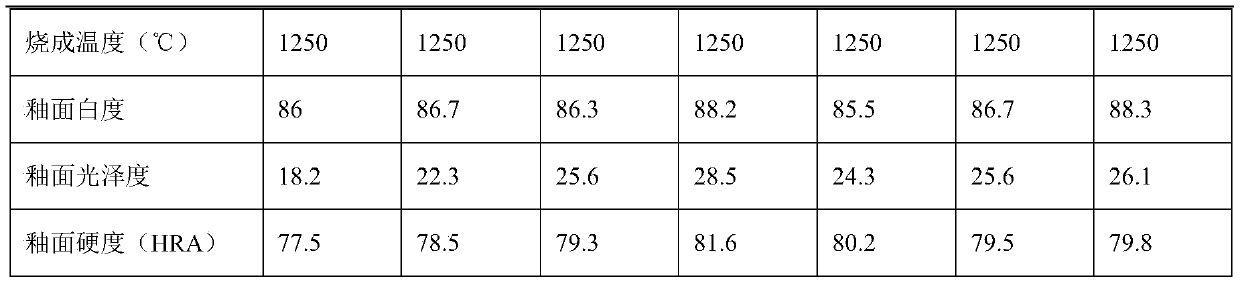

Slip glaze and preparation method of domestic ceramic with the same

The invention discloses a slip glaze and a preparation method of domestic ceramic with the same. The slip glaze comprises the following raw materials by weight: 25-32 parts of red clay, 6-9 parts of red loam, 18-22 parts of feldspar, 20-26 parts of quartz, 2.5-3.5 parts of niobium disilicide, 3-5 parts of nano silicon dioxide, 1.5-2 parts of nano boron nitride, 5-8 parts of nano zinc oxide, 1.7-2.4 parts of nano magnesium oxide and 5-7 parts of calcium hydroxyphosphate. The slip glaze disclosed by the invention is used for domestic ceramics, and is low in cost, high in yield and energy-saving;the wear resistance of the prepared domestic ceramic is far better than that of common slip glaze domestic ceramics, and the wear resistance is good; the glossiness is much higher than that of commonslip glaze domestic ceramics; the thermal shock resistance is obviously superior to that of common slip glaze domestic ceramics, and the thermal shock resistance is good; and the glaze surface is bright, smooth and bright in color.

Owner:德化县嘉祥陶瓷有限公司

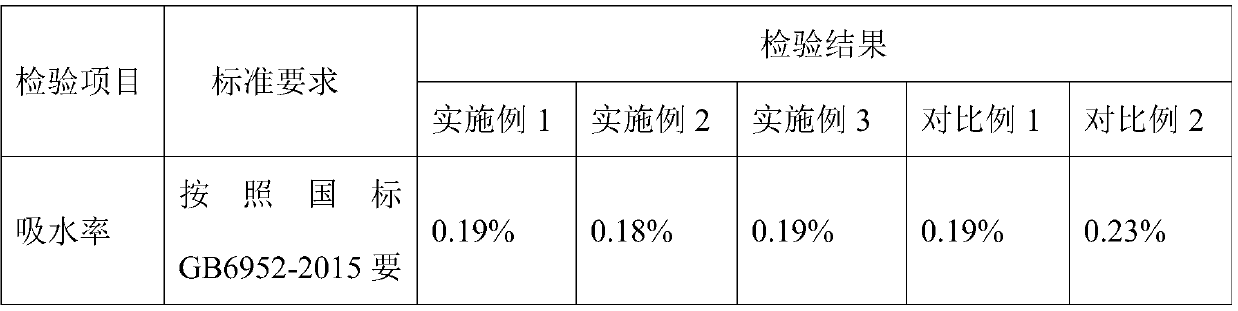

Sanitary ceramic and preparation method thereof

InactiveCN112125644AImprove flexural strengthLow water absorptionCeramic materials productionClaywaresSlip (ceramics)Ball clay

The invention provides a preparation method of sanitary ceramics, which comprises the steps of (1) pulverizing at least five of albite, western pit mud, quartz, black clay, calcined talc, ball clay, zirconium silicate, calcite and potassium feldspar and waste ceramics to the particle size of 1-30[mu]m to obtain a solid raw material, and uniformly dispersing the solid raw material in water to obtain slurry, wherein the waste ceramic accounts for 15%-40% of the weight of the solid raw material; (2) standing and aging the slurry, and carrying out slip casting, demolding and drying to obtain a green body sample; and (3) firing the green body sample at the temperature of 1100-1300 DEG C to obtain the sanitary ceramic. According to the preparation method of the sanitary ceramic, the waste ceramic is used as a raw material for preparing the sanitary ceramic, so that the waste ceramic is recycled, resources are saved, the bending strength of the sanitary ceramic is remarkably improved, the water absorption rate of the sanitary ceramic is reduced, and moisture is avoided.

Owner:清远市简一陶瓷有限公司

Mixed slip-casting ceramics

Mixed slip-casting ceramics includes the following steps: preparing materials and forming. The preparing step includes preparing ceramic clay slurry. The forming step includes placing a prepared ceramic mold on a rotating plate to allow regular or irregular texture to be formed on the ceramic mold under the rotating action of the rotating plate; or directly injecting the ceramic clay slurry into the ceramic mold, and simultaneously shaking a slurry injecting tube or a slurry injecting barrel to allow the texture to be formed on the ceramic mold during slurry injecting; or injecting few single-color ceramic clay slurry into the ceramic mold, and then using ceramic clay slurry with the other color or multiple colors to form patterns and the texture on the surface of the single-color ceramic clay slurry injected previously to allow the ceramic mold to have mixed patterns with different colors as well as the texture. The mixed slip-casting ceramics has the advantages that forming preparation is simple, the texture and the patterns of ceramic products are clear, vivid and bright, the ceramic products are less prone to fading, and the like.

Owner:涂瑞漫

Preparation method of fiber-reinforced sanitary ceramic green body

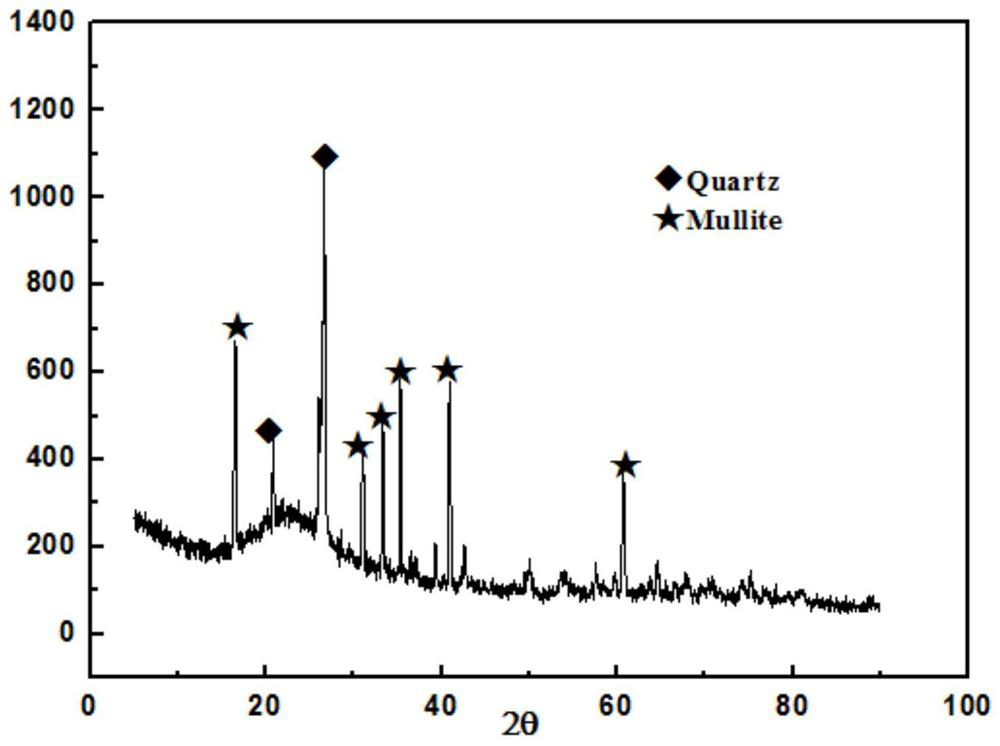

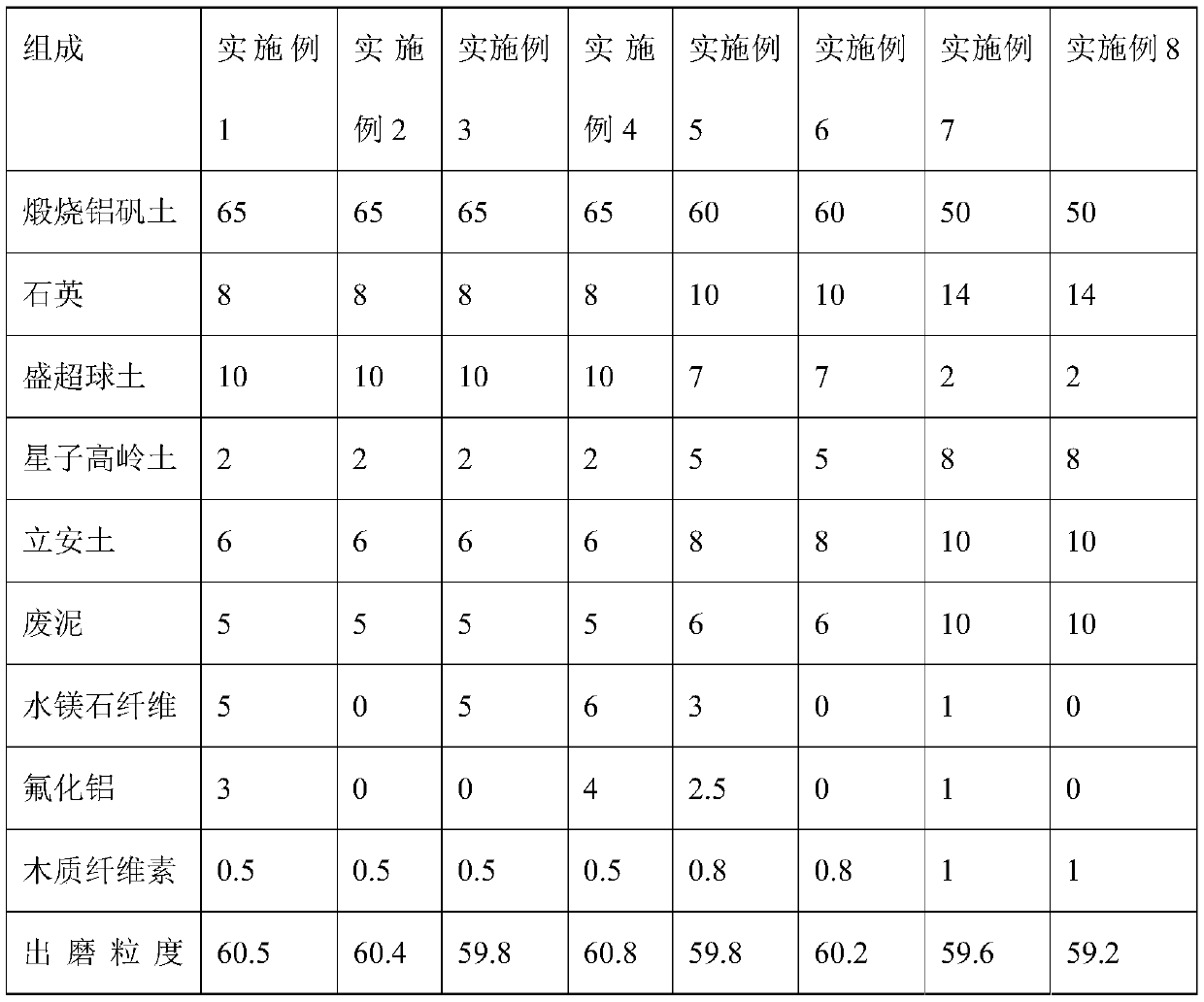

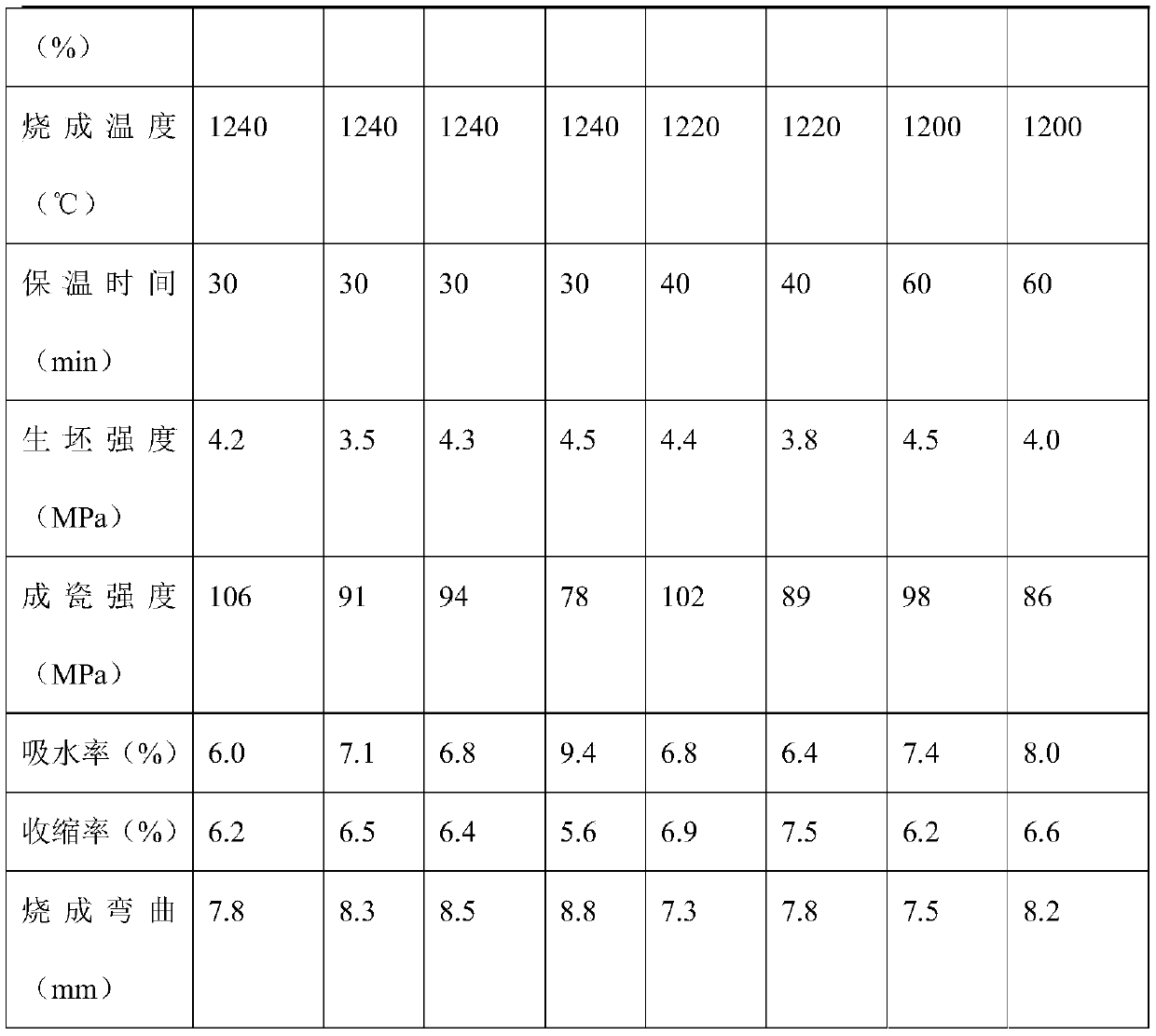

The invention discloses a preparation method of a fiber-reinforced sanitary ceramic green body. The preparation method comprises the following steps: 1) preparing a green body: a, preparing the greenbody from the following components in percentage by mass: 50-70% of calcined bauxite, 8-16% of quartz, 2-10% of ball clay, 2-7% of kaolin, 6-14% of washed porcelain clay, 5-15% of waste mud, 1-5% of brucite fiber and 1-3% of aluminum fluoride; putting the weighed raw materials into a horizontal ball mill, then adding a proper amount of sodium carbonate and water, carrying out wet milling and mixing until the ratio of product with the diameter less than 10<mu>m accounts for 52-56%, then adding 0.5-1% of lignocellulose, continuing ball milling until the ratio of product with the diameter less than 10<mu>m accounts for 58-61%, discharging an obtained slurry; removing iron, sieving, refining and aging to prepare the slurry for later use; b, performing slip casting on the slurry in a gypsum model, and naturally air-drying or drying in an environment of 55 DEG C until the water content is below 5% after grouting, consolidation and demolding to obtain a sanitary ceramic green body; and 2) sintering. The water absorption rate of the sanitary ceramic green body provided by the invention is 6-8% and is lower than that of most ultrathin sanitary ceramics in the industry.

Owner:JOMOO KITCHEN & BATHROOM

Wear-resistant color-assisting frit for wear-resistant glaze, super wear-resistant glaze and ceramic tile preparation method

PendingCN114573233AImprove thermal stabilityGood chemical resistanceCeramic materials productionSlip (ceramics)Glaze

The invention relates to the technical field of architectural ceramics, and discloses a wear-resistant color-assisting frit for wear-resistant glaze, super wear-resistant glaze and a ceramic tile preparation method. The wear-resistant color-assisting frit comprises the following raw materials: potassium feldspar, albite, quartz powder, calcined kaolin, alumina powder, calcite, calcined talc, zinc oxide, barium carbonate, strontium carbonate, calcium fluoride and boric acid. The raw materials of the super wear-resistant glaze comprise raw glaze and wear-resistant color-assisting frits. According to the wear-resistant color-assisting frit for the wear-resistant glaze, the glaze layer transparency and the color development effect of the wear-resistant glaze can be improved, so that the wear-resistant glaze can be applied in a relatively large thickness; according to the super wear-resistant glaze and the preparation method thereof, the silica-alumina ratio of the glaze is controlled within the range of 4-6, so that the glaze surface has certain gloss, and the texture of the glaze surface and the antifouling effect after polishing are ensured; the performance of the glaze slip is adjusted by glue, so that the glaze slip is conveniently applied in a bell-jar glaze spraying manner; according to the preparation method of the brick, the ultra-wear-resistant glaze is applied in a bell jar glaze spraying mode, the glaze surface after firing is good in light transmission and color development effect, and very high wear resistance is achieved.

Owner:佛山市禅城区科捷陶瓷原料有限公司

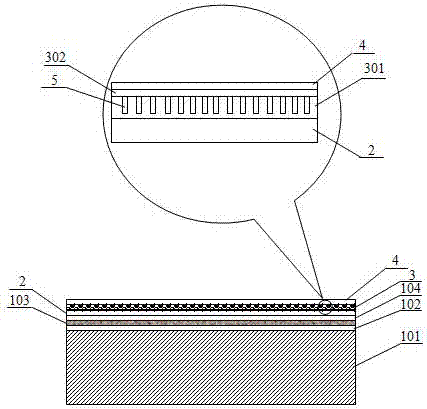

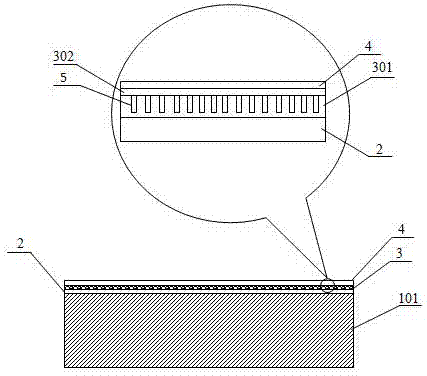

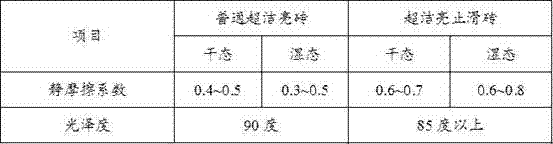

Super-clean-light slip-stopping brick and manufacturing method thereof

PendingCN107476528AHigh glossGood effectCovering/liningsSynthetic resin layered productsStatic friction coefficientBrick

The invention belongs to the technical field of architectural ceramics and particularly relates to a super-clean-light slip-stopping brick and a manufacturing method thereof. The super-clean-light slip-stopping brick sequentially comprises a base layer, a super-clean-light layer, a nanoscale slip-stopping layer and an antifouling layer from top to bottom. The manufacturing method of the super-clean-light slip-stopping brick is suitable for a super-clean-light slip-stopping polishing brick and a super-clean-light slip-stopping glazing brick. According to the super-clean-light slip-stopping brick manufactured through the manufacturing method, the glossiness can reach 85 degrees or above, the static friction coefficient can reach 0.6 or above under the dry or wet state, the effect is better in the wet state, the super-clean-light and slip-stopping functions are both achieved, the antifouling grade is equal to that of an ordinary super-clean-light brick, and the super-clean-light slip-stopping brick and the manufacturing method thereof can be widely applied to various public places; falling accidents caused in the damp state are greatly reduced, and the safety factor of the daily life of people is increased; and meanwhile the appearance characteristics of high glossiness, lightness and attractiveness are achieved, and using and popularization in the more upscale public places are facilitated.

Owner:海鸥冠军有限公司

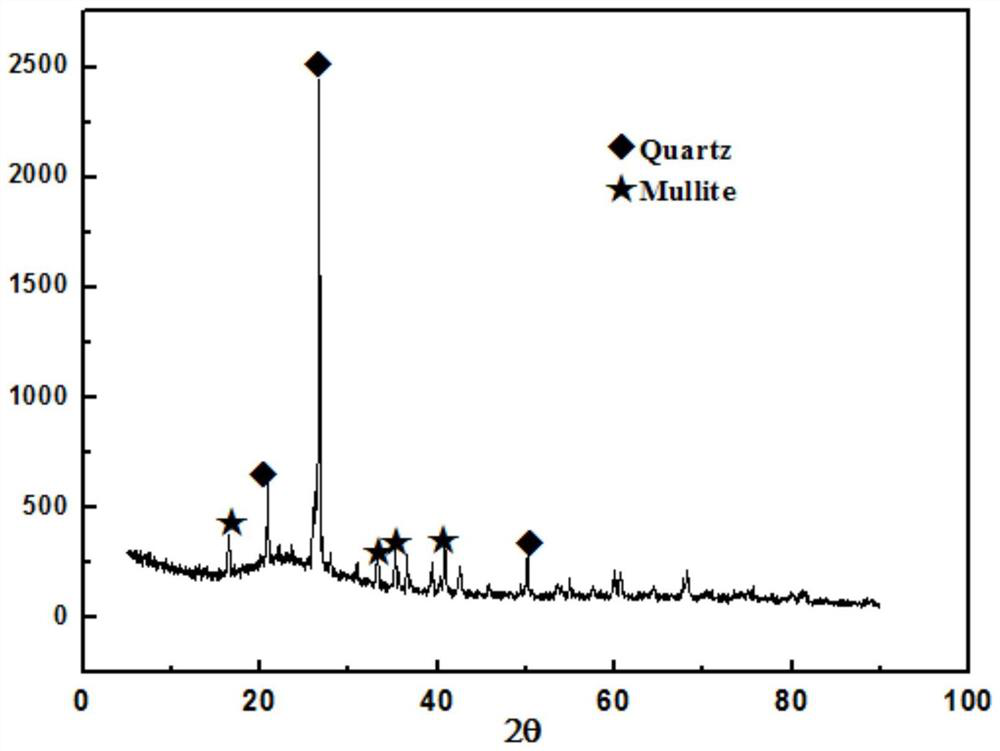

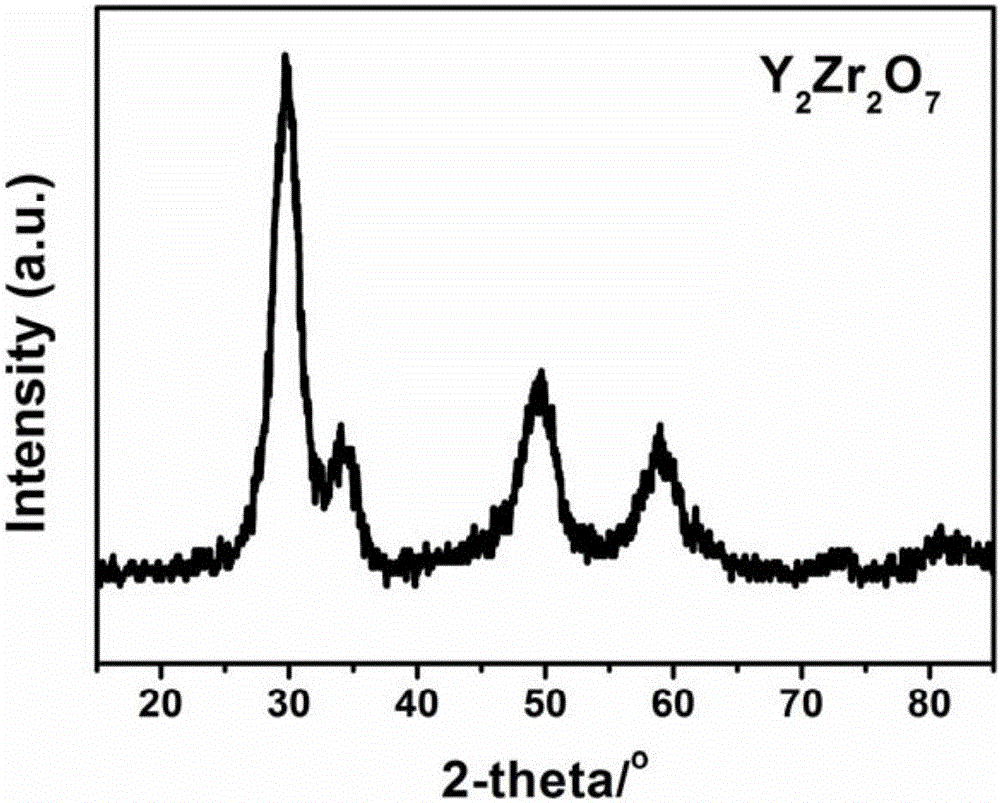

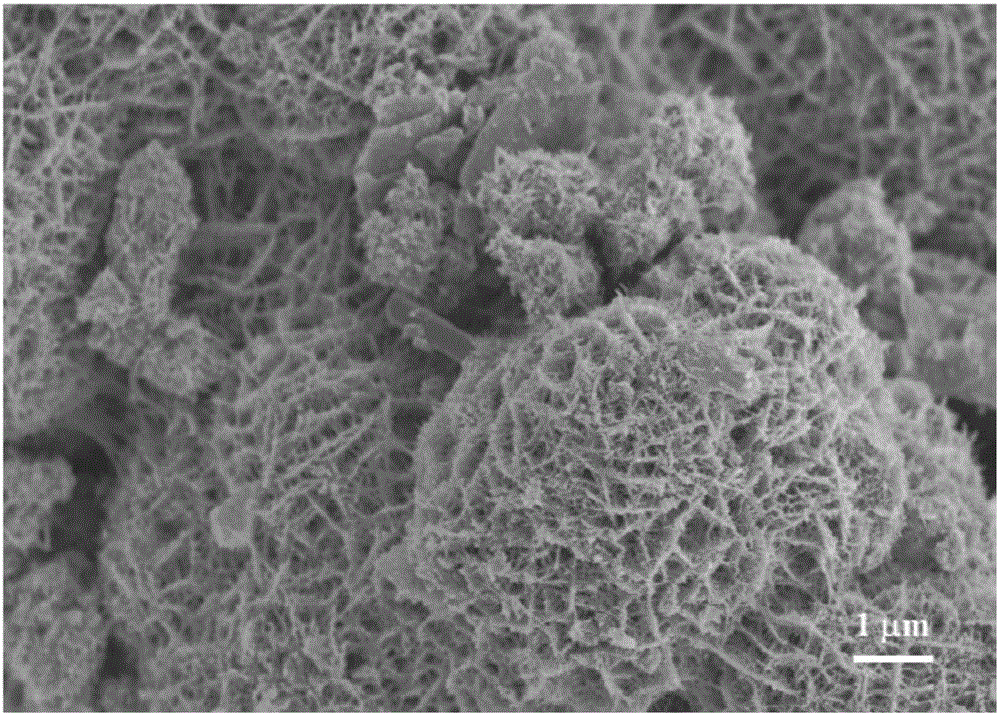

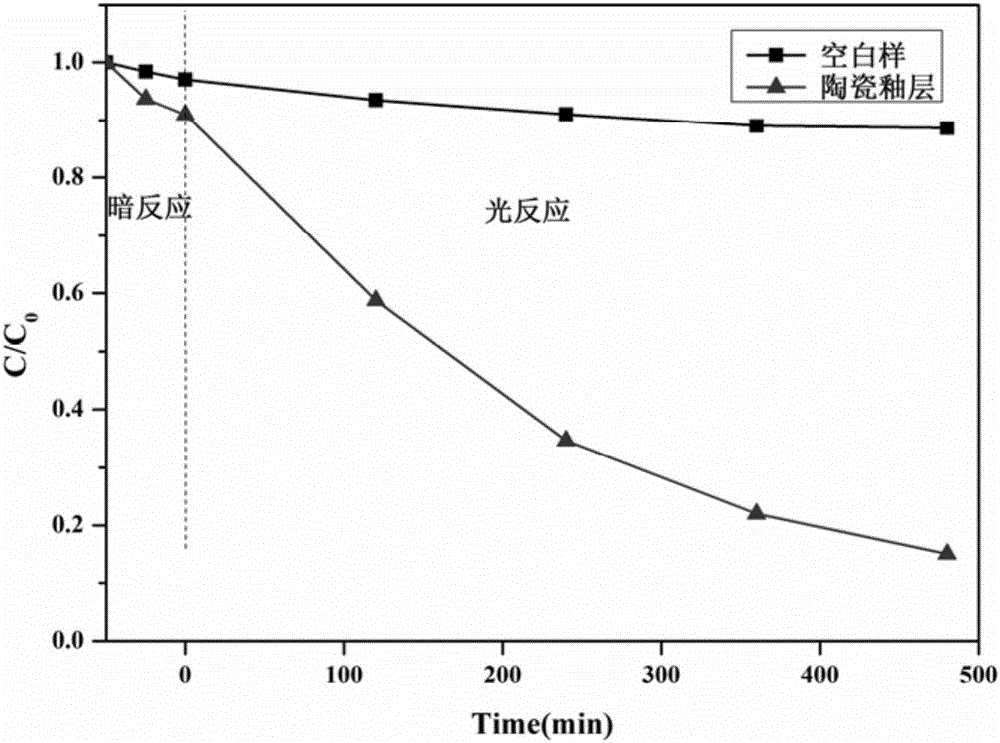

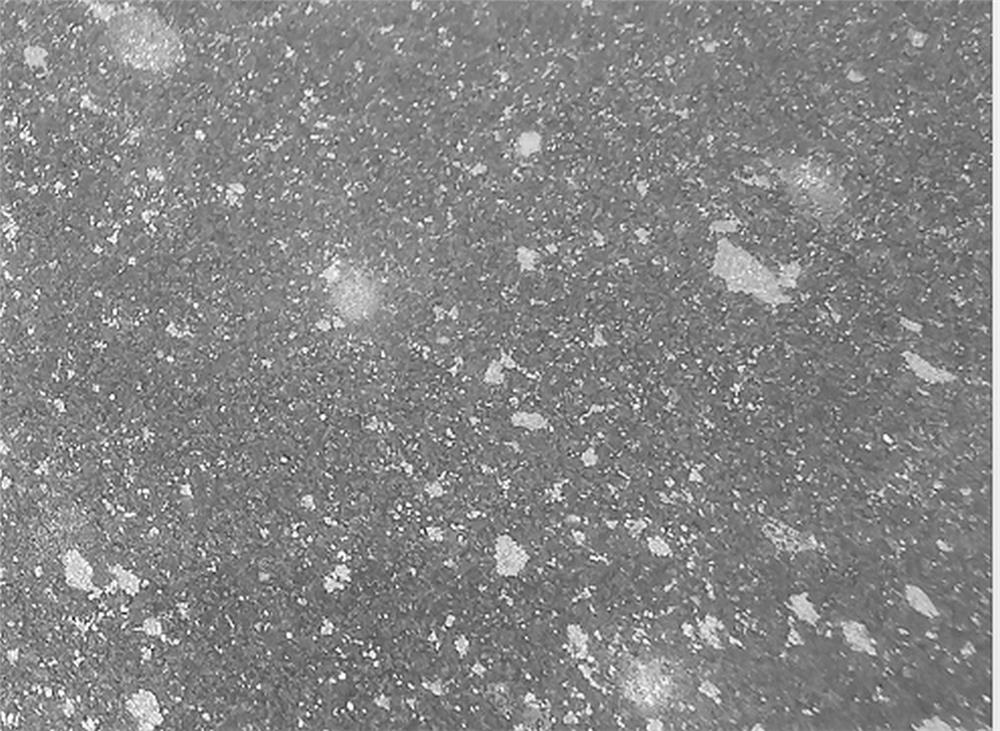

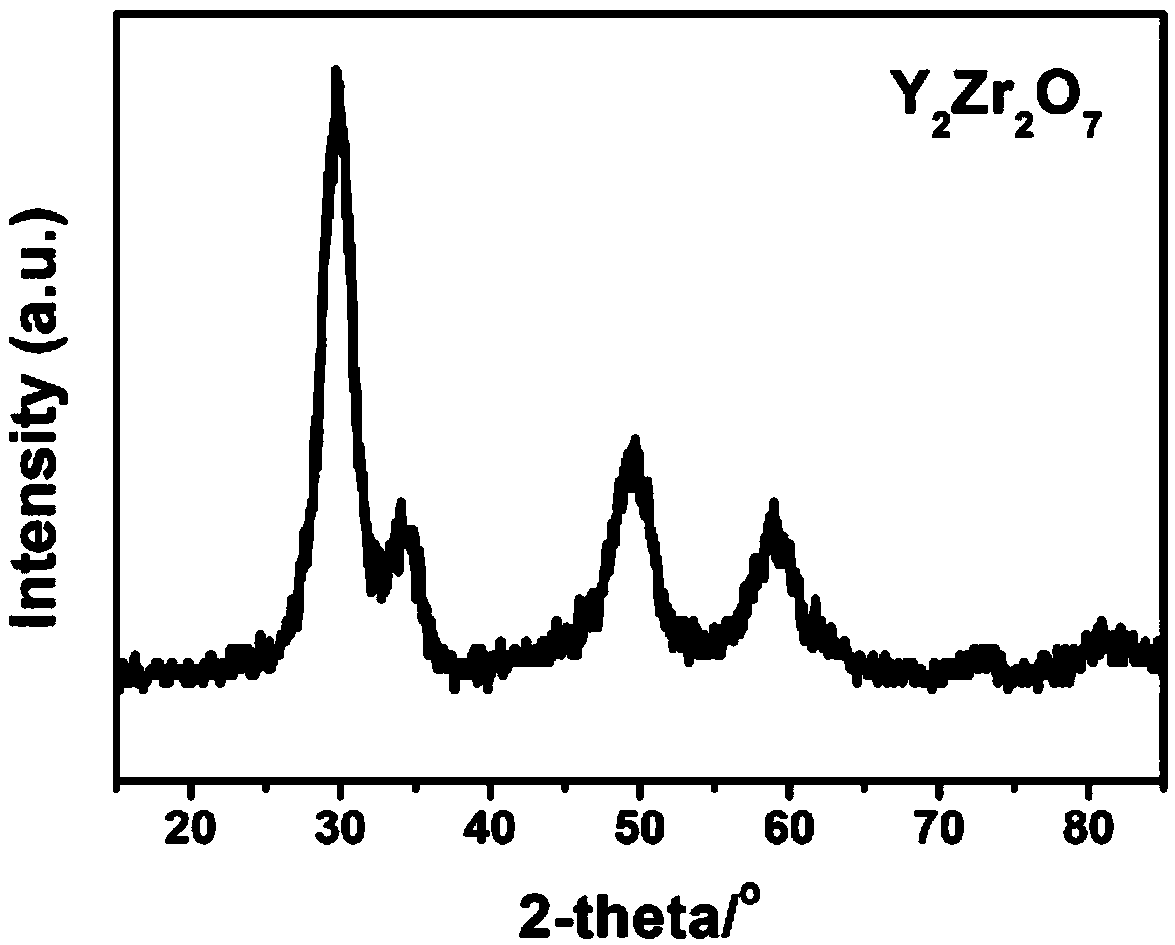

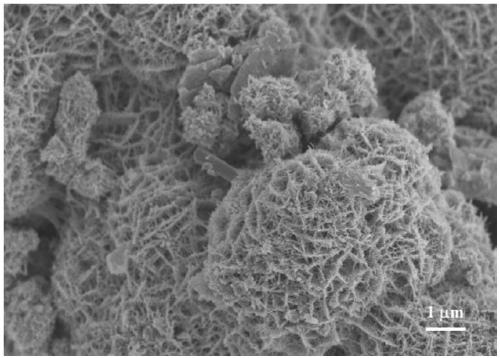

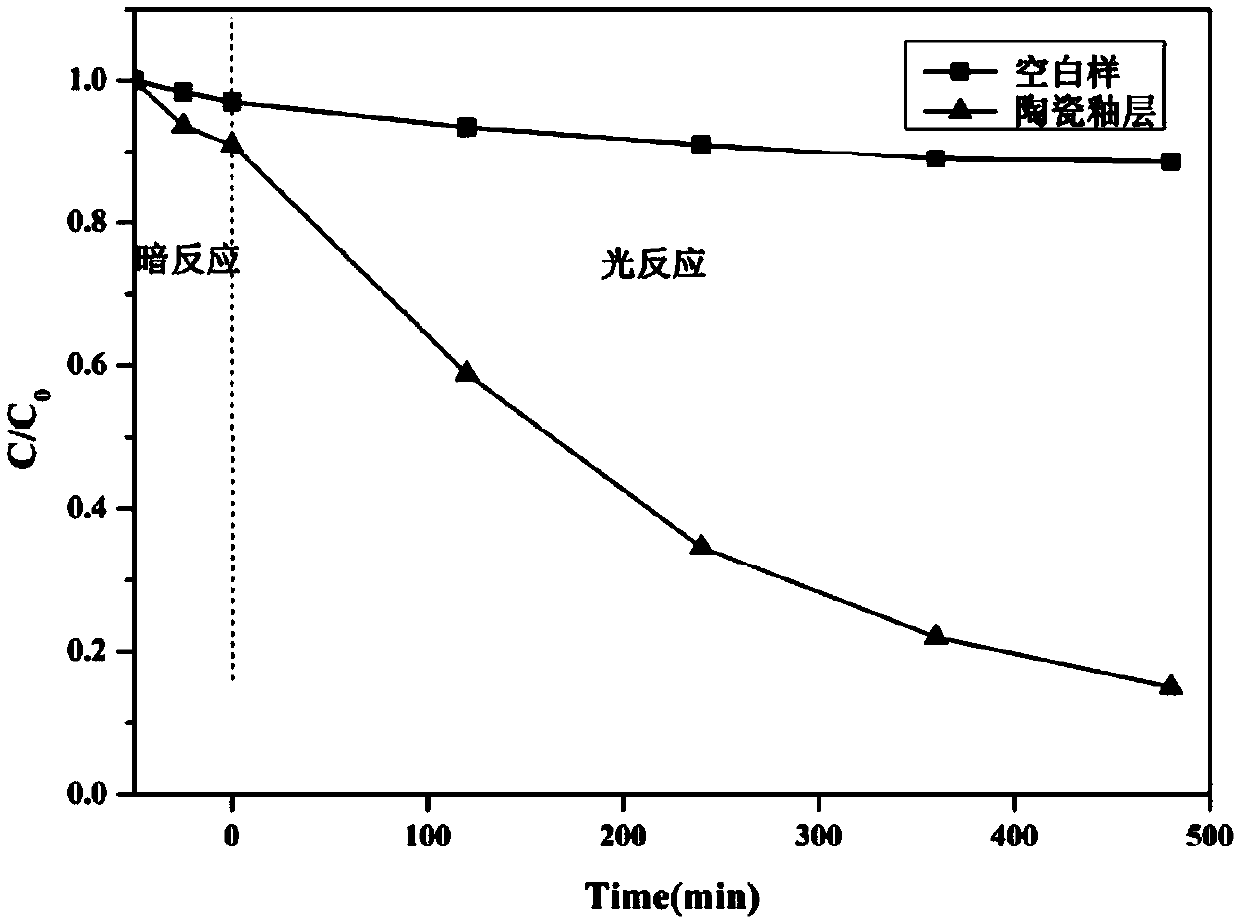

Preparation method of yttrium zirconate microcrystal ceramic glaze having photocatalytic function

The invention relates to a preparation method of a yttrium zirconate microcrystal ceramic glaze having a photocatalytic function. The preparation method comprises the following steps: preparing quartz, potash feldspar, albite, borax, Y2O3, Suzhou clay and lithium carbonate, keeping the above raw materialsat 1270-1290 DEG C for 20-40 minutes, taking out, pouring into water, quenching to prepare a fusion cake, and grinding the fusion cake to obtain a material A; preparing the material A, Y2O3, ZrO2 and Suzhou clay to obtain a material B; adding the material B and dispersing agent into water, and uniformly stirring and mixing to prepare a glaze slip; and applying the glaze slip to the surface of ceramics, and firing to obtain the yttrium zirconate microcrystal ceramic glaze having a photocatalytic function. According to the invention, the ceramic glaze is prepared through a firing process and does not need coating, so that the prepared functional ceramic glaze material can be tightly combined with a ceramic matrix; and the photocatalyst Y2Zr2O7 generated in the sintering process of Y2O3 and ZrO2 is uniformly distributed in the glaze material, thereby avoiding the condition that the aesthetic property of the glaze material is influenced due to a rainbow effect.

Owner:SHAANXI UNIV OF SCI & TECH

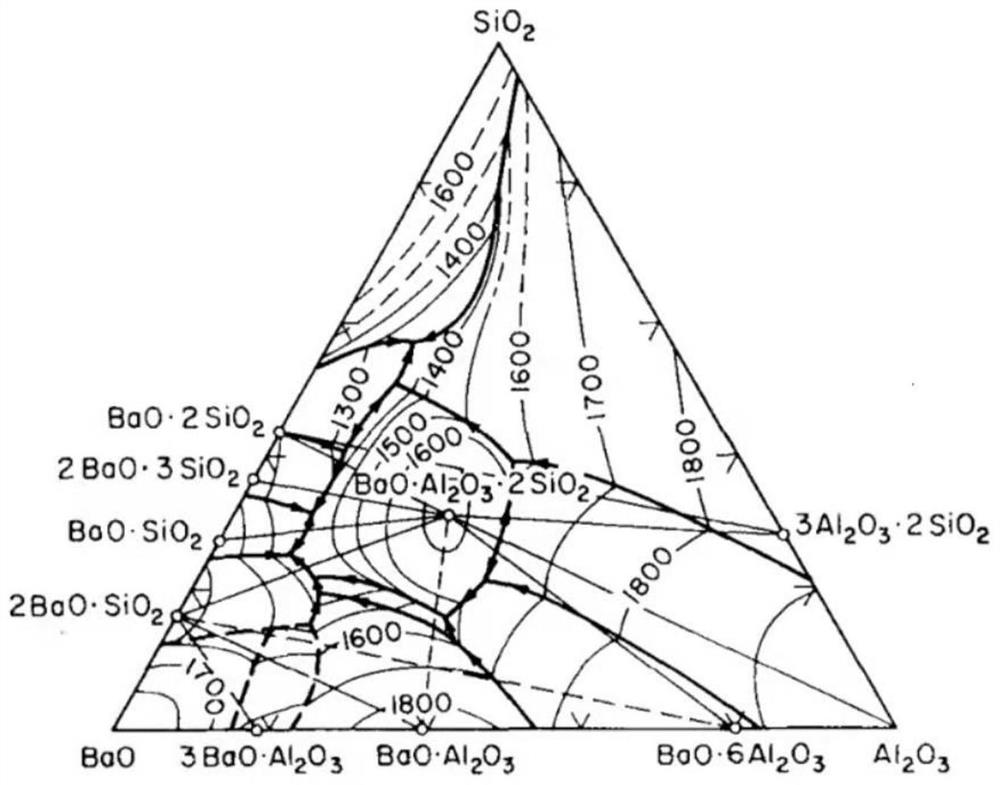

Gold foil effect particle for ceramic, ceramic, preparation method of ceramic and glaze

The invention belongs to the field of ceramics, and discloses gold foil effect particles for ceramic, the ceramic, a preparation method of the ceramic and a glaze. The chemical composition of the sintered gold foil effect particles comprises silicon dioxide, aluminum oxide, barium oxide, sodium oxide, potassium oxide, magnesium oxide, zinc oxide, strontium oxide, chromium sesquioxide, titanium dioxide, copper oxide or iron oxide. According to the gold foil effect particles in some examples, the reflectivity can reach 186%, and the gold foil effect particles have good metal luster and metal texture and highlight the atmosphere style of ceramic tiles; good acid and alkali resistance is achieved, the acid and alkali resistance reaches the GA level or above, and metallic luster is not lost after long-term use; and the compatibility with the existing dry granules and glaze slip is good, and various decorative effects can be obtained by being matched with various dry granules and glaze slip for use and compounding.

Owner:FOSHAN DOWSTONG TECH +1

Process for manufacturing high density slip-cast fused silica bodies

ActiveUS8795581B2Simple and cost-effectiveGlass shaping apparatusCeramic shaping apparatusVolumetric Mass DensitySlurry

Fused silica ceramics plays demanding role in high velocity missile / aircraft'radome development. Slip casting is the most common and commercially viable process utilized for radome production. Unfortunately slip casting cannot afford high density due to its poor green packing density which in turn results in poor rain erosion resistance. Present invention discloses process for preparing high density fused silica bodies by adding boron oxide (B2O3) with the commercially available high purity fused silica as sintering aid cum de-vitrification inhibitor. Various concentrations of B2O3 were added to high purity fused silica. Thus formed compositions were made into slip-castable slurries in aqueous medium without any addition of dispersing agents. The reheological properties like mild shear thinning and low thixotropic behaviour of the slurries were established. These slurries were then slip-casted in plaster of parries mold. The green and sintered properties of the casted samples were studied. The sintered sample with density higher than 2 g / cc (90-95% of the theoretical density) was achieved without de-vitrification. XRD studies on sintered samples showed the amorphous nature of the sample. The improved properties of fused silica system can favor its utilization in radome applications.

Owner:COUNCIL OF SCI & IND RES

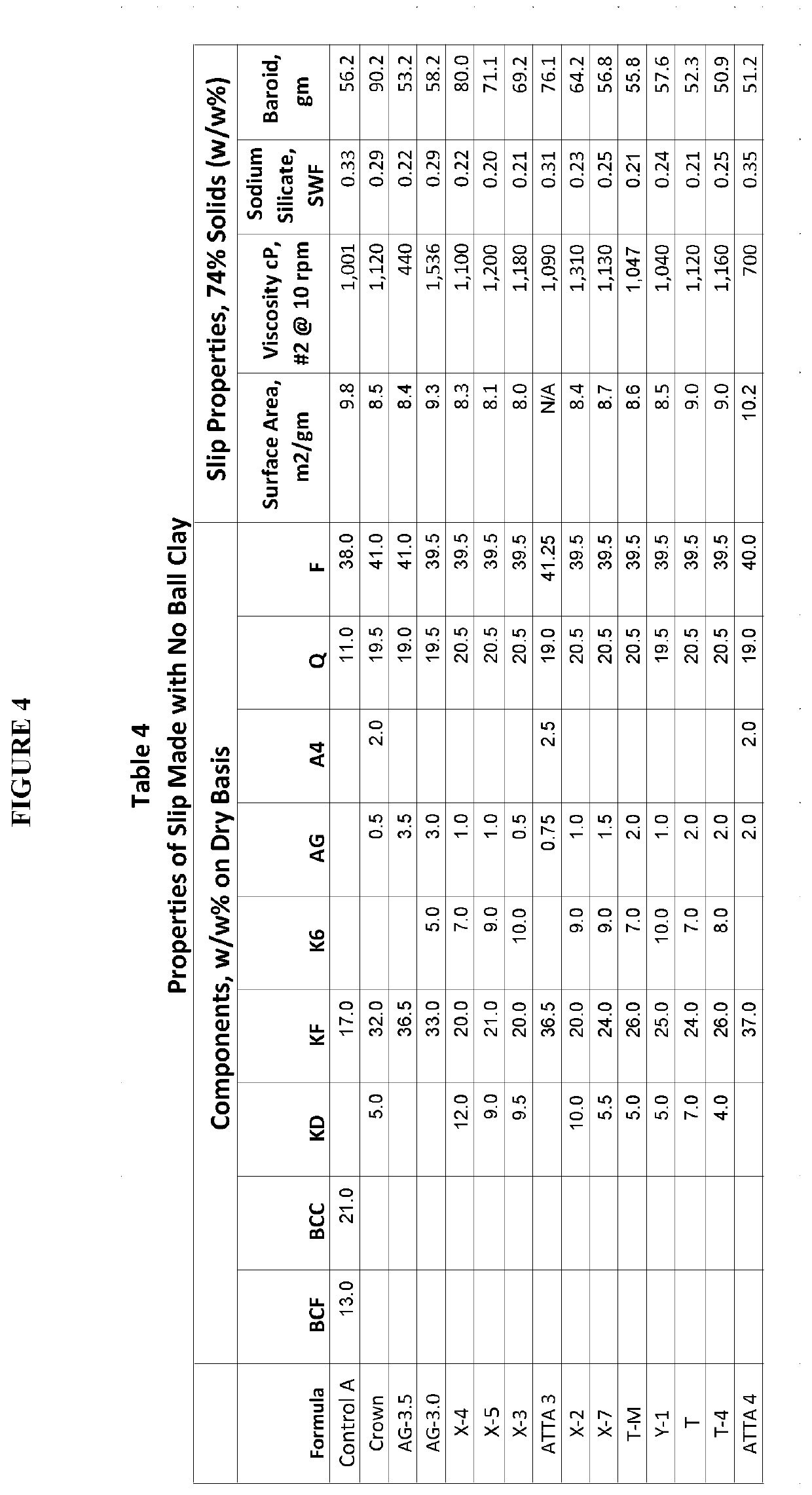

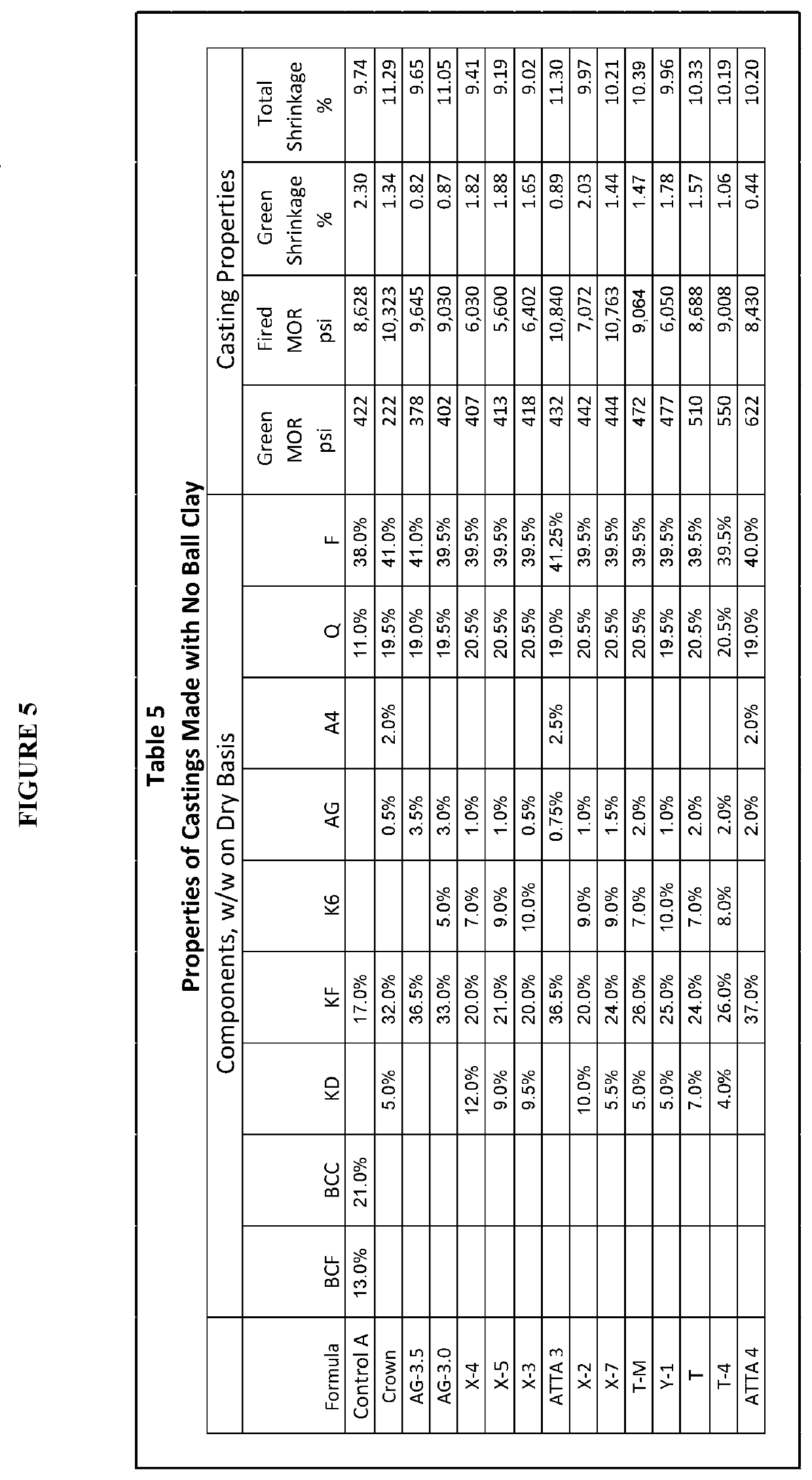

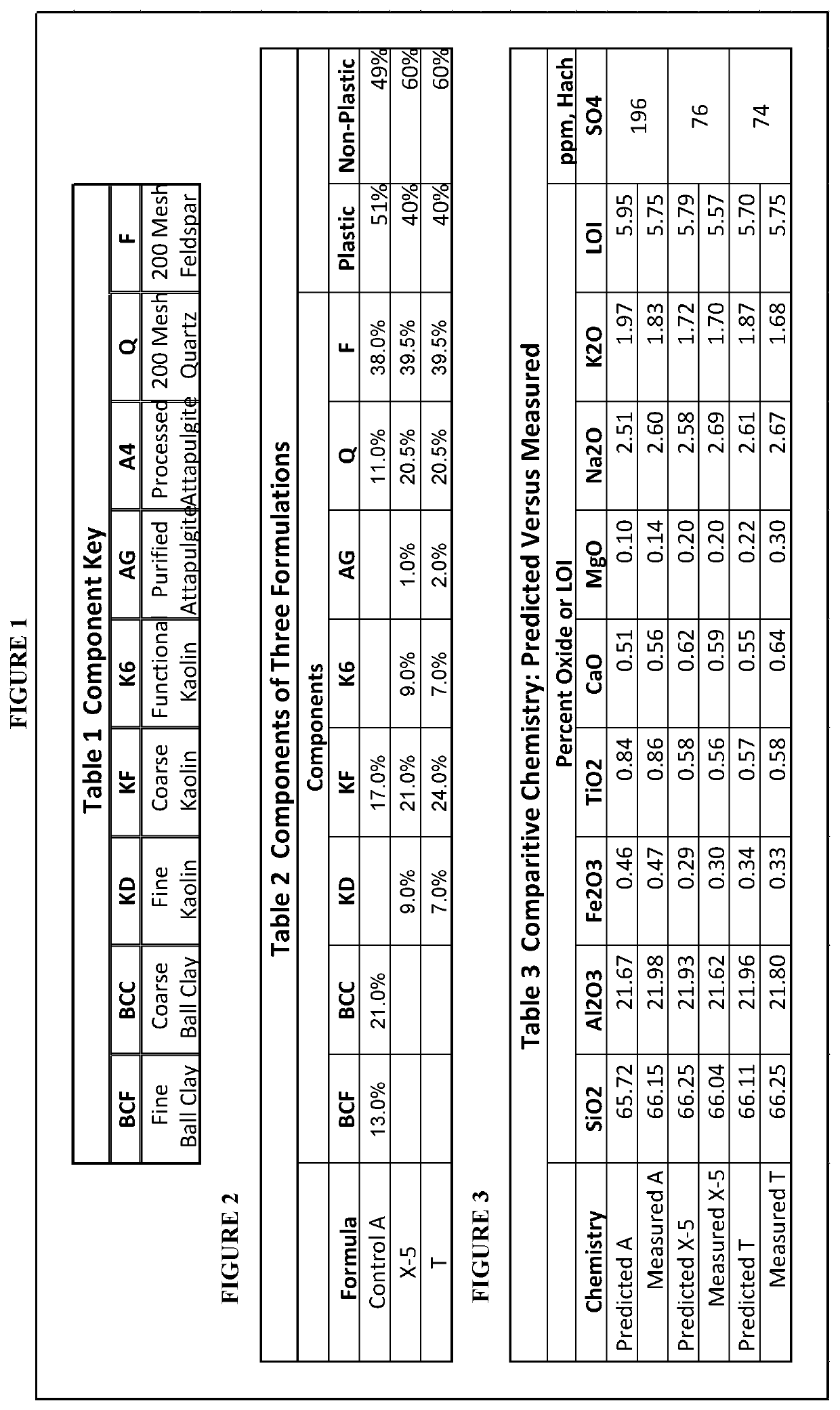

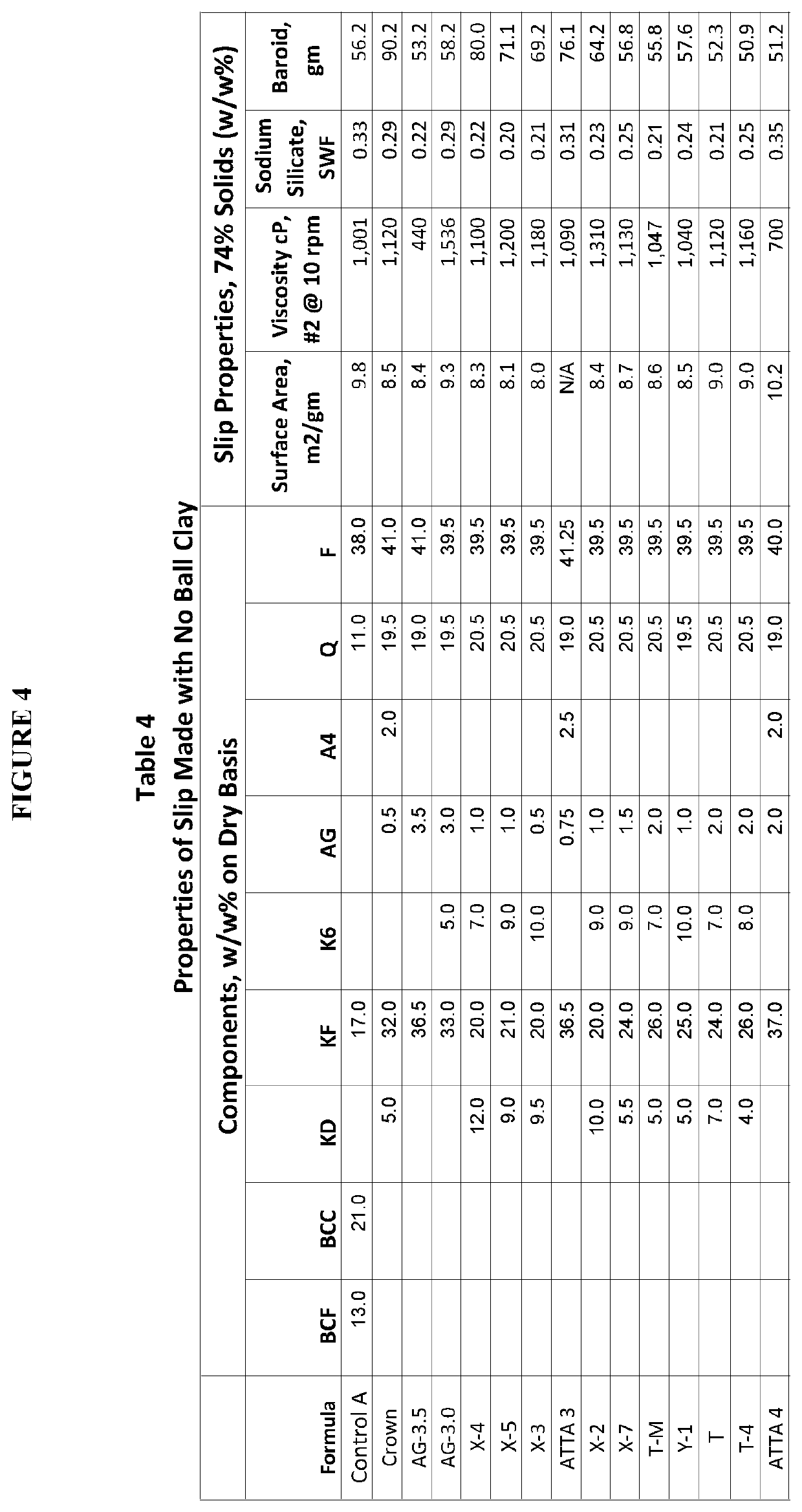

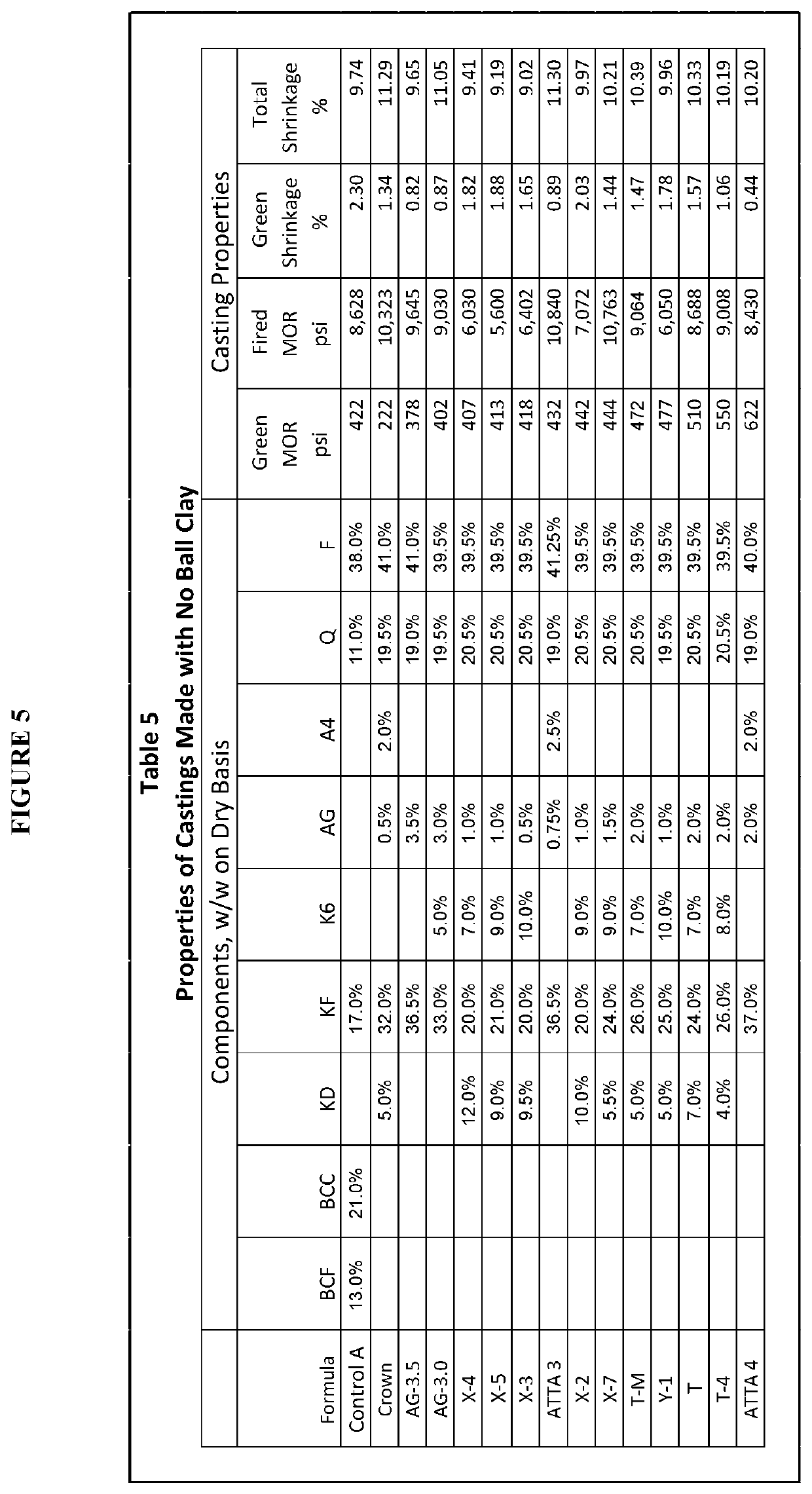

Composition to completely or partially replace ball clay in ceramics, method of making, and use thereof

A composition comprises at least one form of attapulgite present in a solid weight fraction amount ranging from 0.25% to 5%; kaolin present in a solid weight fraction amount ranging from 17% to 50%; and optionally Ball Clay in a solid weight fraction amount ranging from 0% to 25%. Although makeable by other processes, in some embodiments, the composition is makeable by mixing component ingredients. Although usable for other purposes, in some embodiments, the composition is used to make ceramic pieces, e.g., via casting, pressing, jiggering or jollying, especially when the slip has solids, chemistry and viscosity suitable for shaping before drying, sintering, and optionally finishing.

Owner:ACTIVE MINERALS INT

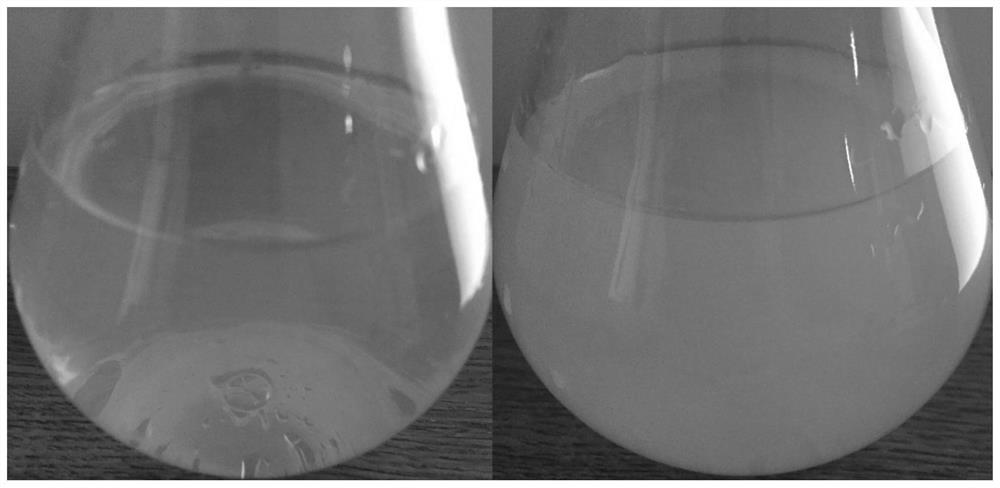

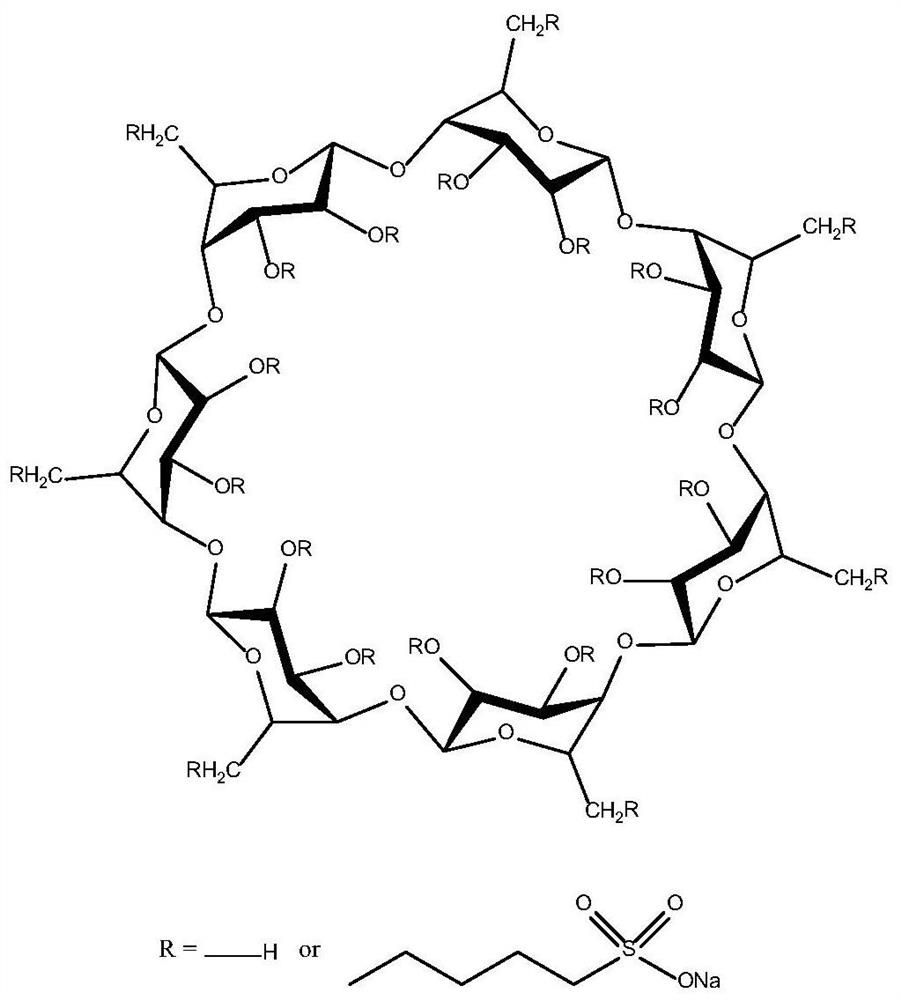

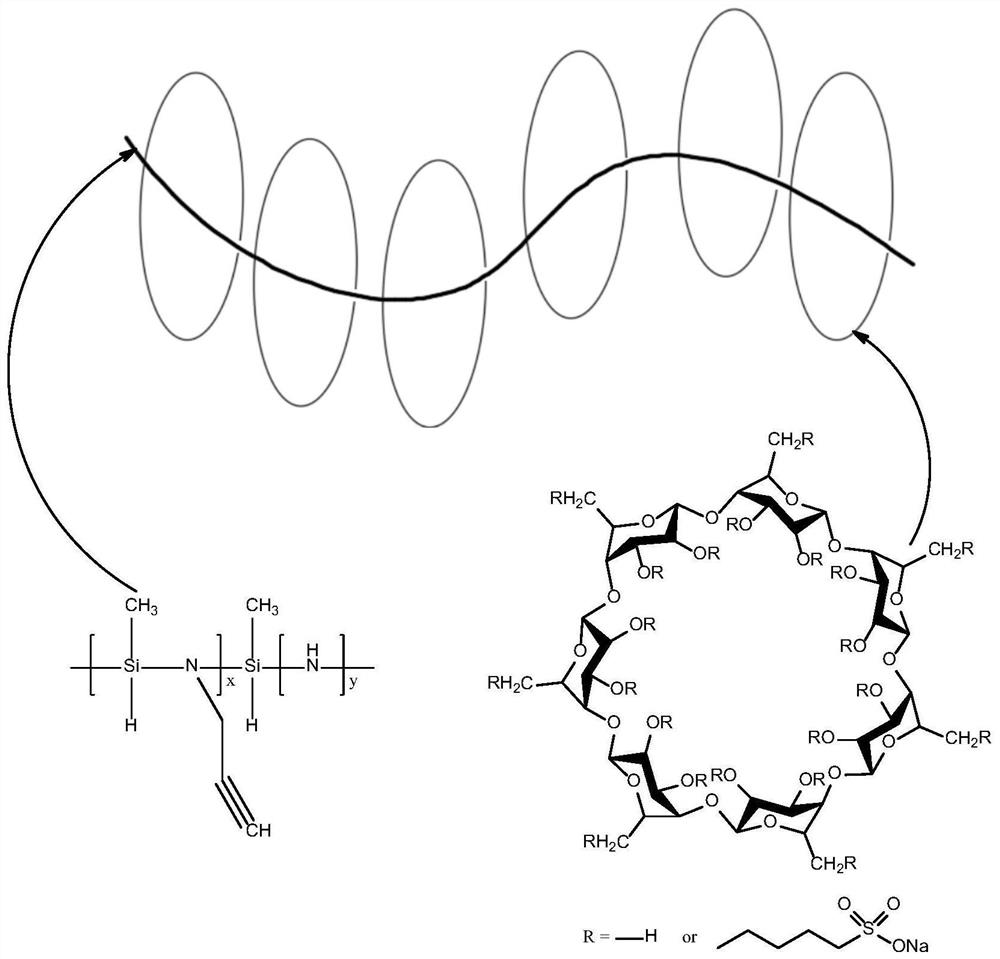

Organic ceramic precursor and ceramic product

ActiveCN111704467AImprove electrochemical performanceImprove mechanical propertiesCarbon compoundsCeramic materials productionAntimicrobial actionDoped graphene

The invention relates to the technical field of ceramics and specifically provides an organic ceramic precursor and a ceramic material based on the organic ceramic precursor. According to the organicceramic precursor, propargyl polysilazane and sulfobutyl ether-beta-cyclodextrin coexist in a system; wherein the organic ceramic precursor is stable in property and high in ceramic conversion rate, the three-dimensional sulfur-nitrogen doped graphene hydrogel is added into the organic ceramic precursor, and the light and porous ceramic material is obtained through dipping and calcining. The ceramic material has excellent mechanical strength, conductivity, heat insulation effect and sound insulation effect. The invention also provides a ceramic product with concave-convex textures, which is prepared through the following steps: printing glaze slip containing polyborosilazane / aluminum oxide composite particles and an Arabic gum loaded antibacterial agent on the surface of the ground coat ofa biscuit, and finally obtaining the ceramic product through other processes. The ceramic product has certain mechanical strength and attractive and diverse concave textures, and can also play a lasting and efficient antibacterial role at the same time.

Owner:深圳市科思飞科技有限公司

Ceramic glaze spraying device with dust collecting function

PendingCN114261008AImplement collection processingSmall sizeAuxillary shaping apparatusSlip (ceramics)Spray nozzle

The invention belongs to the field of ceramic glaze spraying, and particularly relates to a ceramic glaze spraying device with a dust collection function, which comprises an upper partition plate, a lower partition plate and an annular side plate rotationally arranged between the upper partition plate and the lower partition plate, and further comprises a power part for driving the annular side plate to rotate, the upper partition plate is provided with a glaze spraying assembly, the lower partition plate is provided with a mounting opening used for mounting ceramics, the glaze spraying assembly comprises a spray head and an annular driving part used for driving the spray head to rotate around the mounting opening, and the exhaust channel always corresponds to the spray head in direction. The exhaust channel corresponding to the direction of the glaze spraying nozzle is arranged on the annular side plate in an extending mode, dust collection treatment in the glaze spraying process is achieved, the exhaust channel always corresponds to the direction of the nozzle, it is guaranteed that the flow direction of sprayed atomized glaze slip in the glaze spraying process is accurate, and glaze spraying is more uniform.

Owner:HUNAN HUALIAN CHINA IND

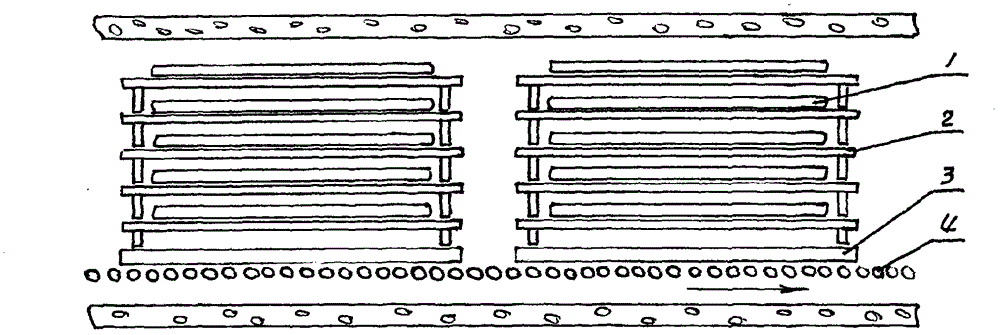

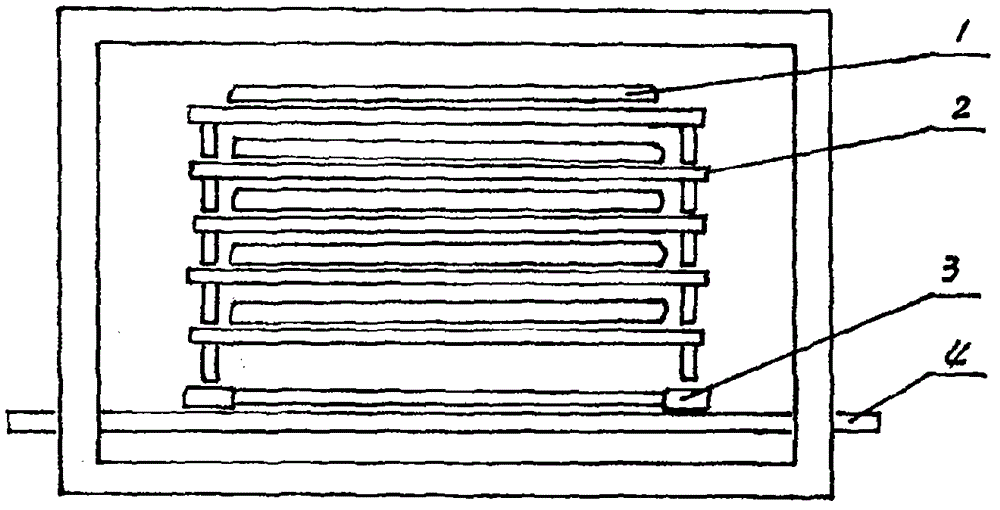

Drying method for hollow ceramic solar panel matrix biscuits formed by slip casting

ActiveCN102564091BSave operating spaceImprove transportation efficiencyDrying gas arrangementsDrying machines with progressive movementsComposite ceramicSlip (ceramics)

Grouting molding hollow ceramic solar panel substrate green body drying equipment belongs to the ceramic green body drying equipment, which uses rotating steel rollers as the operating power, and the rotating steel rollers form the roller table, and ordinary ceramic slurry is grouted in the plaster mold to form hollow ceramics. The solar panel base blanks are placed on pallets and placed in a stack one by one. The stacks of pallets with wet hollow ceramic solar panel substrate blanks pass through the channel equipped with roller tables. The temperature and humidity in each section of the channel can be adjusted. The controlled airflow heats and dries the blank of the hollow ceramic solar panel substrate, which greatly improves the drying efficiency compared with the traditional drying room. The surface of the dried hollow ceramic solar panel substrate blank is sprayed with black porcelain slurry, and after firing, the surface is black. The ceramic layer is a black porcelain composite ceramic solar panel whose substrate is a hollow ceramic plate.

Owner:曹树梁

A kind of high temperature resistant solar energy collector ceramic material and preparation method thereof

ActiveCN110128147BIncrease temperatureGood high temperature oxidation resistanceSlip (ceramics)Materials science

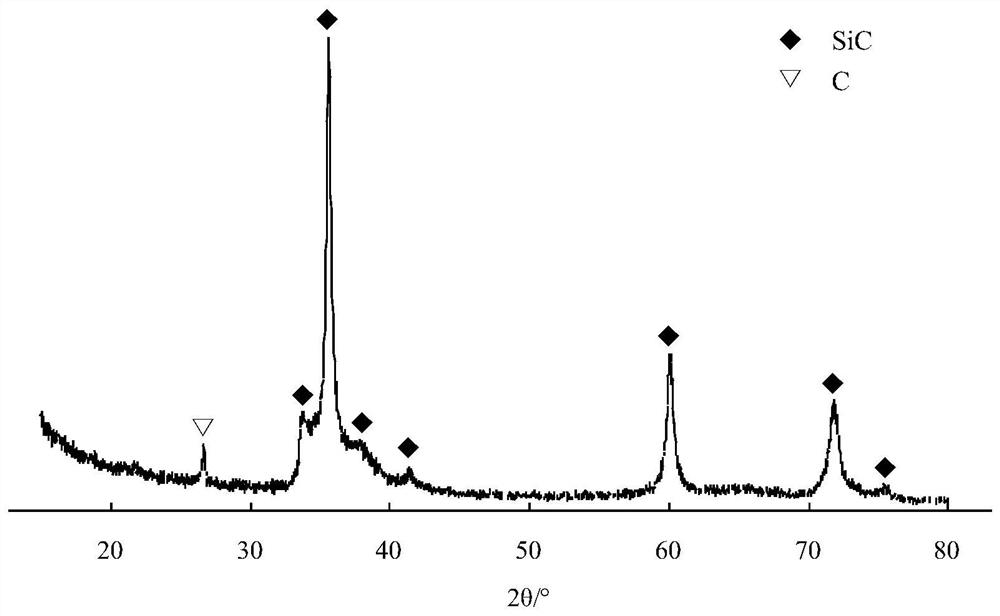

The invention relates to a high-temperature-resistant solar heat-collecting ceramic material and a preparation method thereof, which is composed of components containing the following weight percentages: SiC 35-55%, HfB 2 25‑45%, Al 2 o 3 -Y 2 o 3 ‑MgO composite sintering aid 10‑18%, B 4 C 1‑3%, carbon black 3‑8%, high temperature resistant SiC / HfB prepared by slip casting and pressureless sintering process 2 Solar collector ceramics. The use temperature of the high-temperature-resistant solar heat-collecting ceramics of the present invention is as high as above 1500° C., which can solve the problem of serious attenuation of high-temperature mechanical properties of the current solar heat-collecting ceramics. Moreover, the preparation method has simple process and high production efficiency.

Owner:SHANDONG UNIV OF TECH

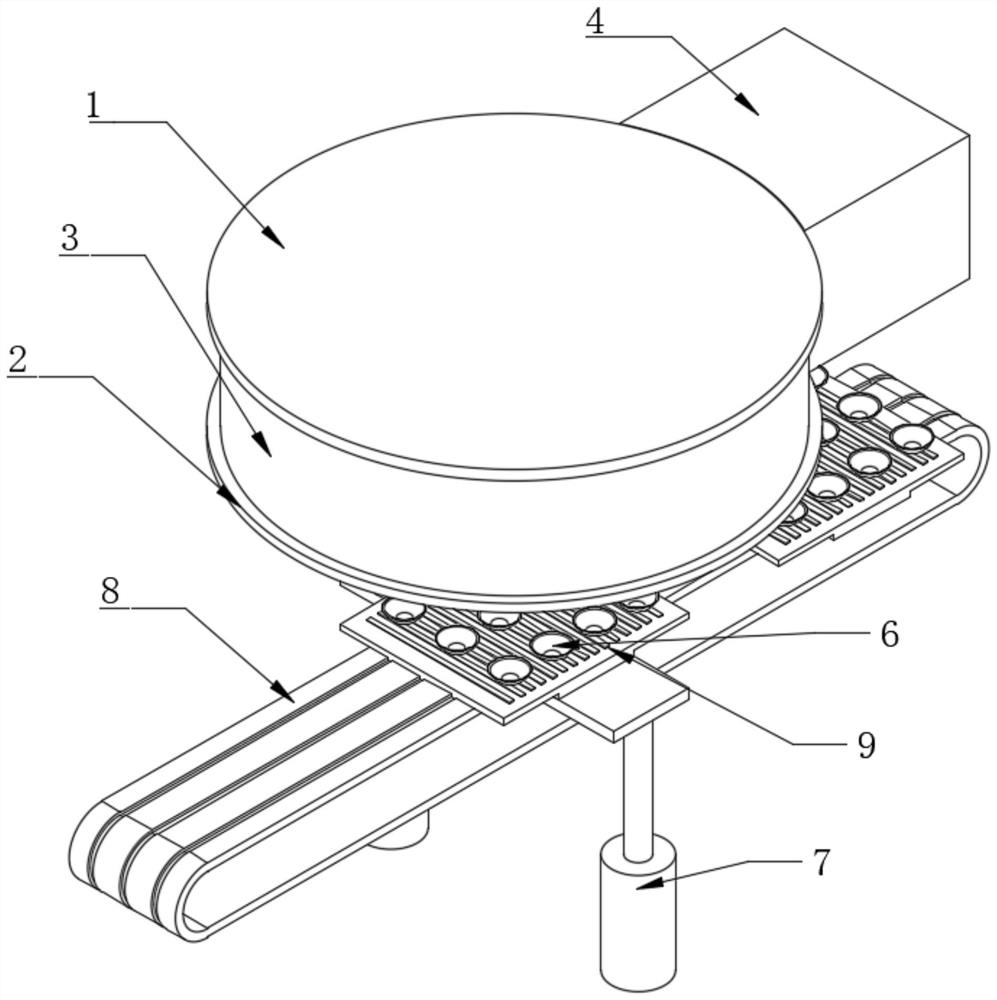

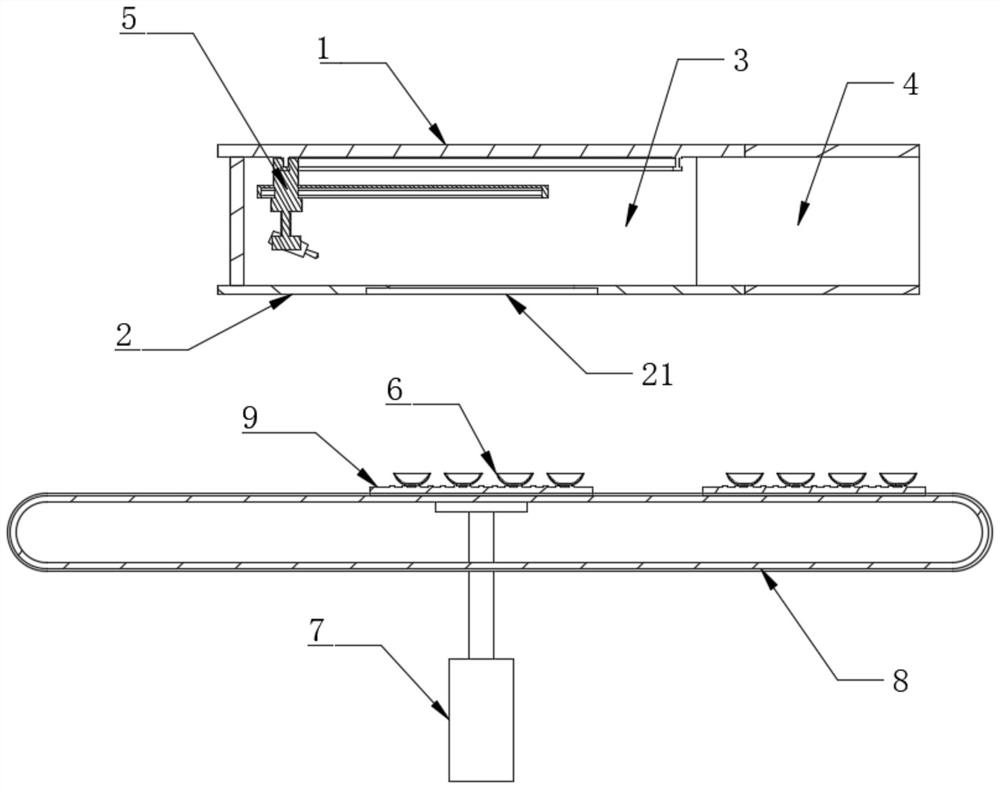

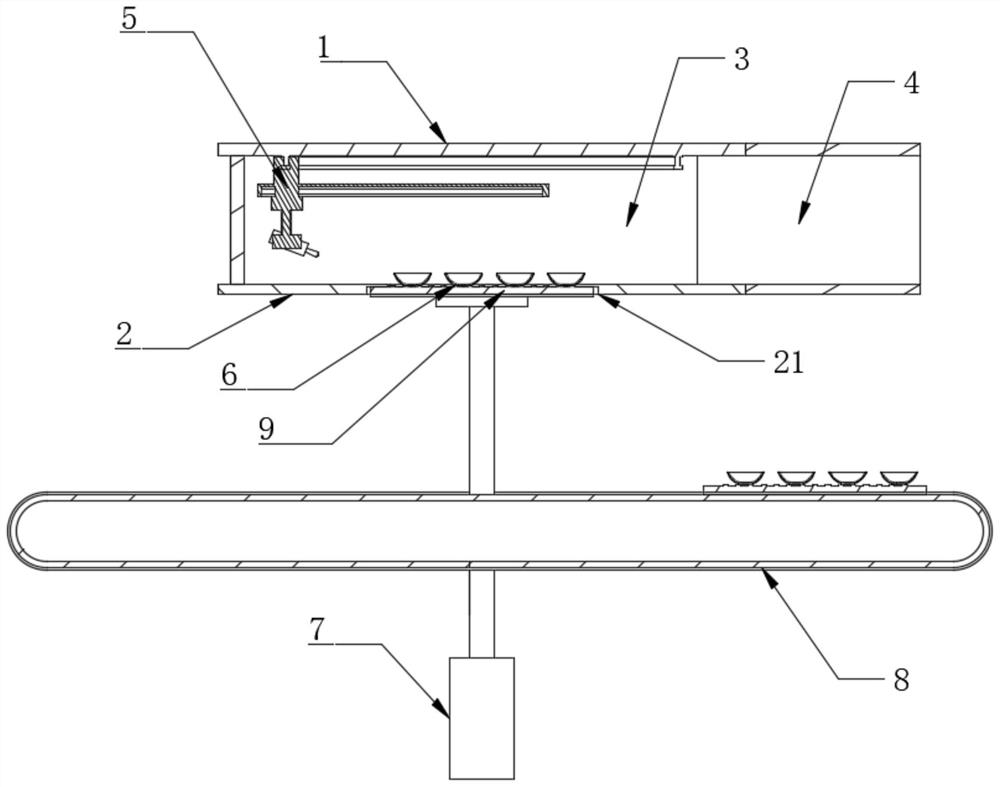

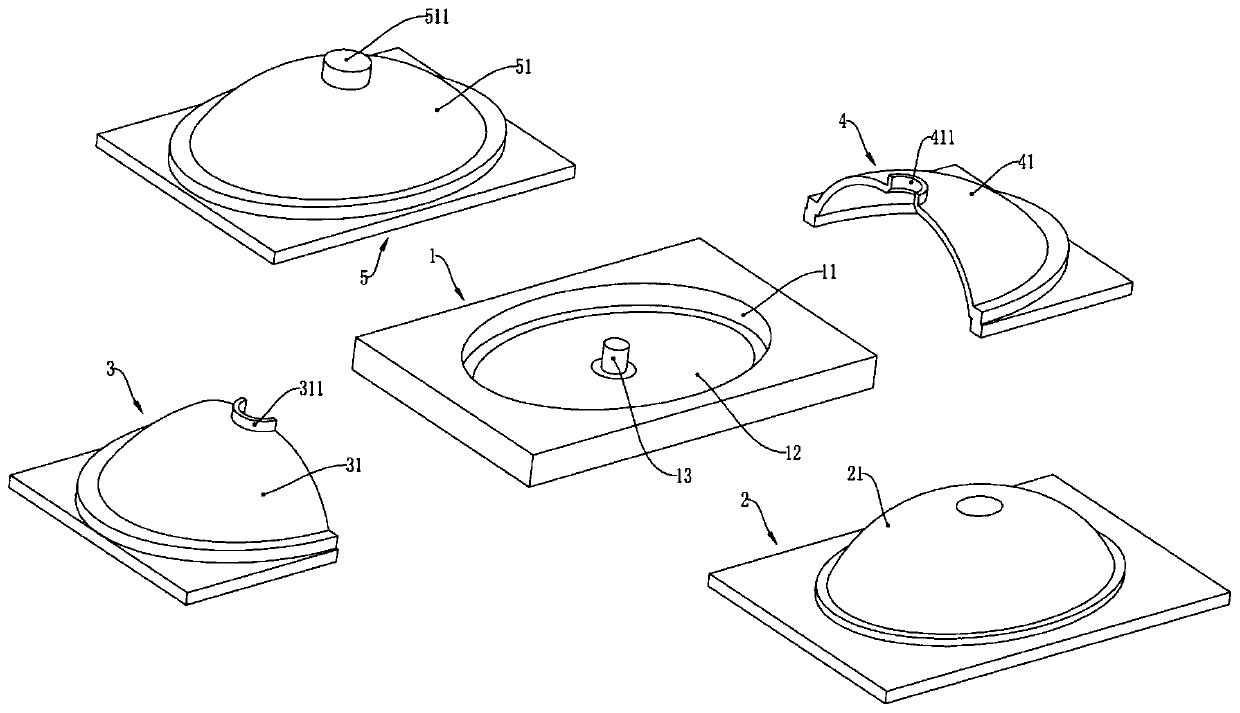

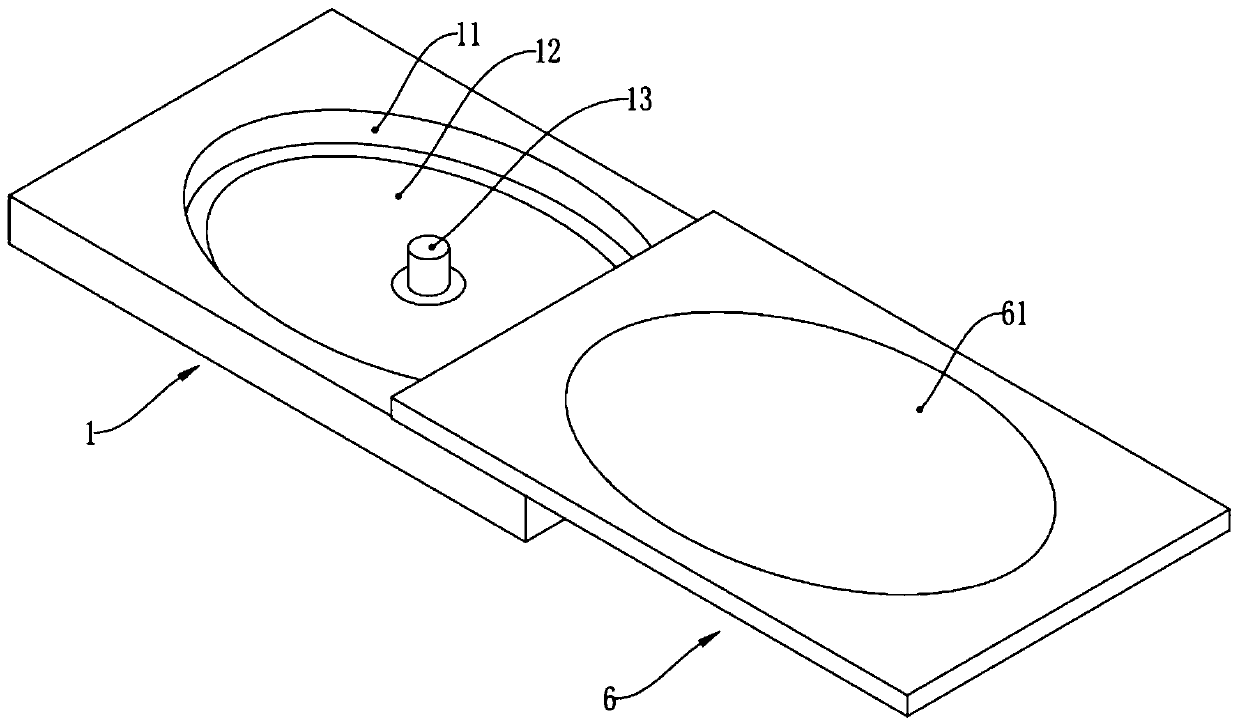

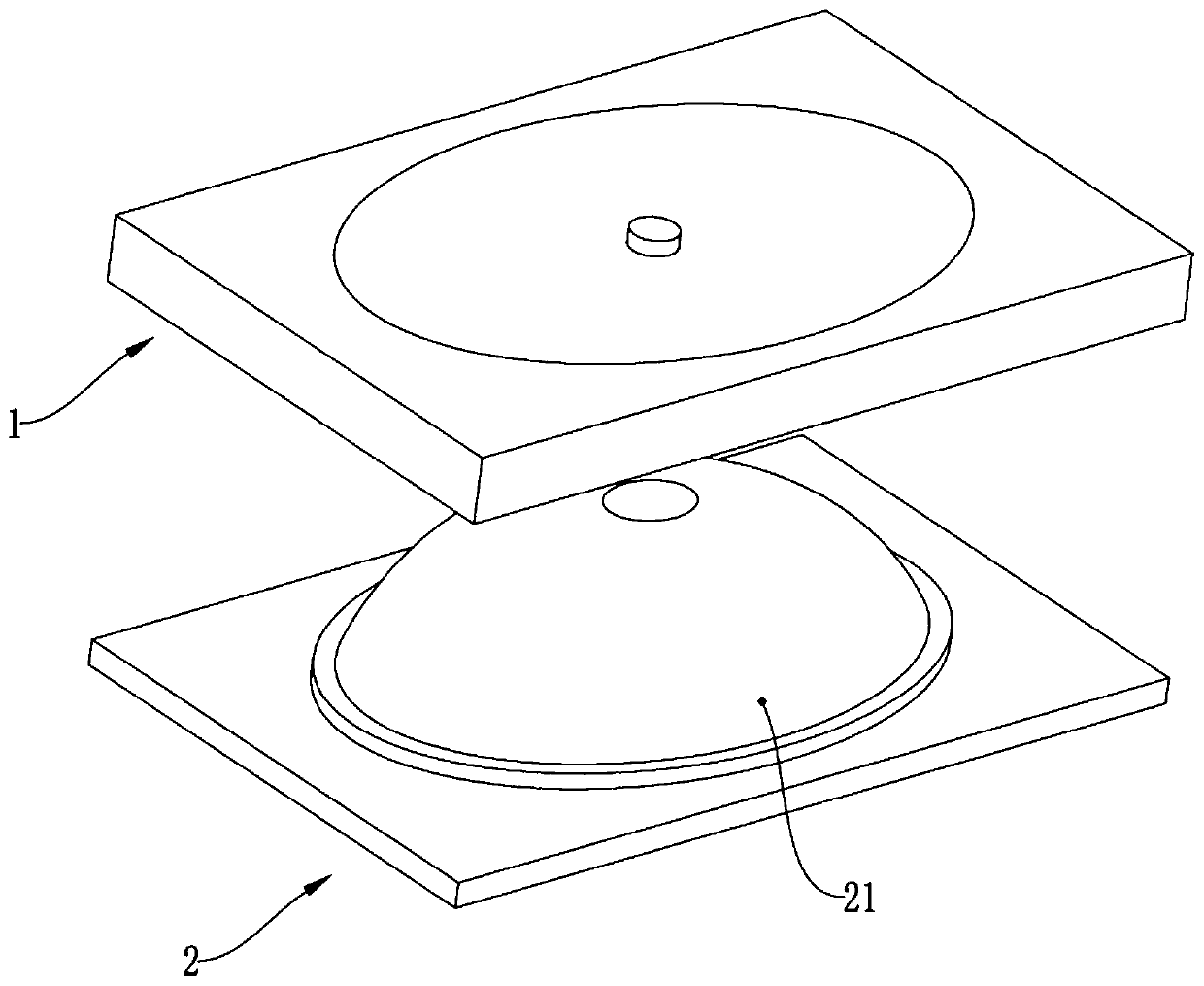

Die assembly for stamping molding of sanitary ceramics and stamping system using the same

ActiveCN108789774BReduce deformation rateImprove stress resistanceFeeding arrangmentsSlip casting mouldsPunchingSlip (ceramics)

The invention discloses a mold component for punch formation of sanitary ceramics and a punching system using the mold component. The mold component comprises a middle mold, a bottom mold, a left mold, a right mold and a top mold; the middle mold is provided with a mold cavity; the bottom of the mold cavity is covered by an elastic molding part; the mold cavity of the middle mold is used for bearing ceramic powder; the bottom mold is provided with a lower punching part; the left mold is provided with a left punching part; the right mold is provided with a right punching part; the left mold andthe right mold are used for punching; the top mold is provided with an upper punching part; and the top mold and the bottom mold are used for punching. The punching mold component is used for punch formation of a blank body; and due to increment of pressure, the density of the blank body is much larger than that of the slip-cast blank body, the deformation rate of a prepared finished product is reduced, and the compression resistance is improved.

Owner:FOSHAN DONGPENG SANITARY WARE +2

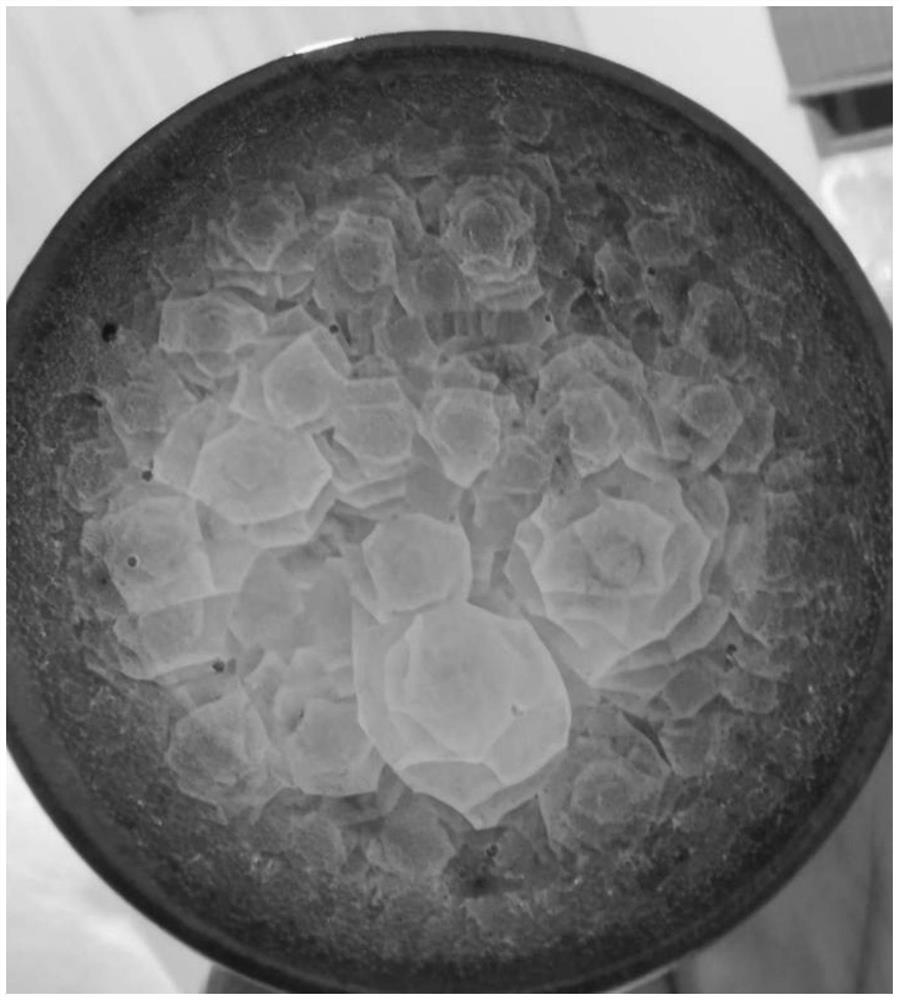

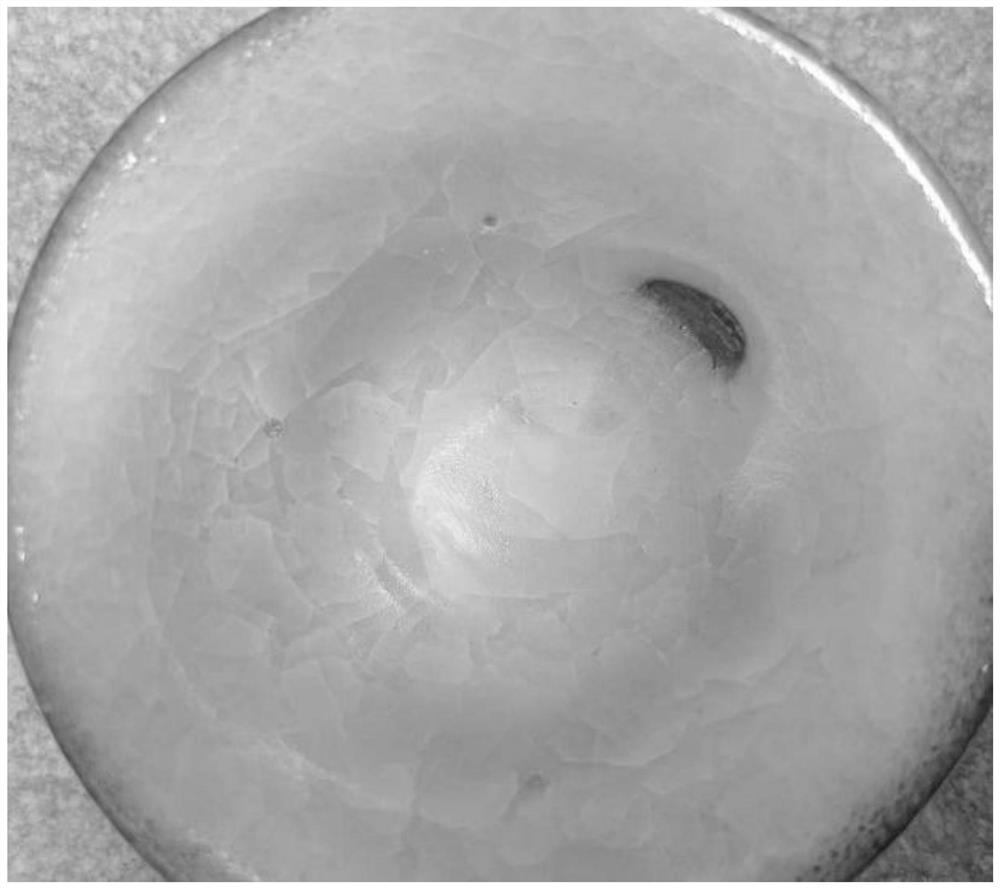

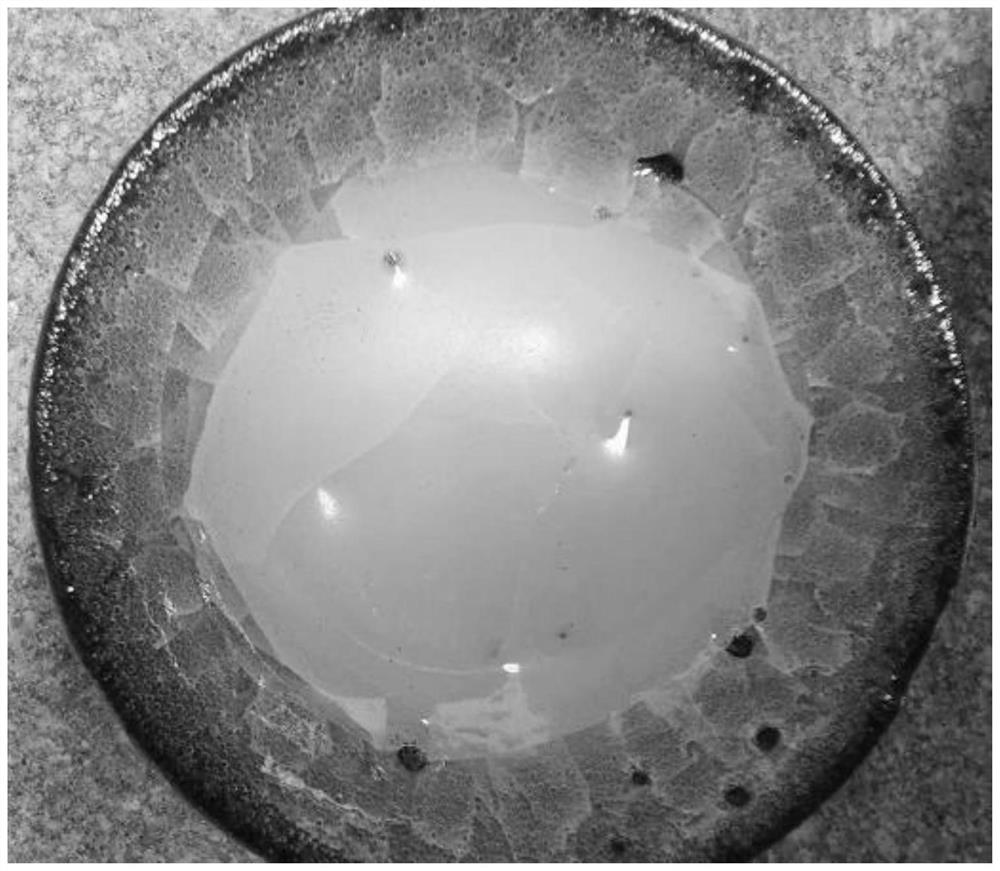

Crystal ice crack porcelain and preparation method thereof

ActiveCN114873989AImprove thermal stabilityGood chemical stabilityCeramic materials productionClaywaresSlip (ceramics)Slurry

The invention provides crystal ice crack porcelain and a preparation method thereof, and relates to the technical field of ceramics. The crystal ice crack porcelain comprises a blank and glaze, and the glaze comprises the following raw materials in parts by weight: 28-52 parts of potassium feldspar, 28-52 parts of albite, 10-20 parts of limestone, 2-4 parts of Zijin clay, 0.5-1.5 parts of fluorite, 0.5-1.5 parts of zinc oxide and 2-6 parts of barium carbonate. The preparation method comprises the following steps: grinding blank raw materials, adding water for wet grinding, preparing blank mud, drying and molding, and sintering in a kiln to obtain a biscuit firing blank; mixing the raw materials of the glaze, performing wet ball milling on the ballstone, the mixed raw materials of the glaze and water, and grinding to obtain glaze slip; glazing slurry is applied to the cooled biscuit firing blank, and the bottom foot of the biscuit firing blank is scraped and washed; the glazed biscuit firing blank is put into a kiln to be fired, and the crystal ice crack porcelain is obtained after firing. The crystal ice crack porcelain has the advantages of complete and attractive patterns, uniform distribution and high glaze glossiness.

Owner:李刘旒 +1

Composition to completely or partially replace ball clay in ceramics, method of making, and use thereof

Owner:ACTIVE MINERALS INT

Lead-containing assistant of frit used for preparation of ceramics

The invention discloses a lead-containing assistant of a frit used for preparation of ceramics. The assistant is prepared from the following raw materials by weight: 20-40 parts of SiO2, 5-15 parts of Al2O3, 5-15 parts of an alkali metal, 10-20 parts of PbO, 3-8 parts of acetophenone, and 3-5 parts of a defoaming agent. The lead-containing assistant of the frit used for preparation of ceramics provided by the invention has scientific and reasonable component proportioning, can promote frit fusion, lower fusion temperature, and prevent high temperature volatilization of materials. And the prepared glaze slip has good performance and can be used in a wide range.

Owner:CARLOBBIA GLAZE KUNSHAN

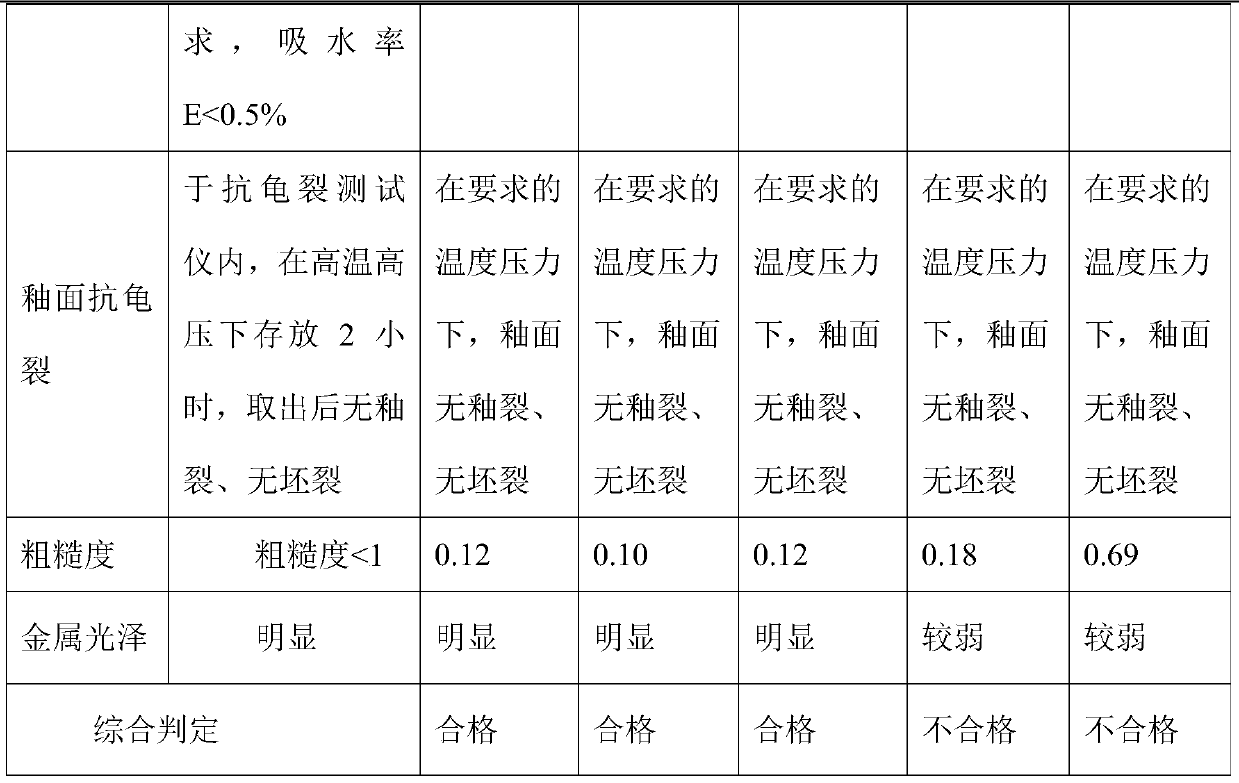

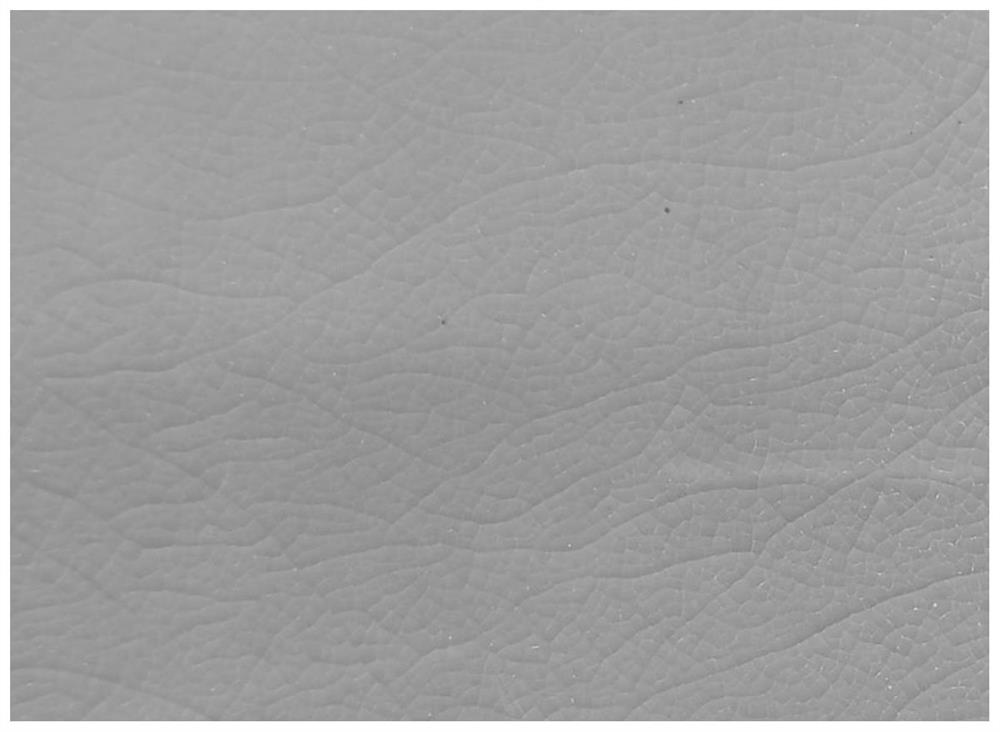

Grignard metal glaze with silver white color effect and processing technology of Grignard metal glaze

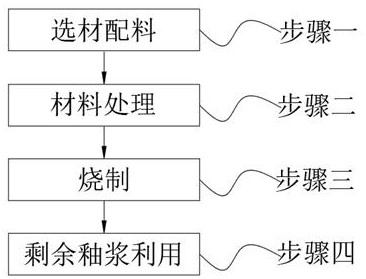

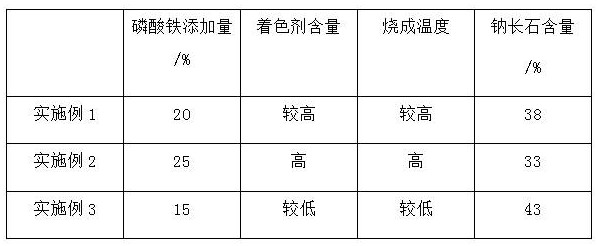

The invention discloses Grignard metal glaze with silvery white color effect, which is prepared from washing mud, rock quartz, lithium carbonate, albite, iron phosphate, aluminum phosphate, zinc oxide, a color developing agent, rutile and manganese carbonate. The mass percentage of each component is respectively as follows: 1-6% of washing mud, 1-6% of rock quartz, 5-15% of lithium carbonate, 30-45% of albite, 15-25% of iron phosphate, 5-15% of aluminum phosphate, 0.5-3% of zinc oxide, 3-10% of a color developing agent, 3-8% of rutile and 0.5-3% of manganese carbonate; the processing technology comprises the following steps: 1, selecting and preparing materials; 2, performing material treatment; 3, firing; and 4, utilizing residual glaze slip. The metal glaze has rich colors and strong metal texture; and the technological process is basically the same as that of common ceramics, the technological parameters and the firing control range are wide, especially the firing curve of the product is the same as that of the common ceramics, special devitrification and heat preservation are not needed, and an enterprise can rapidly enter a stable production state.

Owner:醴陵市格瑞瓷陶瓷科技有限公司

A metal glaze prepared by recycling iron impurities from sanitary ceramics and its method

ActiveCN107892481BEnable recyclingImprove mechanical propertiesCarboxymethyl celluloseSlip (ceramics)

The invention discloses a metal glaze prepared from iron impurities recovered from sanitary ceramics. The metal glaze comprises the components: quartz, iron phosphate, aluminum oxide, calcite, albite,kaoline, glass powder, iron impurities recovered by using a sanitary ceramic iron removal process, copper oxide and sodium carboxymethyl cellulose, wherein the particle sizes of the iron impurities recovered by using the sanitary ceramic iron removal process are 100-250 meshes. The invention further provides a method for preparing metal glaze from iron impurities recovered from sanitary ceramics,and the method comprises the steps: sieving, calcining and grinding the iron impurities recovered from sanitary ceramics, then, mixing the iron impurities recovered from sanitary ceramics with othercomponents, and carrying out ball milling to obtain glaze slip; spraying the glaze slip on the surfaces of the sanitary ceramics; and carrying out high-temperature firing to form a metal glaze layer with a bronze metal texture. On one hand, the recycle of sanitary ceramic iron removal wastes is realized, and the energy source is saved; and on the other hand, an individual sanitary ceramic productis obtained, and the demand of diversification is met.

Owner:JOMOO KITCHEN & BATHROOM

Star drill crackle glaze, glaze slip and ceramic thereof

ActiveCN114702242AHave unexpected effectsOvercoming the shortcomings of easy to absorb dirt and limited application occasionsCrazingSlip (ceramics)

Owner:广东道氏陶瓷材料有限公司 +1

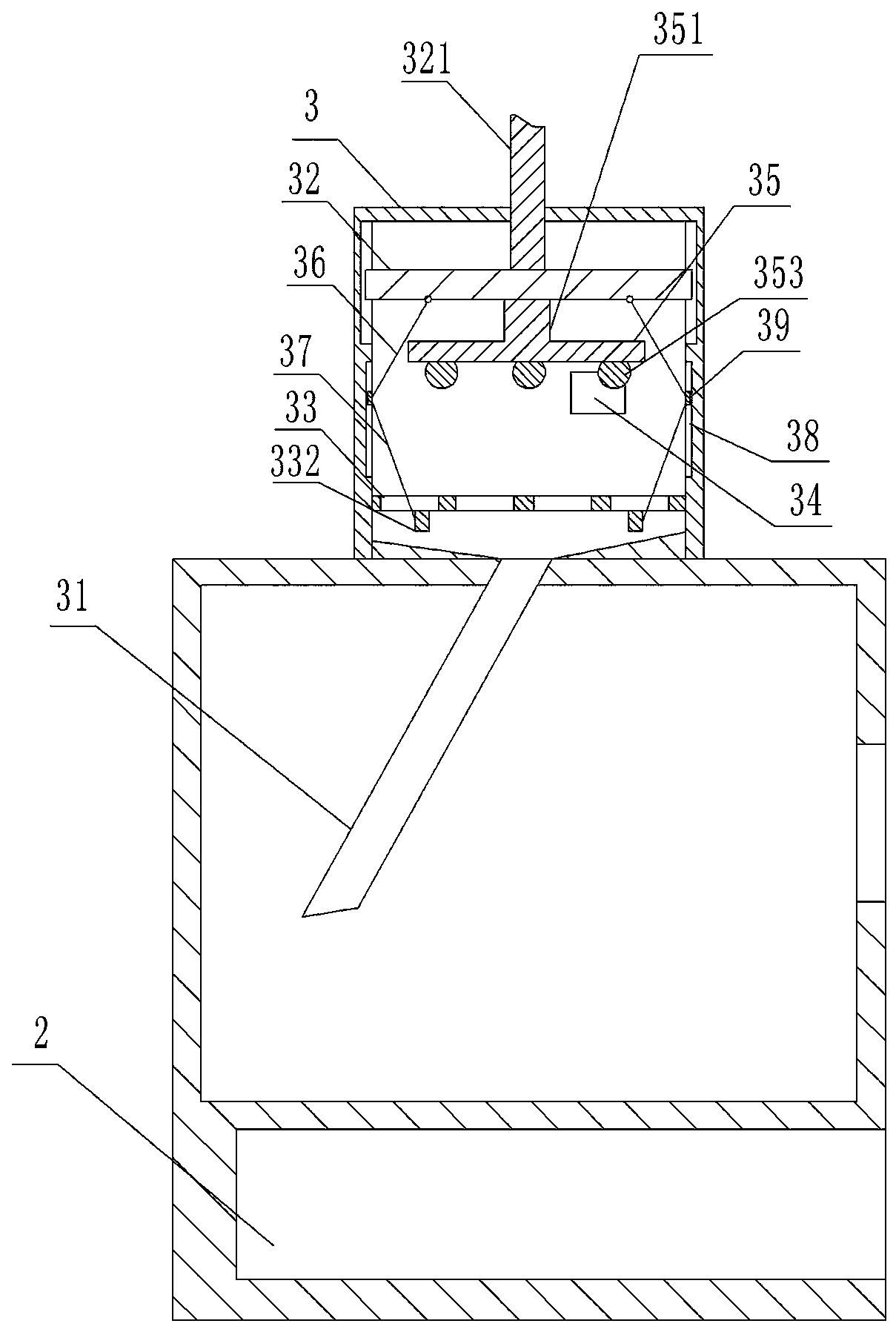

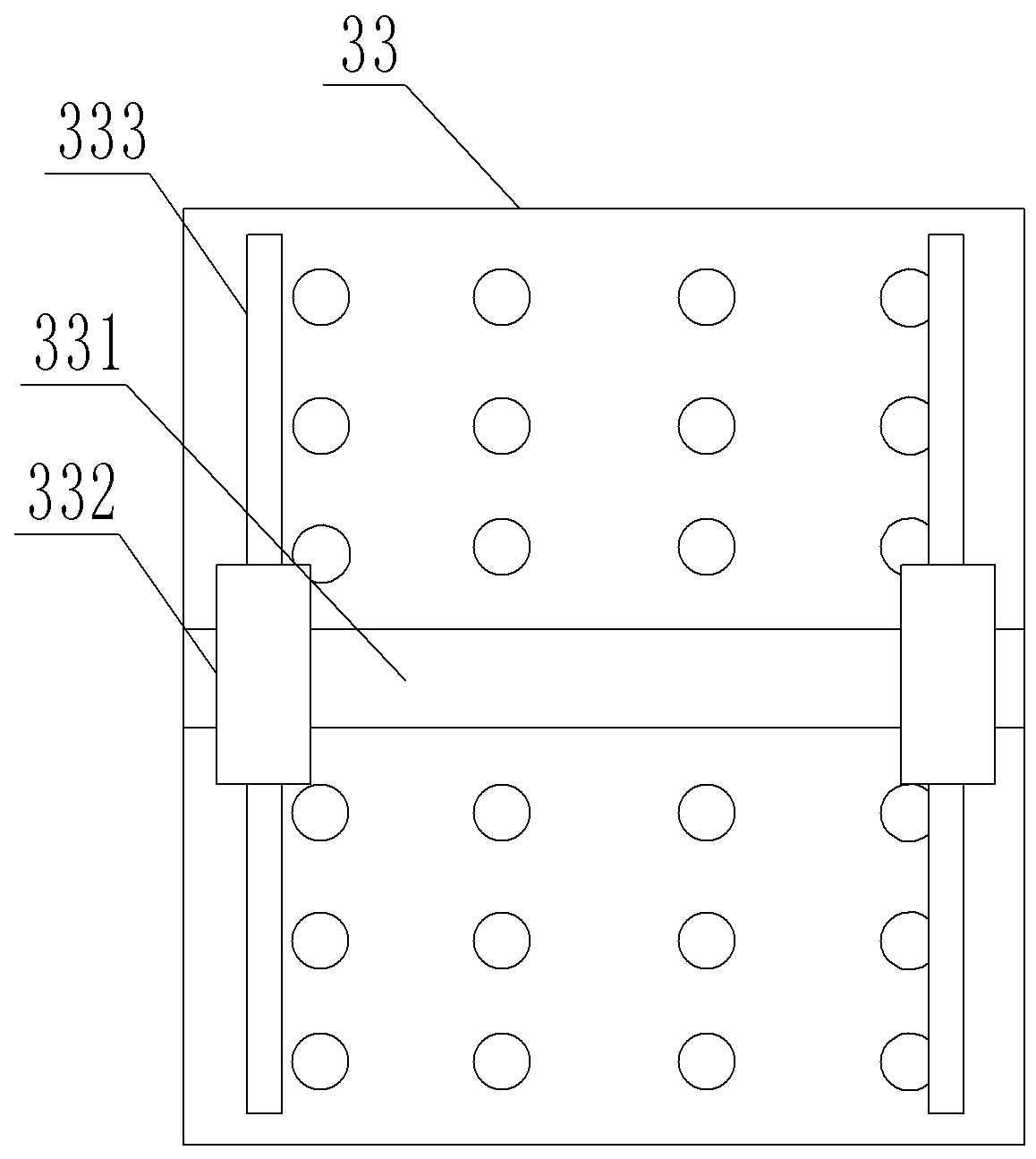

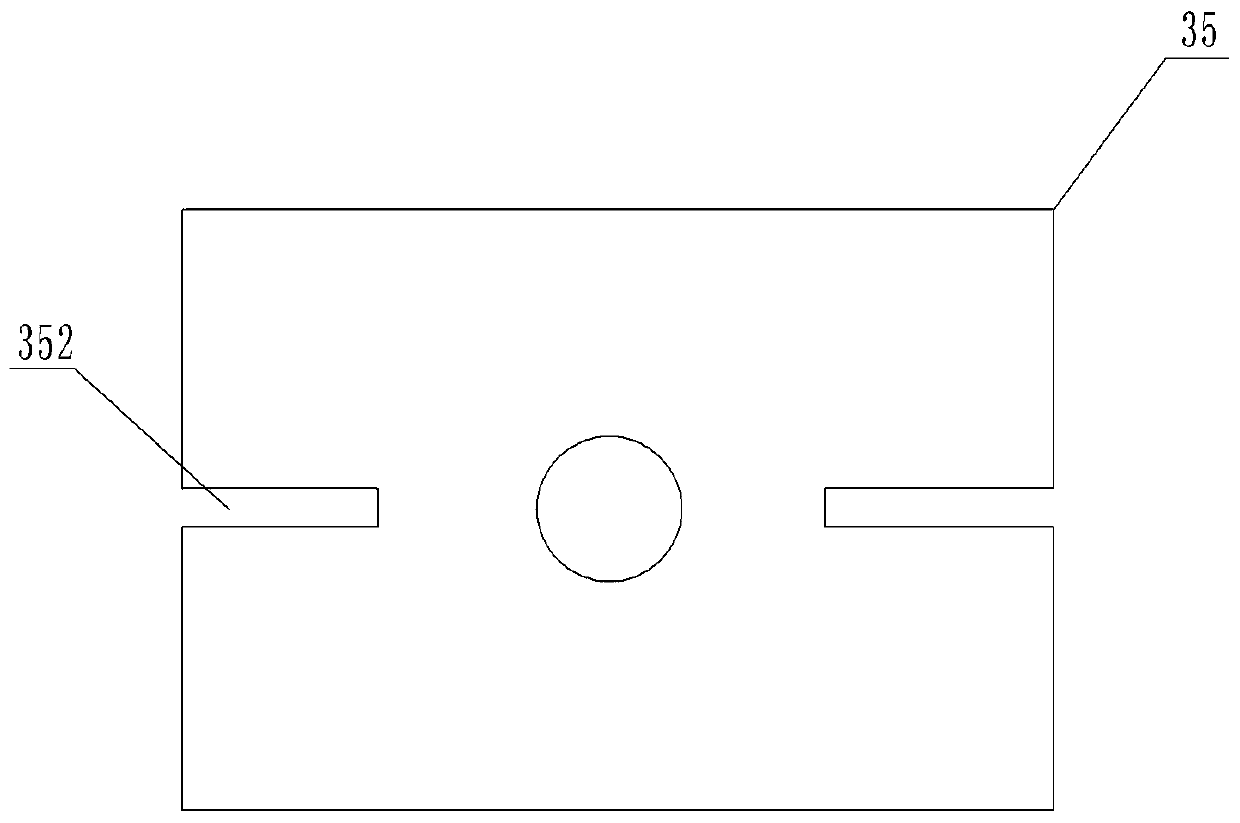

Furnace charging device

ActiveCN107739140BPrevent splashImprove securityCharging furnaceGlass productionMelting tankSlip (ceramics)

The invention relate to the technical field manufacturing glass, pottery or other ceramics, in particular to a furnace charging device. The furnace charging device comprises a melting pot, wherein a heating part is arranged at the lower part of the melting pot; the upper part of the melting pot is provided with a power device and a charging part for charging materials into the melting pot; the melting pot is also provided with a material taking port; the charging part comprises a charging barrel and a heat conducting pipe, one end of the heat conducting pipe is communicated with the charging barrel, and the other end of the heat conducting pipe extends into the melting pot; the end, extending into the melting pot, of the heat conducting pipe is arranged far away from the material taking port; a piston is in slip connection in the charging barrel, and the top surface of the piston is connected with a piston rod driven by a power device to move up and down; the bottom surface of the piston is connected with a crushing part for crushing glass; a screen mesh is also arranged in the charging barrel; and the side wall of the charging barrel is provided with a charging port with a cover,and the charging port is positioned between the piston and the screen mesh. According to the technical scheme, the residual glass melt or glass fragments in the melting pot can be prevented from splashing out of the melting pot when glass blocks enter the melting pot.

Owner:重庆兆峰玻璃晶品有限公司

Ball milling process of sanitary ceramic glaze slip

ActiveCN114534865AImprove solubilityImprove ball milling effectGrain treatmentsCeramic materials productionCarboxymethyl celluloseCellulose

The invention relates to the technical field of sanitary ceramics, in particular to a ball milling process of sanitary ceramic glaze slip. A ball milling process of sanitary ceramic glaze slip comprises the following steps: (1) weighing glaze raw materials, medium-viscosity sodium carboxymethyl cellulose and water according to a glaze formula, and adding the glaze raw materials, the medium-viscosity sodium carboxymethyl cellulose and the water into a ball mill; (2) adding ballstone into the ball mill; (3) performing ball milling for the first time, and stopping ball milling until the fineness requirement of the glaze slip is met; and (4) adding instant sodium carboxymethyl cellulose, and carrying out secondary ball milling to obtain the sanitary ceramic glaze slip. According to the ball-milling process of the sanitary ceramic glaze slip, the ball-milling effect of the glaze slip can be improved, the stability of parameters of the glaze slip can be controlled, and the ball-milling time is effectively shortened, so that the consumption of production energy is reduced, and the production cost is effectively reduced; the problems of high production cost and unstable ball-milling effect caused by long ball-milling time and high ball-milling energy consumption of the existing sanitary ceramic glaze slip are solved.

Owner:FOSHAN DONGPENG SANITARY WARE +2

A preparation method of yttrium zirconate microcrystalline ceramic glaze with photocatalytic function

The invention relates to a preparation method of a yttrium zirconate microcrystal ceramic glaze having a photocatalytic function. The preparation method comprises the following steps: preparing quartz, potash feldspar, albite, borax, Y2O3, Suzhou clay and lithium carbonate, keeping the above raw materialsat 1270-1290 DEG C for 20-40 minutes, taking out, pouring into water, quenching to prepare a fusion cake, and grinding the fusion cake to obtain a material A; preparing the material A, Y2O3, ZrO2 and Suzhou clay to obtain a material B; adding the material B and dispersing agent into water, and uniformly stirring and mixing to prepare a glaze slip; and applying the glaze slip to the surface of ceramics, and firing to obtain the yttrium zirconate microcrystal ceramic glaze having a photocatalytic function. According to the invention, the ceramic glaze is prepared through a firing process and does not need coating, so that the prepared functional ceramic glaze material can be tightly combined with a ceramic matrix; and the photocatalyst Y2Zr2O7 generated in the sintering process of Y2O3 and ZrO2 is uniformly distributed in the glaze material, thereby avoiding the condition that the aesthetic property of the glaze material is influenced due to a rainbow effect.

Owner:SHAANXI UNIV OF SCI & TECH

Simulated marble glaze and ceramic product with simulated marble glaze and preparation method

The invention relates to a simulated marble glaze, a ceramic product with the simulated marble glaze and a preparation method and belongs to the technical field of ceramics. The simulated marble glaze comprises the following raw materials in parts by weight: 23-26 parts of potassium feldspar, 19-23 parts of quartz, 7-11 parts of talc, 12-17 parts of waste ceramic powder, 6-10 parts of limestone, 26-35 parts of Longyan kaolin, 9-11 parts of zirconium oxide and 4-7 parts of chitin. The ceramic product with the simulated marble glaze is prepared according to the steps of pre-treating, ball-milling, regulating glaze slip, spraying glaze and burning; the glaze surface is high in quality and high in strength; the ceramic product has excellent antibacterial and anti-stains capacities and is suitable for the places, such as, kitchen and shower room; the production cost is lowered, the energy is saved, the emission is reduced and the ceramic product is green and environment-friendly.

Owner:FUJIAN DEHUA YOUSHENG CERAMICS

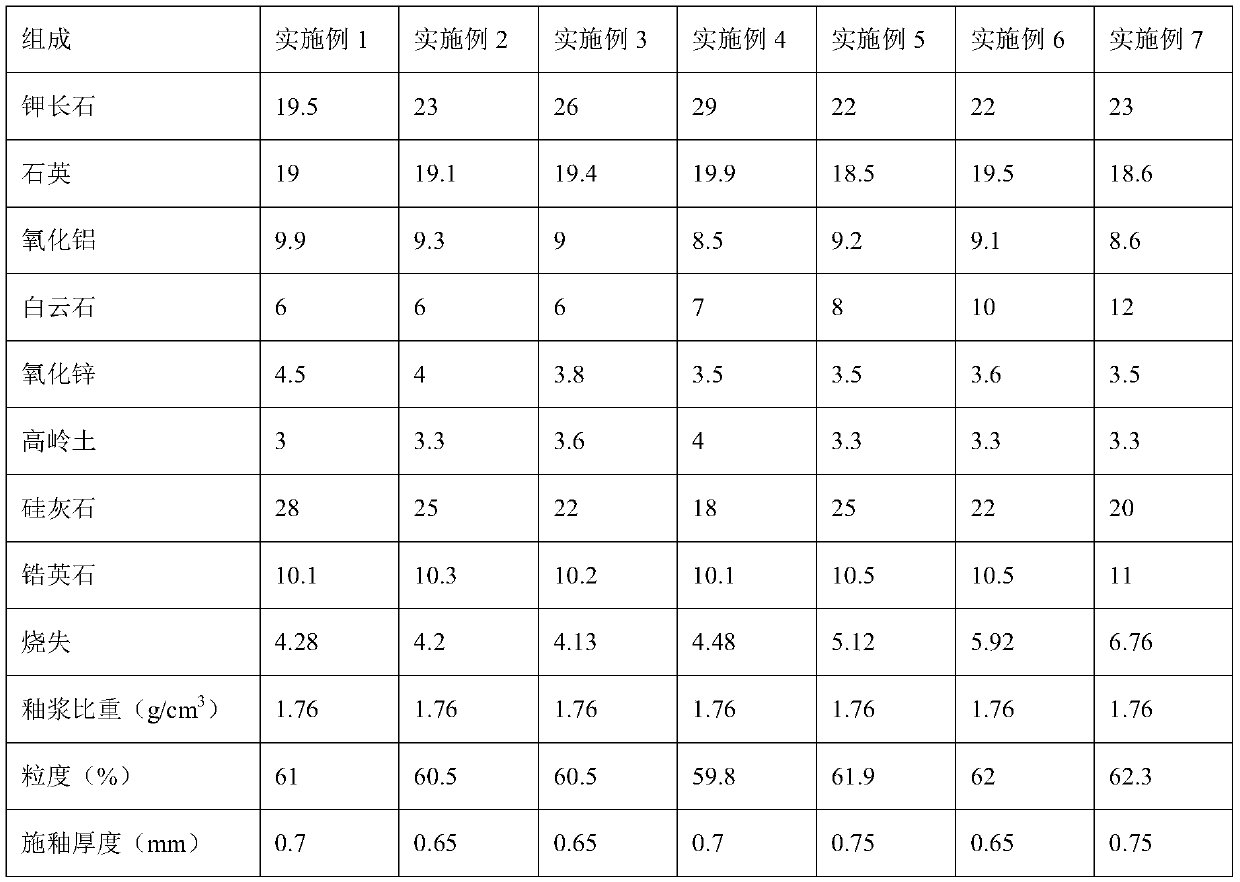

A kind of preparation method of sand glaze sanitary ceramics

ActiveCN106977103BMeet special requirements for health and safetySimple production processClaywaresCelluloseSlip (ceramics)

The invention discloses a preparation method of sand glazed sanitary ware, 19.5-29% by mass of potassium feldspar, raw materials of 18.5-19.9% by mass of quartz, 8.5-9.9% by mass of alumina, 6-12% by mass of dolomite, 3.5-4.5% by mass of zinc oxide, 3-4% by mass of kaolin, 18-28% by mass of wollastonite, 10.1-11% by mass of zirconite are filled in a ball mill, wherein ignition lost is 4.13-6.76%, a proper amount of sodium carboxymethyl cellulose is added, water is added for ball milling, the ball milling is stopped until slurry with the particle size smaller than 10 mu m accounts for 59 to 63%, the slurry is sieved with a 100 mesh sieve, the slurry is deironed for 3 to 6h, and the property of glaze slip is adjusted until the concentration of the glaze slip reaches 1.76+ / -0.02g / cm<3> to obtain uniform sand glaze slip, the uniform sand glaze slip is sprayed on the surface of a sanitary ware blank, the sanitary ware blank is fed in a kiln for first firming at 1200-1250 DEG C to obtain a sand glazed sanitary ware product. A prepared glaze layer can form a sparkling effect similar as river sand and sea sand under light, and the prepared glaze layer is safe, non-toxic, good in anti pollution performance, high in mechanical strength, and suitable for application in the field of sanitary ware.

Owner:JOMOO KITCHEN & BATHROOM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com