Grignard metal glaze with silver white color effect and processing technology of Grignard metal glaze

A processing technology and metal glaze technology, applied in the field of Grignard metal glaze, can solve the problems of discounting decorative embellishment effects, limiting the wide application of glaze materials, unsatisfactory, etc., to achieve loose process parameters and firing control range, strong metal The effect of texture, soft glaze luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

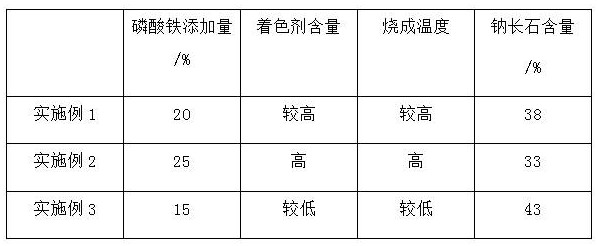

[0026] A Grignard metallic glaze with a silver-white color effect, the formula includes: 3% washing mud, 3% lithified quartz, 9% lithium carbonate, 38% albite feldspar, 20% iron phosphate, 10% Aluminum phosphate, 1% zinc oxide, 8% developer, 6% rutile and 2% manganese carbonate.

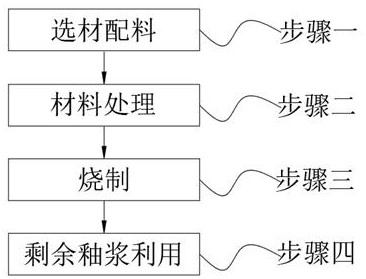

[0027] A processing technology of Grignard metallic glaze with silver-white color effect, comprising the following steps: Step 1, material selection and ingredients; Step 2, material processing; Step 3, firing; Step 4, utilization of remaining glaze slurry;

[0028] Wherein in the above-mentioned step one, according to the mass percentage of each component, it is respectively: 3% washing mud, 3% lithified quartz, 9% lithium carbonate, 38% albite, 20% iron phosphate, 10% aluminum phosphate, 1% zinc oxide, 8% color developer, 6% rutile and 2% manganese carbonate are selected, and weighed according to the sum of the weight percentages being 1; due to the thermal expansion of the metallic glaze The coef...

Embodiment 2

[0038] A Grignard metallic glaze with a silver-white color effect, the formula includes: 3% washing mud, 3% lithified quartz, 9% lithium carbonate, 33% albite feldspar, 25% iron phosphate, 10% Aluminum phosphate, 1% zinc oxide, 8% developer, 6% rutile and 2% manganese carbonate.

[0039] A processing technology of Grignard metallic glaze with silver-white color effect, comprising the following steps: Step 1, material selection and ingredients; Step 2, material processing; Step 3, firing; Step 4, utilization of remaining glaze slurry;

[0040] Wherein in above-mentioned step 1, by the mass percentage composition of each component is respectively: 3% washing mud, 3% lithified quartz, 9% lithium carbonate, 33% albite, 25% ferric phosphate, 10% aluminum phosphate, 1% zinc oxide, 8% color developer, 6% rutile and 2% manganese carbonate are selected, and weighed according to the sum of the weight percentages being 1; due to the thermal expansion of the metallic glaze The coefficien...

Embodiment 3

[0050] A Grignard metallic glaze with a silver-white color effect, the formula includes: 3% washing mud, 3% lithified quartz, 9% lithium carbonate, 43% albite feldspar, 15% iron phosphate, 10% Aluminum phosphate, 1% zinc oxide, 8% developer, 6% rutile and 2% manganese carbonate.

[0051] A processing technology of Grignard metallic glaze with silver-white color effect, comprising the following steps: Step 1, material selection and ingredients; Step 2, material processing; Step 3, firing; Step 4, utilization of remaining glaze slurry;

[0052] Wherein in the above-mentioned step one, according to the mass percentage of each component, it is respectively: 3% washing mud, 3% lithified quartz, 9% lithium carbonate, 43% albite, 15% iron phosphate, 10% aluminum phosphate, 1% zinc oxide, 8% color developer, 6% rutile and 2% manganese carbonate are selected, and weighed according to the sum of the weight percentages being 1; due to the thermal expansion of the metallic glaze The coef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com