Environment-friendly coating capable of releasing anions

An environmentally friendly coating and negative ion technology, applied in the field of coatings, can solve problems such as impact and coating hazards, and achieve the effects of improving dissolution characteristics, promoting fusion, and increasing reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

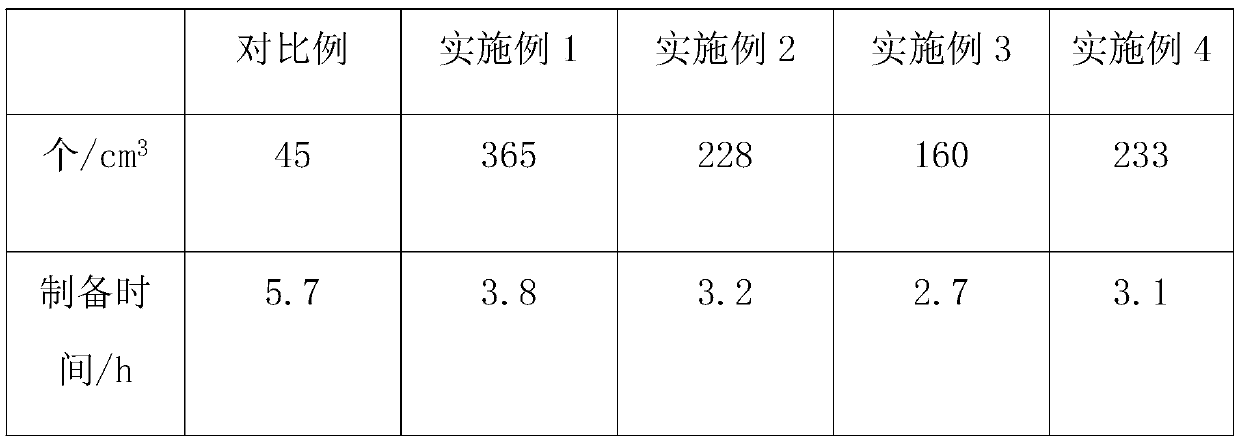

Examples

Embodiment 1

[0034] Step 1: Prepare the working device: Use clean tap water to clean the device that participates in the paint preparation work, and dry it for later use;

[0035] Step 2: Prepare the initial production environment: preheat the cleaned reaction device for 2 minutes, then add 100 parts of negative ion reducing water and 50 parts of negative ion powder, and stir well;

[0036] Step 3: Gradually add ingredients: After the above materials are fully stirred and mixed, reduce the speed of the stirring shaft, and then gradually add 60 parts of cationic surfactant, 40 parts of modified water-based epoxy resin, and 10 parts of glass phosphor flakes through the material addition tube. 10 parts of non-ionic surfactant, 5 parts of wetting agent, 10 parts of organotin drier, 20 parts of defoamer, 1 part of water-based multifunctional PH value regulator, 10 parts of nano-silica hardener, strong touch 5 parts of variable thickener, 30 parts of fluorocarbon resin, 15 parts of nano-montmorilloni...

Embodiment 2

[0040] Step 1: Prepare the working device: Use clean tap water to clean the device that participates in the paint preparation work, and dry it for later use;

[0041] Step 2: Prepare the initial production environment: preheat the cleaned reaction device for 3 minutes, then add 120 parts of negative ion reducing water and 60 parts of negative ion powder, and stir well;

[0042] Step 3: Gradually add ingredients: After the above materials are fully stirred and mixed, reduce the speed of the stirring shaft, and then gradually add 80 parts of cationic surfactant, 45 parts of modified water-based epoxy resin, 12 parts of glass phosphor flakes through the material addition tube, 15 parts of non-ionic surface active agent, 15 parts of wetting agent, 12 parts of organotin drier, 22 parts of defoamer, 5 parts of water-based multifunctional pH regulator, 15 parts of nano-silica hardener, strong touch 15 parts of variable thickener, 40 parts of fluorocarbon resin, 18 parts of nano-montmorill...

Embodiment 3

[0046] Step 1: Prepare the working device: Use clean tap water to clean the device that participates in the paint preparation work, and dry it for later use;

[0047] Step 2: Prepare the initial production environment: preheat the cleaned reaction device for 4 minutes, then add 140 parts of negative ion reducing water and 70 parts of negative ion powder, and stir well;

[0048] Step 3: Gradually add ingredients: After the above materials are fully stirred and mixed, reduce the speed of the stirring shaft, and then gradually add 100 parts of cationic surfactant, 50 parts of modified water-based epoxy resin, 15 parts of glass phosphor sheet through the material addition tube, 20 parts of non-ionic surfactant, 25 parts of wetting agent, 15 parts of organotin drier, 25 parts of defoamer, 8 parts of water-based multifunctional PH value regulator, 20 parts of nano-silica hardener, strong touch 25 parts of variable thickener, 50 parts of fluorocarbon resin, 22 parts of nano-montmorillonit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com