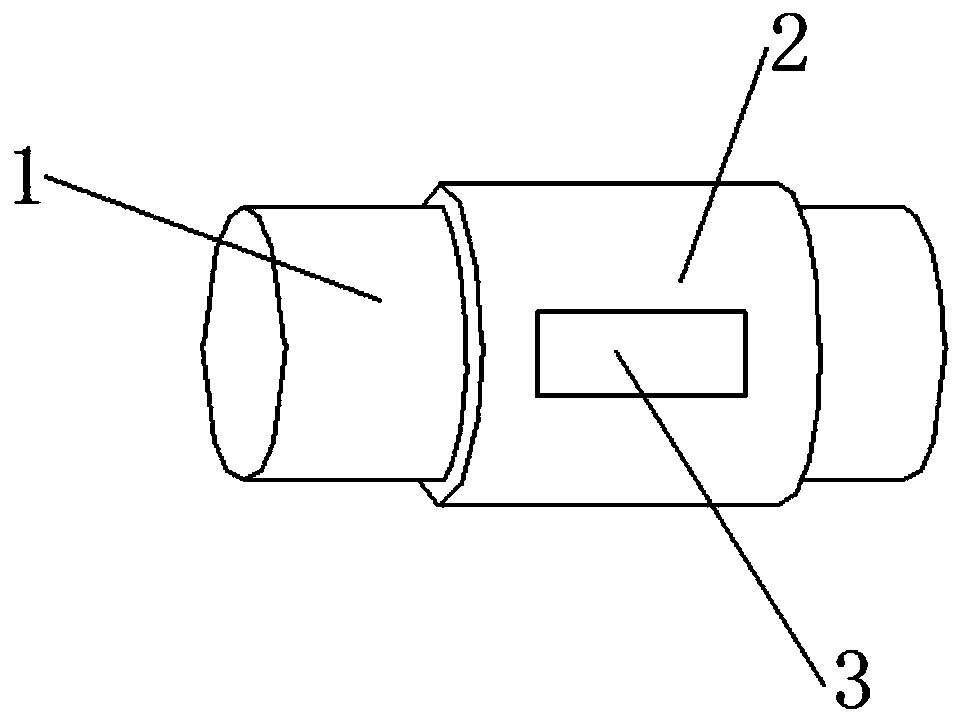

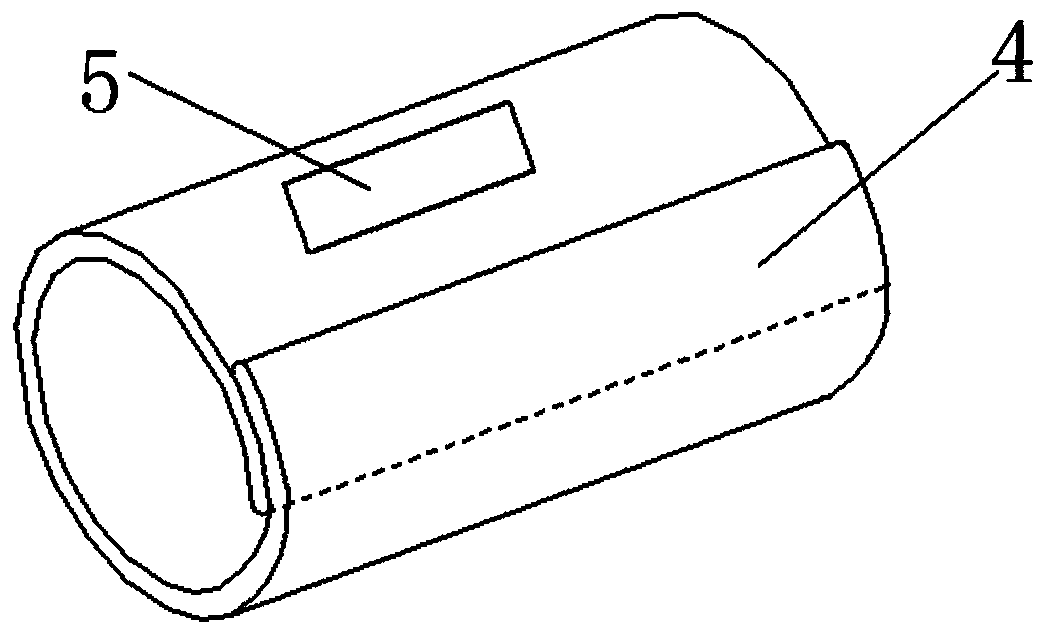

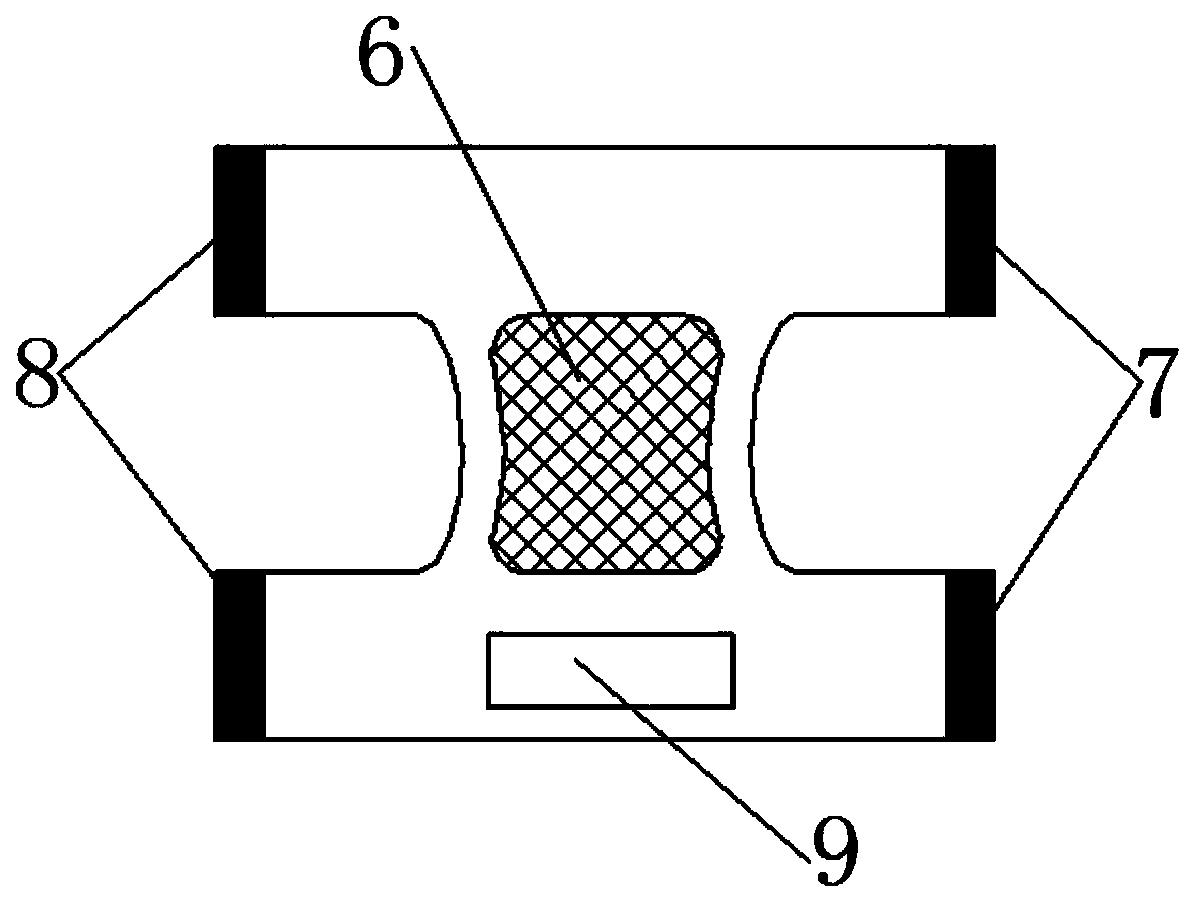

Intelligent protector four-in-one kit with microcirculation physiotherapy function

A four-piece, intelligent technology, applied in the field of protective gear, can solve the problems that users cannot provide physical therapy, health care and constant monitoring, etc., achieve good far-infrared and negative ion emission, improve iodine adsorption value, and increase far-infrared emissivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of antibacterial far infrared promoting microcirculation functional fabric comprises the following steps:

[0032] The first step: preparing buckwheat husk charcoal: take buckwheat husks and soak them in a sodium hydroxide solution with a mass fraction of 6-10% for 2-4 hours, filter them out and soak them in hydrogen peroxide with a mass fraction of 2-3% for 2- 6h, after filtering, rinse with water, dry, dry at 80-100°C for 2-4h, pre-carbonize at 120-150°C for 6-10h, then heat up to 310-350°C in a nitrogen environment for carbonization 3- 3.5h, the jet mill is crushed into a fine powder with a particle size of less than 0.8 μm, and it is set aside;

[0033]Step 2: Prepare buckwheat hull carbon fiber: add dispersant and chitosan to water, heat up to 60-75°C, keep warm and add buckwheat hull charcoal under high-speed stirring, stir evenly, keep warm for 2-3 hours to prepare buckwheat hull charcoal slurry , wherein the mass ratio of water: buckwheat...

Embodiment 2

[0042] Soak buckwheat husks in 10% sodium hydroxide solution for 4 hours, filter out and soak in 3% hydrogen peroxide for 2 hours, rinse with water after filtration, dry, and dry at 80°C for 4 hours Finally, pre-carbonize at 120°C for 6 hours, then raise the temperature to 350°C for 3 hours in a nitrogen atmosphere, and then pulverize it into a fine powder with a particle size of less than 0.8 μm by a jet mill for use. Preparation of buckwheat husk charcoal embodiment 3

Embodiment 3

[0043] Take buckwheat husks and soak in 6% sodium hydroxide solution for 2 hours, filter out and soak in 2-3% hydrogen peroxide for 3 hours, rinse with water after filtering, dry, and store at 80°C After drying for 2 hours, pre-carbonize at 150°C for 10 hours, then raise the temperature to 310°C for 3.5 hours in a nitrogen atmosphere, and then pulverize it into a fine powder with a particle size of less than 0.8 μm by jet milling for use.

[0044] Prepare buckwheat husk charcoal embodiment 4 (comparative example)

[0045] Prepare according to the method for preparing buckwheat husk charcoal Example 1, without soaking in hydrogen peroxide, and set aside.

[0046] For the effect test, the bacteriostatic rate and bactericidal rate were tested according to AATCC100-2004 "Evaluation of Antibacterial Performance of Textiles", and the tested bacteria were Staphylococcus aureus.

[0047] Table 1 Preparation and detection of buckwheat hull charcoal

[0048]

[0049] Preparation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com