Stirring device for oil blending system

A technology of stirring device and oil agent, which is applied to mixers with rotary stirring devices, circuit devices, and accessories of mixers, etc., can solve problems such as affecting the spinning quality, and achieve the goal of improving profit margins, reducing production costs, and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

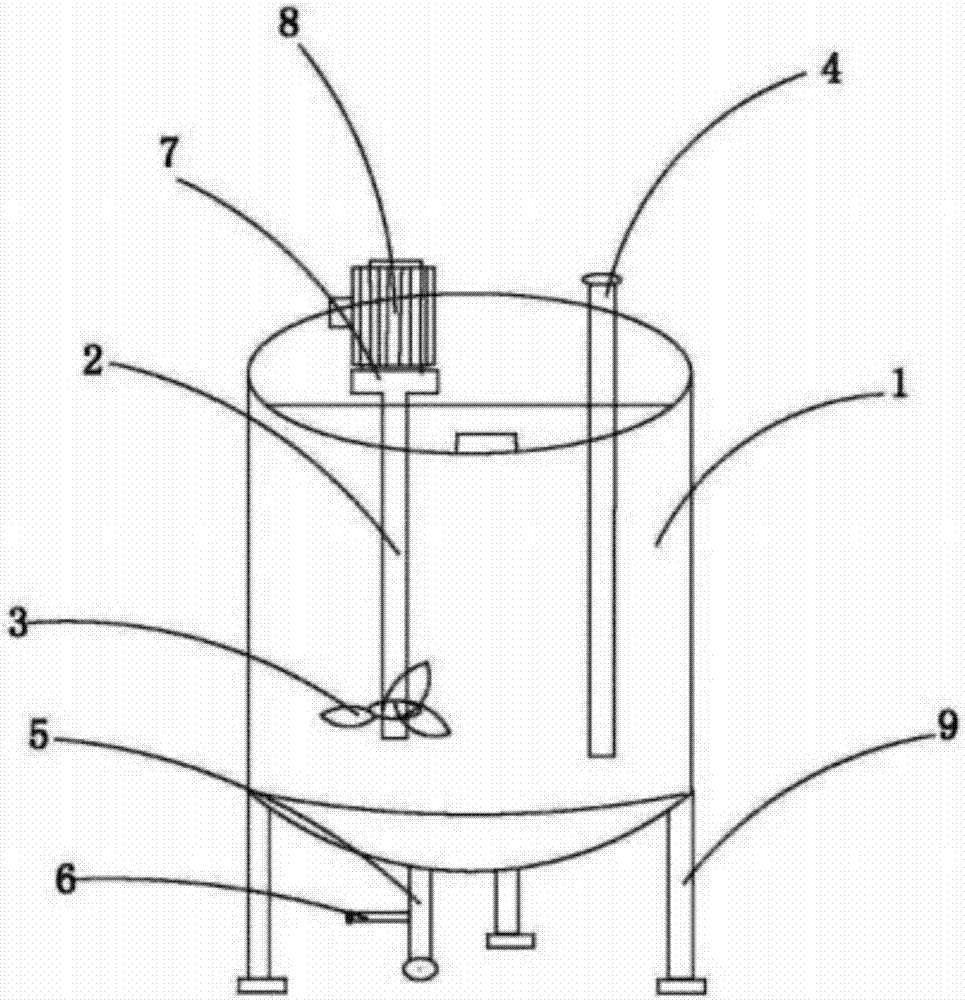

[0020] Embodiment 1: as figure 1 As shown, a stirring device for an oil preparation system includes a high-level oil tank 1, a stirring shaft 2 is inserted in the high-level oil tank 1, and a stirring impeller 3 is provided at the lower end of the stirring shaft 2. The high-level oil tank 1 is provided with an oil inlet pipe 4, the bottom of the high-level oil tank 1 is provided with a sewage pipe 5, and the side wall of the sewage pipe 5 is provided with an oil outlet 6. The top of the stirring shaft 2 is provided with a speed reducer 7, and the speed reducer 7 is rotated by a motor 8. The bottom of the high-level oil tank 1 is supported by legs 9 . A layer of thin-film solar cells is wrapped on the outside of the high-level oil tank.

[0021] The thin film solar cells are preferably CIGS, CIS thin film solar cells.

[0022] A storage battery can also be placed outside the stirring device and connected with the thin film solar cell. Used to store points generated by solar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com