Dryer regeneration gas heater system

A technology for heaters and dryers, which is applied in the fields of filter regeneration, combustible gas purification, chemical instruments and methods, etc., and can solve problems such as failure to meet regeneration gas volume and temperature requirements, insufficient self-produced dry gas volume, etc., and achieve simple structure, prevent Leakage, effect of meeting regeneration gas volume and temperature requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

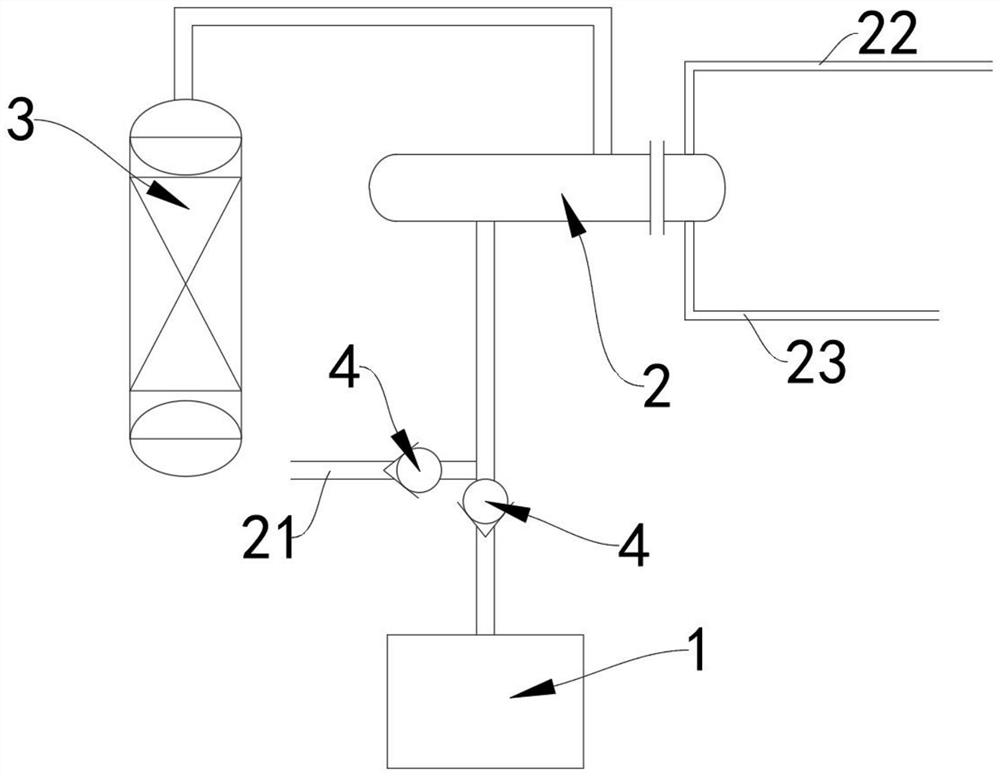

[0022] like figure 1 As shown, a dryer regeneration gas heater system includes a gas source 1, a heat exchanger 2 and a dryer 3; the gas outlet of the gas source 1 communicates with the material inlet of the heat exchanger 2; the The material outlet of the heat exchanger 2 communicates with the air inlet of the drier 3; the material inlet of the heat exchanger 2 is also provided with a propane pipeline 21, and the air inlet of the propane pipeline 21 is passed into propane; The gas outlet of the gas source 1 is connected with a one-way valve 4 , and the propane pipeline 21 is also provided with the one-way valve 4 .

[0023] The present invention heats the dry gas provided by the gas source 1 through the heat exchanger 2 to ensure a better heating effect, and removes adsorbed water, hydrogen sulfide, etc. from the heated dry gas through the dryer 3 material, to ensure that subsequent production will not be affected, and to better meet the regeneration gas volume and temperatu...

Embodiment 2

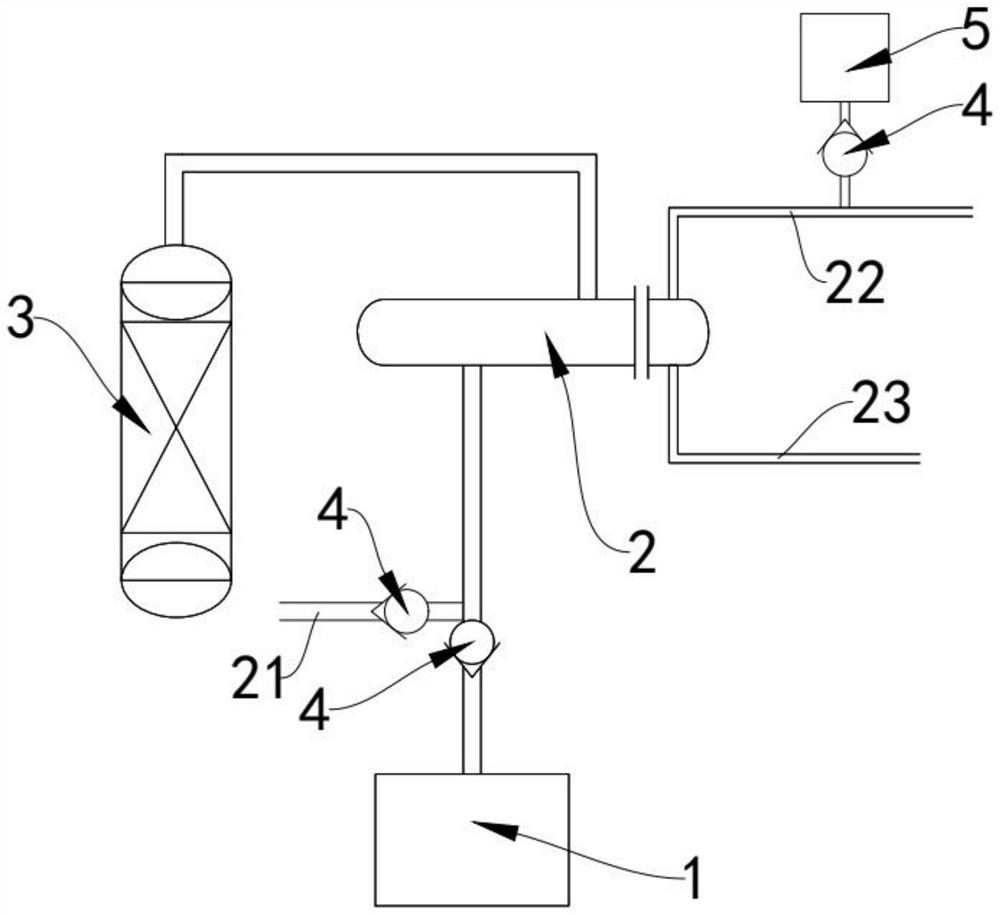

[0031] like figure 2 As shown, a dryer regeneration gas heater system includes a gas source 1, a heat exchanger 2 and a dryer 3; the gas outlet of the gas source 1 communicates with the material inlet of the heat exchanger 2; the The material outlet of the heat exchanger 2 communicates with the air inlet of the drier 3; the material inlet of the heat exchanger 2 is also provided with a propane pipeline 21, and the air inlet of the propane pipeline 21 is passed into propane; The gas outlet of the gas source 1 is connected with a one-way valve 4 , and the propane pipeline 21 is also provided with the one-way valve 4 .

[0032] The present invention heats the dry gas provided by the gas source 1 through the heat exchanger 2 to ensure a better heating effect, and removes adsorbed water, hydrogen sulfide, etc. from the heated dry gas through the dryer 3 material, to ensure that subsequent production will not be affected, and to better meet the regeneration gas volume and temperat...

Embodiment 3

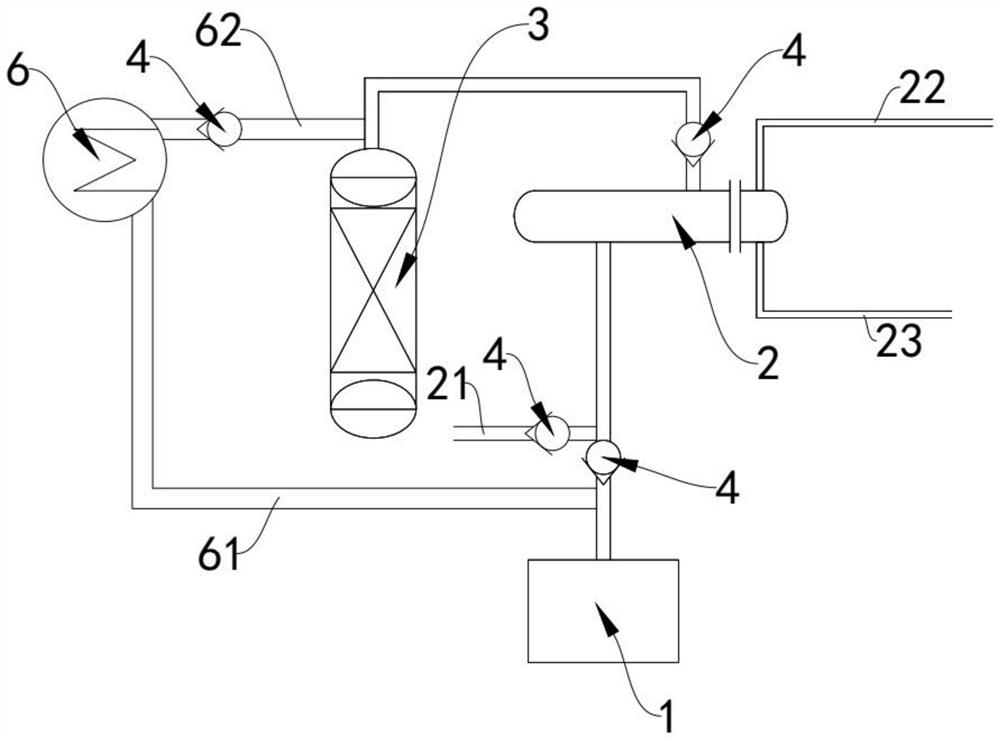

[0043] like image 3 As shown, a dryer regeneration gas heater system includes a gas source 1, a heat exchanger 2 and a dryer 3; the gas outlet of the gas source 1 communicates with the material inlet of the heat exchanger 2; the The material outlet of the heat exchanger 2 communicates with the air inlet of the drier 3; the material inlet of the heat exchanger 2 is also provided with a propane pipeline 21, and the air inlet of the propane pipeline 21 is passed into propane; The gas outlet of the gas source 1 is connected with a one-way valve 4 , and the propane pipeline 21 is also provided with the one-way valve 4 .

[0044] The present invention heats the dry gas provided by the gas source 1 through the heat exchanger 2 to ensure a better heating effect, and removes adsorbed water, hydrogen sulfide, etc. from the heated dry gas through the dryer 3 material, to ensure that subsequent production will not be affected, and to better meet the regeneration gas volume and temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com