Crystal ice crack porcelain and preparation method thereof

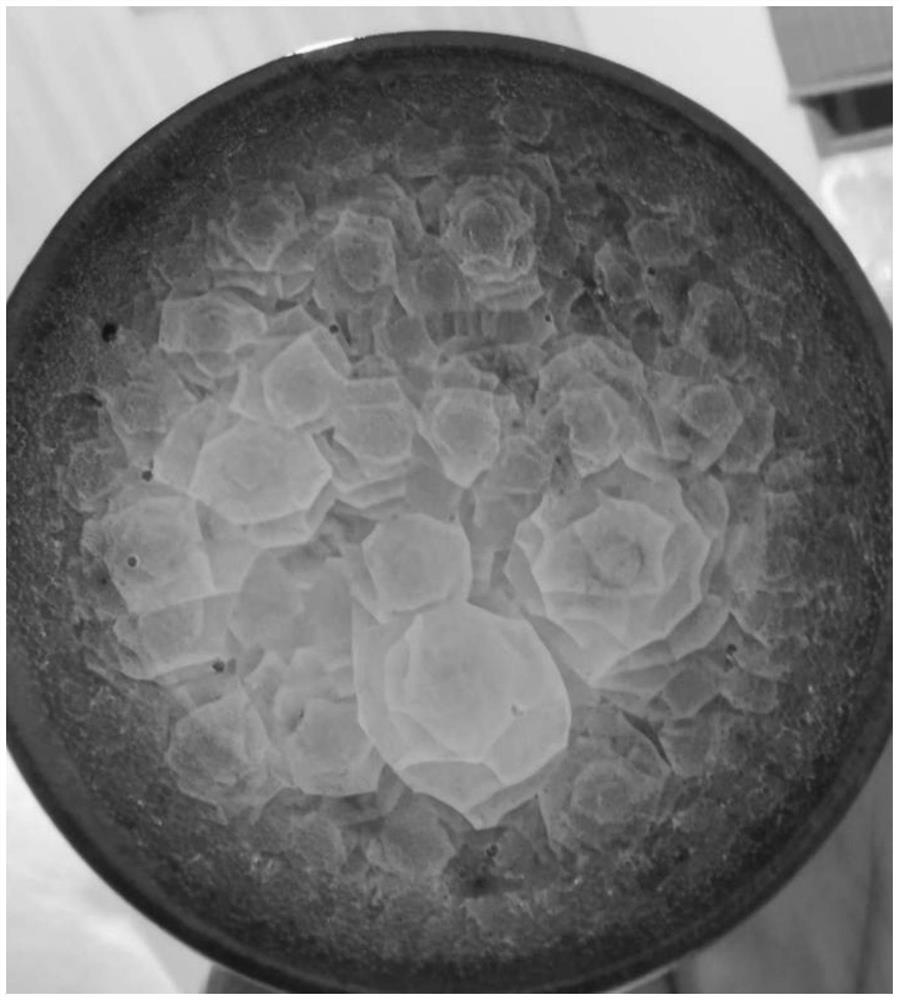

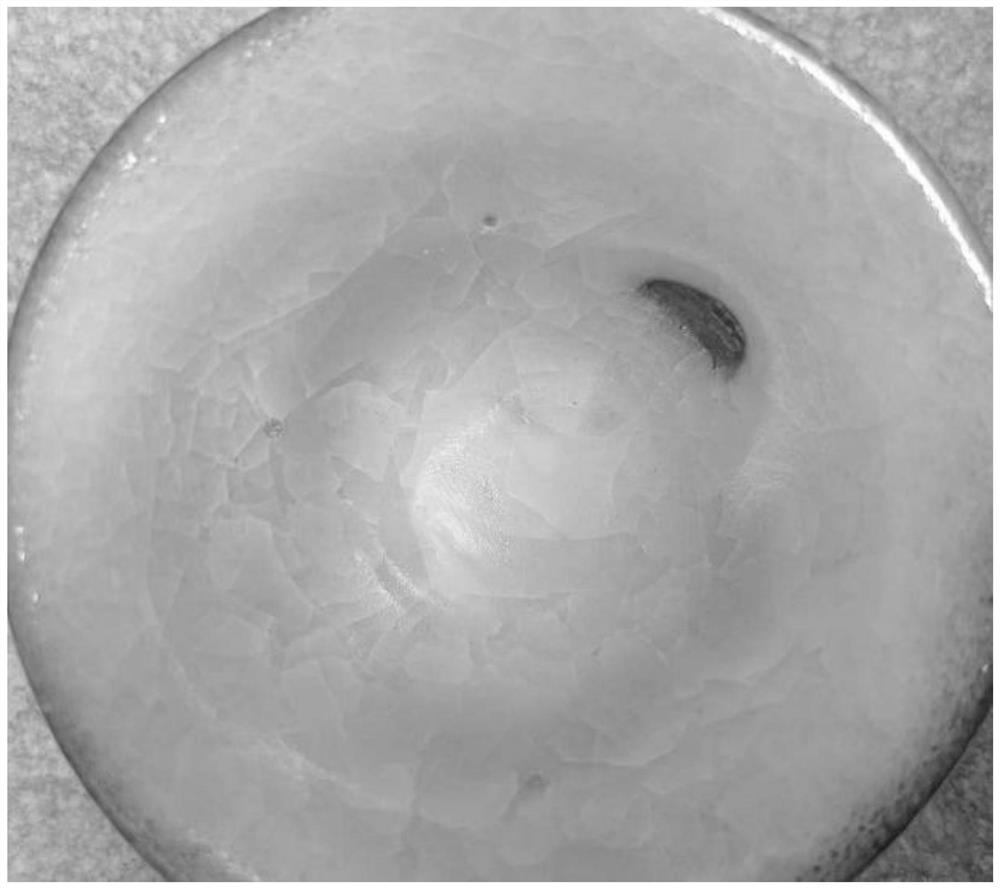

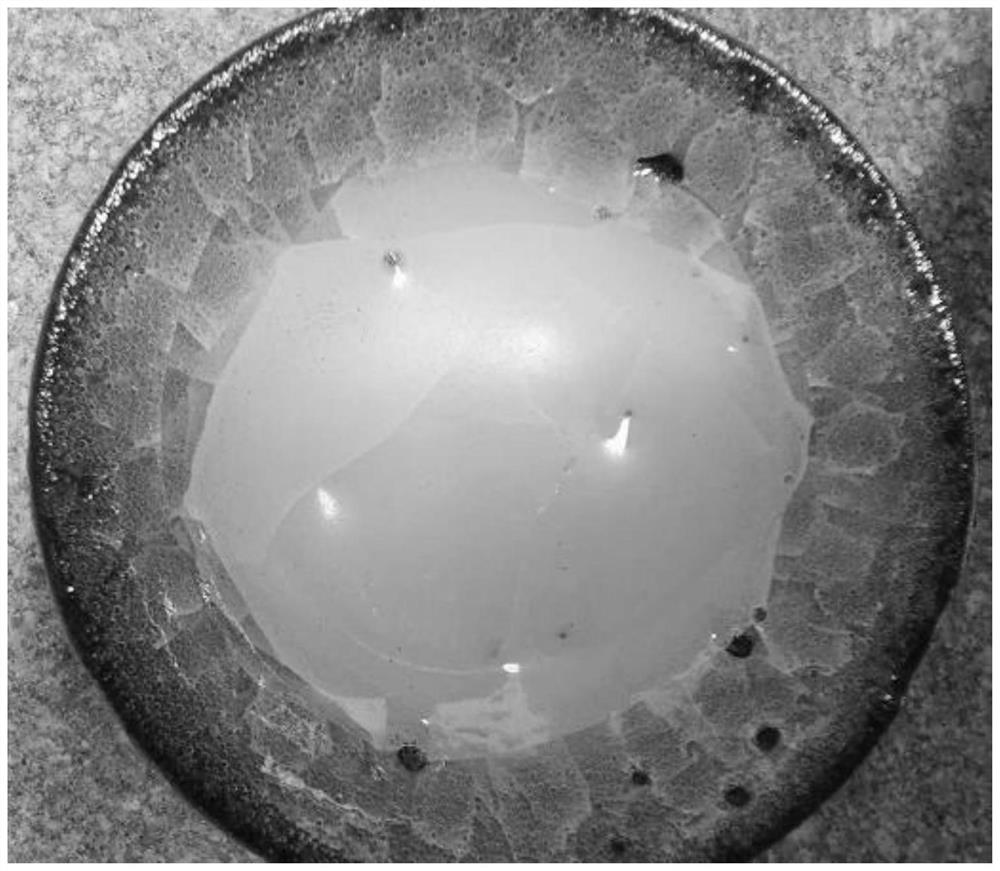

A technology of ice cracks and porcelain, applied in the field of ceramics, can solve the problems of difficult firing of ice cracked porcelain, incomplete petals of ice flower roses, uneven distribution of bubble sizes, etc., and achieve good gloss, gloss and beauty, and light refraction and good reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present embodiment also provides a preparation method of crystal ice cracked porcelain, comprising the following steps:

[0027] After grinding the raw material of the billet, add water to wet grinding, and then make the billet mud, dry and shape, and put it into a kiln for biscuit firing;

[0028] After mixing the glaze raw materials, the ball stone, the glaze mixed raw materials and water are subjected to wet ball milling, and the glaze slurry is obtained after grinding;

[0029] Apply glaze slurry to the cooled bisque, and scrape the bottom of the bisque;

[0030] The glazed biscuit blank is fired in a kiln, and after low-temperature firing, medium-temperature firing and high-temperature firing, the temperature is lowered, and the kiln is opened to obtain crystal ice cracked porcelain. During the preparation of the present application, the blank is made into a bisque-fired blank, and the bisque-fired blank is reddish-brown. After firing, it cooperates with the g...

Embodiment 1

[0040] A preparation method of crystal ice cracked porcelain, comprising the following steps:

[0041] Glaze: potassium feldspar 2.8kg, albite 2.8kg, limestone 1kg, purple gold soil 0.2kg, fluorite 0.05kg, zinc oxide 0.05kg and barium carbonate 0.2kg.

[0042] Billet: purple gold soil (the mass ratio of lion cage purple gold soil: dayao purple gold soil is 1:3) 5.2kg and kaolin 2.4kg.

[0043] After grinding the raw material of the billet, add water to wet grinding, and then make the billet mud, dry and shape, and put it in a kiln for biscuit firing at 850 °C;

[0044] After mixing the glaze raw materials, wet ball milling the ball stones, glaze mixed raw materials and water according to the mass ratio of 1.5:0.5:0.2, grinding for 18h, and passing through an 80-mesh sieve to obtain a glaze slurry with a Baume degree of 45. ;

[0045] Apply the bottom glaze to the cooled bisque-fired blank first, and then spray glaze on the surface, so that the thickness of the glaze layer on...

Embodiment 2

[0048] A preparation method of crystal ice cracked porcelain, comprising the following steps:

[0049] Glaze: potassium feldspar 3.6kg, albite 3.6kg, limestone 1.2kg, purple gold soil 0.2kg, fluorite 0.08kg, zinc oxide 0.08kg and barium carbonate 0.3kg.

[0050] Billet: purple gold soil (the mass ratio of lion cage purple gold soil: dayao purple gold soil is 1:3.2) 5.8kg and kaolin 3kg.

[0051] After grinding the raw material of the billet, add water to wet grinding, and then make the billet mud, dry and shape, and put it into a kiln for biscuit firing at 860 °C;

[0052] After the glaze raw materials are mixed, the balls, the glaze mixed raw materials and water are subjected to wet ball milling according to the mass ratio of 2:1:0.6, ground for 19 hours, and passed through a 150-mesh sieve to obtain a glaze slurry with a Baume degree. is 48;

[0053] Apply the bottom glaze to the cooled bisque blank first, and then spray the glaze on the surface, so that the thickness of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com