Drying method for hollow ceramic solar panel matrix biscuits formed by slip casting

A ceramic solar panel, grouting molding technology, applied in the direction of progressive dryer, drying gas arrangement, drying, etc., to achieve low cost of use, simple structure, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

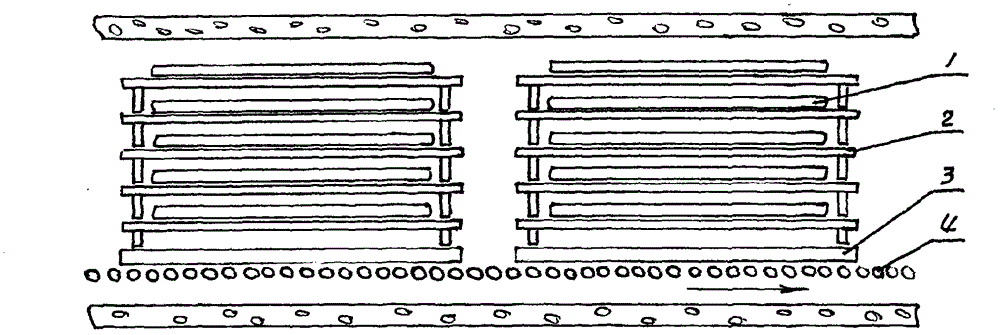

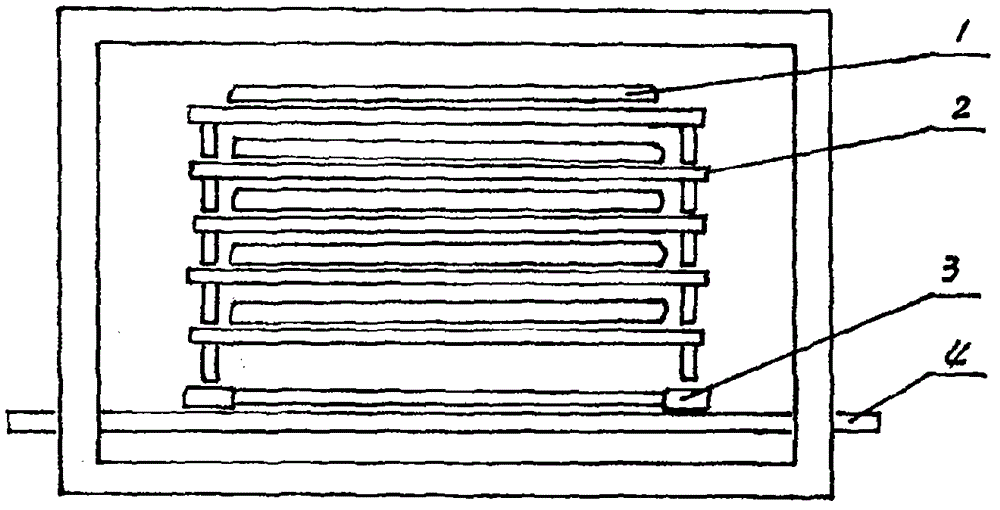

[0030] 1. The drying equipment for hollow ceramic solar panel base body is channel-type continuous drying equipment, which uses rotating steel rollers as the operating power. The steel rollers have a diameter of 60 mm and a length of 3 meters. The length of the steel rollers in the channel is 2500 mm. The roller table is formed, and the roller table is at the bottom of the channel-type drying equipment; ordinary ceramic slurry is used for grouting in the gypsum mold to form a wet hollow ceramic solar panel substrate green body, the water content of the green body is 16%, and the length of the green body is 912 mm , width 912 mm, total thickness 36 mm, wall thickness 3 mm, the wet hollow ceramic solar panel base blank is turned over from the opened gypsum mold to the pallet, and 6 pieces of wet hollow ceramic solar panel base blanks are placed Put the pallets up and down in a stack in turn, put two rows of pallets with wet hollow ceramic solar panel substrate blanks on the entra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com