A metal glaze prepared by recycling iron impurities from sanitary ceramics and its method

A technology for sanitary ceramics and iron recovery, applied in the field of sanitary ceramics, can solve problems such as wasting resources and affecting the environment, achieve energy saving, meet diversified needs, and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

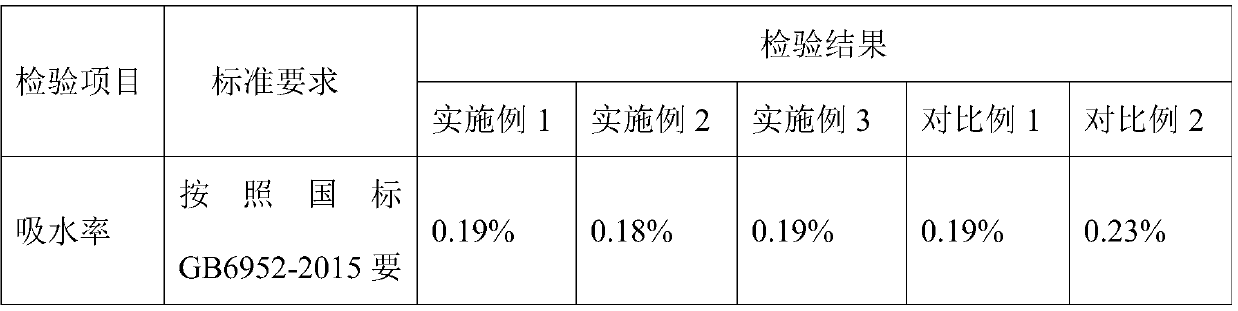

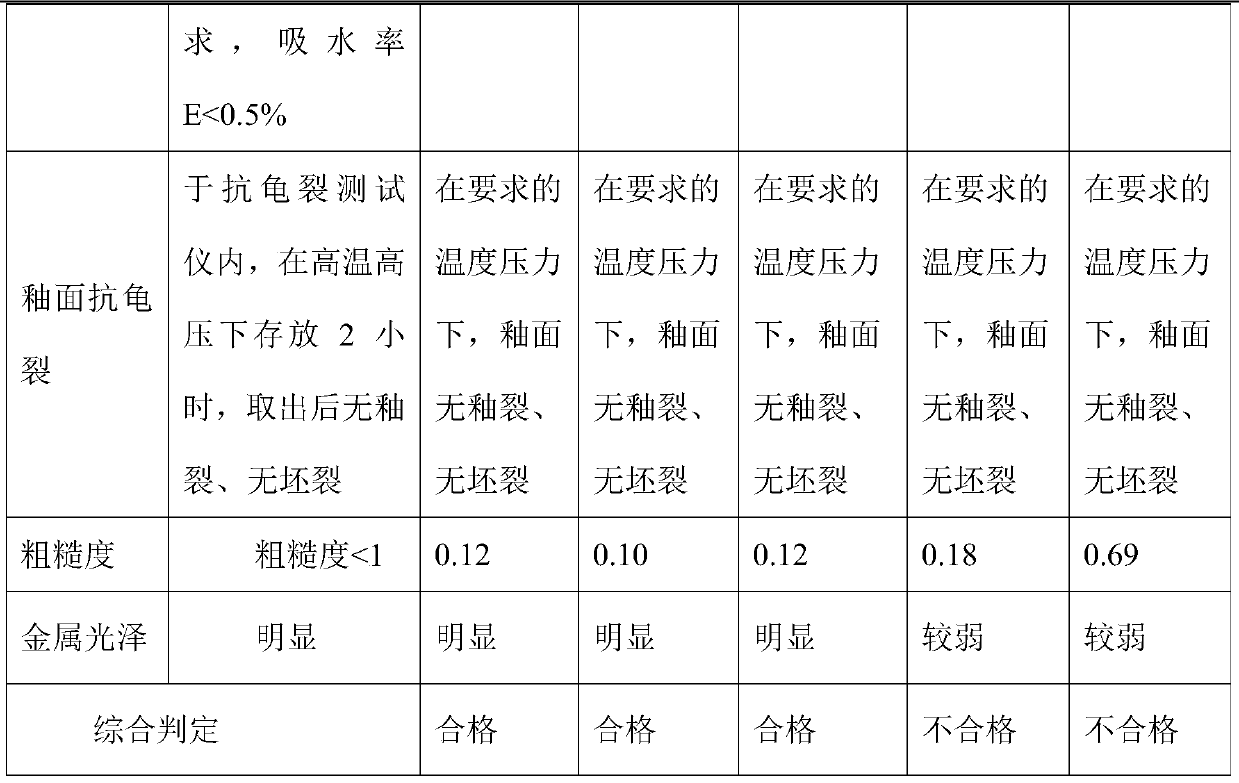

Examples

Embodiment 1

[0025] The mass percent composition of metal glaze raw materials is: 36.1% of quartz, 2.7% of iron phosphate, 7.1% of aluminum oxide, 5.1% of calcite, 13.9% of albite feldspar, 8.0% of kaolin, 22.6% of glass powder, 3.0% iron impurities and 1.5% copper oxide are recovered from sanitary ceramics, the sum of the above components is 100%, and then CMC (sodium carboxymethyl cellulose) not exceeding 2% of the total mass of the above components is added. Among them, the recovery of iron impurities in sanitary ceramics is to pass the iron impurities recovered by the conventional sanitary ceramics iron removal process through an 80-mesh sieve to remove large particles of impurities, and then calcine at 350°C to remove organic impurities, grease and other pollutants, and then Grind to a particle size ranging from 100 mesh to 250 mesh.

[0026] Using water as the medium, mix the above ratio of quartz, aluminum oxide, calcite, albite, kaolin, glass powder, copper oxide and sodium carboxy...

Embodiment 2

[0028] The mass percent composition of metal glaze raw materials is: 36.5% quartz, 2.5% iron phosphate, 7.3% aluminum oxide, 5.3% calcite, 13.7% albite, 8.1% kaolin, 21.6% glass powder, 3.5% iron impurities recovered from sanitary ceramics and 1.5% copper oxide, the sum of the above components is 100%, and then CMC (sodium carboxymethyl cellulose) not exceeding 2% of the total mass of the above components is added. Among them, the recovery of iron impurities in sanitary ceramics is to pass the iron impurities recovered by the conventional sanitary ceramics iron removal process through an 80-mesh sieve to remove large particles of impurities, and then calcine at 400°C to remove organic impurities, grease and other pollutants, and then Grind to a particle size ranging from 100 mesh to 250 mesh.

[0029] Using water as the medium, mix the above ratio of quartz, aluminum oxide, calcite, albite, kaolin, glass powder, copper oxide and sodium carboxymethyl cellulose into a ceramic ba...

Embodiment 3

[0031] The mass percent composition of metal glaze raw materials is: 36.6% quartz, 2.3% iron phosphate, 7.3% aluminum oxide, 5.8% calcite, 14.1% feldspar, 8.2% kaolin, 20.1% glass powder, 3.9% Iron impurities and 1.7% copper oxide recovered from the sanitary ceramics, the sum of the above components is 100%, and then CMC (sodium carboxymethylcellulose) not exceeding 2% of the total mass of the above components is added. Among them, the recovery of iron impurities in sanitary ceramics is to pass the iron impurities recovered by the conventional sanitary ceramics iron removal process through an 80-mesh sieve to remove large particles of impurities, and then calcine at 400°C to remove organic impurities, grease and other pollutants, and then Grind to a particle size ranging from 100 mesh to 250 mesh.

[0032]Using water as the medium, mix the above ratio of quartz, aluminum oxide, calcite, albite, kaolin, glass powder, copper oxide and sodium carboxymethyl cellulose into a cerami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tackiness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com