Method for preparing high-performance foamed ceramic by combining template method with chemical vapor infiltration method

A technology of chemical vapor infiltration and foamed ceramics, applied in the field of foamed ceramics preparation, can solve the problems of high sintering temperature, unfavorable for large-scale industrial production, low strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

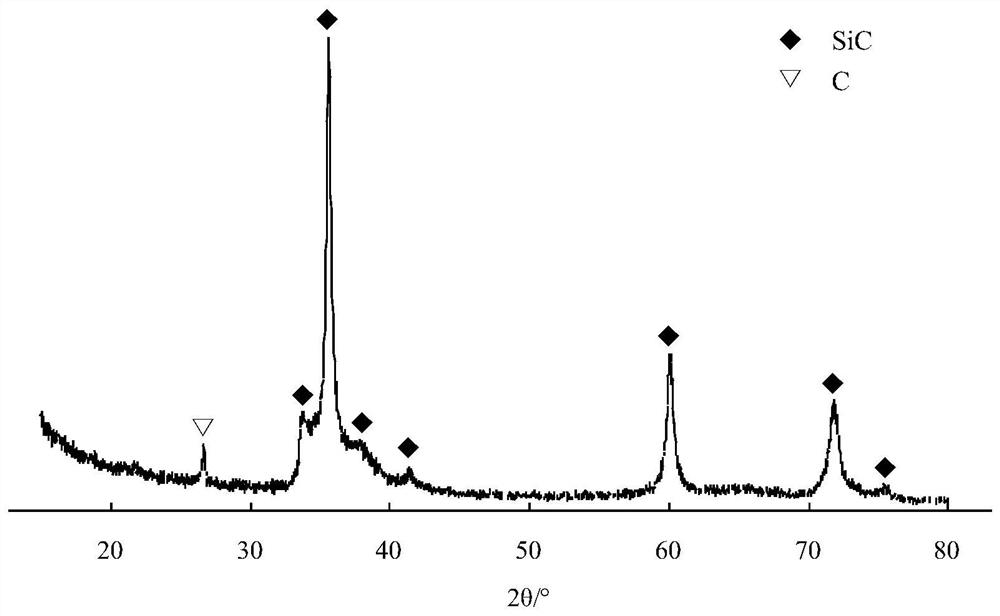

[0048] The method for preparing high-performance silicon carbide foamed ceramics by template method combined with chemical vapor infiltration process comprises the following steps:

[0049] (1) With high-purity silicon carbide powder (particle size d50=0.05 μm, purity: 99%) and ethanol, binder, defoamer, plasticizer, dispersant, with a mass ratio of 30wt%: 60wt%: 3wt%: 2wt%: 3wt%: 2wt% After mixing, put it into a ball mill jar and mill it for 12 hours;

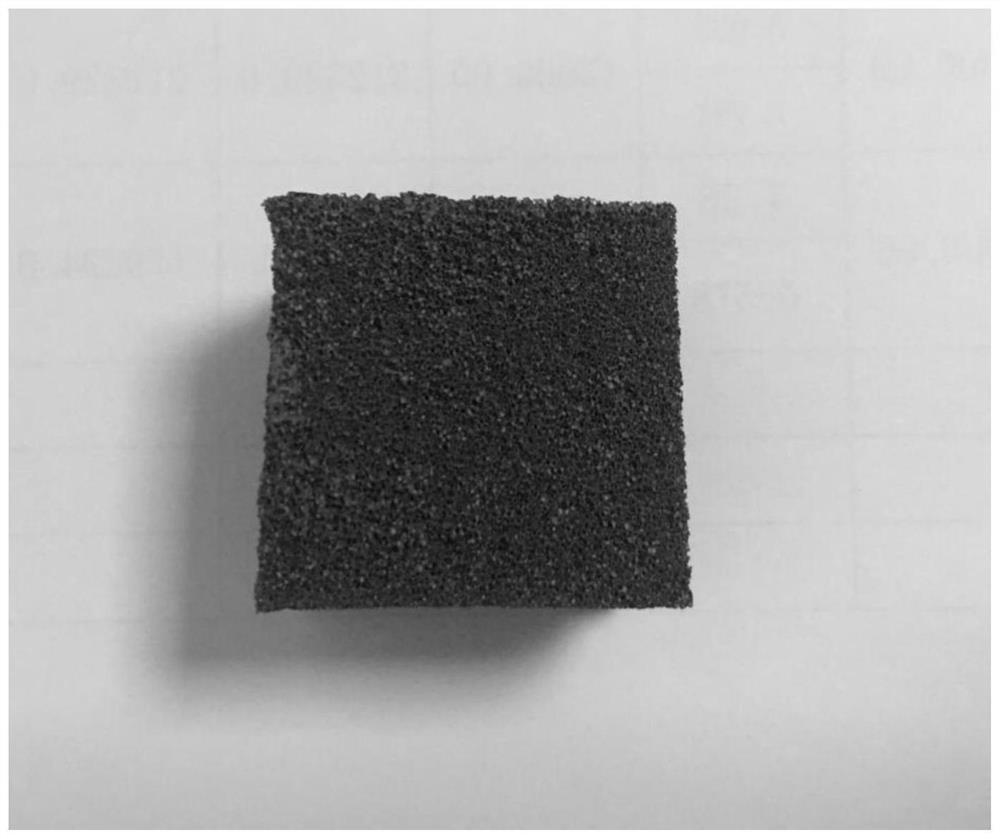

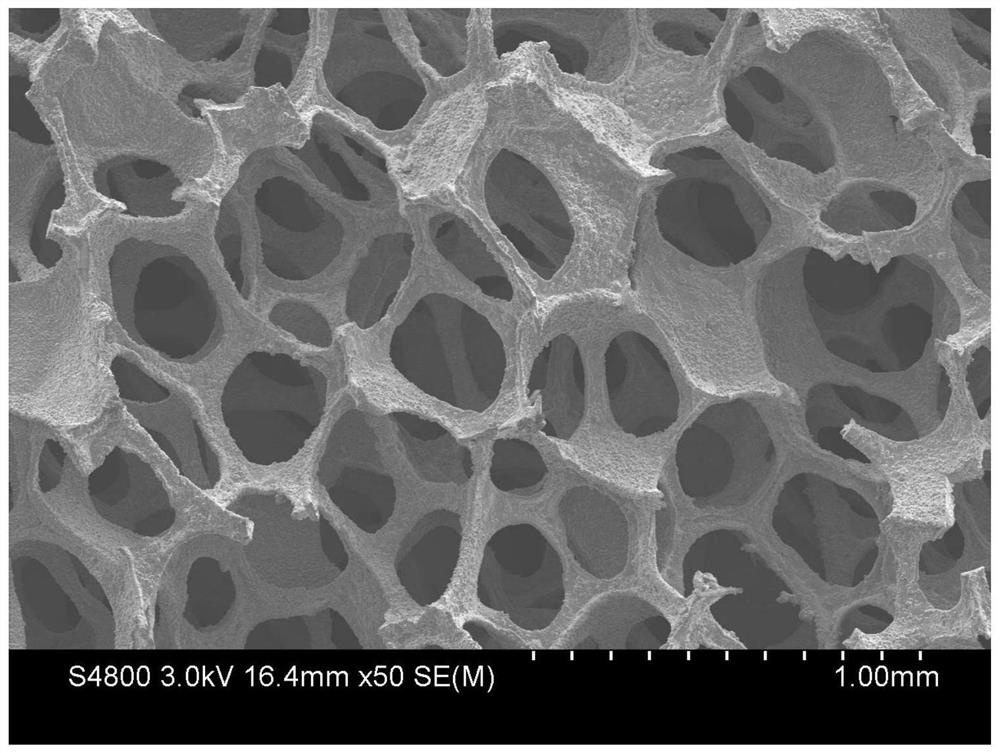

[0050] (2) Take the polyurethane foam and cut it into a cube shape as a template, soak the slurry, then remove the excess slurry by extrusion, place it in an air environment at 30°C for 72 hours, make it fully dry, and obtain a foam prefabricated body;

[0051] (3) Place the foam prefabricated body after slurry drying in a tube furnace, and perform pyrolysis-oxidation treatment in an air atmosphere at a heating rate of 0.5°C / min, from room temperature to 300°C, and keep it warm for 2 hours. Then continue to heat up to 450°C a...

Embodiment 2

[0055] The method for preparing high-performance silicon carbide foamed ceramics by template method combined with chemical vapor infiltration process comprises the following steps:

[0056] (1) Silicon carbide whiskers (diameter = 1 μm, aspect ratio 10-15, purity: 99%) and ethanol, methyl ethyl ketone, binder, defoamer, plasticizer, dispersant, with a mass ratio of 30wt %: 30wt%: 30wt%: 3wt%: 2wt%: 3wt%: 2wt% After mixing, put it into a ball mill jar and mill it for 18 hours;

[0057] (2) Take the polyurethane foam and cut it into a cube shape as a template, soak the slurry, then remove the excess slurry by extrusion, place it in a drying oven at 50°C for 48 hours, make it fully dry, and obtain a foam prefabricated body;

[0058] (3) Place the foam prefabricated body after slurry drying in a tube furnace, and perform pyrolysis-oxidation treatment in an air atmosphere at a heating rate of 0.5°C / min, from room temperature to 300°C, and keep it warm for 2 hours. Then continue to...

Embodiment 3

[0063] The method for preparing high-performance silicon nitride foamed ceramics by template method combined with chemical vapor infiltration process comprises the following steps:

[0064] (1) Silicon nitride whiskers (diameter = 1 μm, aspect ratio 5-10, purity: 95%) and ethanol, methyl ethyl ketone, toluene, binder, defoamer, plasticizer, dispersant, and Mass ratio 40wt%: 15wt%: 15wt%: 15wt%: 4wt%: 3wt%: 4wt%: 4wt% After mixing, put it into a ball mill jar and mill for 12 hours;

[0065] (2) Take the polyurethane foam and cut it into a cube shape as a template, soak the slurry, then remove the excess slurry by extrusion, place it in an air environment at 30°C for 72 hours, make it fully dry, and obtain a foam prefabricated body;

[0066] (3) Place the foam prefabricated body after slurry drying in a tube furnace, and perform pyrolysis-oxidation treatment in an air atmosphere. The heating rate is 0.1°C / min, and the temperature is raised from room temperature to 300°C, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com