Bearing structure suitable for large combined water slide table

A horizontal slide table and combined technology, which is applied in the testing of machines/structural components, measuring devices, vibration testing, etc., can solve the problems of insufficient assessment of spacecraft products and the inability to fully expose product design and manufacturing defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The bearing layout method applicable to the large-scale combined horizontal slide table of the present invention will be further described below in conjunction with the accompanying drawings. This description is only exemplary and is not intended to limit the protection scope of the present invention.

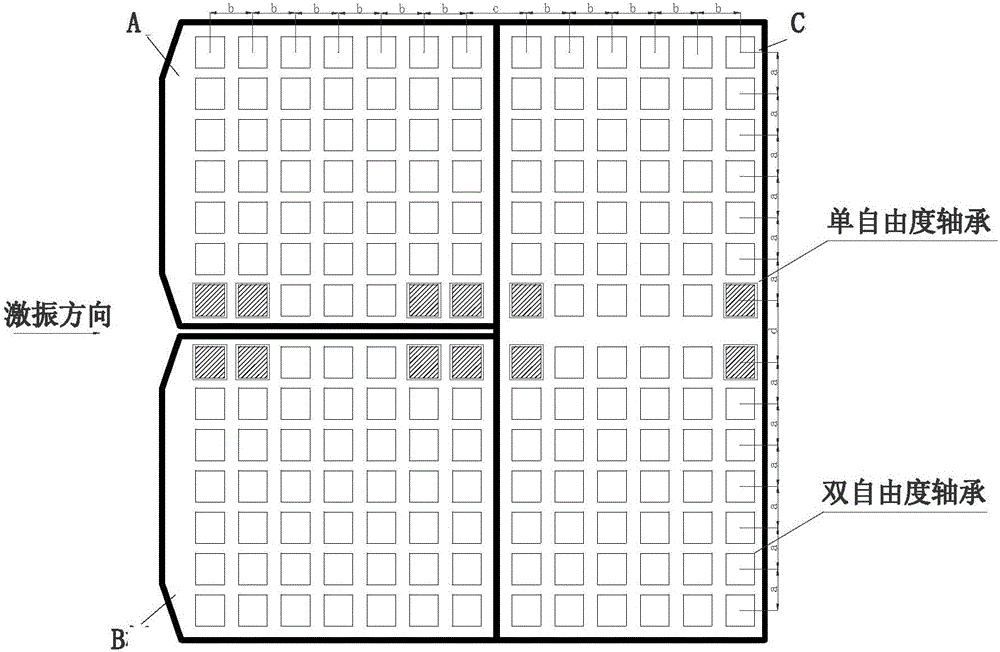

[0017] figure 1 It shows the bearing structure of the present invention suitable for large combined water slide table. The bearing structure includes a bearing structure for a large-scale combined horizontal slide table, including a base, a bearing plate supported on the base, and several bearings arranged on the bearing plate. The large-scale combined horizontal slide table is composed of three sliding tables. And it has an excitation direction, in which two sliding tables A and B are connected with another sliding table C in parallel, and several bearings on the bearing plate are connected with the first support area, the second support area, and the third support area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com