Star drill crackle glaze, glaze slip and ceramic thereof

A cracked glaze and ceramic technology, applied in the field of ceramics, can solve the problems of limited application, difficult cleaning, single decorative effect, etc., and achieve the effect of overcoming easy dirt absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] In some examples of star-diamond cracked ceramics, the preparation method includes: body process: mixing the star-diamond crack glaze described in the first aspect of the present invention or the star-diamond crack glaze slurry described in the second aspect of the present invention into Or digitally positioned cloth into the whole body or thin layer of cloth, pressed into shape, applied with transparent glaze, fired, fully polished, semi-polished or unpolished.

[0070] In some examples of star-diamond cracked ceramics, the preparation method includes: glaze process: directly on the blank or surface glaze, through the production method of spraying glaze or glazing combined with other materials to locate or apply on the whole surface of the invention. The star-diamond crack glaze described in the aspect, or the star-diamond crack glaze slurry described in the second aspect of the present invention, is glazed, fired, fully polished, semi-polished or not polished.

[0071...

Embodiment S1

[0080] Process flow: green body → inkjet design → star diamond crack glaze spray → full polishing glaze spraying → firing → full polishing

[0081] The glaze thickness of star diamond crack glaze is 0.8mm, and the thickness of transparent polishing glaze is 0.3mm. A brick surface with a star diamond crack effect with a smooth glazed surface and a good antifouling effect is obtained.

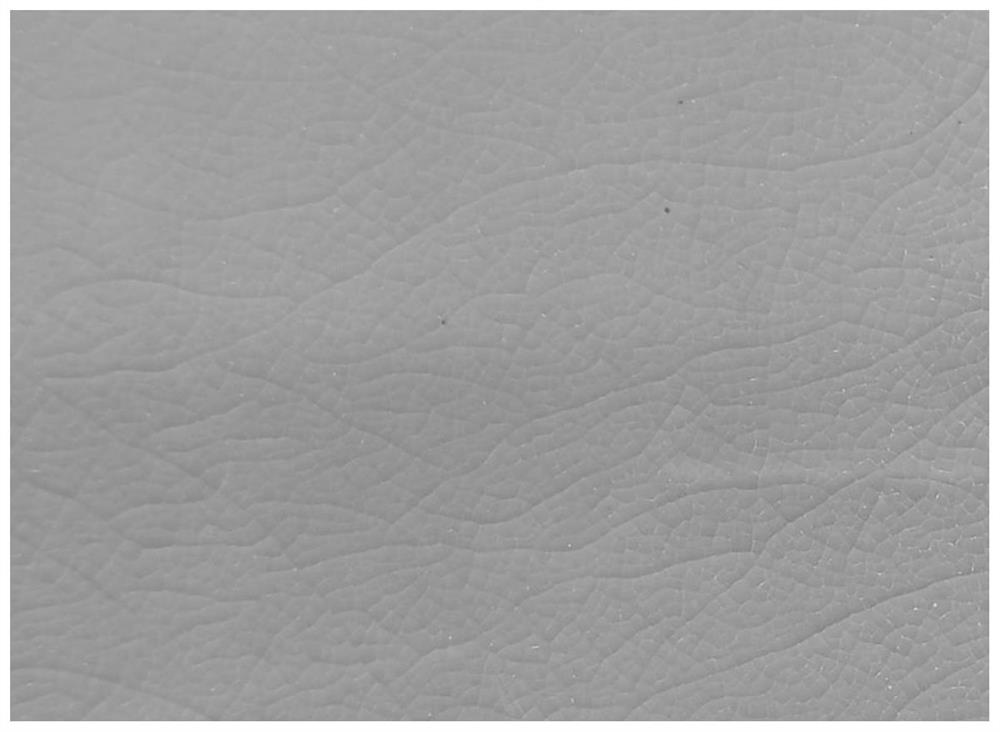

[0082] fired tile samples such as figure 1 shown.

Embodiment S2

[0084] Process flow: green body → inkjet design → star diamond crack glaze spray → full polishing glaze spraying → firing → full polishing

[0085] The glaze thickness of star diamond crack glaze is 0.8mm, and the thickness of transparent polishing glaze is 0.3mm. A brick surface with a star diamond crack effect with a smooth glazed surface and a better antifouling effect is obtained.

[0086] fired tile samples such as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com