Ceramic glaze spraying device with dust collecting function

A technology for dust collection and ceramics, which is applied to the field of ceramic glaze spraying devices with dust collection function, can solve the problems of deviation of spraying direction of atomized glaze slurry, influence on spraying effect, huge structure, etc. Post-processing, compact overall size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

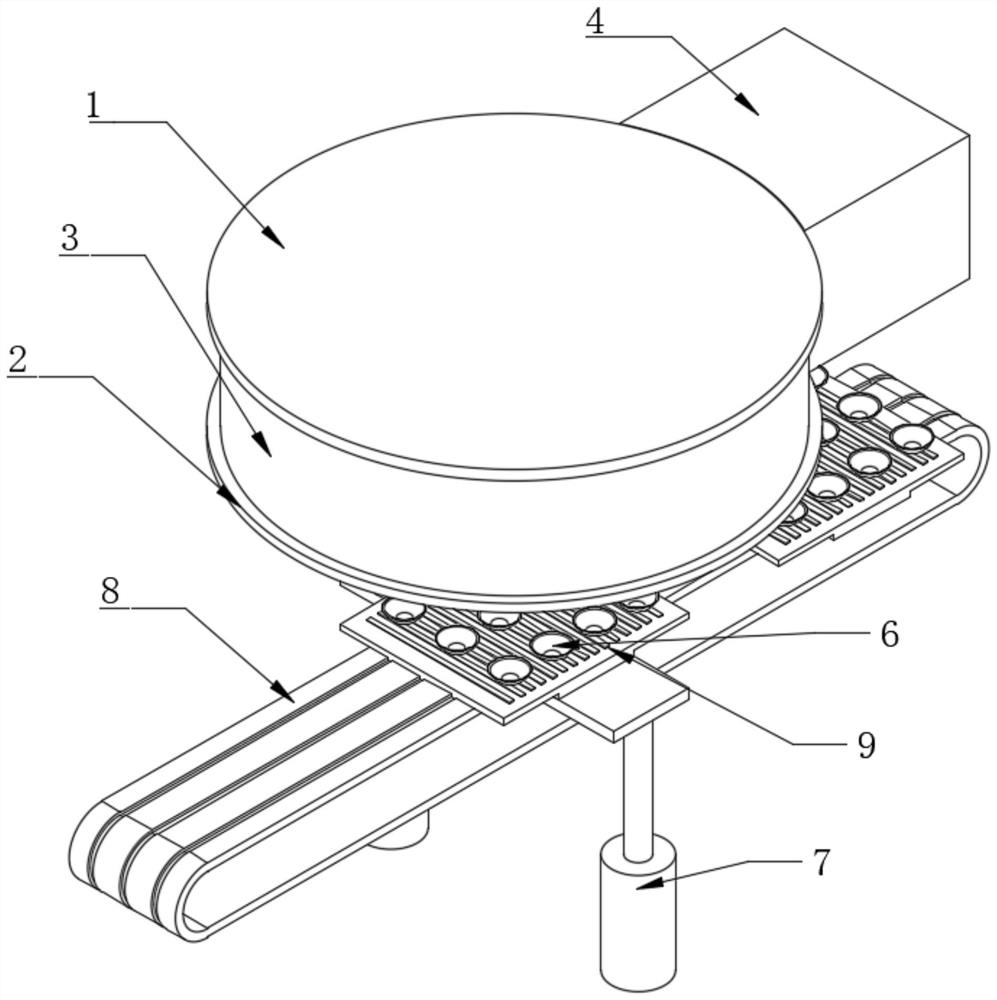

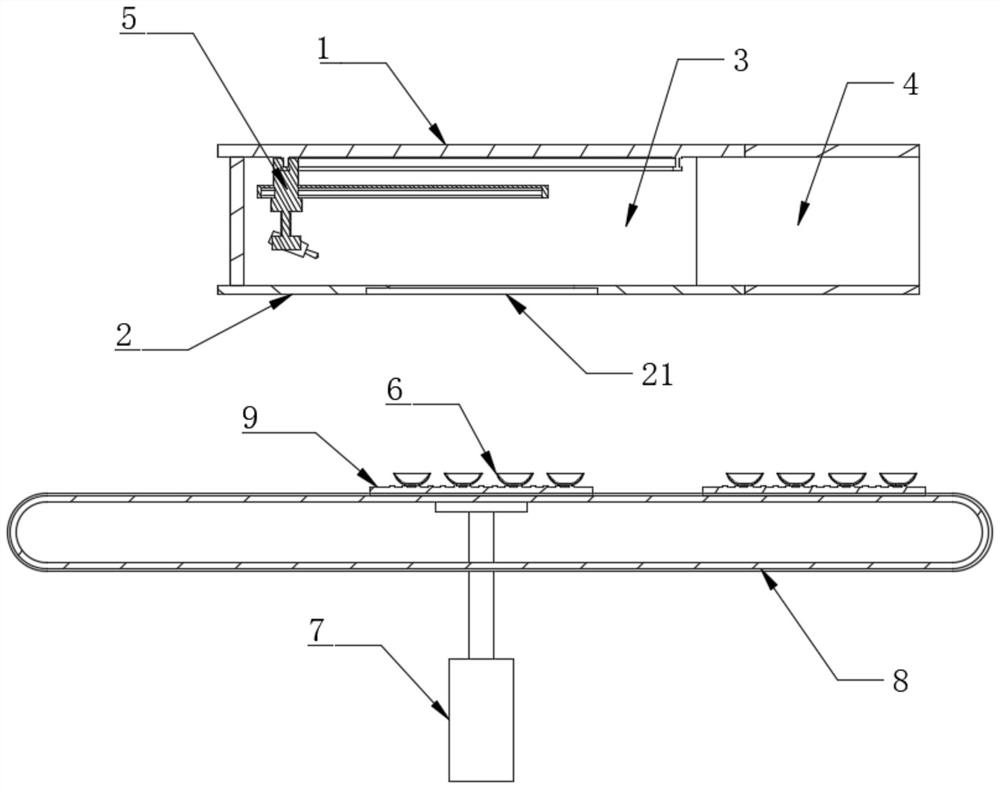

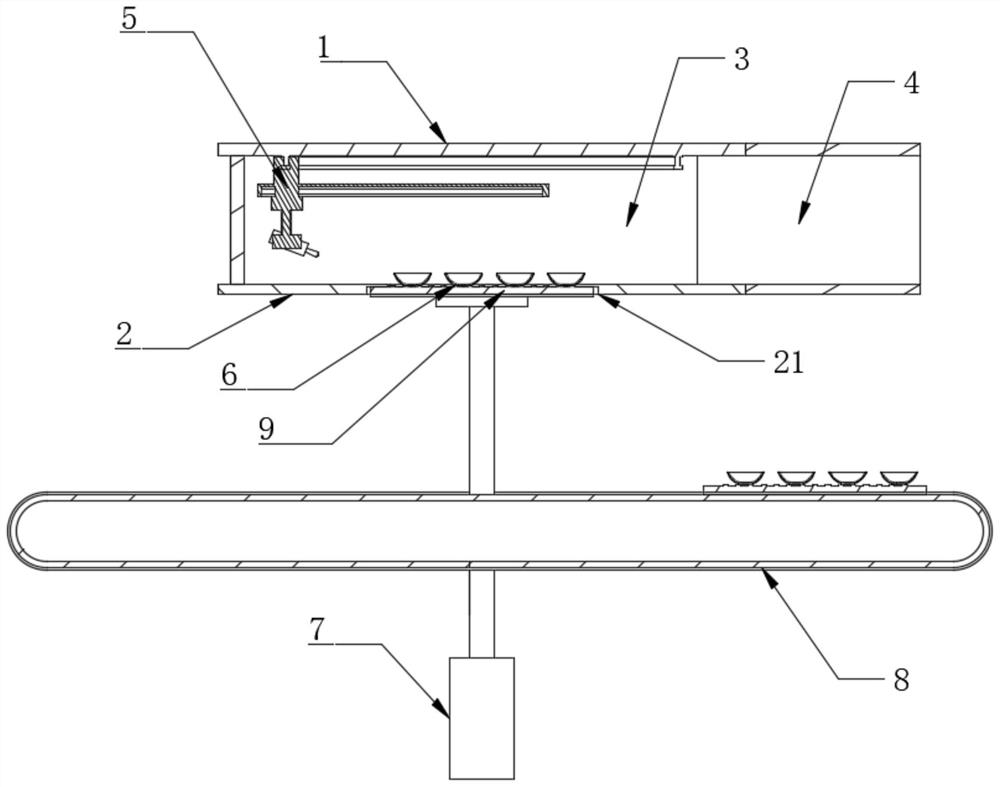

[0022] like Figure 1-6 As shown, the present invention includes an upper baffle 1, a lower baffle 2, and an annular side plate 3 rotatably arranged between the upper baffle 1 and the lower baffle 2, and also includes a power member for driving the annular side plate 3 to rotate. The annular side plate 3 is provided with an exhaust channel 4 extending outward, the upper partition 1 is provided with a glaze spray assembly 5, and the lower partition 2 is provided with an installation port 21 for installing ceramics 6, and the glaze spray assembly 5 includes a nozzle 51 and the annular driving member that drives the spray head 51 to rotate around the installation port 21, the exhaust passage 4 always corresponds to the direction of the spray head 51.

[0023] In the present invention, an annular side plate 3 is arranged between the upper partition plate 1 and the lower partition plate 2, and an exhaust channel 4 corresponding to the direction of the glaze spraying nozzle 51 is ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com