Pin header forming equipment for optical fiber connector and forming method thereof

A technology for optical fiber connectors and molding equipment, which is applied in grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, metal processing equipment, etc., and can solve cumbersome operations, low automation, and non-linkage between fixtures and polishing main parts And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

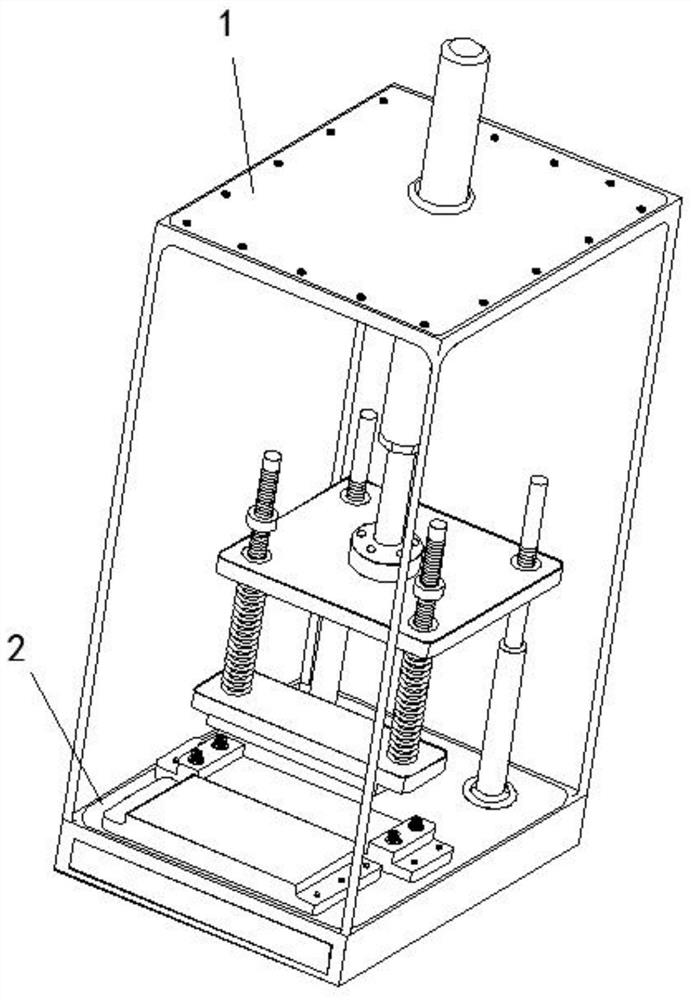

[0044] Such as Figure 1-6 As shown, the pin header forming equipment for optical fiber connectors includes a support frame 1 and a polishing main part 2; a supporting frame 1 is arranged above the polishing main part 2, and the supporting frame 1 is connected with the polishing main part 2 for supporting polishing Main piece 2.

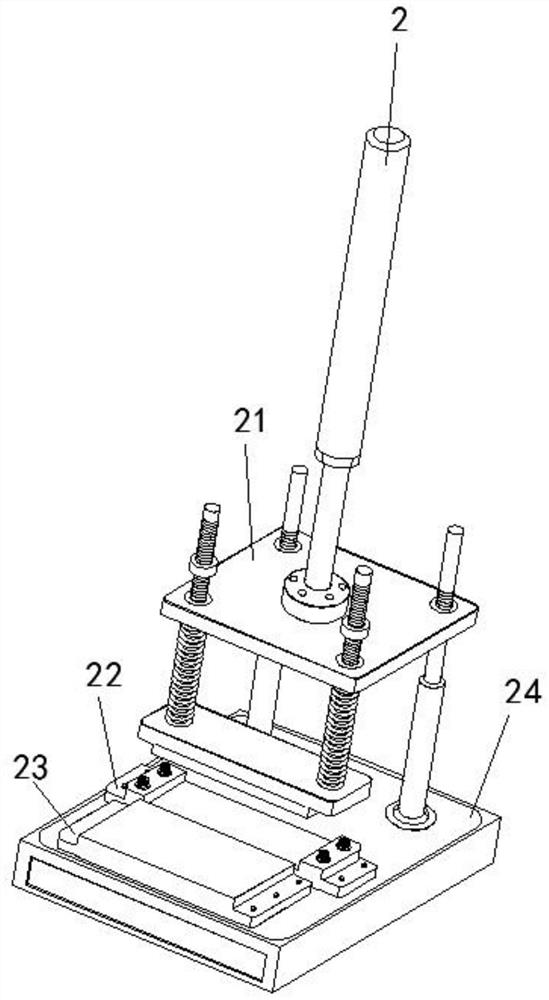

[0045] The polishing main part 2 includes a stamping assembly 21, and an isolation base 24 is provided under the stamping assembly 21. The isolation base 24 is plugged and connected with the stamping assembly 21, and is used to pump air into the isolation base 24. The stamping assembly 21 is connected to the support frame 1. The upper top phase is fixedly connected; the top of the isolation base 24 is provided with a material platform 22, and the material platform 22 is located below the stamping assembly 21, and is used for the stamping assembly 21 to be in contact with the material platform 22 during the plugging action relative to the isolation ba...

Embodiment 2

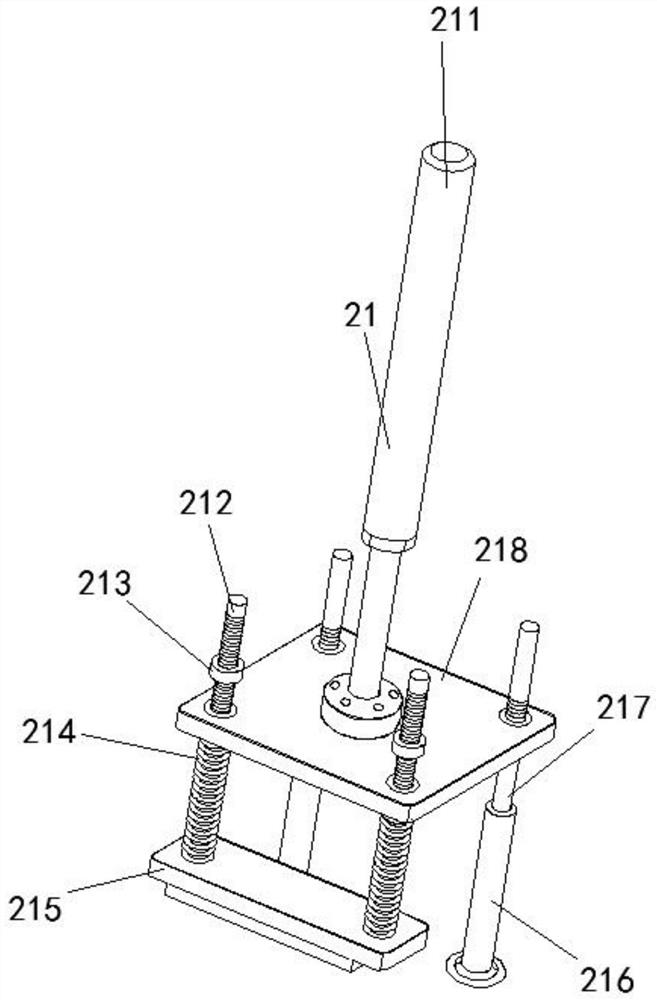

[0050] Such as Figure 1-6 As shown, the pin row forming equipment used for optical fiber connectors, the stamping assembly 21 includes a platen 218, the platen 218 is located above the isolation base 24 and is parallel to the isolation base 24, and the top of the platen 218 is provided with a pneumatic drive member perpendicular to it 211, the pneumatic drive part 211 is fixedly connected to the top of the support frame 1, the pneumatic drive part 211 includes a pneumatic sleeve and a drive rod, wherein the pneumatic sleeve is fixedly connected to the top of the support frame 1, and the drive rod is placed in the pneumatic sleeve , and its lower end is connected with the platen 218 for driving the platen 218 to move up and down.

[0051] A briquetting block 215 is arranged above the material table 22, and two parallel threaded rods 212 are arranged symmetrically on the top of the briquetting block 215. The threaded rods 212 are movably interspersed with the platen 218 and ext...

Embodiment 3

[0059] Such as Figure 1-6 As shown, the isolation base 24 includes a support box 242 for the needle row forming equipment for optical fiber connectors. The support box 242 is connected with the support frame 1 to form an integrated frame. Below the plate 241, a spacer 243 is arranged in the support box 242. The ends on both sides of the spacer 243 are fixed to the two ends of the support box 242, and are used to divide the inner cavity of the support box 242 into two. The top of the spacer 243 Contradicting against the bottom of the supporting plate 241, the separator 243 divides the inner cavity of the support box 242 into an air blowing cavity and a collecting cavity, and the grinding assembly 23 is inserted into the collecting cavity.

[0060] Wherein, the grinding assembly 23 includes a grinding medium box 234, the grinding medium box 234 is inserted into the support plate 241, and extends upward relative to the support plate 241, and a cover box 231 is arranged above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com