Gold foil effect particle for ceramic, ceramic, preparation method of ceramic and glaze

A particle and ceramic technology, which is applied in the field of metal luster effect particles, can solve the problems of high metal particle density, loss of metallic luster, poor acid and alkali tolerance, etc., and achieve good metallic luster, good metallic texture, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] A method for preparing ceramics, comprising:

[0063] Green body process: digitally position the foil gold effect particles on the surface of the green body, press together with the green body, fire, fully polish, semi-polish or matte polish, to obtain finished ceramics; or

[0064] Underglaze process: On the bricks that have been designed by inkjet, use dry positioning process or wet process to apply foil gold effect particles, and then use spray / spray to apply polished glaze or dry glaze, firing, full polishing, semi-glazing polished or matted to obtain finished ceramics; or

[0065] In-glaze process: Mix the foil gold effect particles with dry glaze or polished glaze evenly, and then spread it on the brick adobe with inkjet design by spraying / spraying, firing, full polishing, semi-polishing or matte polishing, to get the finished product Ceramic; or

[0066] On-glaze process: on the tiles that have been applied with polished glaze or dry glaze, adopt dry positionin...

Embodiment S1

[0087] The S1 foil gold particles are digitally positioned and distributed on the surface of the green body through a digital distributing machine, pressed, fired, and polished.

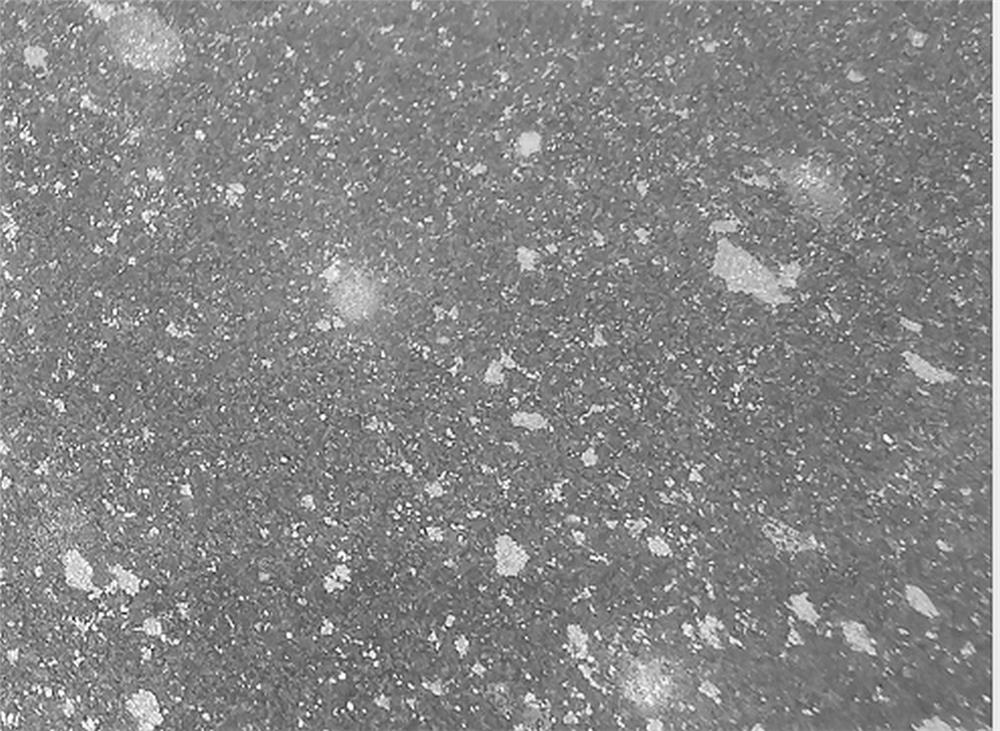

[0088] The surface of the tiles shows a strong metallic luster and has the most authentic metal texture, highlighting the atmospheric style of the tiles (see figure 1 ).

Embodiment S2

[0090] The compacting machine presses the green body once to form a green body, and uses a silk screen to print S2 gold foil particles on the green body once formed, and then performs secondary pressing, firing, and polishing.

[0091] The special metal pattern formed on the surface of the tiles adds a sense of design to the tiles and improves the grade of the tiles (see details figure 2 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com