Preparation method of fiber-reinforced sanitary ceramic green body

A sanitary ceramic and fiber-reinforced technology, which is applied in the field of preparation of fiber-reinforced sanitary ceramic blanks, can solve the problems of high cost and restrictions on the development of high-strength and high-toughness sanitary ceramics, and achieve low cost, improve the production environment, and meet the requirements of lightweight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Green body preparation:

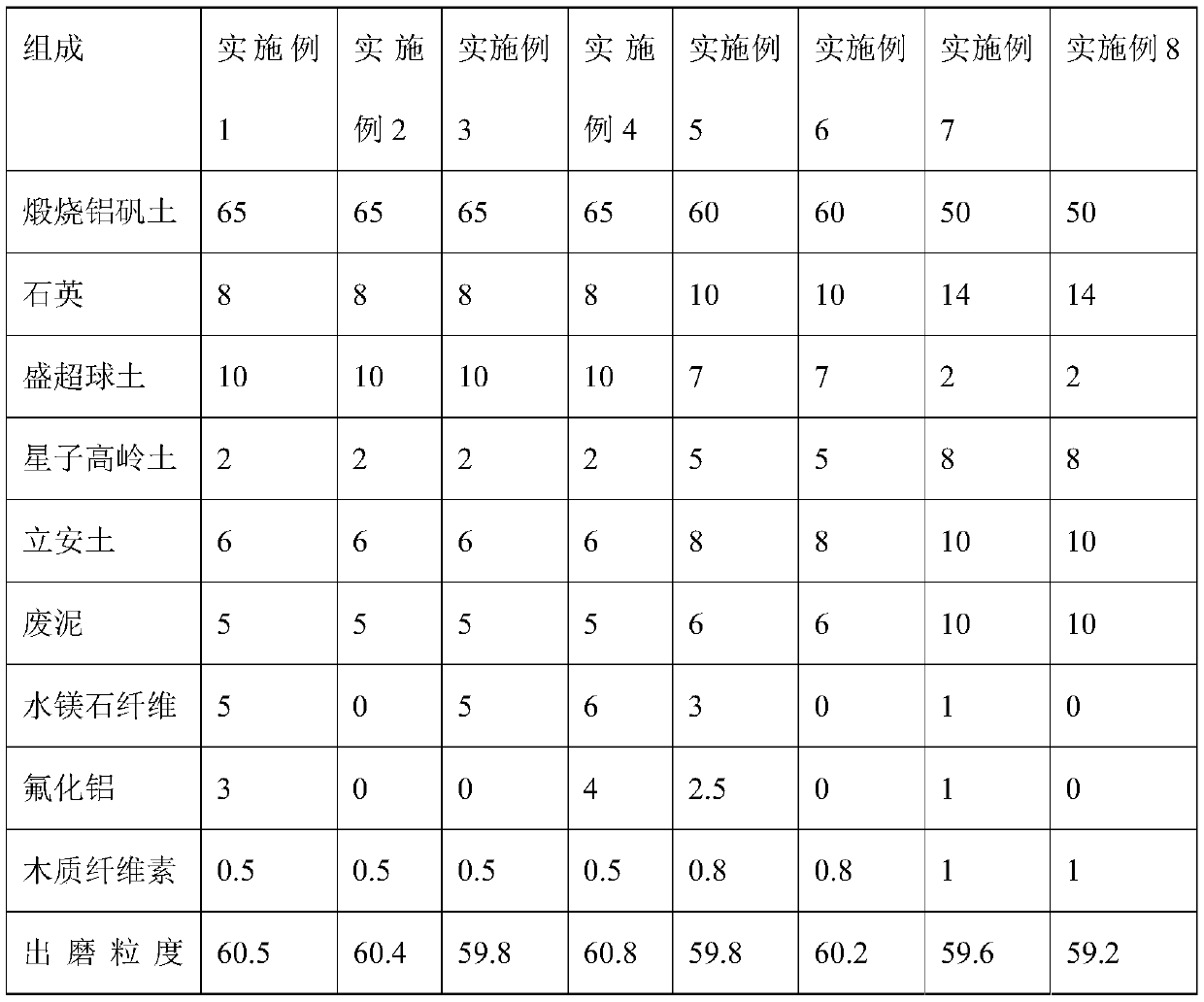

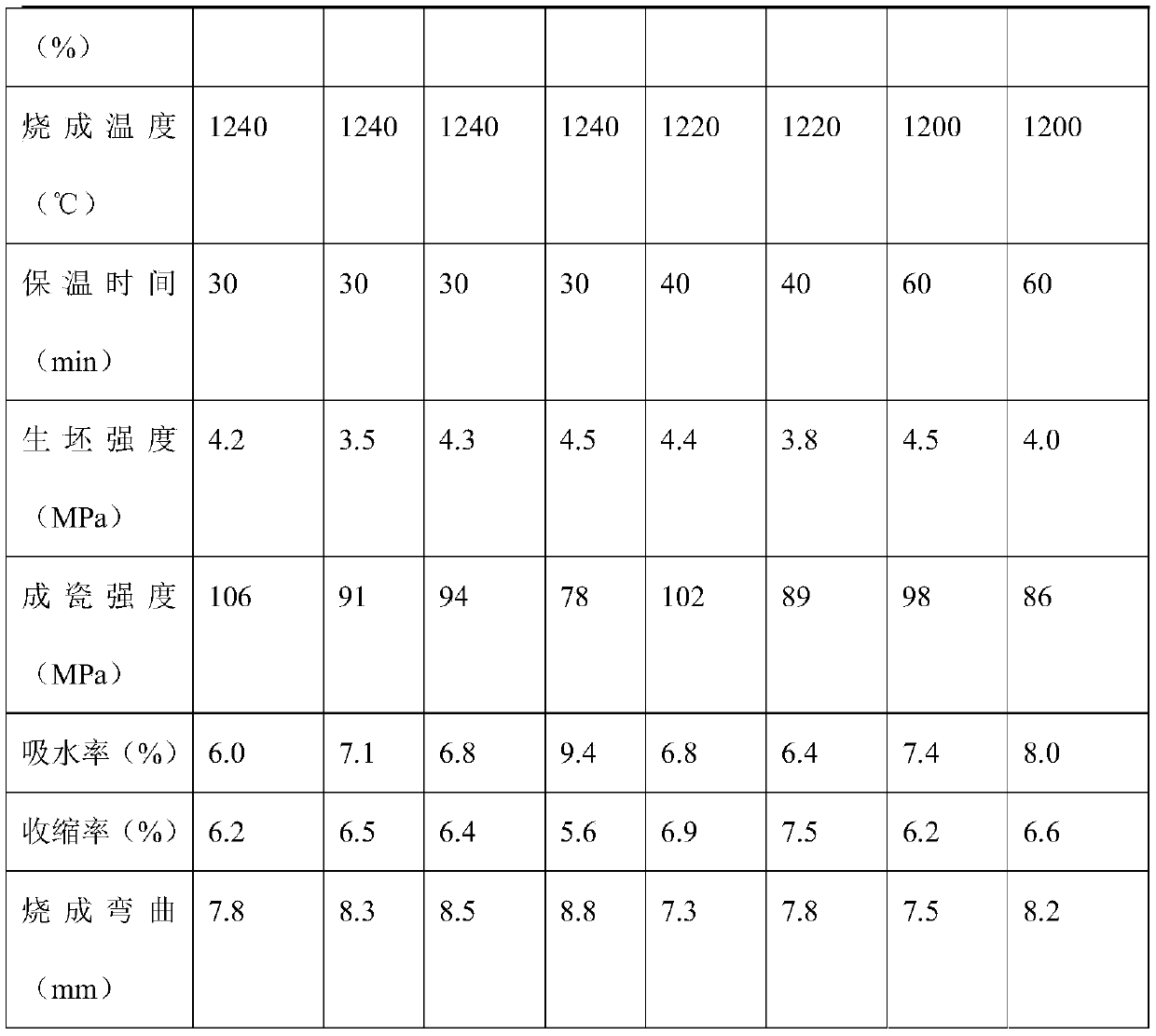

[0024] a. According to the following blank composition and mass percentage ingredients: calcined bauxite 50-70%, quartz 8-16%, Shengchao ball clay (Jiangmen Shengchao Ceramic Material Co., Ltd.) 2-10%, Xingzi kaolin (Jiangxi Xingzi) 2-8%, washed china clay (Li'an soil, Guangzhou Li'an Ceramics Industry Co., Ltd.) 6-12%, waste mud 5-15%, brucite fiber 1-5%, aluminum fluoride 1-3%; will be called Put the above-mentioned raw materials in a good amount into a horizontal ball mill, and then add an appropriate amount of alkali flour (the main component is soda) and water to wet mill the mixture until the proportion is 52-56% of <10 μm, and then add 0.5-1% wood fiber Continue ball milling until the proportion of <10μm is 58-61%, then carry out the pulping and milling. After removing iron, sieving, refining and aging to make mud for later use; at this time, the mud concentration is 365±2g / 200mL, the viscosity V0 is 68±10s / 100mL, the viscosity V30 is 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com