Sanitary ceramic and preparation method thereof

A technology for sanitary ceramics and waste ceramics, applied in the field of building decoration materials, can solve problems such as water absorption performance to be improved, poor mechanical properties, etc., and achieve the effects of improving bending strength, reducing water absorption rate, and avoiding moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

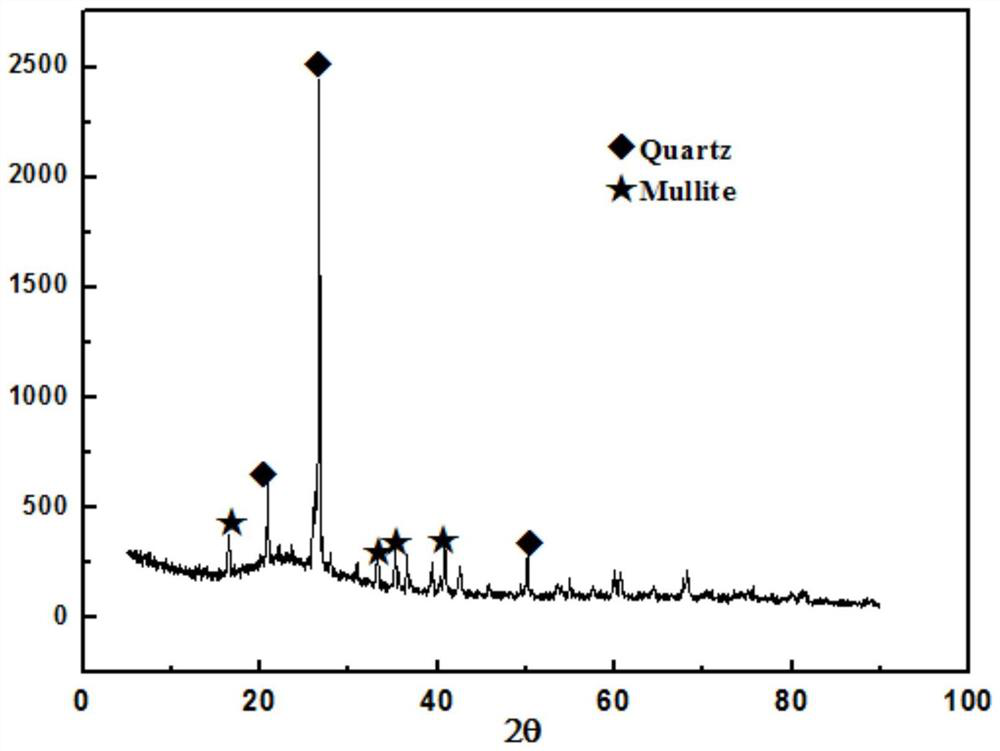

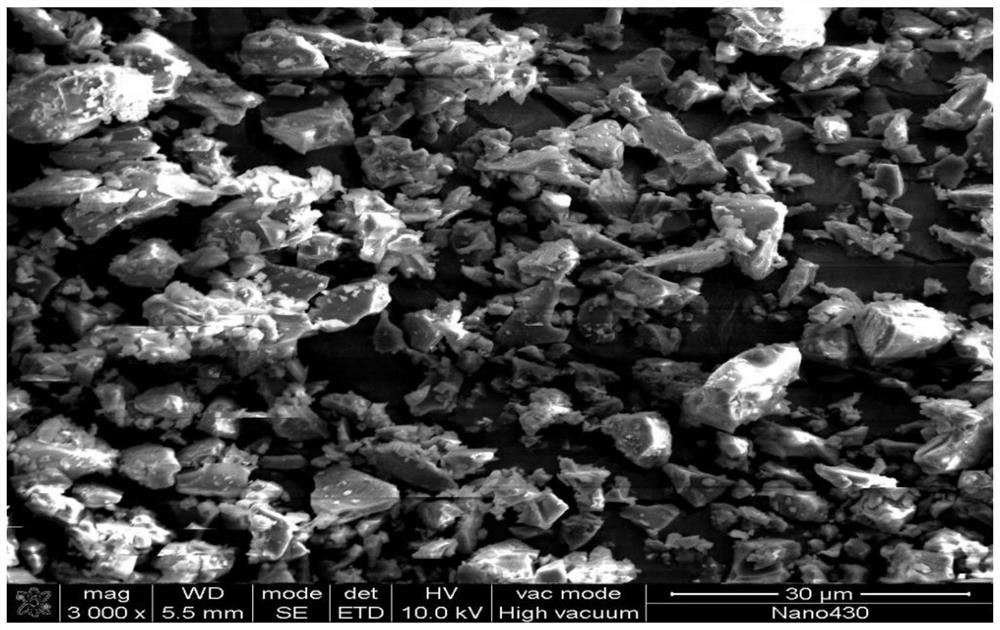

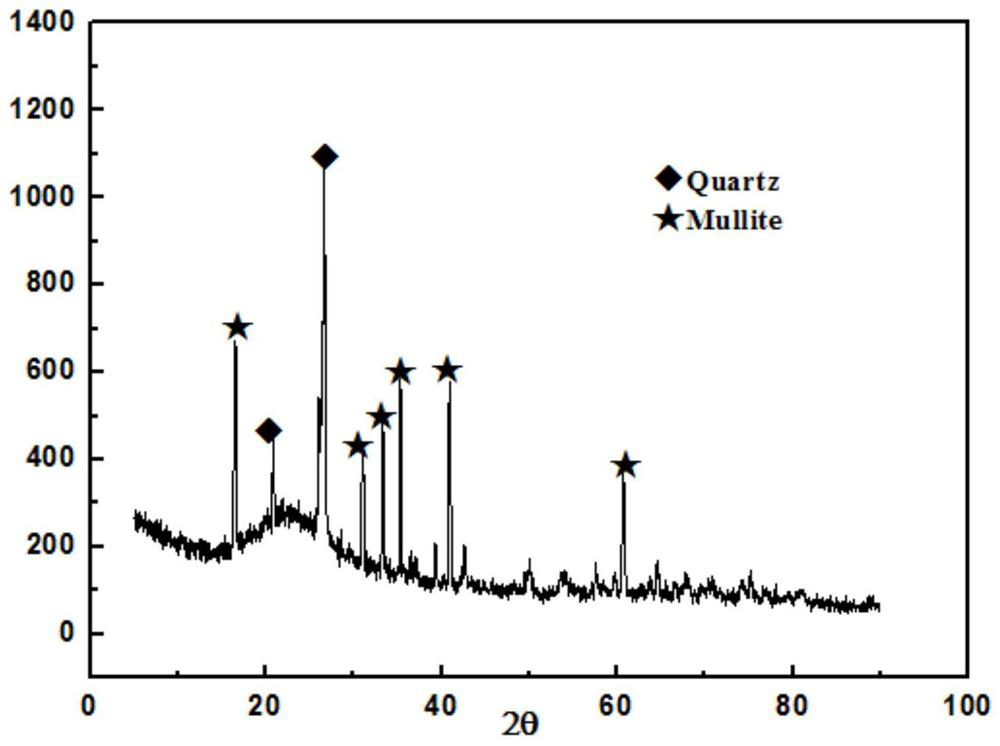

Image

Examples

Embodiment 1

[0040] The preparation method of a kind of sanitary ceramics as the embodiment of the present invention, described method comprises the following steps:

[0041] (1) 10g of albite feldspar, 23g of Xikeng mud, 10g of black clay, 2g of calcined talc, 30g of ball clay and 15g of waste ceramics were ball milled for 45 minutes until the particle size was 3 μm to 20 μm and used as solid raw materials. 0.3% of water glass is uniformly dispersed in water to make a slurry, and the waste ceramics are crushed by a crusher in advance and ball milled;

[0042] (2) After the slurry was left to stand for 24 hours, the surface of the gypsum mold was wetted and left to stand for 3 hours after grouting, and after demoulding, it was dried at 110°C to obtain a green sample;

[0043] (3) The green body sample was fired in a muffle furnace at a temperature of 1200° C. for 60 minutes to obtain the sanitary ceramics.

[0044] The Xikeng mud of this embodiment is purchased from Chaozhou Sitong Cerami...

Embodiment 2-10

[0047] The difference between embodiment 2-10 and embodiment 1 is: the ball milling time in the step (1), the firing temperature in the step (3) and the holding time under the firing temperature, the component of the solid raw material is: albite feldspar 8g, Xikeng mud 23g, black soil 8g, burnt talc 2g, ball soil 30g, waste ceramics 30g.

[0048] Embodiment 1-Example 9 designed an orthogonal experiment with 3 factors and 3 levels, and the factor levels of the orthogonal experiment are shown in Table 1. Through 9 sets of experiments, the results of orthogonal experiments can be obtained as shown in Table 2, and the range analysis is shown in Table 3.

[0049] Table 1 Orthogonal experiment factor level table

[0050]

[0051] Table 2 Orthogonal experiment results

[0052]

[0053] Table 3 range analysis table

[0054]

[0055] According to the characteristics of orthogonal experiments, the greater the range, the greater the impact of the factor level on the evaluati...

Embodiment 11

[0057] As a preparation method of sanitary ceramics according to the embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is: (1) 10 g of albite feldspar, 23 g of Xikeng mud, 10 g of black clay, 2 g of burnt talc, and ball clay 30 g and 20 g of waste ceramics were crushed to a particle size of 3 μm to 20 μm as solid raw materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com