Super-clean-light slip-stopping brick and manufacturing method thereof

A manufacturing method, ultra-clean and bright technology, applied in the field of architectural ceramics, can solve the problems of poor anti-fouling, reduced surface gloss, etc., and achieve the effect of improving safety factor, reducing fall accidents, and high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Super clean and bright non-slip glazed tile

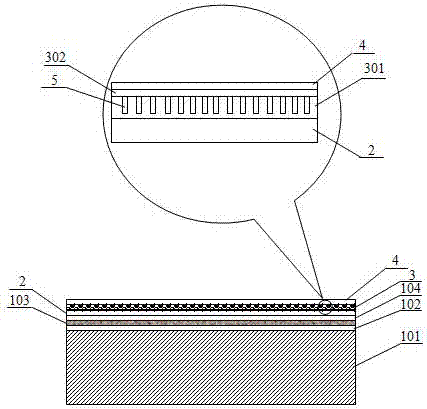

[0028] Such as figure 1 A super-clean and bright non-slip polished glazed tile includes a base layer, a super-clean and bright layer 2, a nano-scale anti-slip layer 3 and an anti-fouling layer 4 from bottom to top, and the base layer consists of a body from top to bottom. layer 101, bottom glaze layer 102, inkjet decoration layer 103 and transparent glaze layer 104; the nano-scale anti-slip layer 3 is formed on the surface of the ultra-clean bright layer 2, including the anti-slip layer 301 and repair layer 302; the anti-slip layer 301 The slippery layer 301 is formed after partial erosion of the ultra-clean and bright layer 2 by an anti-slip agent, and its surface is densely covered with micropores 5, the depth of which is no more than 10 μm; the repairing agent used in the repairing layer 302 has a particle size of 40 ~100nm, partially repair the anti-slip layer 301 to ensure the gloss and stain resistance of t...

Embodiment 2

[0039] Example 2: Super clean and bright non-slip polished tiles

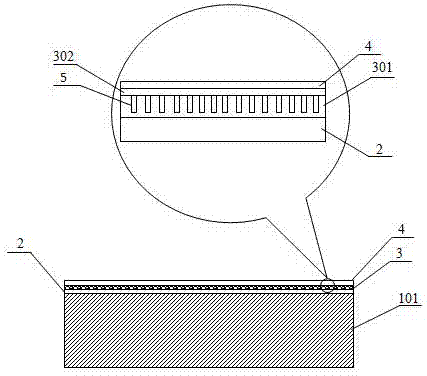

[0040] Such as figure 2 An ultra-clean and bright non-slip polished tile is shown, which respectively includes a base layer (green body layer 101), a super-clean and bright layer 2, a nano-scale anti-slip layer 3, and an anti-fouling layer 4 from bottom to top; the nano-scale anti-slip layer 3 is formed on the surface of the ultra-clean bright layer 2, including an anti-slip layer 301 and a repair layer 302; the anti-slip layer 301 is formed after partial erosion of the ultra-clean bright layer 2 by an anti-slip agent, and its surface is densely covered with micropores 5, The depth of the micropores 5 does not exceed 10 μm; the particle size of the repair agent used in the repair layer 302 is 40-100 nm, and the anti-slip layer 301 is partially repaired to ensure the gloss and stain resistance of the product.

[0041] A method for manufacturing an ultra-clean and bright non-slip polished tile, comprising the s...

Embodiment 3

[0051] Main performance tests:

[0052]

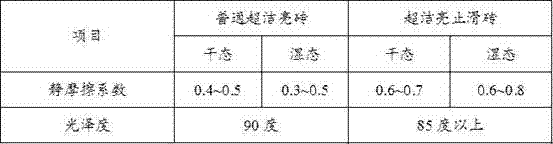

[0053] The above table is the main performance comparison table between the super clean and bright non-slip tiles of the present invention and ordinary super clean and bright tiles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com