A kind of preparation method of sand glaze sanitary ceramics

A sanitary ceramics and sanding technology, which is applied in the field of preparation of sanded glazed sanitary ceramics, can solve the problems affecting the compactness of the glaze, complicated process, high crystal refractive index, etc., and achieve the advantages of shortening the ball milling time, simple production process and low high temperature viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

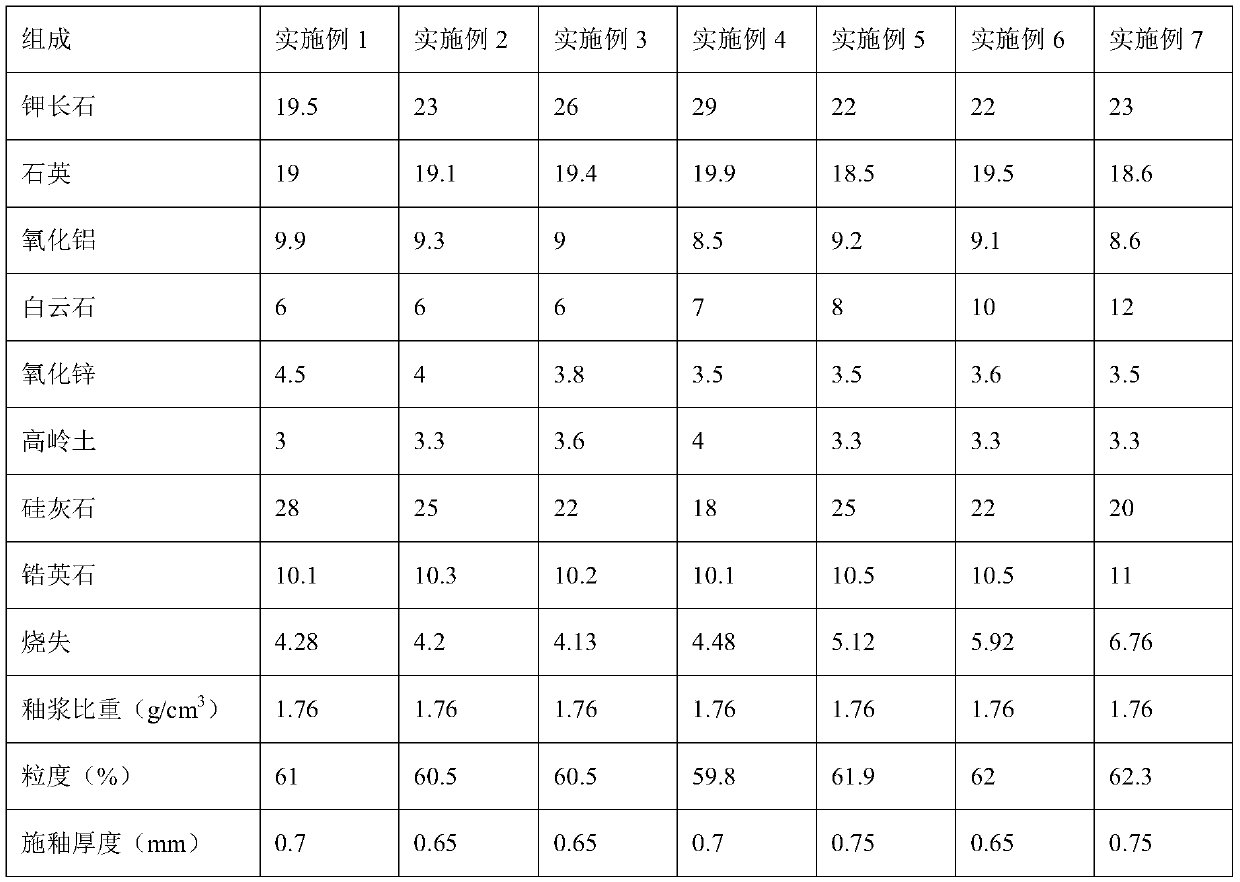

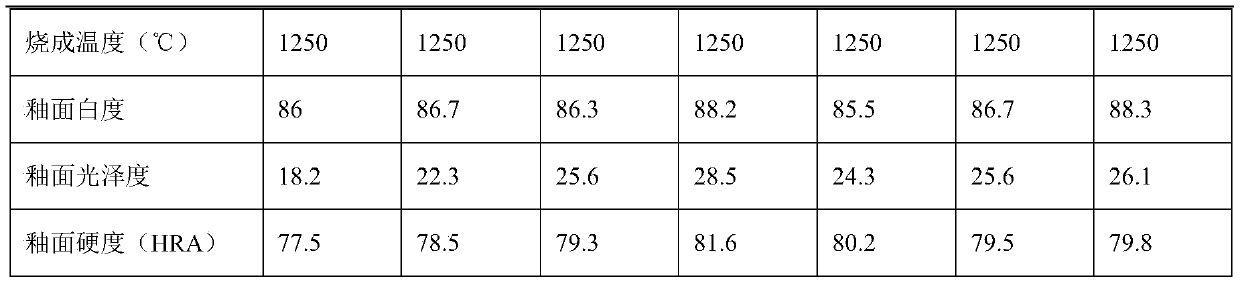

[0029] The preparation of sandy glaze sanitary ceramics of the present invention is realized through the following method steps:

[0030] 1) The ingredients are formulated according to the following mass percentages: 19.5-29% of potassium feldspar, 18.5-19.9% of quartz, 8.5-9.9% of alumina, 6-12% of dolomite, 3.5-4.5% of zinc oxide, 3-4% of kaolin, silicon Limestone 18-28%, zircon 10.1-11%, loss on ignition 4.13-6.76%; put the above raw materials into a ball mill, add sodium carboxymethyl cellulose not exceeding 2% of the total mass of raw materials, add water for ball milling , Ball milling until the slurry particle size is less than 10μm accounts for 59-63% of the ball milling, pass through a 100-mesh sieve, remove iron for 3-6 hours, adjust the performance of the glaze slurry so that the concentration of the glaze slurry reaches 1.76±0.02g / cm 3 , to obtain a uniform sanding glaze slurry;

[0031] 2) Spray the sand glaze slurry obtained in step 1) on the surface of the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tackiness | aaaaa | aaaaa |

| tackiness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com