Automatic sand-blasting machine for combing roller

A technology of opening roller and sand blasting machine, which is applied in abrasive jet machine tools, spray guns, used abrasive treatment devices, etc., can solve problems such as damage to opening rollers, economic losses of enterprises, uneven bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

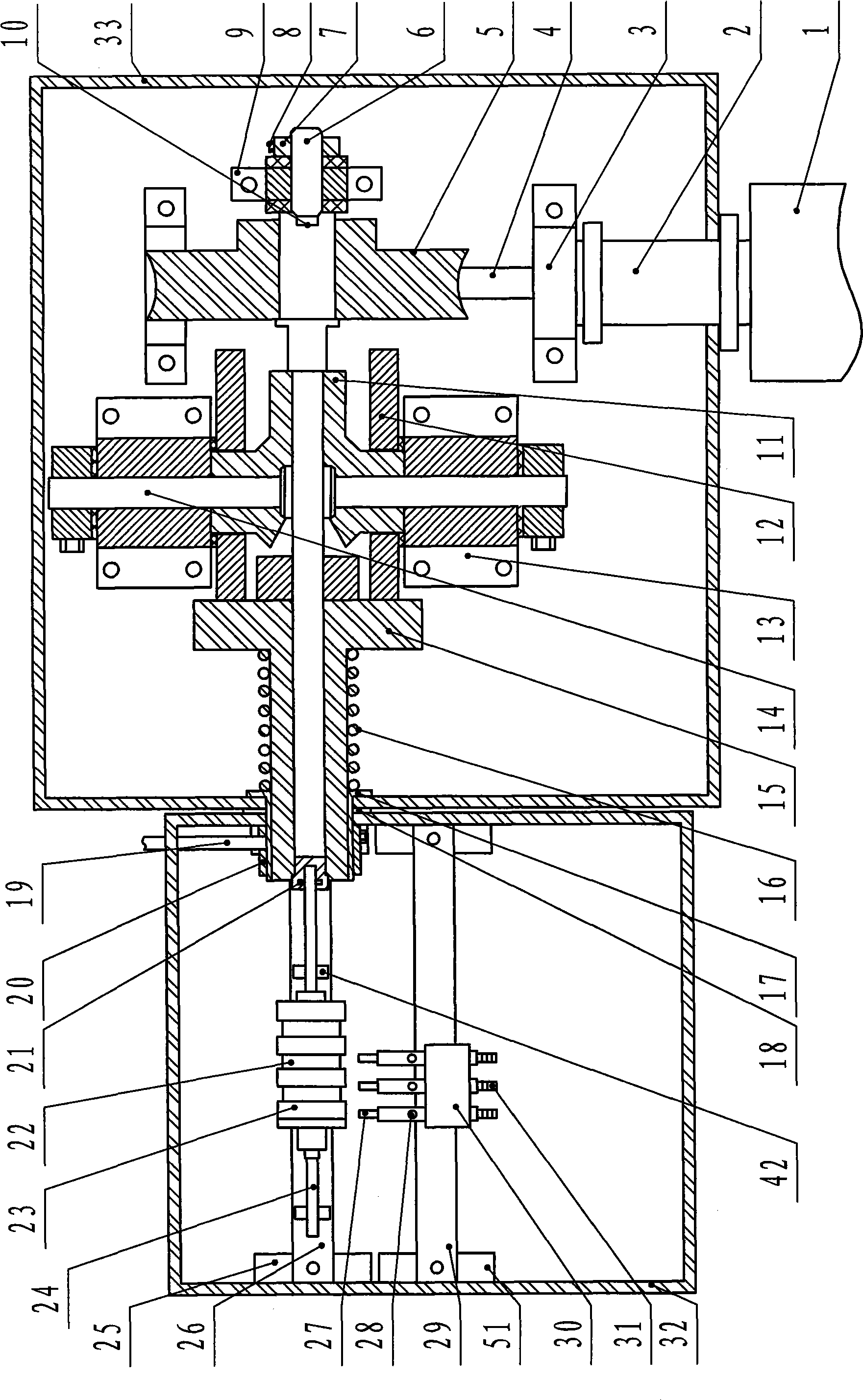

[0043] Example: figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Fig. 15, Fig. 16, shown in Fig. 17, the transmission device of the present embodiment is arranged in the transmission box 33, and the transmission box 33 is a rectangular box body, and the motor 1 is arranged outside the transmission box 33, and the axle sleeve of the motor 1 is covered with an end The phase connection sleeve 2 and the end phase connection sleeve 2 pass through the box wall of the transmission box 33, and the motor 1 is connected to the transmission device.

[0044] The transmission device is composed of a worm 4, a turbine 5, a transmission shaft 6, and a bevel gear 11. The motor 1 is connected to the transmission shaft 6 through the worm 4 and the turbine 4. The transmission shaft 6 is connected to the roller mandrel 24 through the cross joint 21. The worm 4 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com