A method for manufacturing emulsified explosives mixed on site

A manufacturing method and technology for emulsified explosives, which are applied in the directions of explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of reducing equipment safety, increasing pressure, affecting operation efficiency and scope of use, etc., so as to improve transportation efficiency, reduce processing costs, The effect of good blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

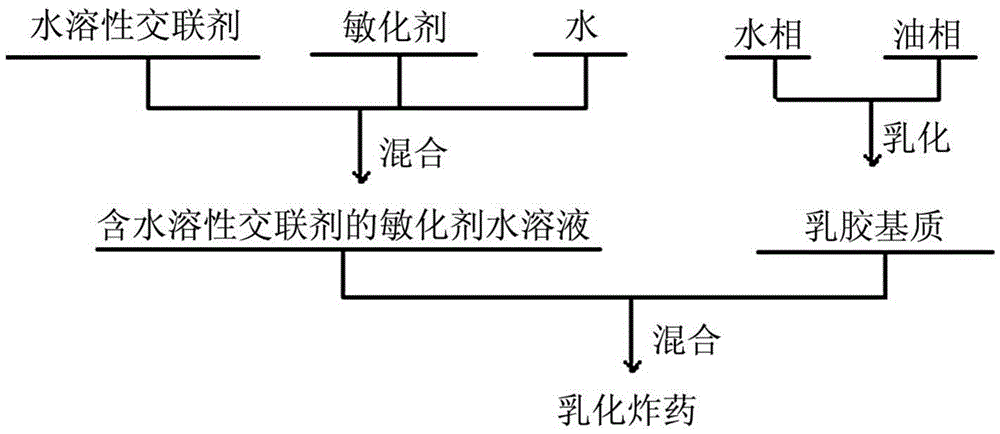

Method used

Image

Examples

Embodiment 1

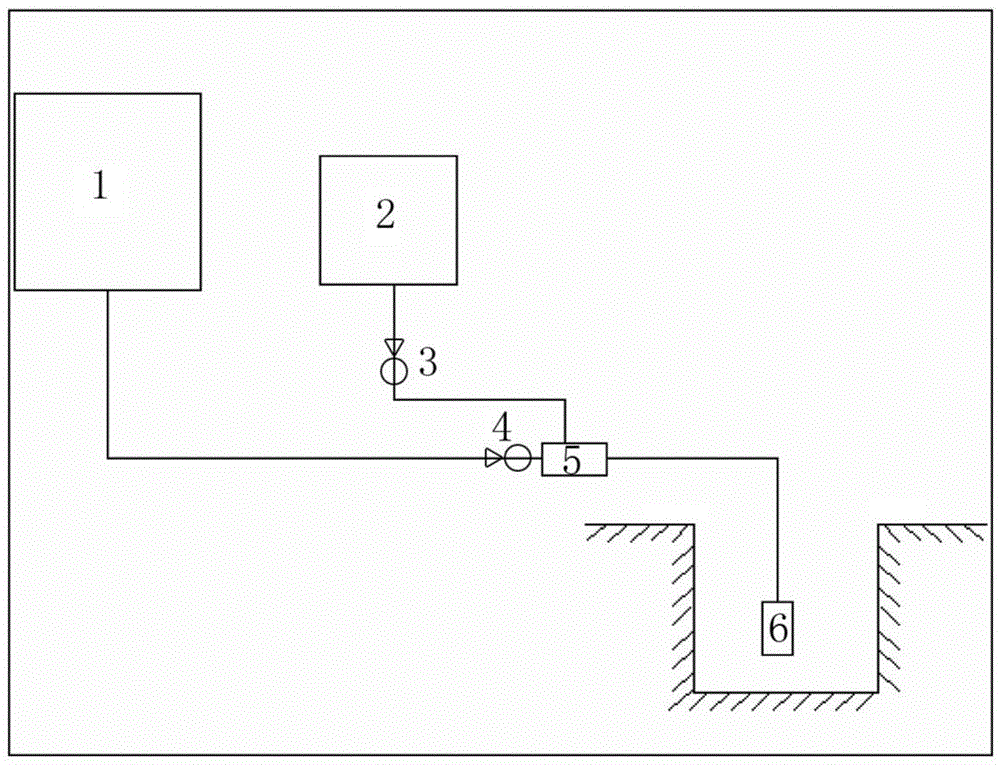

[0056] First prepare the latex matrix: in the first step, mix 697kg of ammonium nitrate, 80kg of sodium nitrate, 150kg of water, and 3kg of citric acid under the condition of heating to about 90°C to form an aqueous phase material; The BEF-4 emulsifier produced by the hospital (the main component of the BEF-4 emulsifier is polyisobutylene succinate monoglyceride), mixed with 50kg of 32# mechanical oil, heated to about 60°C to melt it, and formed an oil phase material In the third step, the water-phase material and the oil-phase material are emulsified into a water-in-oil type cross-linkable latex matrix by using a first-stage emulsifier at atmospheric pressure, and the emulsification temperature is about 90°C; in the fourth step, the latex matrix is directly transported to Latex matrix box for the charging cart of the charging equipment.

[0057] The temperature of the latex matrix in the latex matrix box of the charging equipment is 40°C, and the absolute viscosity of the l...

Embodiment 2

[0063] First prepare the latex matrix: in the first step, mix 697kg of ammonium nitrate, 80kg of sodium nitrate, 150kg of water, and 3kg of acetic acid under the condition of heating to about 90°C to form an aqueous phase material; in the second step, mix 20kg of The SMO emulsifier produced (the main component of the SMO emulsifier is sorbitan monooleate), 50kg of 68# mechanical oil is mixed and heated to about 60°C to melt it to form an oil phase material; the third step, The water-phase material and the oil-phase material are emulsified into a water-in-oil latex matrix with a first-stage emulsifier at atmospheric pressure, and the emulsification temperature is about 90°C; in the fourth step, the latex matrix is cooled by the steel belt and then transported to the latex of the charging equipment in the substrate storage box.

[0064] The temperature of the latex matrix in the latex matrix box of the charging equipment is 40°C, and the absolute viscosity of the latex matrix ...

Embodiment 3

[0070] First prepare the latex matrix: in the first step, mix 697kg of ammonium nitrate, 80kg of sodium nitrate, 150kg of water, and 3kg of citric acid under the condition of heating to about 90°C to form an aqueous phase material; The SMO emulsifier produced by the hospital (the main component of the SMO emulsifier is sorbitan monooleate), 45kg of 68# mechanical oil, and 5kg of oleic acid are mixed and heated to about 60°C to melt to form an oil phase Materials; in the third step, the water-phase material and the oil-phase material are emulsified into a water-in-oil latex matrix with a first-stage emulsifier at atmospheric pressure, and the emulsification temperature is about 90°C; in the fourth step, the latex matrix is cooled by static pipeline Delivered to latex-based storage tanks of charge equipment.

[0071] The temperature of the latex matrix in the latex matrix box in the charging equipment is 40°C, and the absolute viscosity of the latex matrix at this temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com