Acidic cleaning agent for pasture milking equipment

An acidic cleaning agent and equipment technology, applied in the directions of non-surface-active detergent compositions, detergent compositions, organic non-surface-active cleaning compositions, etc., can solve the problems of complicated steps, bacterial infection, large amount of sewage discharged with water consumption, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

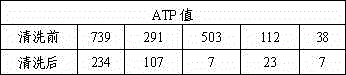

Examples

Embodiment 1

[0033] The acid cleaning agent for milking equipment provided in the present embodiment is composed of the following components in parts by mass:

[0034] phosphoric acid 18,

[0035] methanesulfonic acid 15,

[0036] Sodium Gluconate 6,

[0038] calcium acetate 3,

[0039] 65 for water.

[0040] Production process (according to this process, the system of acid cleaning agent can be kept stable):

[0041] serial number Steps Remark 1 Clean and disinfect related equipment according to cleaning and disinfection operating procedures; 2 Confirm that the production water is qualified; 3 Add pure water RM-0000 to the acid reactor Automatic feeding (30% of the total water is reserved water) 4 Start stirring and add phosphoric acid; Automatic feeding 5 Keep stirring, 1 minute; 6 Keep stirring, add methanesulfonic acid; The scale kettle weighs double checks, and the diaphragm pump is...

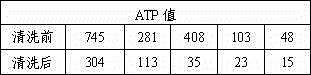

Embodiment 2

[0053] The acid cleaning agent for milking equipment provided in the present embodiment is composed of the following components in parts by mass:

[0054] phosphoric acid 5,

[0055] methanesulfonic acid 10,

[0056] Sodium Gluconate 10,

[0058] calcium acetate 1,

[0059] 35 for water.

[0060] Production technology: with embodiment 1

[0061] Usage method: same as embodiment 1

[0062] The use effect of this embodiment:

[0063] The cleaned metal surface maintains the original color and luster of the metal; after cleaning, the surface is clean, there is no increase in the deposition of dirt such as fat, and the surface has no greasy feeling;

[0064] The acid cleaning agent in this embodiment is specially used for cleaning the milking equipment pipeline, can effectively remove the fat, protein, etc. remaining on the inner wall of the equipment, and has a bactericidal effect;

[0065] During the cleaning process, some foam will be ...

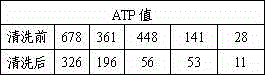

Embodiment 3

[0071] The acid cleaning agent for milking equipment provided in the present embodiment is composed of the following components in parts by mass:

[0072] phosphoric acid 25,

[0073] Methanesulfonic acid 20,

[0074] Sodium Gluconate 1,

[0075] hydrogen peroxide 8,

[0076] calcium acetate 5,

[0077] Water is 75.

[0078] Production technology: with embodiment 1

[0079] Usage method: same as embodiment 1

[0080] The use effect of this embodiment:

[0081] The cleaned metal surface maintains the original color and luster of the metal; after cleaning, the surface is clean, there is no increase in the deposition of dirt such as fat, and the surface has no greasy feeling;

[0082] The acid cleaning agent in this embodiment is specially used for cleaning the milking equipment pipeline, can effectively remove the fat, protein, etc. remaining on the inner wall of the equipment, and has a bactericidal effect;

[0083] During the cleaning process, some foam will be gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com