Sand blasting equipment for outer wall of steel pipe

A kind of sandblasting equipment and sandblasting technology, applied in the direction of metal processing equipment, abrasive jet machine tools, used abrasive processing devices, etc., can solve the problems of low productivity, cumbersome procedures, and heavy workload of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

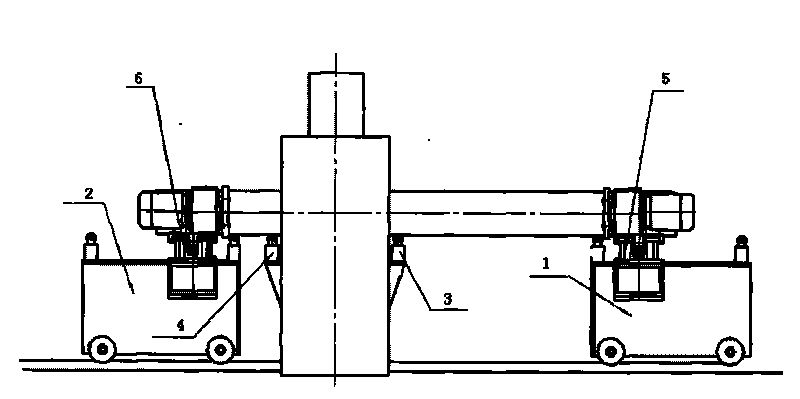

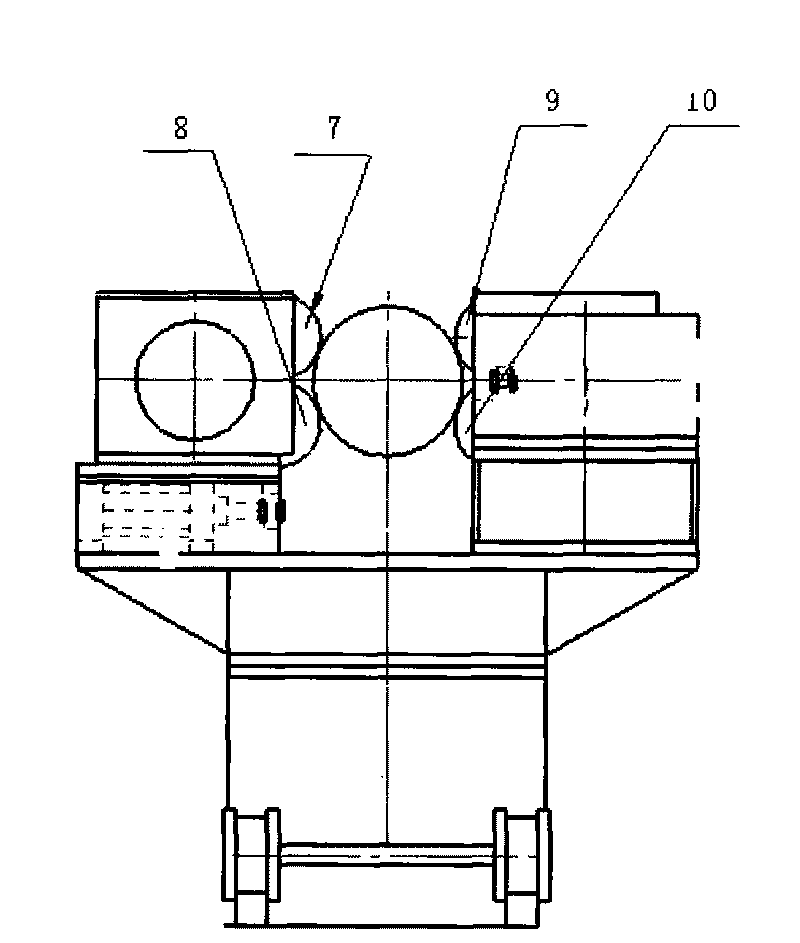

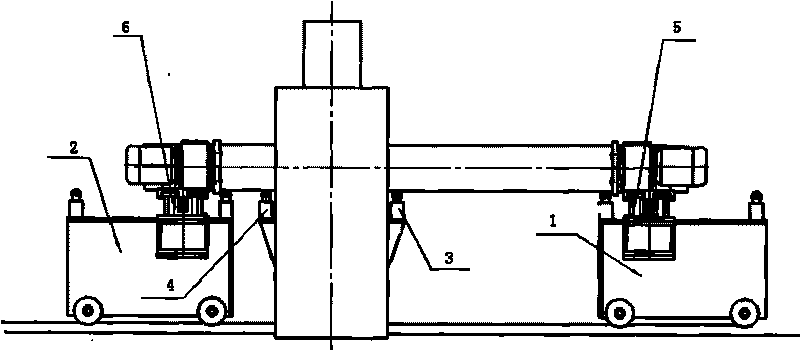

[0021] As shown in the figure, the steel pipe outer wall sandblasting equipment of the present invention supports the steel pipe through the support block 5 on the trolley 1 and the support column 3 on the sandblasting box. The dust board enters the sandblasting box, and after entering the sandblasting box, the sandblasting machine starts at the same time, and the active friction wheels 7 and 8 drive the steel pipe to rotate at a constant speed, ensuring that the outer wall of the steel pipe is sandblasted evenly. Push away the rubber dust-proof plate at the output end of the sandblasting box and reach the upper support block 6 of the trolley 2. The trolley 2 starts and drives the steel pipe to move in the same direction and at the same speed as the trolley 1 until the steel pipe is blasted.

[0022] If the sandblasting effect is unsatisfactory after the steel pipe is completed from input to output, similarly, you can start the trolley 2 to move in reverse, enter from the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com