Isolation structure on spraying device for surface treatment and sandblasting and spraying integrated machine

A spraying device and surface treatment technology, applied in the field of isolation structure and sandblasting and spraying integrated machine, can solve the problems of difficult sandblasting and spraying, other operation interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

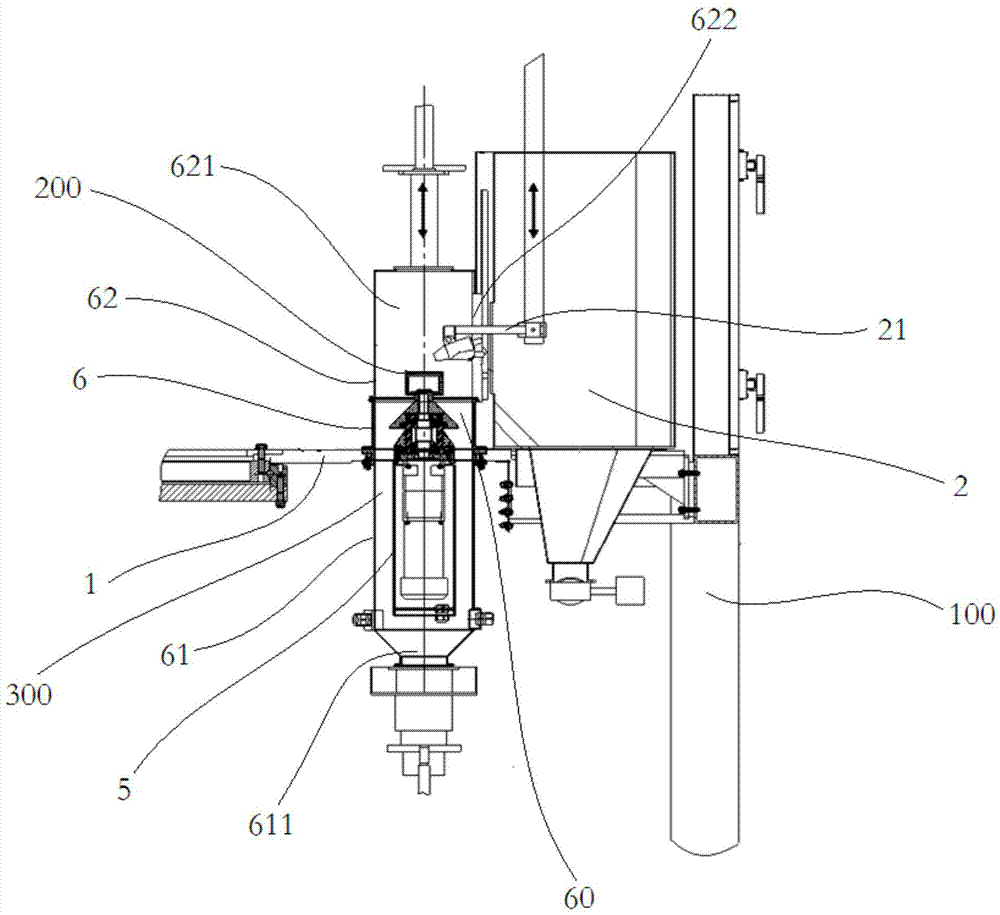

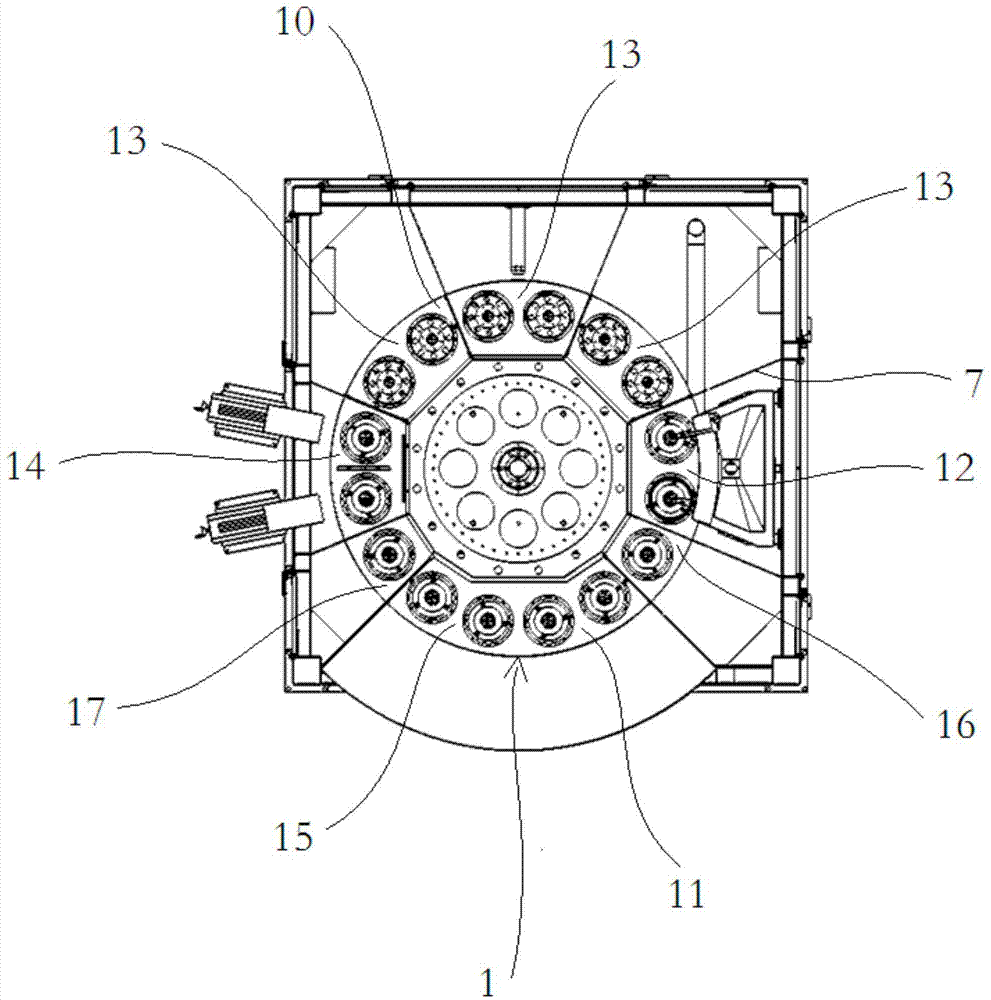

[0047] refer to figure 1 , an isolation structure 6 on a spraying device for surface treatment of the present invention includes a lower cover 61 and an upper cover 62 .

[0048] The lower cover 61 is arranged and connected below the workpiece carrying device 5 of the surface treatment spraying device. The workpiece carrying device 5 is equipped with a workpiece 200. When the lower cover 61 reaches the processing station, its An air duct 300 for blanking and discharging is formed between the inner wall and the workpiece carrying device 5; blanking refers to falling sand and dust;

[0049] The upper cover body 62 is reciprocally arranged above the workpiece carrying device 5 of the surface treatment injection device, and the peripheral wall of the upper cover body 62 is provided with a through hole 622 for the nozzle to extend into. The upper cover body 62 is adapted to move to the combination position and combine with the lower cover body 61 at the processing station to form ...

Embodiment 2

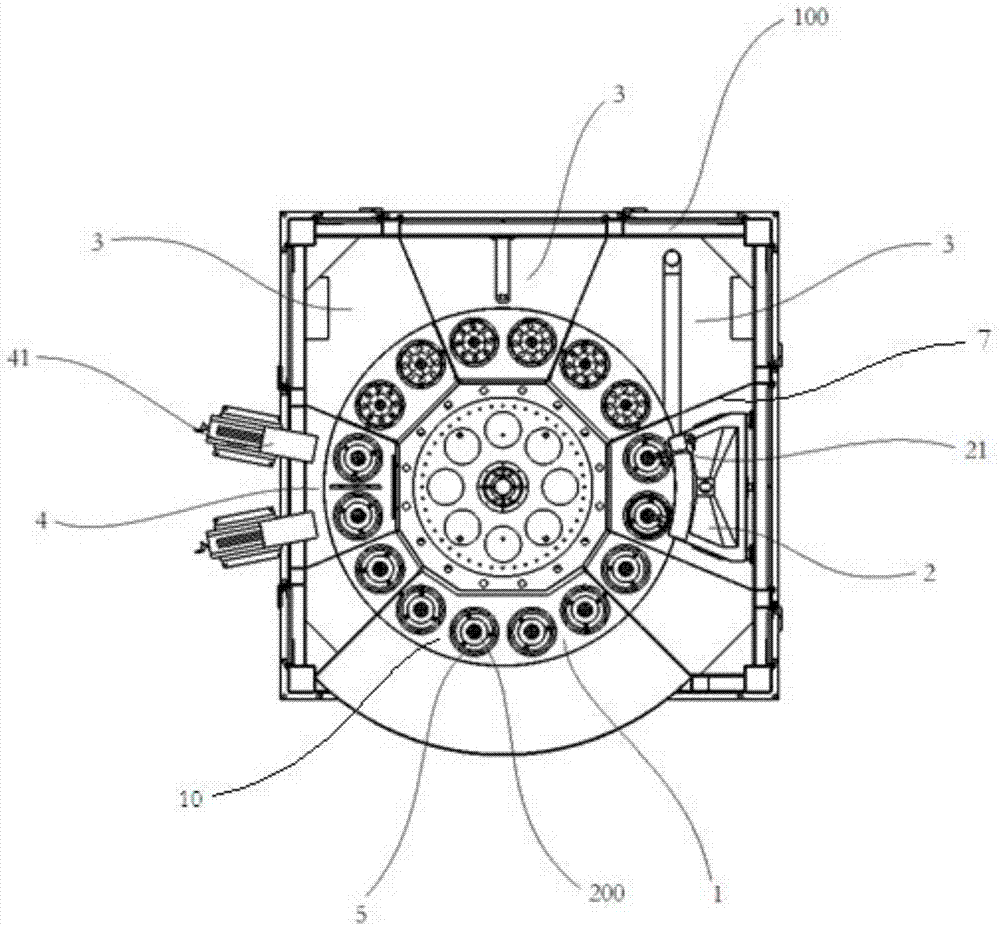

[0077] This embodiment is substantially the same as Embodiment 1, except that the lower cover body 61 is movably arranged below the sandblasting area 12, below the blowing area 13 and below the spraying area 14, and The upper cover body 62 is provided correspondingly. For the sandblasting process, when the workpiece 200 moves to the sandblasting area 12 with the workpiece carrying device 5, the lower cover body 61 moves upward and is placed on the The lower part of the workpiece carrying device 5, the upper cover 62 moves to combine with the lower cover 61 to form the isolation cavity 60. When the sanding area 12 is used, the upper cover body 62 is separated from the lower cover body 61 , and the lower cover body 61 returns to the position below the sandblasting area 12 . The blowing process and the spraying process are substantially the same as the above-mentioned sand blasting process, and will not be described in detail.

Embodiment 3

[0079] This embodiment is substantially the same as Embodiment 1, except that the conveyor belt 10 is straight. That is, the feeding area 11 is at the head of the conveyor belt 10 , and the unloading area 15 is at the tail of the conveyor belt 10 . This form of sandblasting and spraying all-in-one machine is suitable for application in long strips.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com