Patents

Literature

84results about How to "Improve sandblasting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

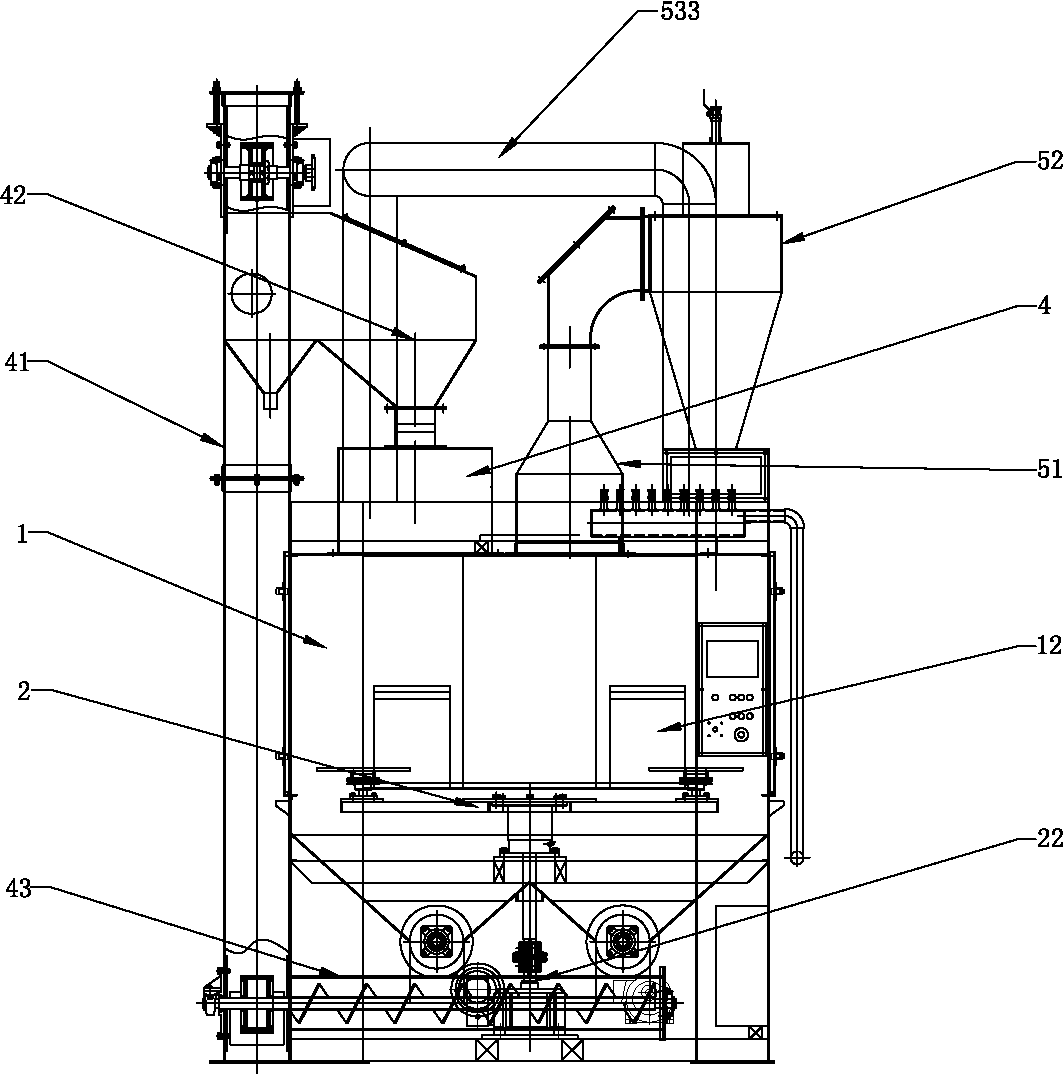

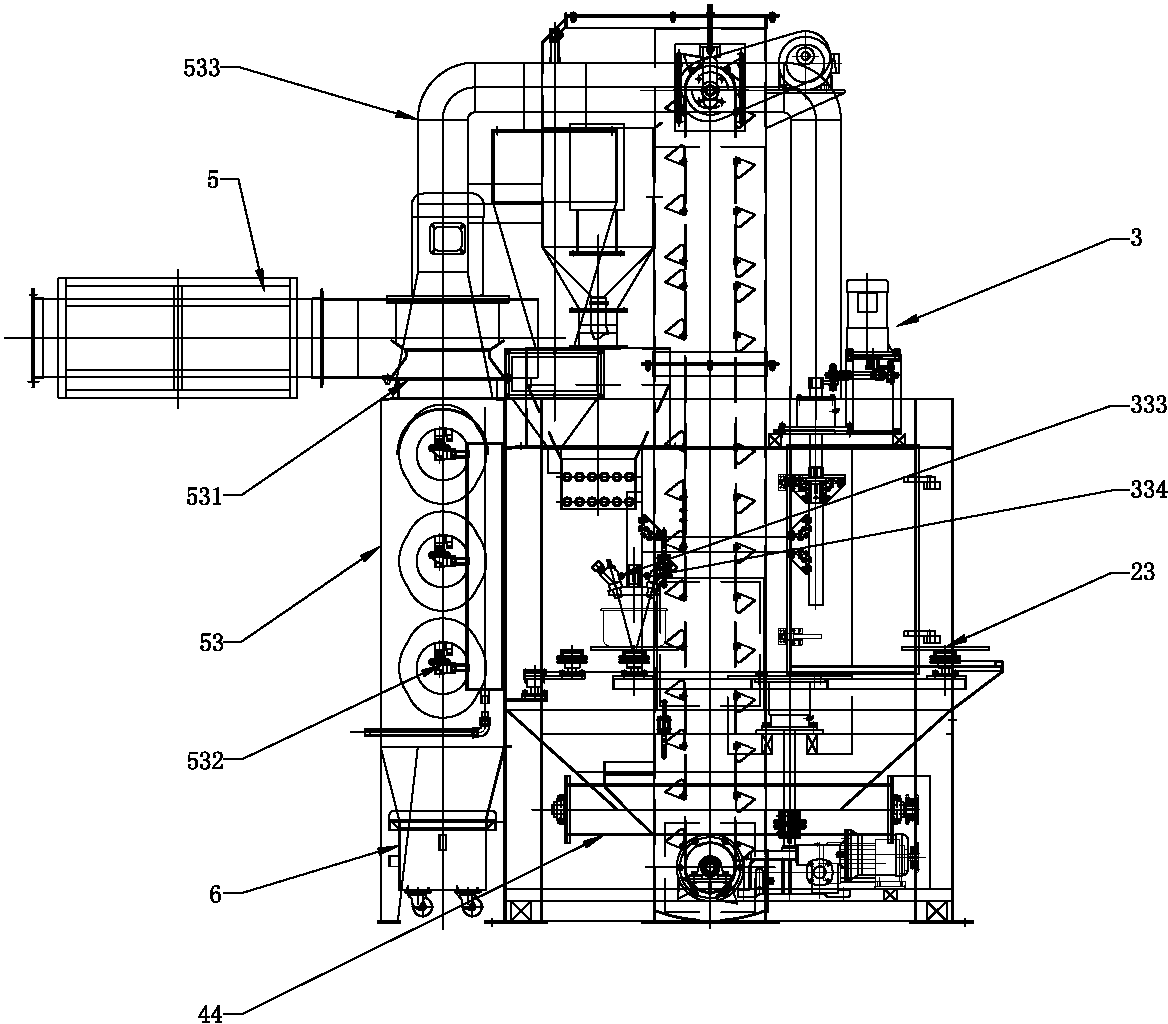

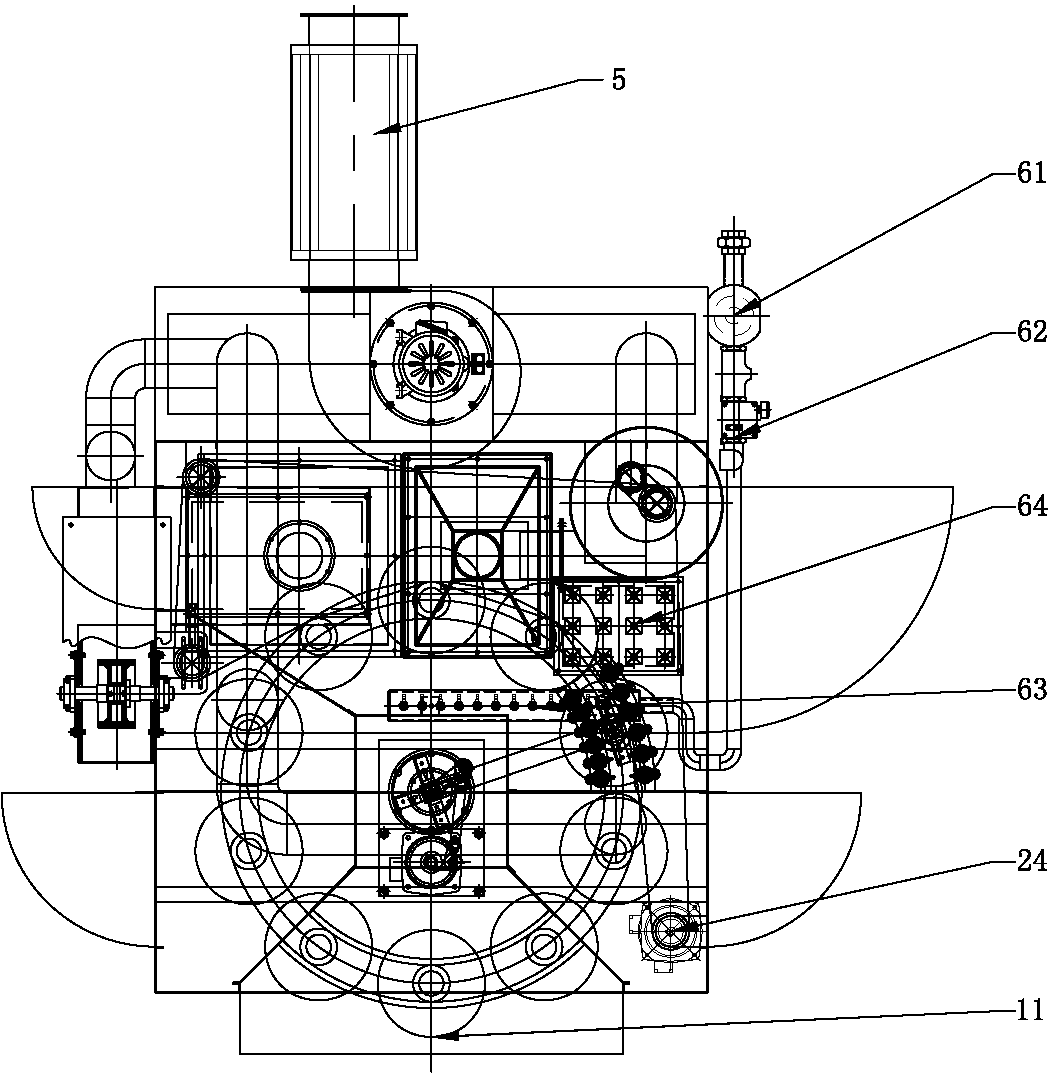

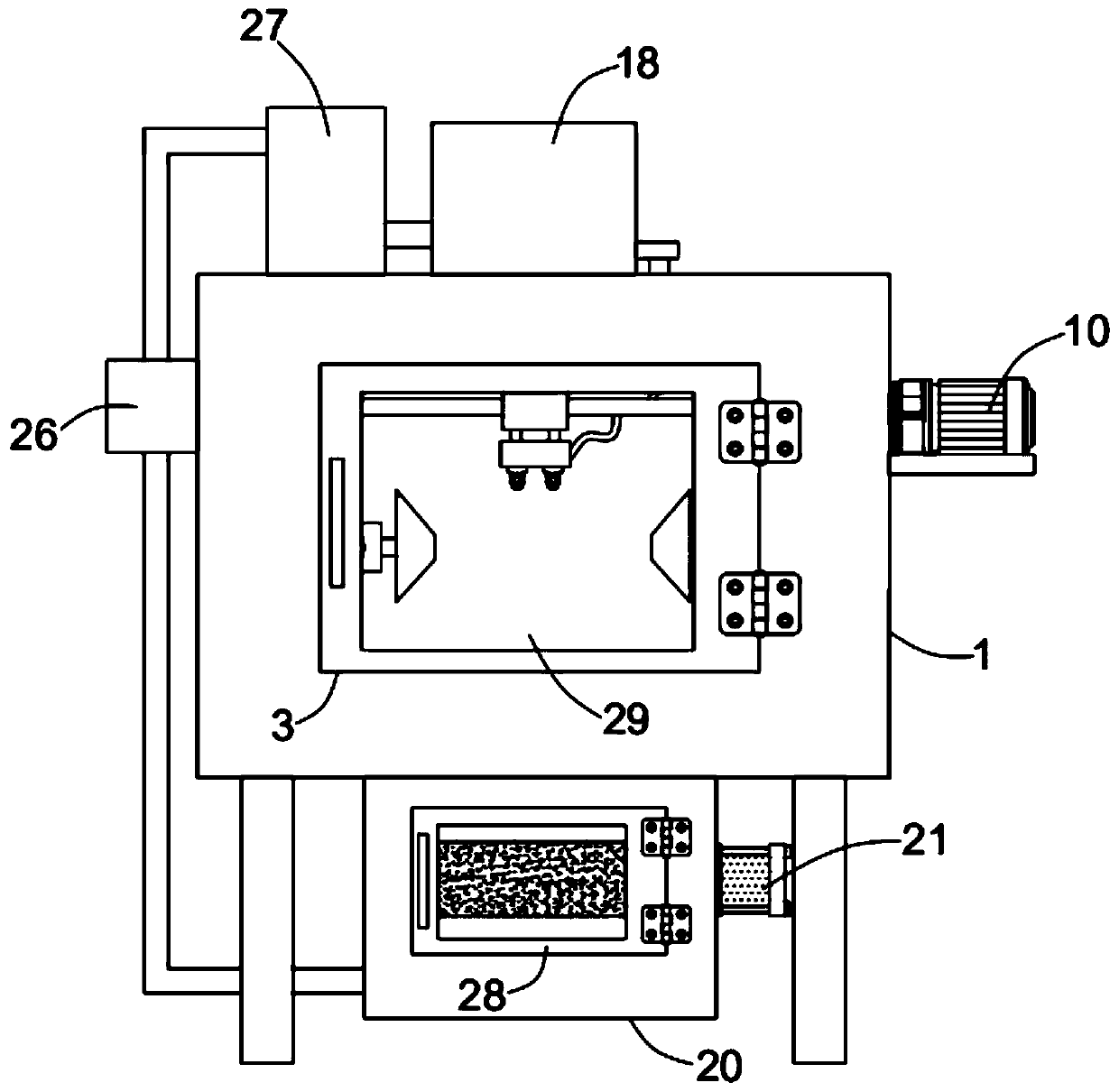

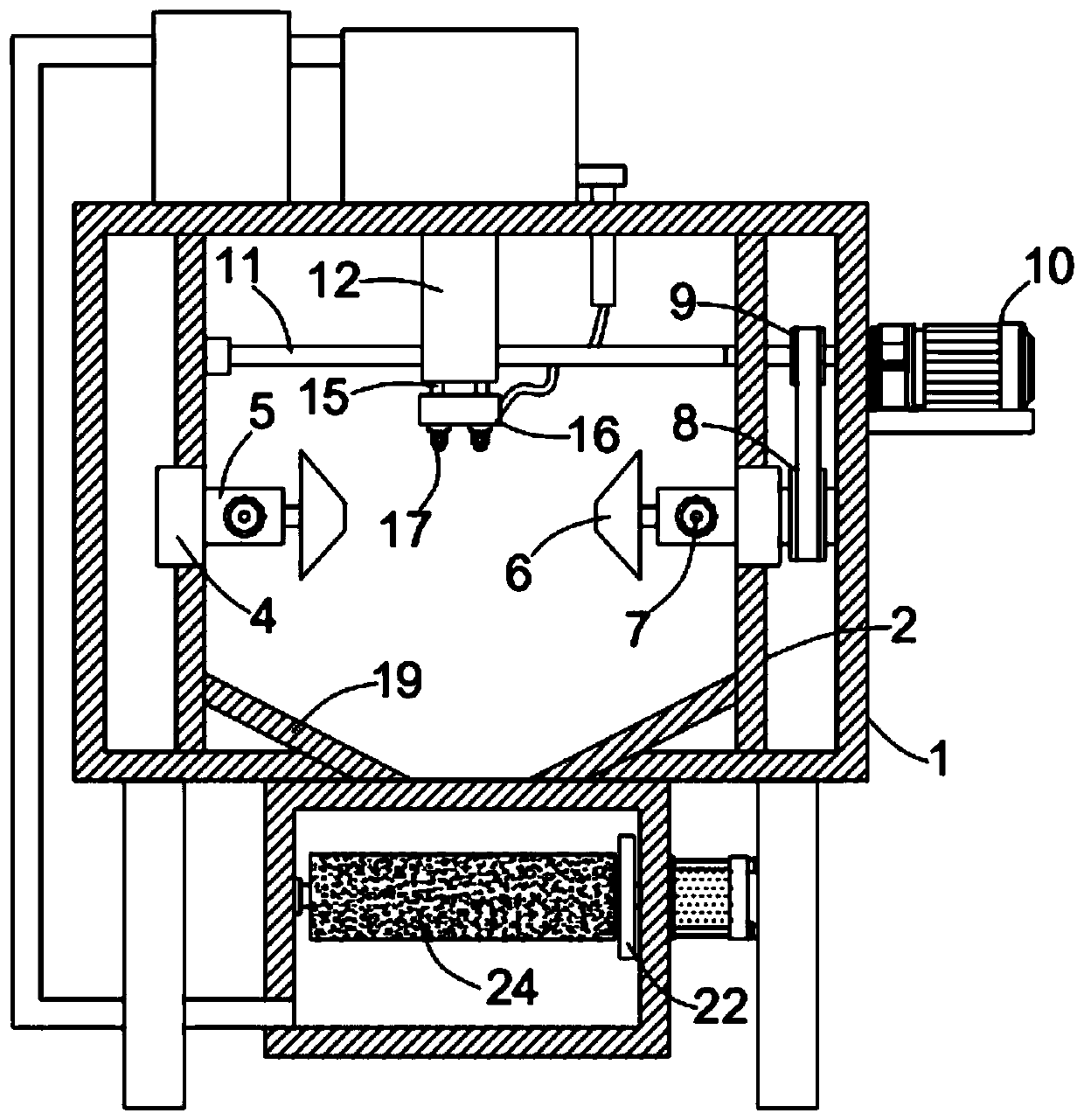

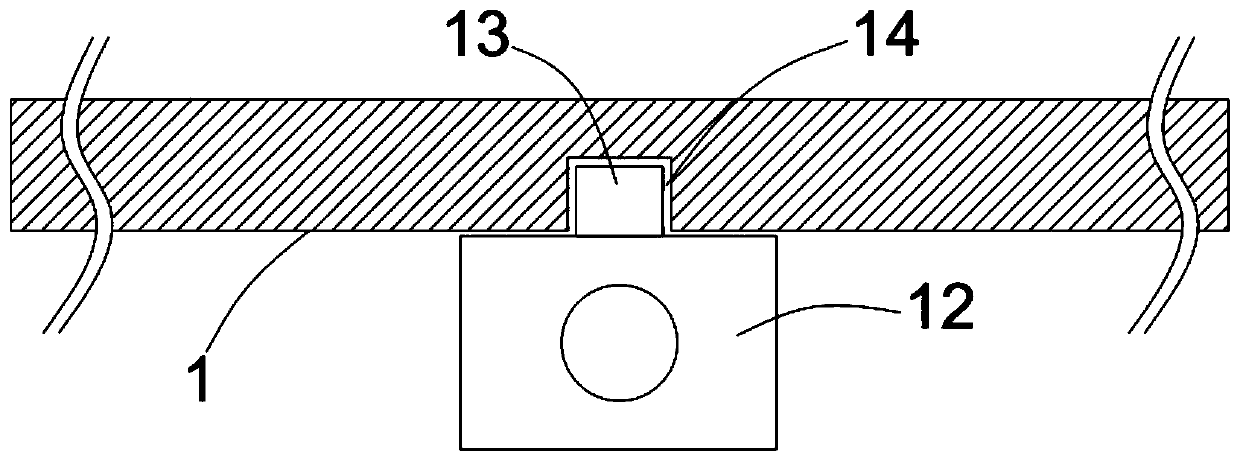

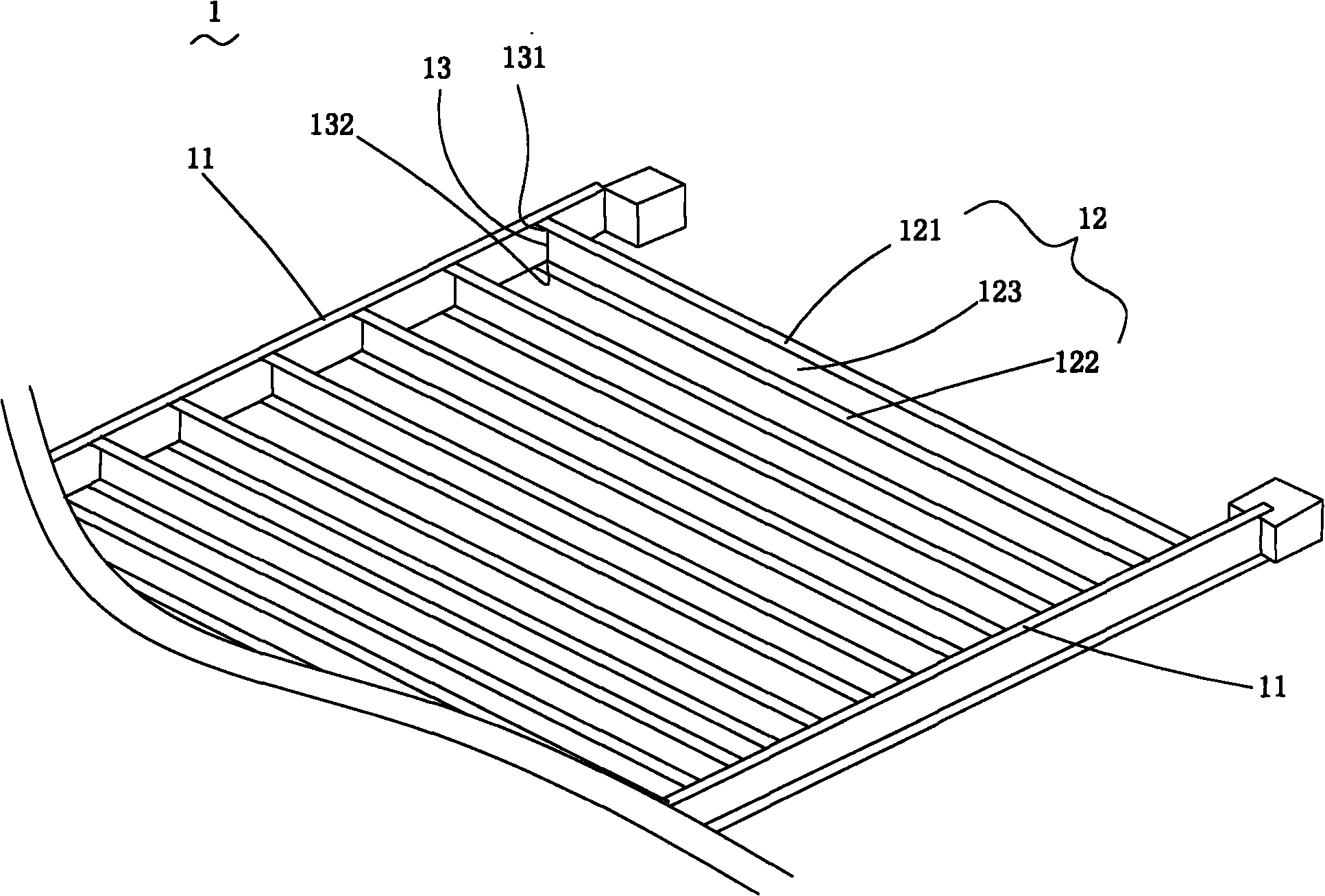

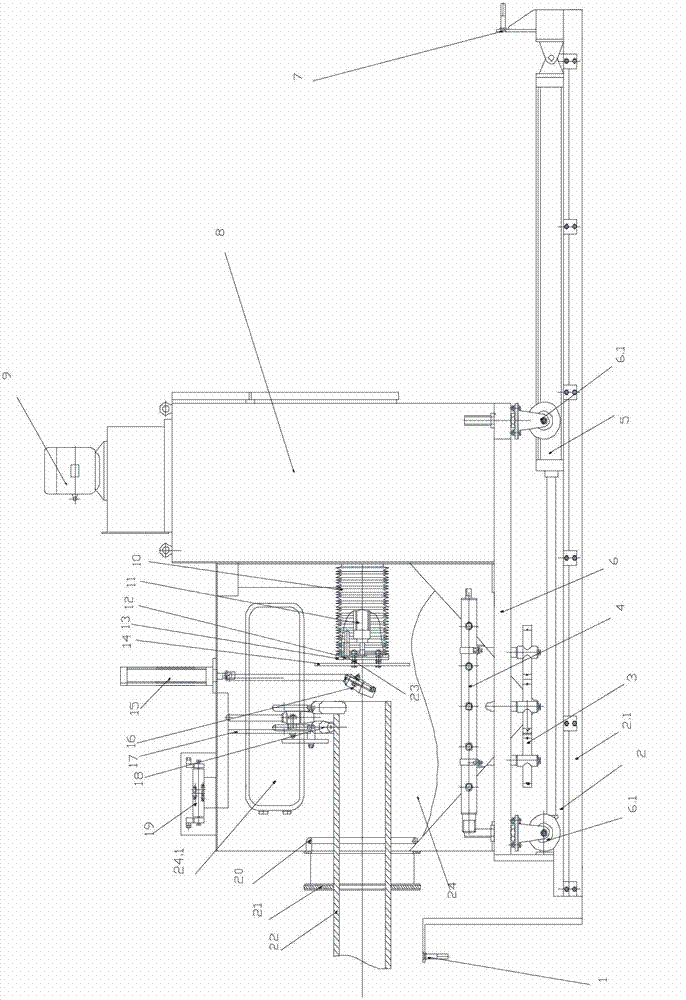

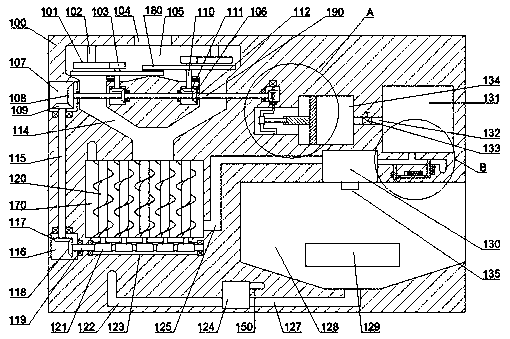

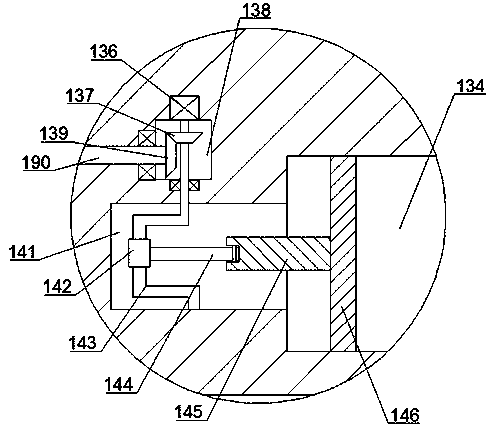

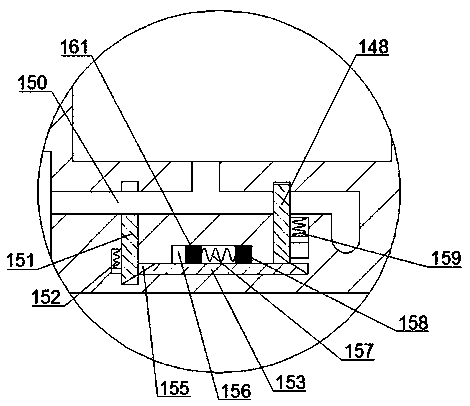

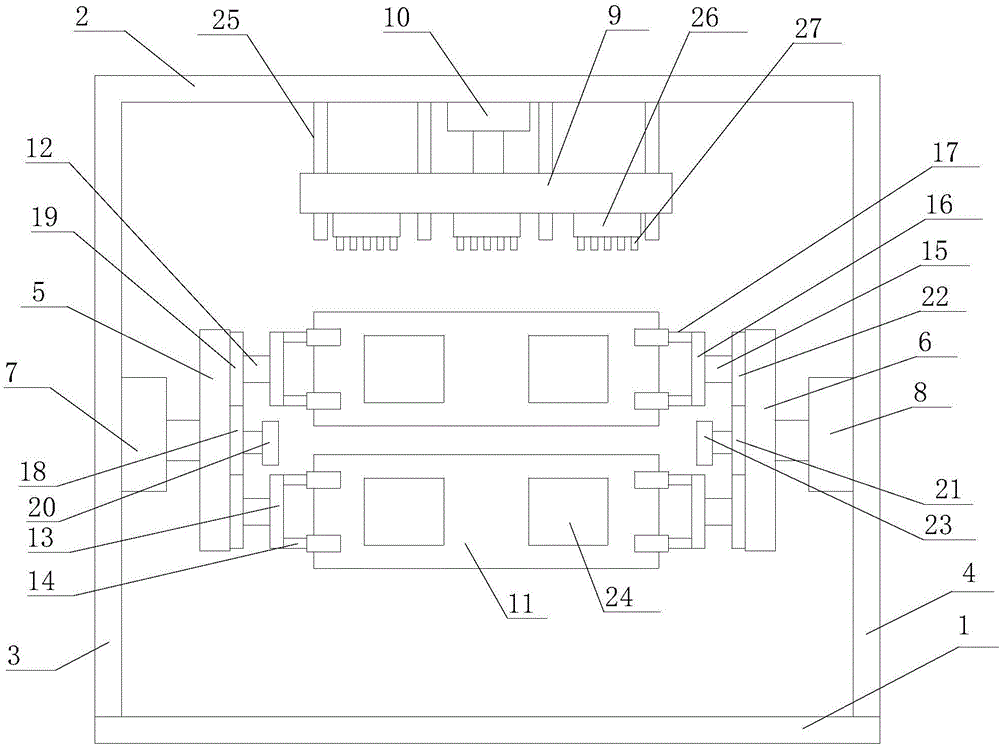

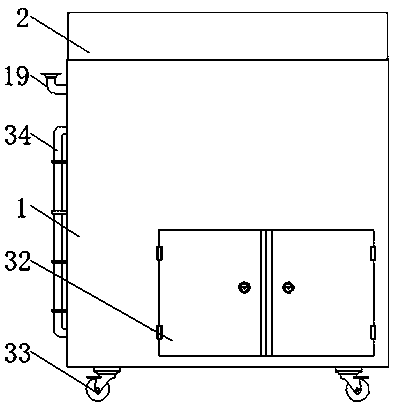

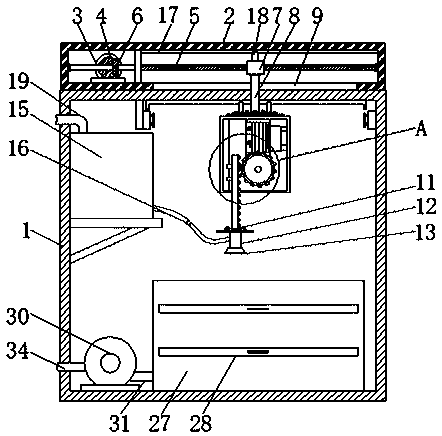

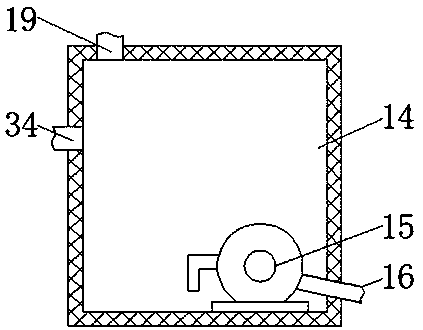

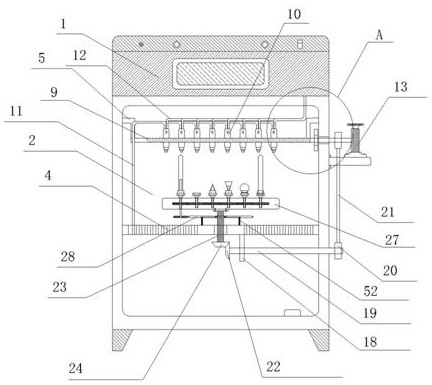

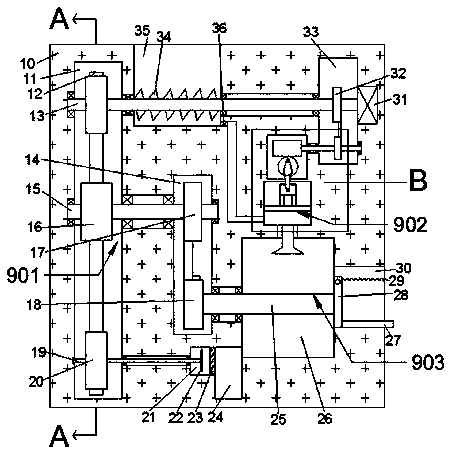

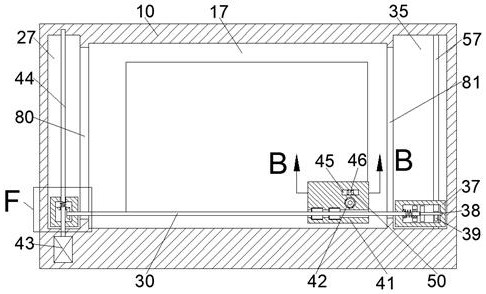

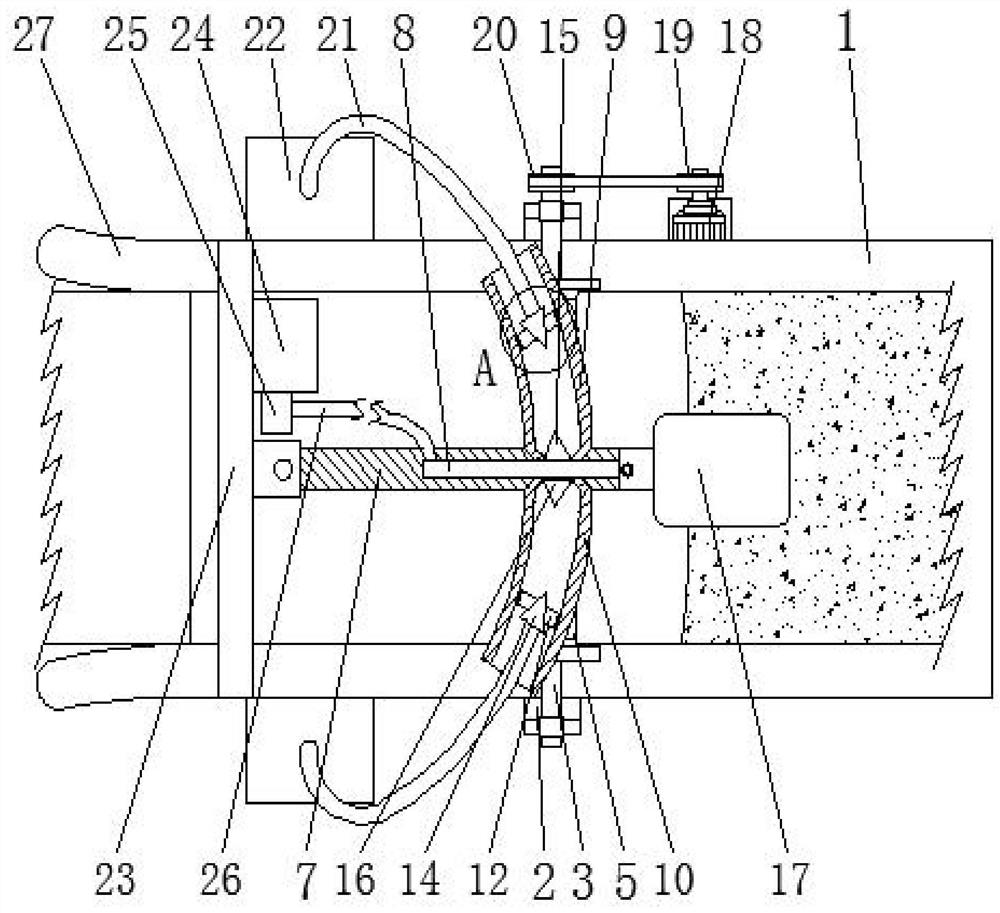

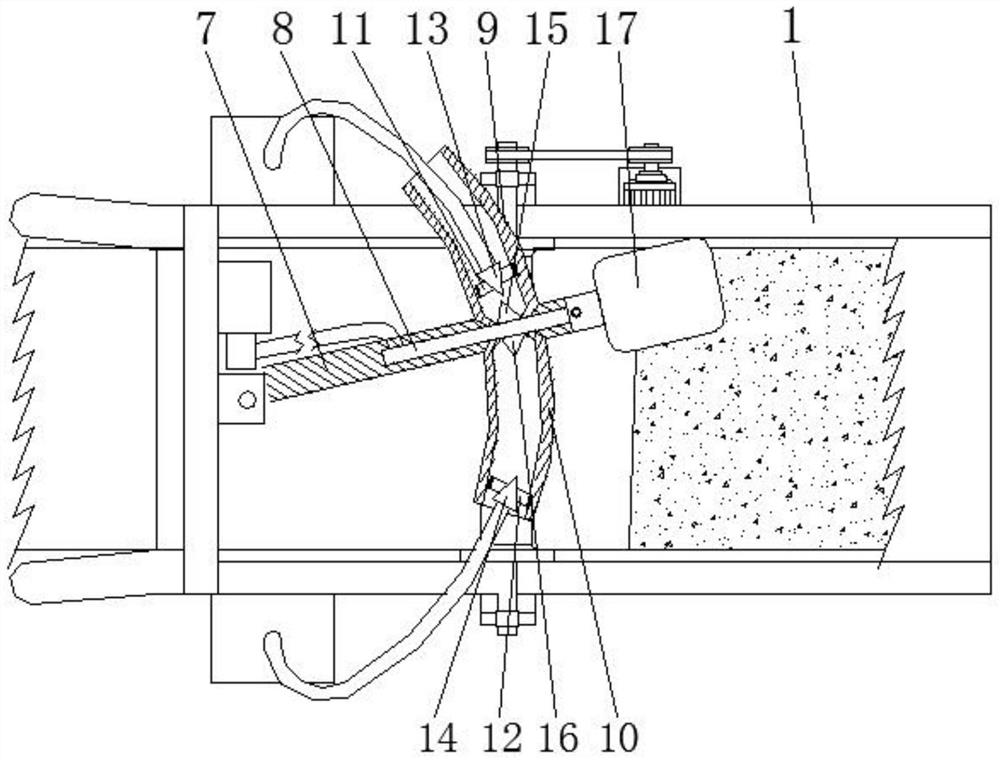

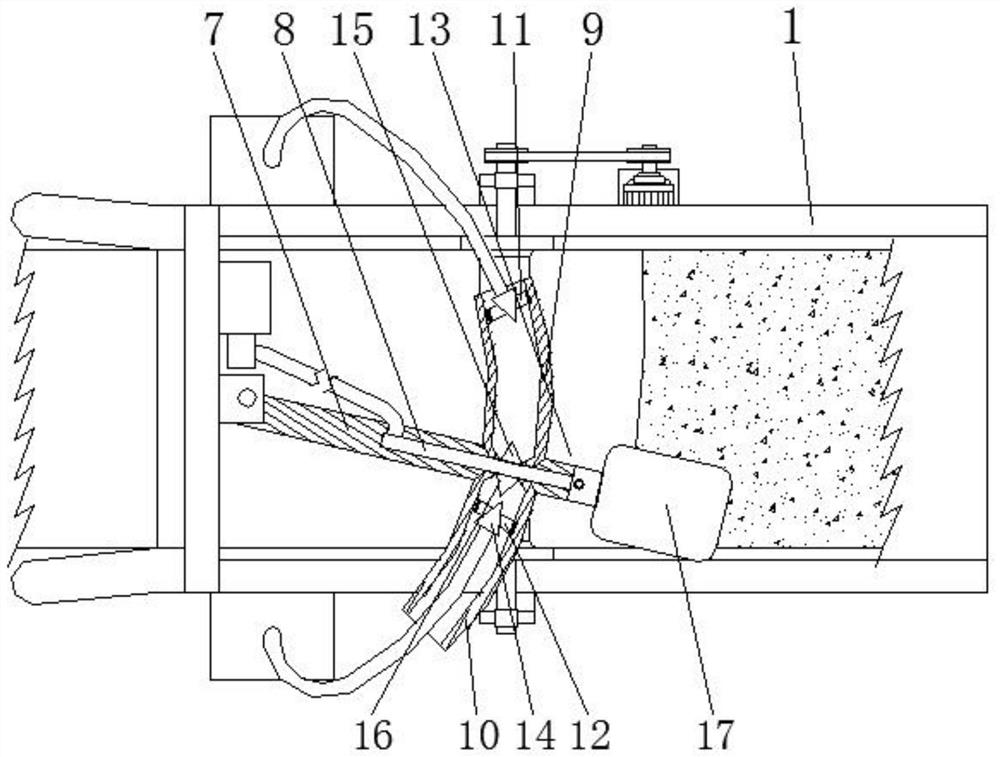

Integrated sandblasting machine

ActiveCN103231314AWork runs smoothlyImprove automationBlast gunsAbrasive feedersAbrasive blastingIntegrated design

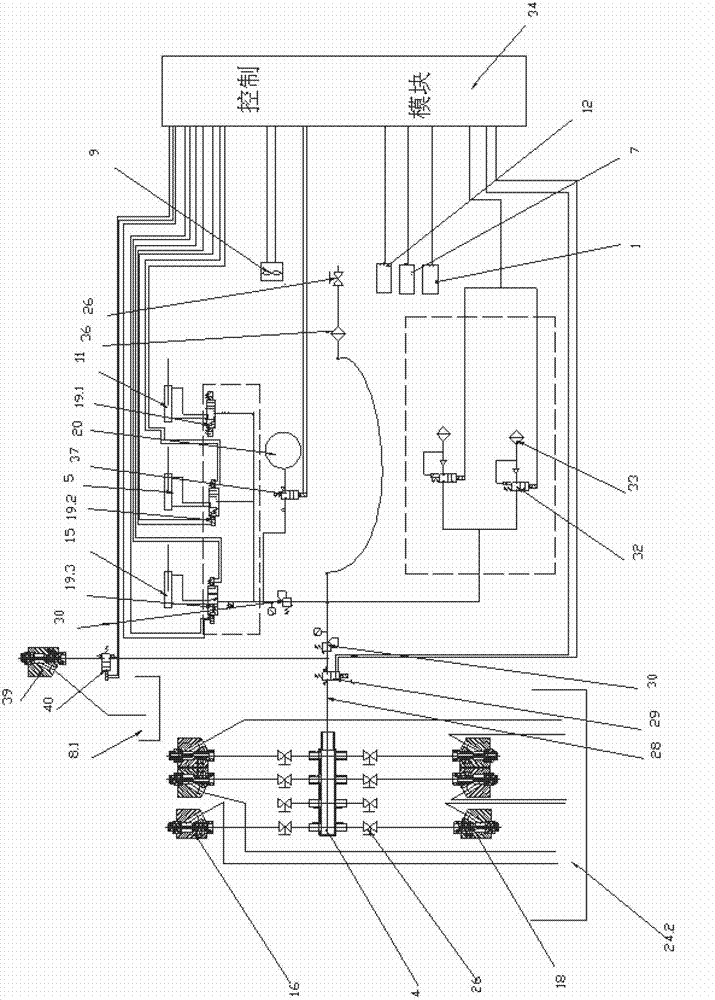

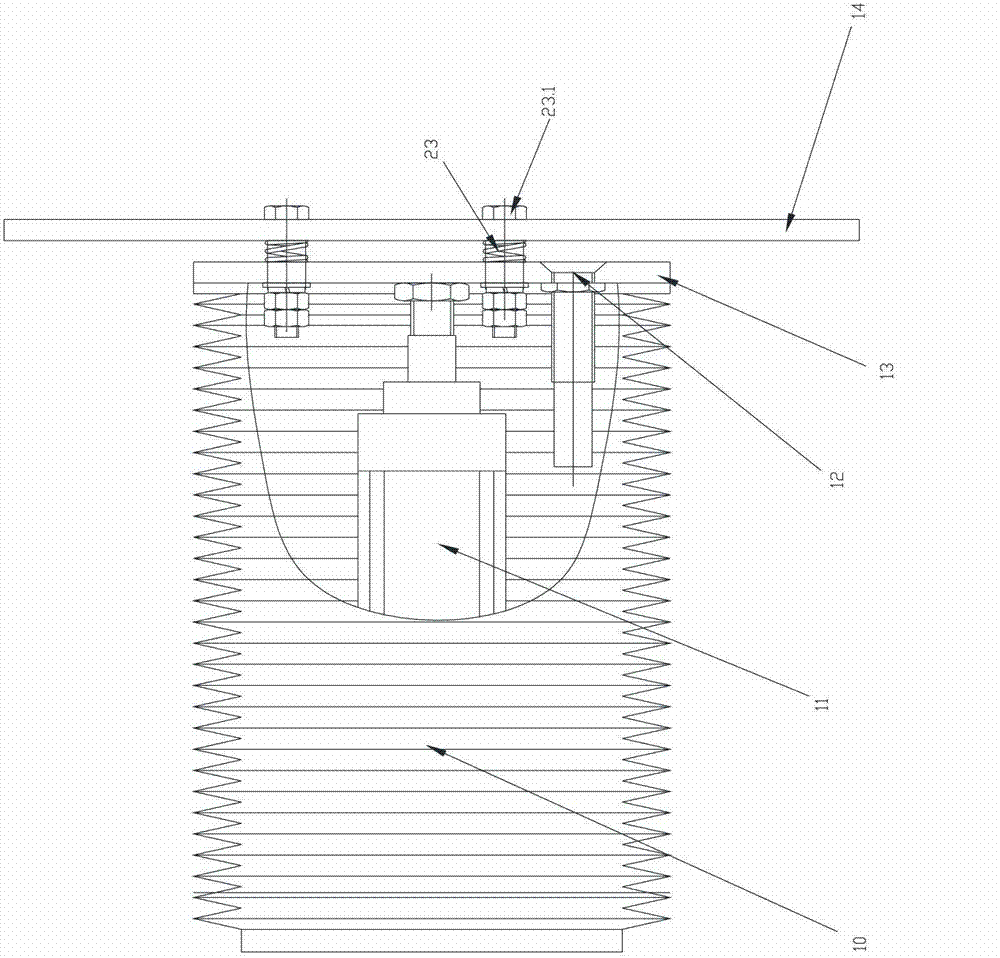

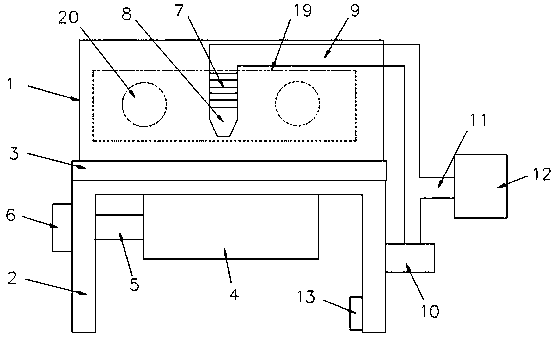

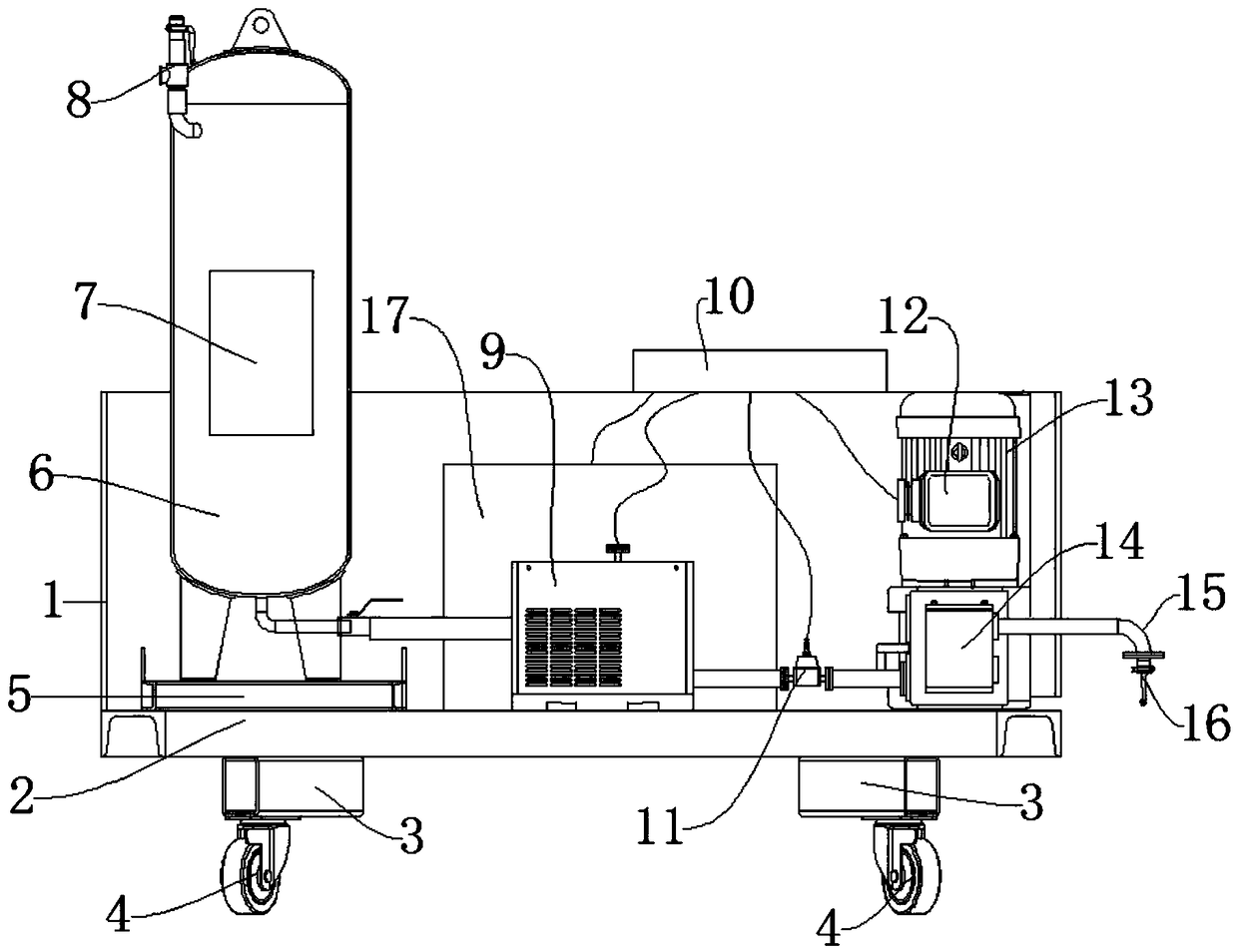

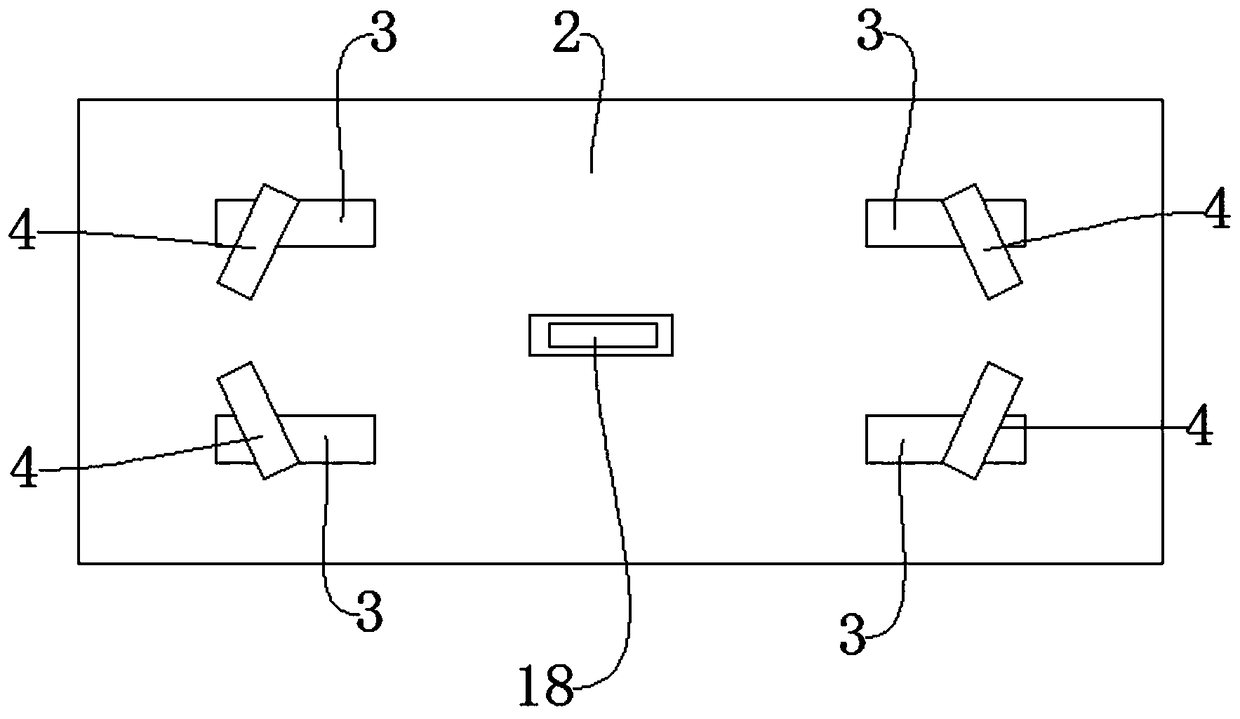

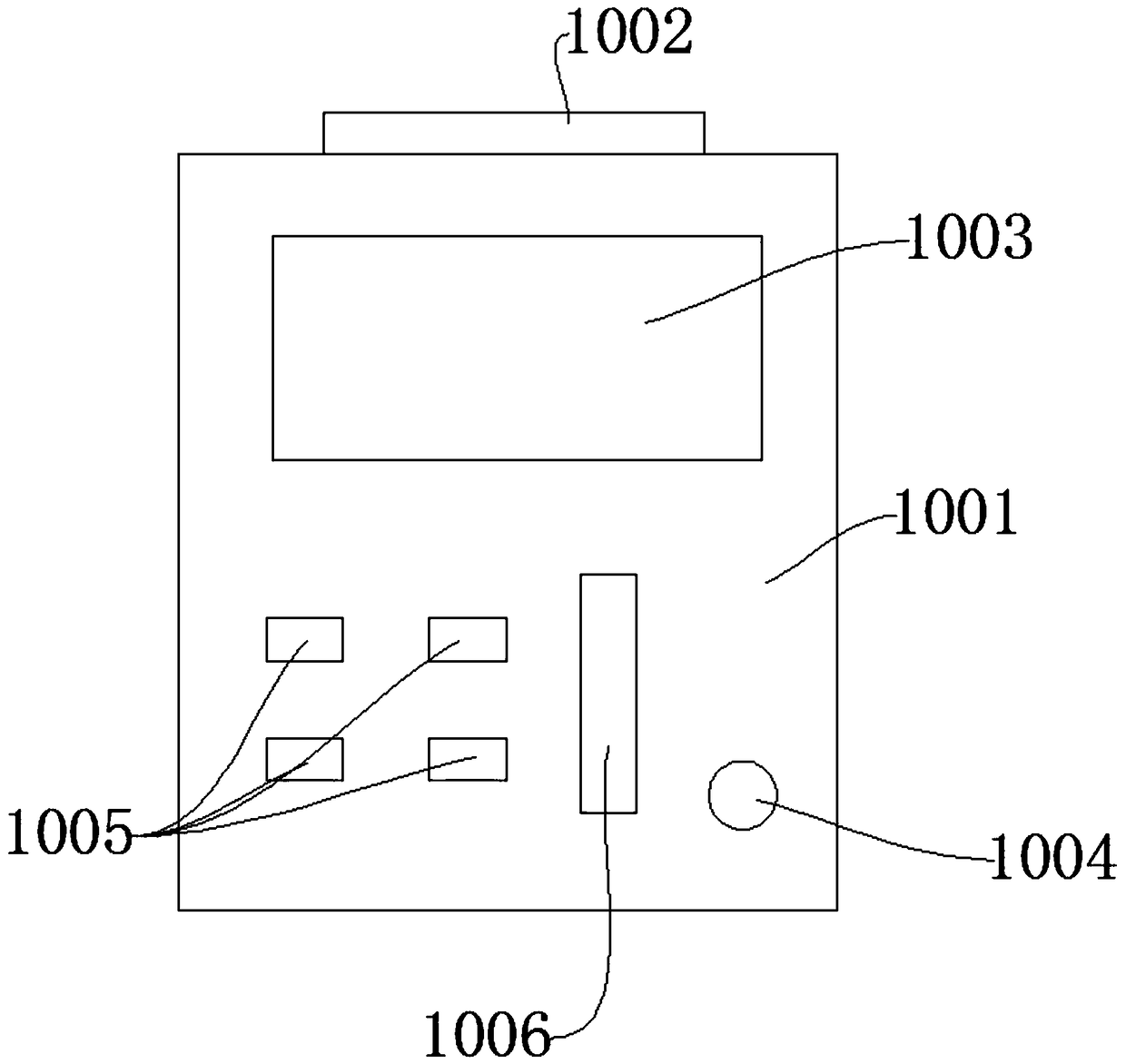

The invention relates to the technical field of sandblasting machines, and in particular relates to an integrated sandblasting machine. The integrated sandblasting machine comprises a main sandblasting cabin, a turntable conveying system, a gun swing mechanism, a compressed air system, a sand material recovery system, a dedusting system and an electric control system. All the system mechanisms adopt an integrated design, more compact connection of the system mechanisms is ensured, the complete machine occupies a small space, the installation cost and the transportation cost are low, and the working operation of the sandblasting machine is more smooth and automatic and high in mechanization degree, thus improving the processing efficiency and the sandblasting effect of the sandblasting machine.

Owner:东莞吉川机械科技股份有限公司

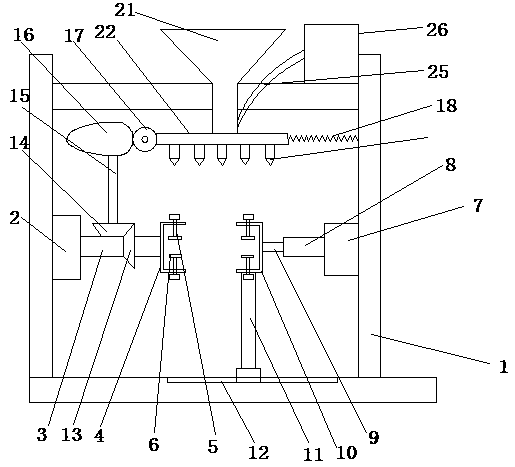

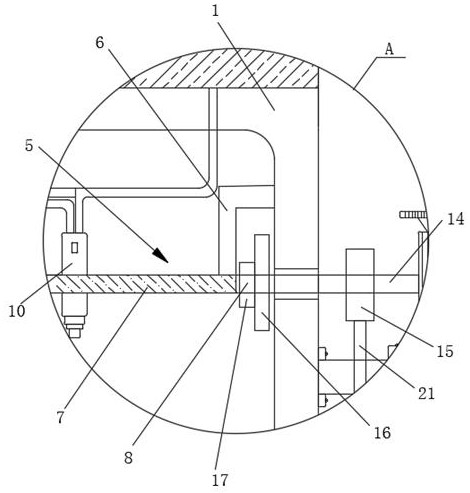

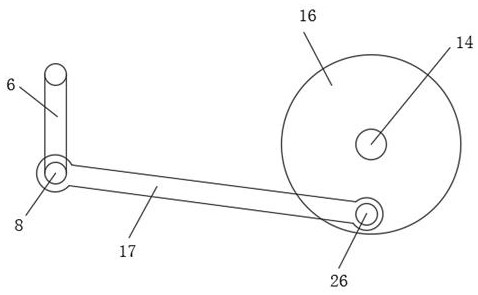

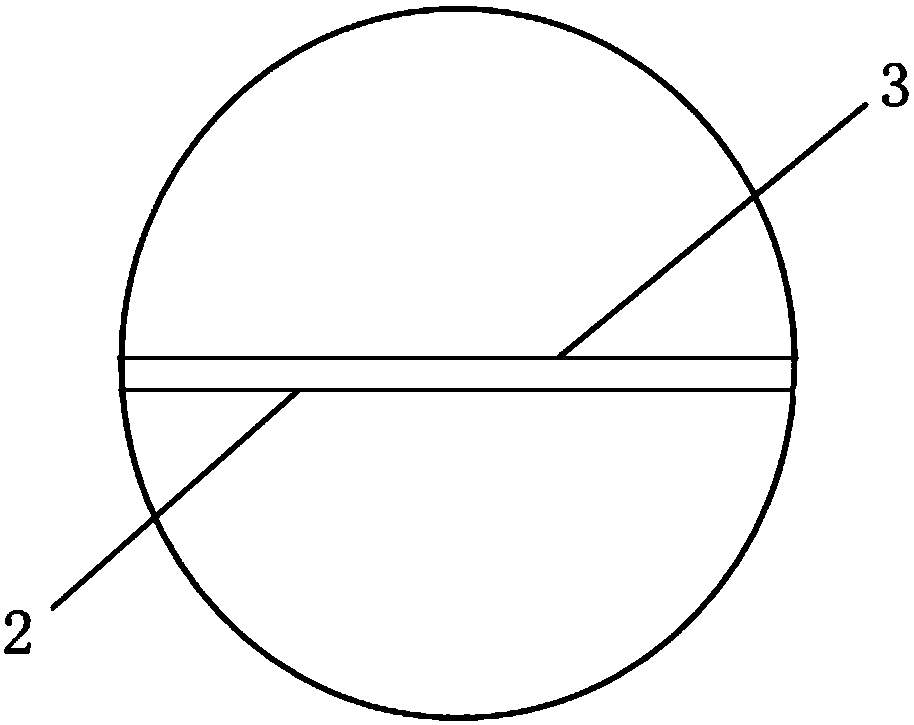

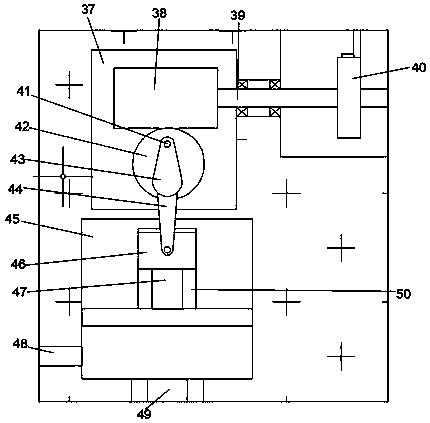

Improved sand-blasting machine

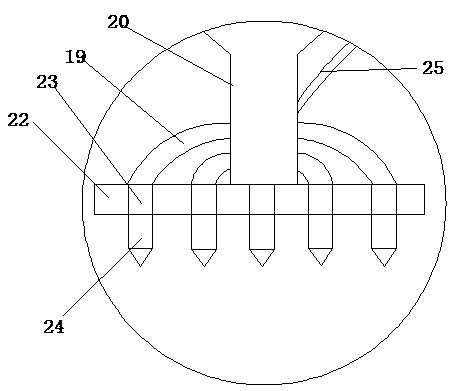

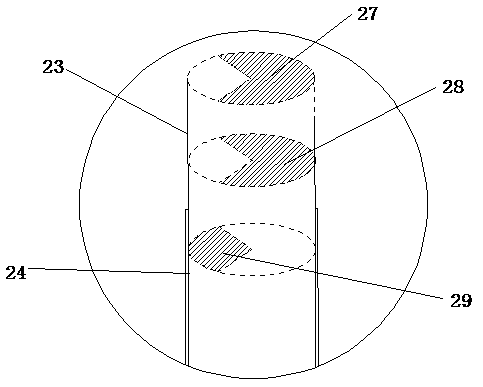

PendingCN108673349AReduce outflowReduce contentAbrasive feedersAbrasive machine appurtenancesSand blastingCam

The invention discloses an improved sand-blasting machine, and belongs to the technical field of machinery. The improved sand-blasting machine comprises a machine frame, a motor, a first rotating shaft, a first guide sleeve, a clamping plate, a driving air cylinder, a rotating rod, and a second guide sleeve. The first rotating shaft is in key connection with a first bevel gear; the first bevel gear meshes with a second bevel gear; the number of teeth of the second bevel gear is twice that of the first bevel gear; a second rotating shaft is in key connection with the upper portion of the secondbevel gear; the second rotating shaft is in connection with a cam; the cam is in contact with a rolling wheel in a matched mode; a plurality of sand-blasting devices are in fixed connection with theother end of the rolling wheel; a spring is in connection with the other end of the sand-blasting devices; the spring is fixedly arranged on the lateral wall of the machine frame; the sand-blasting devices are connected with a feed opening by material sending pipelines; and the feed opening is connected with a sand-storage tank. Automatic sand-blasting is achieved, and omnidirectional sand-blasting is achieved to a workpiece during sand-blasting process, and sand-blasting efficiency is high.

Owner:湖北省麻城市和丰精密机械有限公司

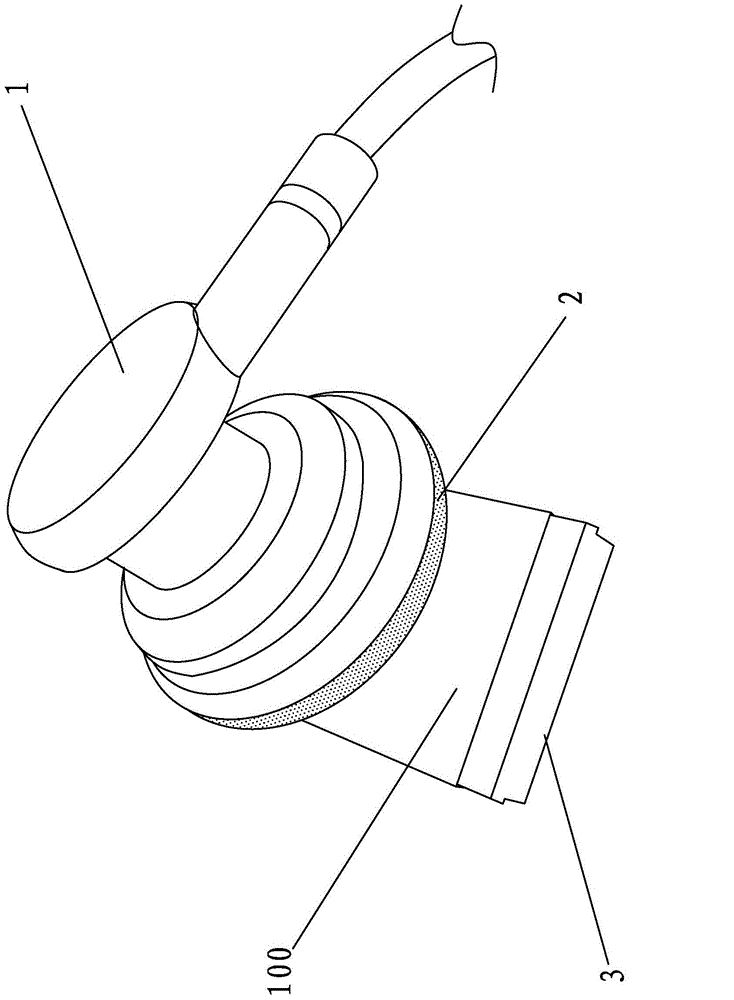

Universal double-gun water mist sand blasting machine

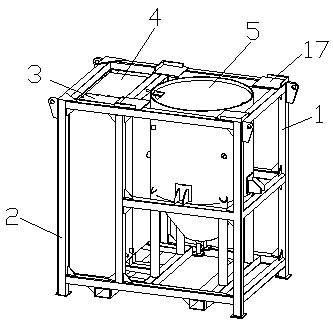

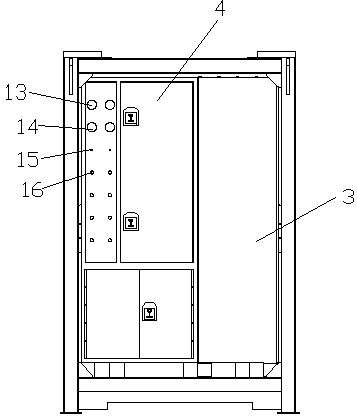

PendingCN108705455AVersatileImprove sandblasting effectAbrasive feedersAbrasive machine appurtenancesElectricitySand blasting

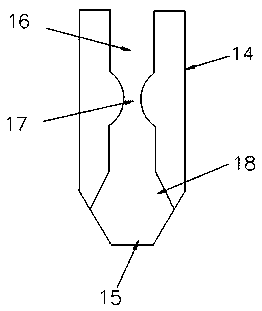

The invention relates to a universal double-gun water mist sand blasting machine. The universal double-gun water mist sand blasting machine comprises a support platform, wherein the support platform is of a cubic framework structure and comprises a first cubic framework and a second cubic framework, a water mist abrasive material mixing cylinder is arranged in the first cubic framework, the secondcubic framework is internally connected with a water tank and an integrated gas electricity control box, two discharging ports are formed in the bottom of the water mist abrasive material mixing cylinder, and the discharge ports are connected with a water mist sand blasting gun. The universal double-gun water mist sand blasting machine is novel in structure, safe and environment-friendly, capableof realizing double-gun water mist sand blasting, and good in sand blasting effect, and enables the functions of the water mist sand blasting machine to be more comprehensive.

Owner:CHENGXI SHIPYARD +1

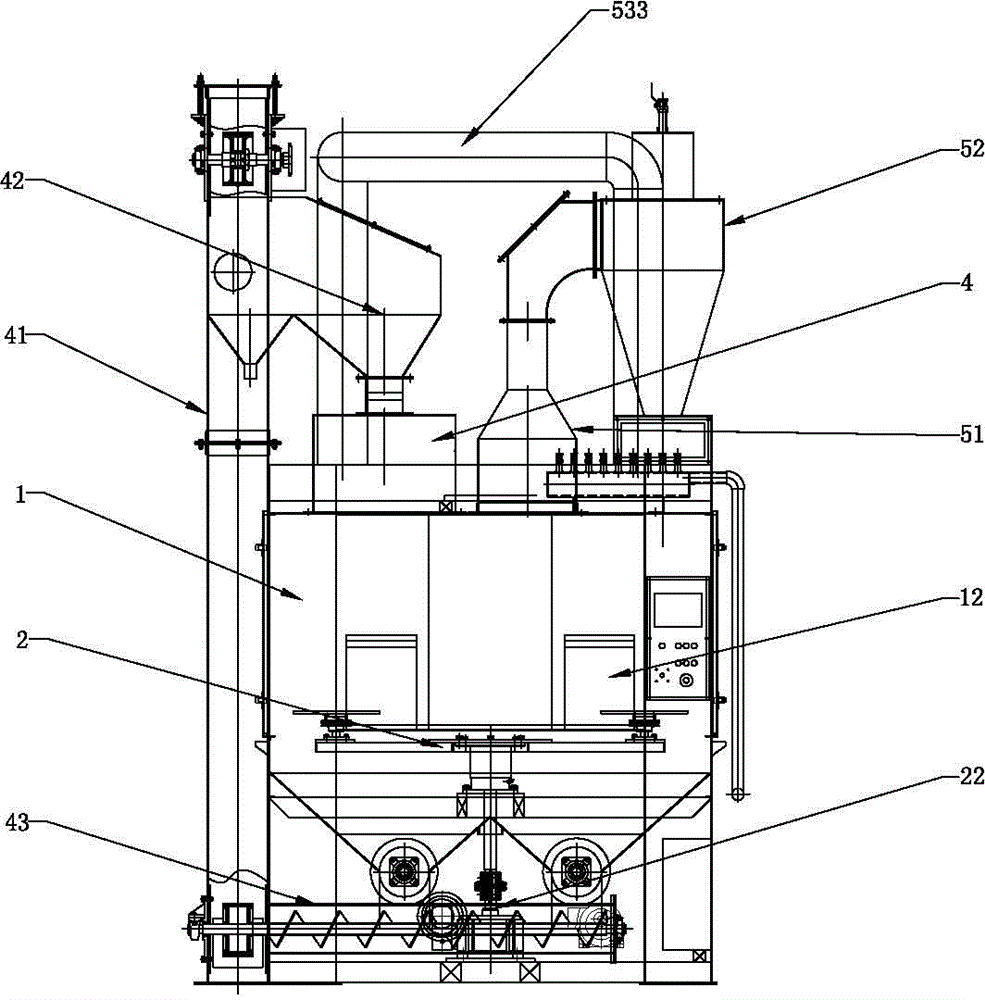

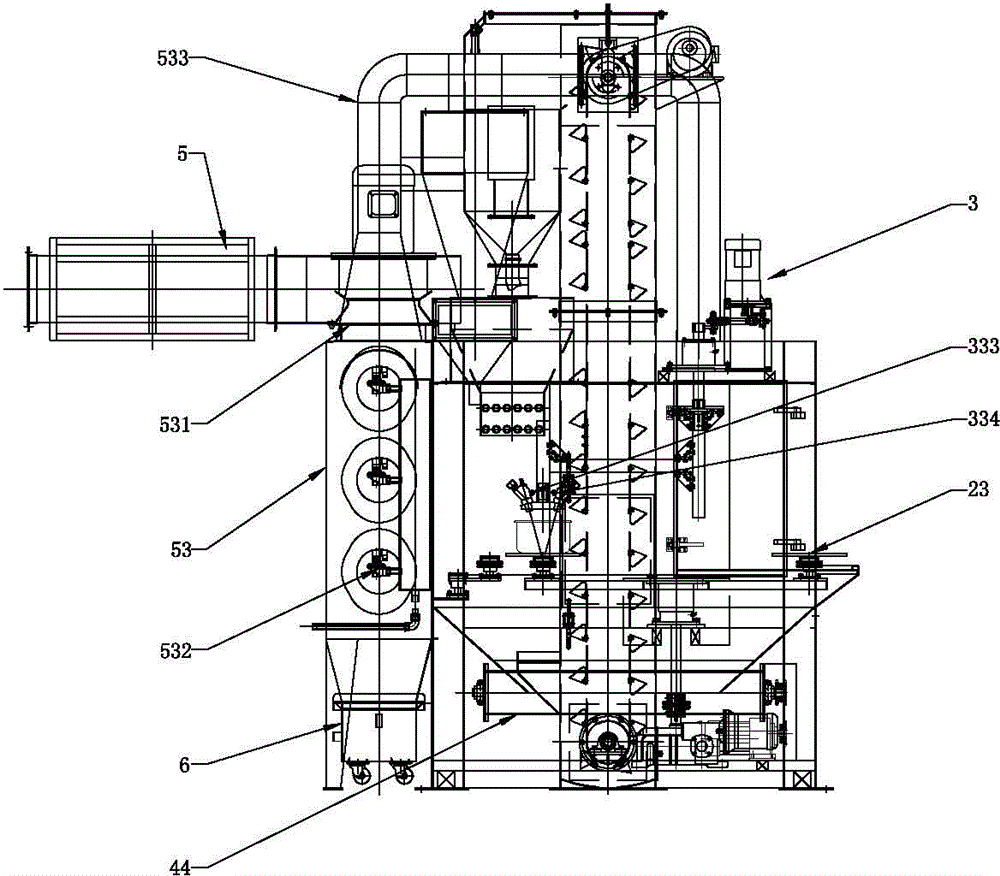

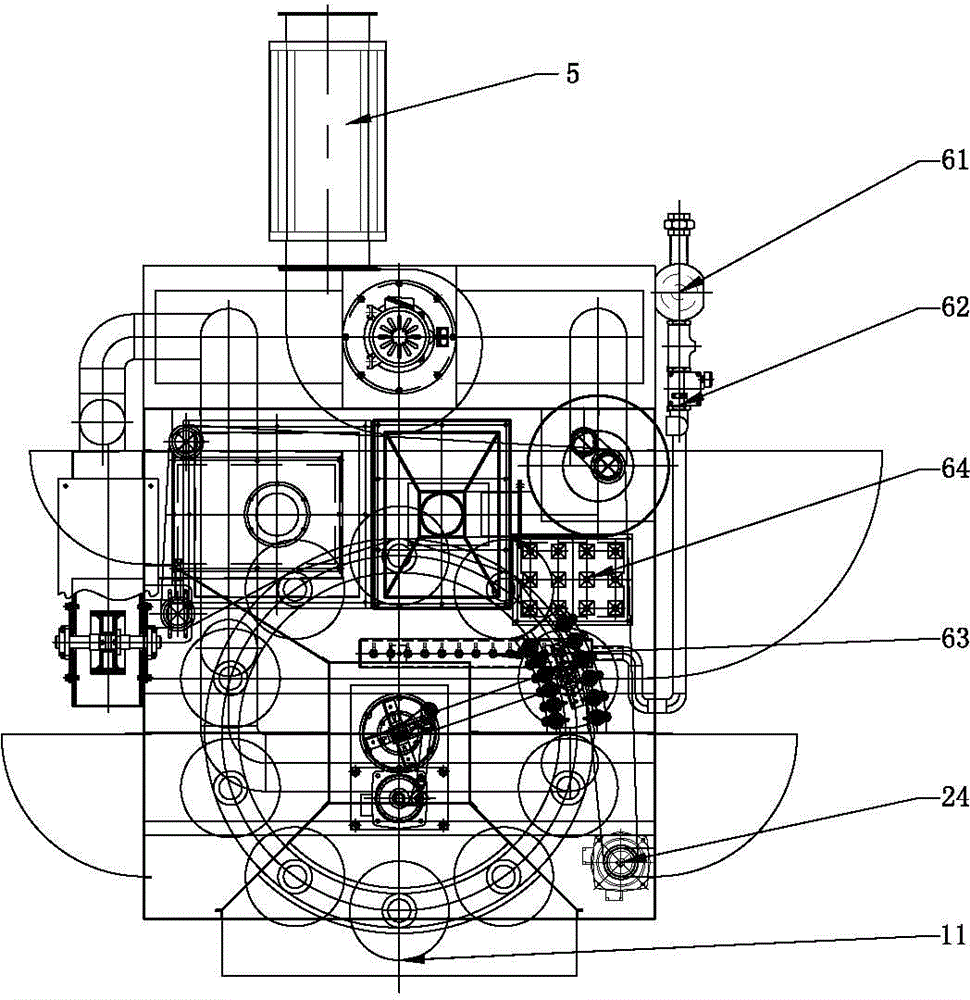

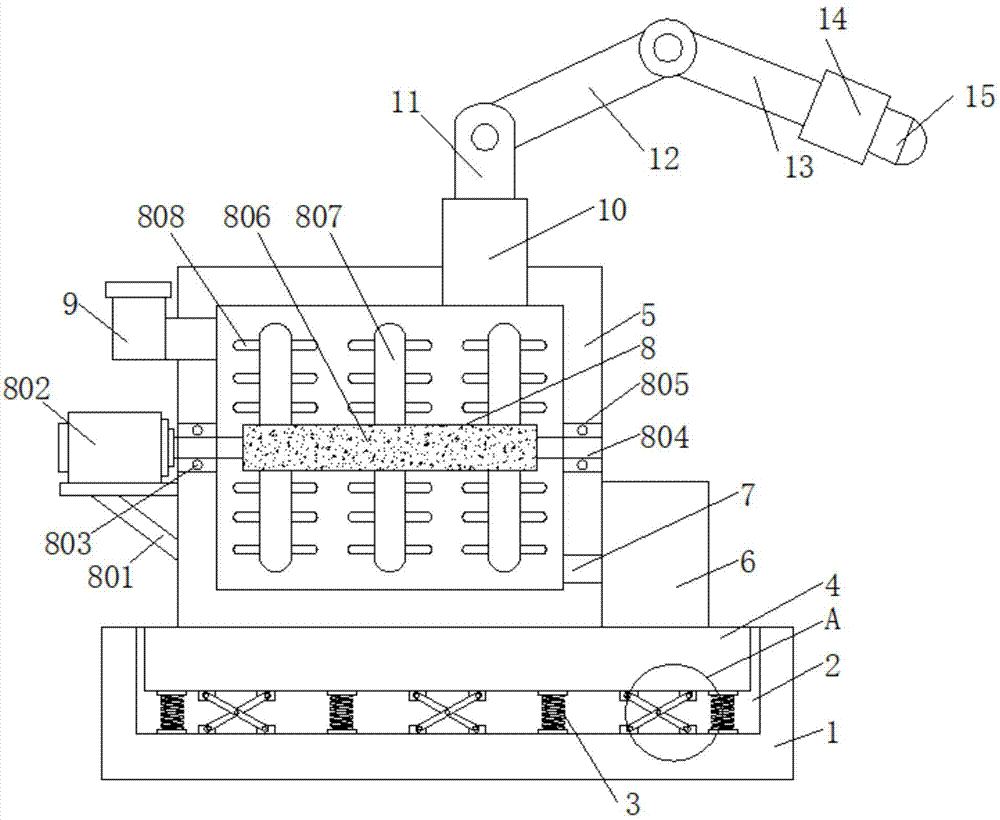

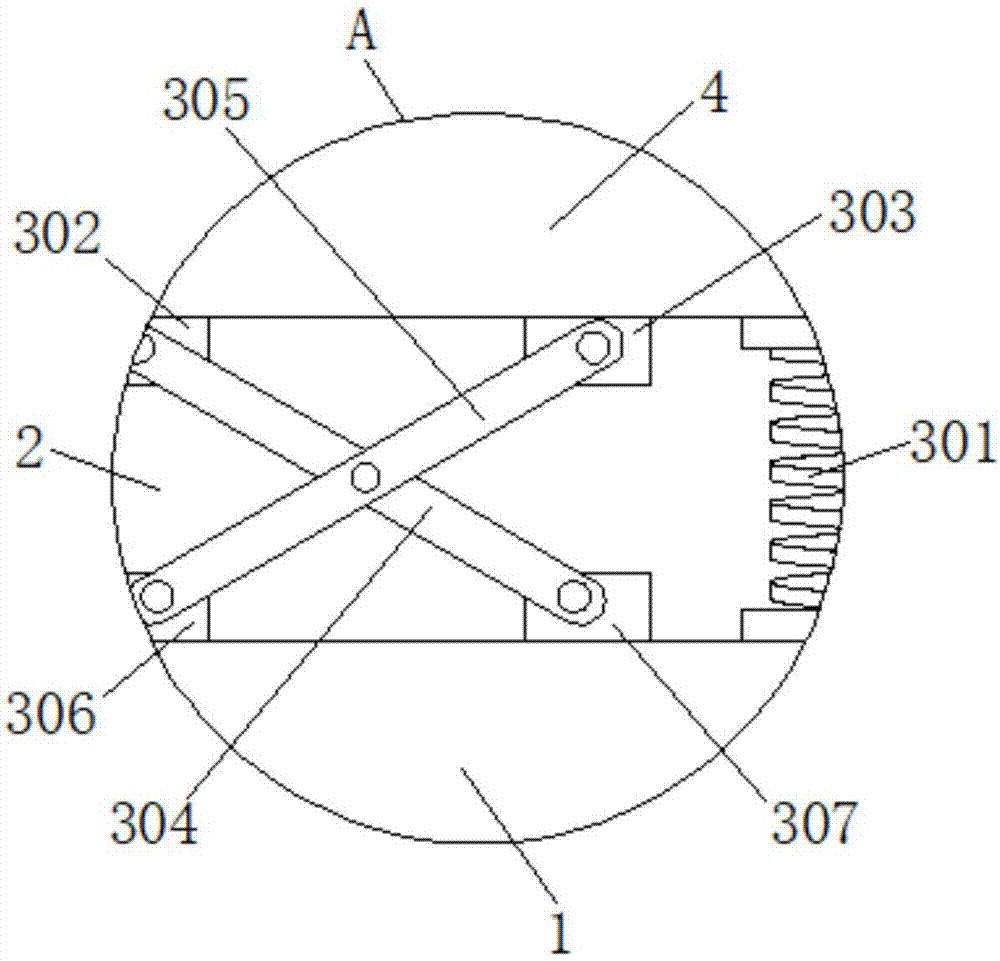

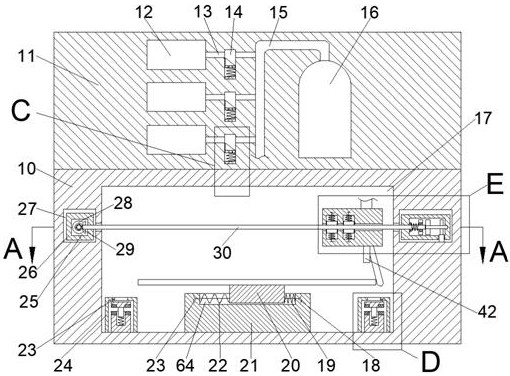

Integrated sandblasting machine

ActiveCN103231314BWork runs smoothlyImprove automationBlast gunsAbrasive feedersIntegrated designEngineering

The invention relates to the technical field of sandblasting machines, and in particular relates to an integrated sandblasting machine. The integrated sandblasting machine comprises a main sandblasting cabin, a turntable conveying system, a gun swing mechanism, a compressed air system, a sand material recovery system, a dedusting system and an electric control system. All the system mechanisms adopt an integrated design, more compact connection of the system mechanisms is ensured, the complete machine occupies a small space, the installation cost and the transportation cost are low, and the working operation of the sandblasting machine is more smooth and automatic and high in mechanization degree, thus improving the processing efficiency and the sandblasting effect of the sandblasting machine.

Owner:东莞吉川机械科技股份有限公司

Method for comprehensively utilizing air quenched slag of steel converter

ActiveCN104141027ALow costImprove sandblasting effectAbrasion apparatusManufacturing convertersSteelmakingAir volume

The invention discloses a method for comprehensively utilizing air quenched slag of a steel converter and belongs to the technical field of comprehensive use of converter slag. The method for comprehensively utilizing the air quenched slag of the steel converter includes the steps that first, the converter slag is preprocessed; second, the converter slag is subjected to thermal refining; third, the slag is subjected to air quenching; fourth, the converter slag is screened; fifth, sand blasting is performed. According to the method, the converter slag is preprocessed and subjected to thermal refining and then subjected to air quenching, and the humidity and the ratio air volume of air are strictly controlled so that the air quenched converter slag can meet the requirement for sand-blasting abrasive, sand-blasting abrasive cost is reduced, a special sand blasting system is adopted in the sand blasting process, and the sand blasting effect is good; the surface smoothness of workpieces processed through the converter air quenched slag is larger than Sa2.5, and the industrial coating requirement is met.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Energy-saving type steel tube sand blasting machine

InactiveCN109807757AAvoid displacementSmooth rotationAbrasive machine appurtenancesAbrasive blasting machinesSand blastingBlast effects

The invention discloses an energy-saving type steel tube sand blasting machine. The energy-saving type steel tube sand blasting machine comprises a box body. A feeding door is hinged to one side of the box body. An extending-and-contracting rotor is movably arranged in each rolling wheel in an inserted manner. A driving belt wheel is fixedly mounted on a driving shaft of a driving motor. A horizontal movement lead screw is further fixedly mounted on the driving shaft of the driving motor. A horizontal movement seat is movably mounted on the horizontal movement lead screw. An extending-and-contracting rod is movably mounted on the horizontal movement seat. Multiple spray heads are fixedly mounted on a sand blasting seat. A gear shaft of a driving gear and a gear shaft of a driven gear are each fixedly provided with a magnetic attraction roller. Each magnetic attraction roller is internally uniformly provided with multiple tile type magnets. A water sand blasting box communicates with asand blasting pump through a pump. By means of the energy-saving type steel tube sand blasting machine, surface sand blasting treatment can be conducted on steel tubes of different diameters and different lengths; in the blasting process, stability of the steel tubes can be guaranteed, and meanwhile, iron chippings formed by sand blasting impact can be recycled; sand blasting liquid obtained afterblasting can enter the sand blasting cycle once again; and energy conservation and environmental protection are achieved, and the sand blasting effect is good.

Owner:ANHUI RUIDA MACHINERY

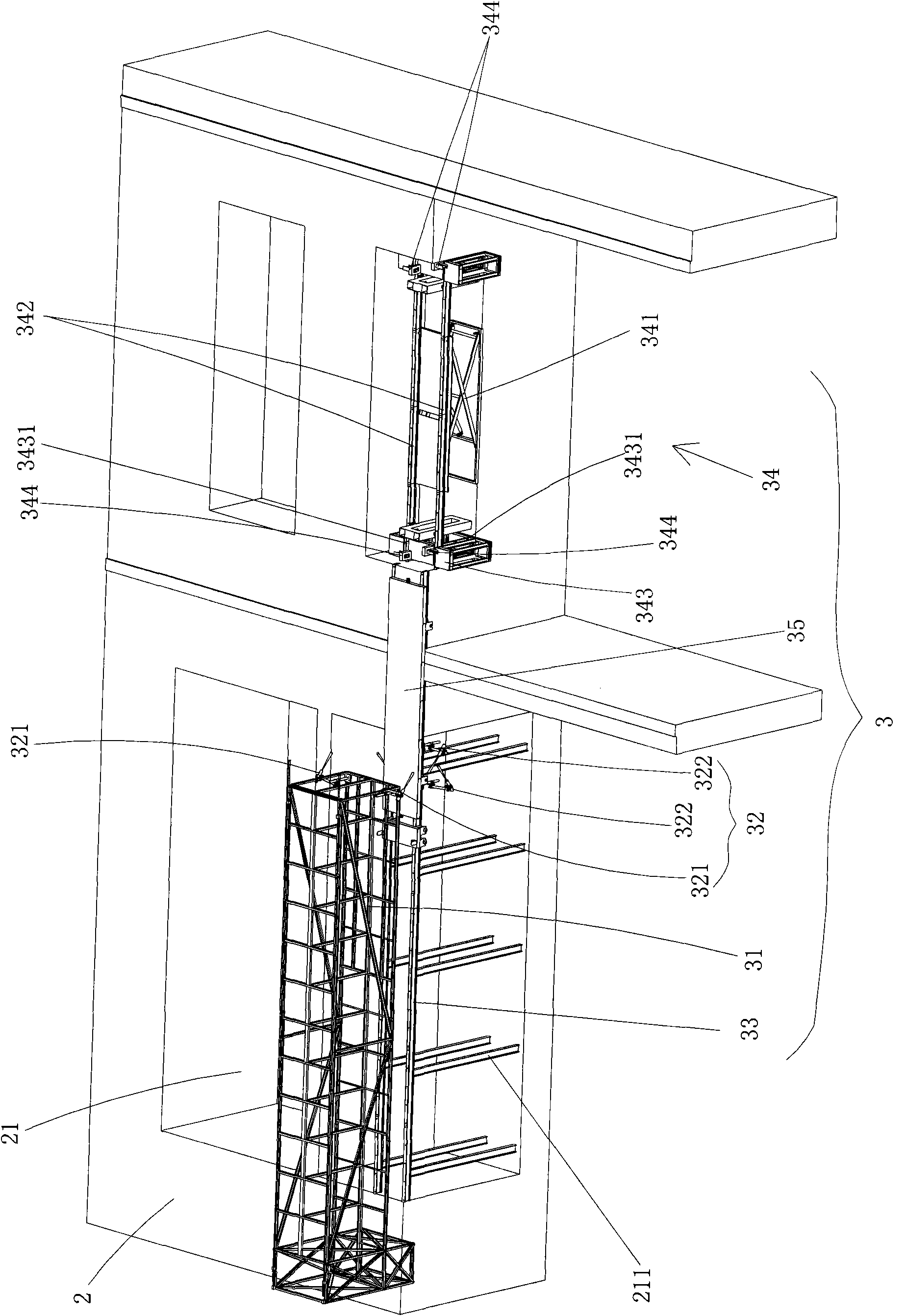

Sand blasting machine and sand blasting system provided therewith

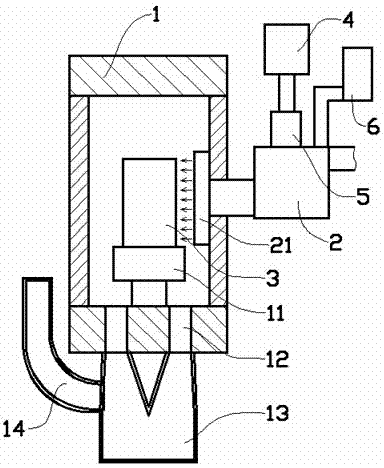

InactiveCN101934499AFully automatedQuick aimAbrasive machine appurtenancesAbrasive blasting machinesSand blastingEngineering

The invention discloses a sand blasting machine and a sand blasting system provided therewith, which can be used for the container chassis welding line to blast sand. The sand blasting machine comprises two first rails, a truss, a cargo carrying platform and at least one driving mechanism, wherein the first rails are erected in parallel; the truss is hung above the first rails; the cargo carrying platform is arranged on the first rails; the driving mechanism drives the cargo carrying platform to slide back and forth on the first rails; two sides of the truss, which correspond to the width direction of the cargo carrying platform, are respectively provided with at least one upper sand box; the position corresponding to each upper sand box below the first rails is respectively provided with two lower sand boxes so as to make the container arranged on the cargo carrying platform and dragged back and forth by the cargo carrying platform for realizing scanning-type sand blasting via an upper sand gun and a lower sand gun. The sand blasting system realizes full-automatic sand blasting of container chassis C-type welding lines, can effectively solve influence on sand blasting quality by illumination or human factors for R-angle welding lines.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

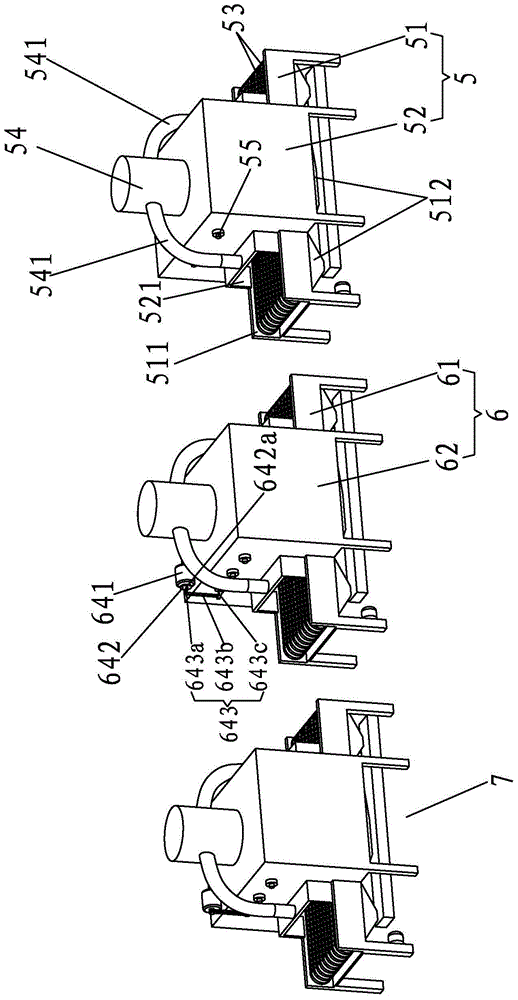

Mechanical arm used for automatic sand blasting

InactiveCN106670982ARealize automatic controlImprove work efficiencyMeasurement devicesAbrasive machine appurtenancesSand blastingBlast effects

The invention discloses a mechanical arm used for automatic sand blasting. The mechanical arm comprises a fixed base, a linear sliding rail and a sand blasting mounting plate; a first sliding groove is formed in the inner wall of one side of the fixed base, a first sliding base is in sliding connection to the inner wall of the first sliding groove, one side of the first sliding base extends to one side of the fixed base, a first motor is arranged above the first sliding base, and is fixedly mounted on the inner wall of the top of the first sliding groove, an output shaft of the first motor is connected with a screw rod, and the bottom of the screw rod is in sliding connection with the inner wall of the bottom of the first sliding groove; the liner sliding rail is arranged on the side, away from the fixed base, of the first sliding base; the mechanical arm is simple in structure, economical, practical, low in manual cost and high in work efficiency, the mechanical arm use for automatic sand blasting can automatically adjust the distance between a sand blasting mounting plate and an object to be treated in the vertical direction and the horizontal direction, and the sand blasting effect of the mechanical arm used for automatic sand blasting is good.

Owner:ANHUI ZHILIANG INVESTMENT GRP

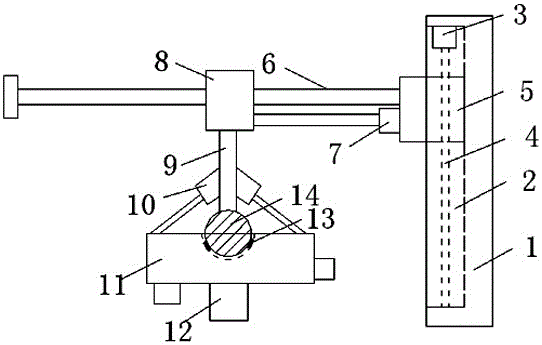

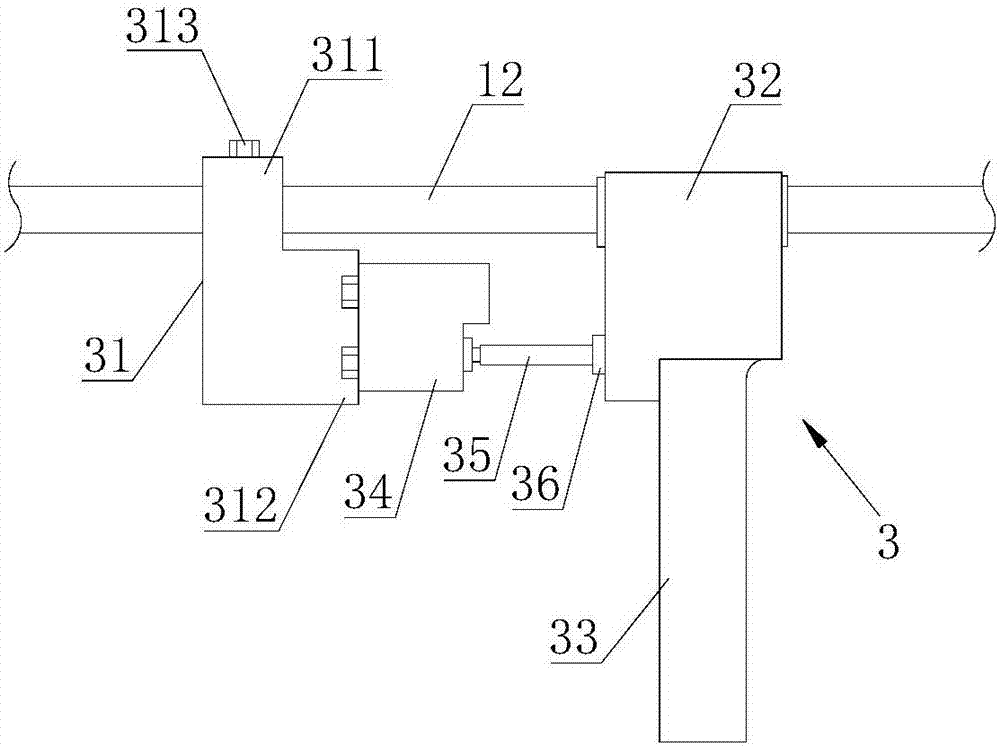

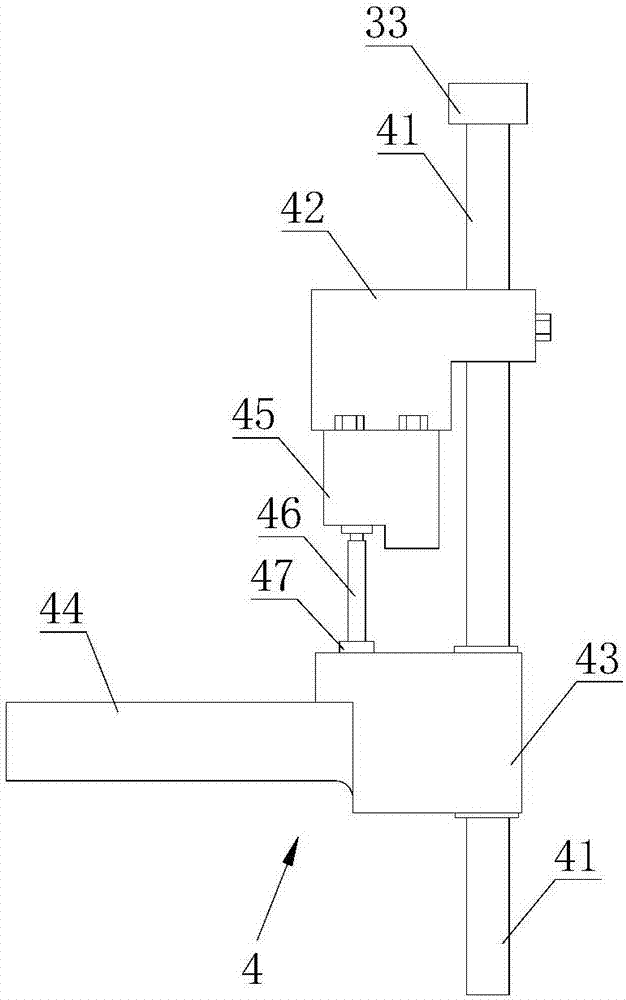

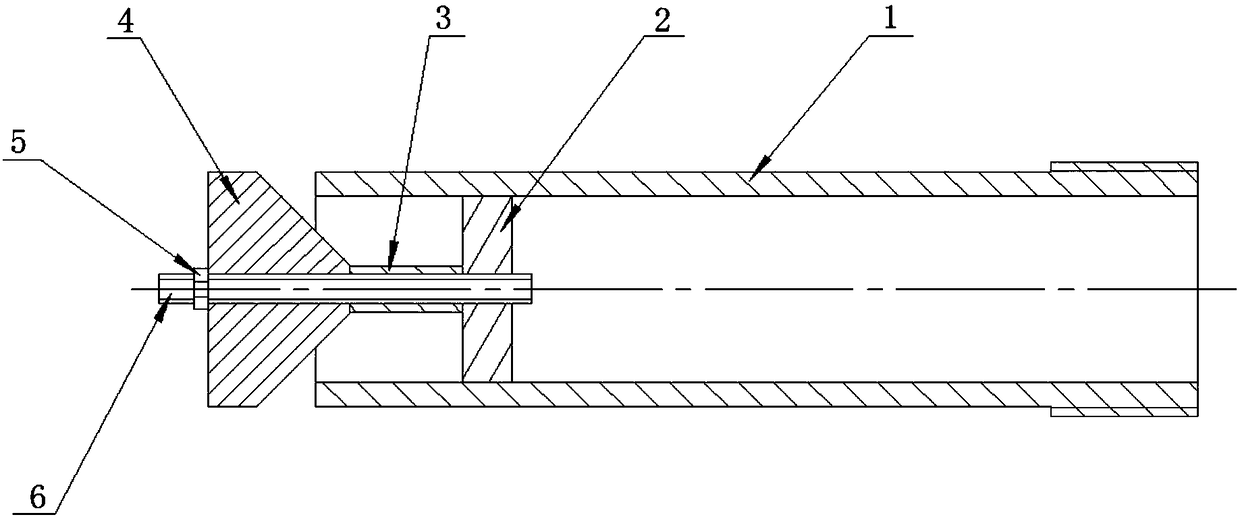

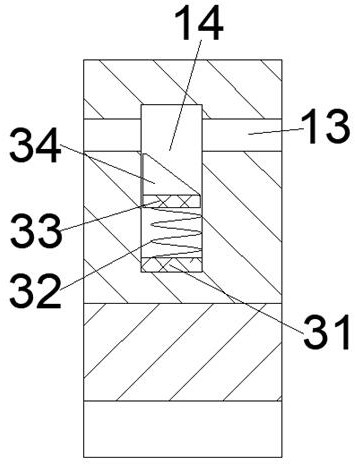

Automatic pipe end thread sandblasting machine

ActiveCN102729154ACompact structureReduce volumeBlast gunsAbrasive machine appurtenancesSteel tubeGalling

The present invention provides an automatic pipe end thread sandblasting machine. The sandblasting machine comprises an online automatic pipe end sandblasting machine comprising a mechanical part, a pneumatic part and an electric apparatus control part. The sandblasting machine of the present invention has the following benefits that: anti-galling and anti-corrosion of the thread portion of the steel pipe are improved. The sandblasting machine of the present invention has characteristics of simple structure, easy maintenance, small size, low pollution, and easy use, and is suitable for online pipe end sandblasting treating. In addition, the sandblasting machine has the following advantages that: the sandblasting machine has effects of other blasting ways, and provides good sandblasting effects after the actual production, the work efficiency is high, the processing cost is significantly reduced. With the actual production practices, the production output is increased by 40%, and the qualified rate of the product is improved by 5%.

Owner:TIANJIN PIPE GROUP CORP

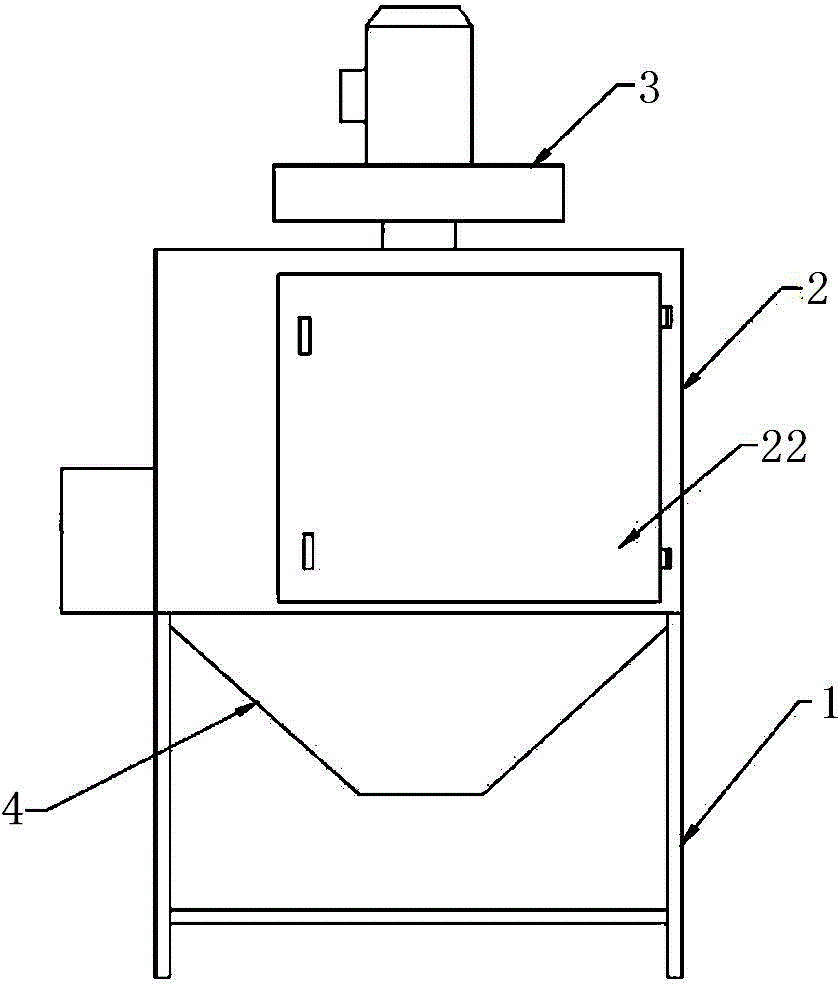

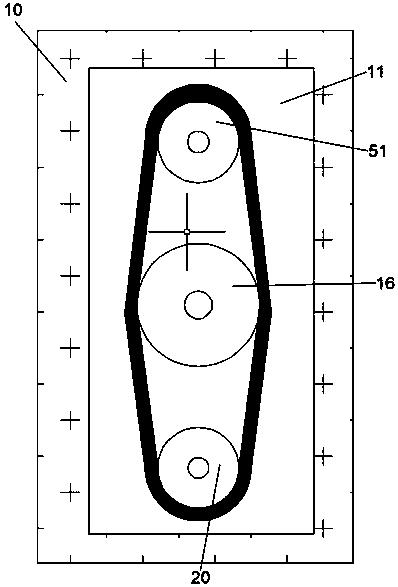

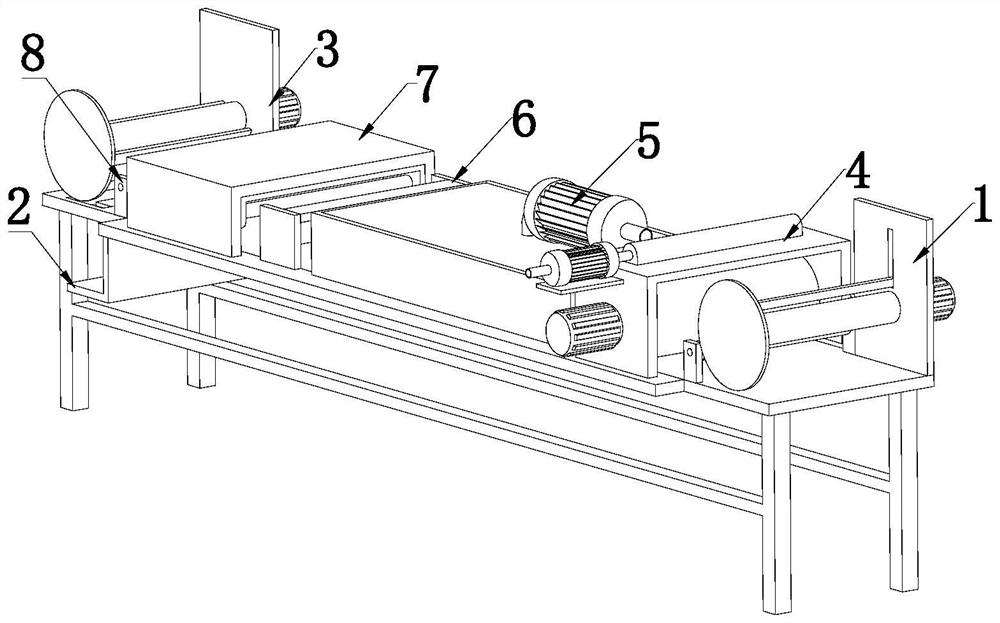

Sand-blast treating equipment used for band saw strip

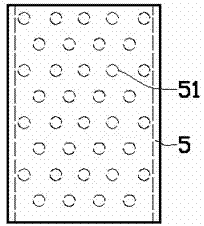

InactiveCN104625973AIncrease the number ofImprove sandblasting effectBlast gunsAbrasive machine appurtenancesEngineeringTransmission channel

The invention relates to a sand-blast treating equipment used for band saw strip, which comprises a pedestal, a blaster case is arranged on the pedestal, a drawing fan for exhausting in the case is arranged at top of the blaster case, the blaster case comprises a sealing door, a saw blade transmission channel is arranged in the case, six sandblast guns are arranged over the saw blade transmission channel, and are uniformly distributed at two sides of the saw blade transmission channel, a sand accommodation groove is arranged at lower part of the blaster case, and the sand accommodation groove is connected to the spray gun through a pipeline. By greatly increasing the quantity of the sandblast gun, sandblast efficiency is greatly increased, due to obvious increase of the sandblast gun quantity, the sandblast effect of the band saw strip is better, and sandblast quality can be ensured. According to the invention, the drawing fan is arranged at top of the blaster case, under effect of the drawing fan, emery in the sand accommodation groove is taken into the sandblast gun and then can be sprayed to the surface of the band saw strip, superfluous sand in the case can be extracted by the drawing fan simultaneously, so that the normal running in the case can be ensured.

Owner:RUI HUI TECH CO LTD HUBEI

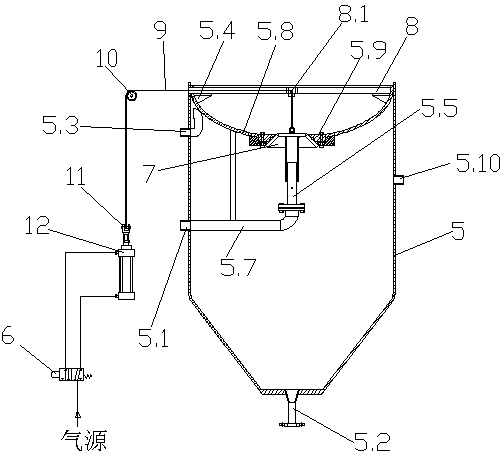

Abrasive sand blasting device

InactiveCN109866113AReduce wasteReduce in quantityAbrasive feedersAbrasive machine appurtenancesSand blastingEngineering

The invention provides an abrasive sand blasting device. The abrasive sand blasting device comprises a main machine body; a feeding hole is formed in the end surface of the top of the main machine body; a grinding cavity is formed in the main machine body at the bottom of the feeding hole in a communicating manner; grinding mechanisms are symmetrically arranged on the left side and the right sideof the grinding cavity; the grinding mechanism positioned on the right side is higher than the grinding mechanism on the left side; material leakage holes which are formed in bilateral symmetry are formed in the main machine body at the bottom of the grinding cavity; the device which can perform sand blasting work in a closed environment is designed; meanwhile, quartz sand can be recycled and reutilized after the sand blasting is completed; and the waste of the quartz sand is reduced; meanwhile, the quartz sand can be ground by the device so that the sand is more refined; therefore, the sand blasting grinding effect is improved; meanwhile, according to the device, most mechanisms can be driven to work by one power source; the number of motors is reduced; the cost is reduced; and moreover,a transmission structure is single and convenient to maintain.

Owner:杭州诚娇服饰有限公司

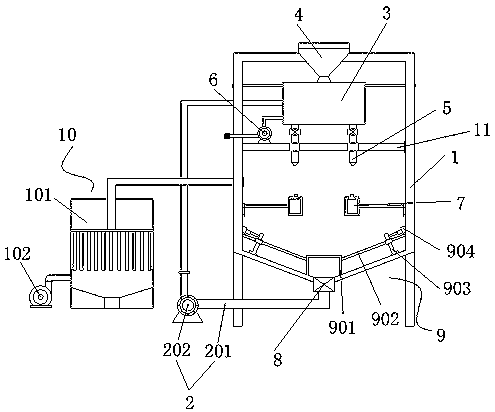

Sand blasting machine with recycling effect

InactiveCN108857911AImprove sandblasting effectAvoid insufficient sandblastingAbrasive machine appurtenancesAbrasive blasting machinesFixed frameBlast effects

The invention discloses a sand blasting machine with recycling effect. The sand blasting machine comprises a sand blasting box, and a grinding material circulating device, wherein the interior of thesand blasting box is fixedly connected with a material storage tank; the upper end of the material storage tank is communicated with a material inlet; a spray head is arranged at the lower end of thematerial storage tank; an aeration pump is arranged at the side wall of the material storage tank; a workpiece fixing frame is arranged just under the spray head; the bottom part of the sand blastingbox is in a cone shape, and the bottom end of the sand blasting box is provided with a sand outlet; a sand cleaning device is arranged at the bottom part of the sand blasting box; and comprises a support frame, and the support frame is fixedly connected with a sand outlet; a slide rod is arranged on the support frame, and is glidingly connected with a sand pushing rod; a circulating pipe is communicated with a sand suction pump. The sand blasting machine has the advantages that by arranging the sand cleaning device at the bottom part of the sand blasting box, the grinding material which is accumulated at the bottom part of the sand blasting box is continuously pushed to a sand outlet to recycle, so as to solve the problem of unenough sand blasting amount due to accumulation of the grindingmaterial; the sand blasting effect of the workpiece can be fundamentally improved.

Owner:南京苏格信息技术有限公司

Workpiece sandblast apparatus and method thereof

InactiveCN108818326AStrong sandblastingExtended service lifeBlast gunsAbrasive machine appurtenancesHand heldAir pump

The invention discloses a workpiece sandblast apparatus and a method thereof. The sandblast apparatus comprises a sandblast case and a bottom rack, the bottom support comprises supporting legs and anoperation platform, the sandblast case is arranged over the bottom support, several sand outlets are uniformly distributed at the operation platform, a sand-collection case is arranged below the operation platform, the sand-collecting case is fixedly connected at a drawing fan at the bottom support through an exhausting pipe, a sandblast component is arranged at an inner chamber of the sandblast case, the sandblast component comprises a hand-held part, a spray gun and an air pipe, the spray gun is arranged at the lower end of the hand-held part, the upper end of the hand-held part is connectedand arranged at an air pump of the bottom support through the air pipe, the air pipe, is communicated with a sand-storage case through a branch pipe, a treading controller is arranged at the bottom of the supporting leg, and the treading controller is electrically connected with the air pump. The workpiece sandblast apparatus has the advantages of simple structure principle, realizes efficient and uniform sandblast on the workpiece, and the employed spray gun has the advantages of large strength and long service life.

Owner:MAANSHAN NIUZE TECH SERVICE

Sand blasting type heat treatment device

The invention provides a sand blasting type heat treatment device which comprises a heat treatment furnace and a sand blaster, wherein a rotating platform capable of performing self-axis rotation along a vertical axis is designed at the bottom of the inner chamber of the heat treatment furnace; a metal workpiece to be subjected to heat treatment is fixed above the rotating platform; the sand blaster is fixed on the outer side of the heat treatment furnace; the sand blasting head of the sand blaster penetrates into the heat treatment furnace; a sand storage box is fixed above the sand blaster; the sand storage box is communicated with the sand blaster through a heating box; the sand blaster is connected with a high-pressure gas circuit. The sand blasting type heat treatment device blasts high-temperature and high-pressure grinding sand to the surface of the metal workpiece to grind the surface of the metal workpiece, and simultaneously heats the metal workpiece so as to facilitate the next heat treatment operation on the metal workpiece.

Owner:WUJIANG JIA BILLION ELECTRONICS TECH

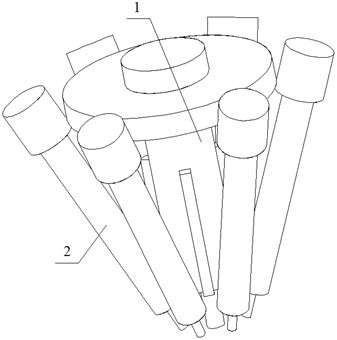

Multifunctional sand blasting device for machining high speed train cast aluminum gear box die

ActiveCN106312833ARealize continuous blastingImprove work efficiencyAbrasive machine appurtenancesAbrasive blasting machinesSand blastingEngineering

The invention provides a multifunctional sand blasting device for machining a high speed train cast aluminum gear box die. The multifunctional sand blasting device comprises a base, a cover body, a clamping mechanism and a sand blasting mechanism. The clamping mechanism comprises a first rotary disc, a second rotary disc, a first drive mechanism, a second drive mechanism and multiple clamping devices. The first drive mechanism is connected with the first rotary disc and drives the first rotary disc to rotate. The second drive mechanism is connected with the second rotary disc and drives the second rotary disc to rotate. The multiple clamping devices are circumferentially distributed with the central axis of the first rotary disc as the central axis. The two ends of each clamping device are connected with the first rotary disc and the second rotary disc correspondingly. The sand blasting mechanism comprises an installation frame, a third drive mechanism, and multiple sand blasting devices used for conducting sand blasting on to-be-machined workpieces. The installation frame is connected with the third drive mechanism and is driven by the third drive mechanism to vertically move in the vertical direction, and the multiple sand blasting device are arranged on the installation frame at intervals. According to the multifunctional sand blasting device, continuous sand blasting can be achieved on the high speed train cast aluminum gear box die under the cooperation of the clamping mechanism and the sand blasting mechanism.

Owner:LAIAN KELAIXING IND CO LTD

Post processing technology of mobile phone rear cover

ActiveCN104618538ASimplify processingLow production costTelephone set constructionsEngineeringSandpaper

The invention discloses a post processing technology of a mobile phone rear cover. The post processing technology of the mobile phone rear cover is achieved through following steps: 1) completing roughing through polishing: sticking a 600 grit abrasive paper to a polishing disk of a first handheld polisher in the polishing; 2) achieving smoothing through polishing: sticking a 1000 grit scouring pad of the 3M (Minnesota mining and manufacturing) company to a polishing disk of a second handheld polisher in the smoothing; 3) firstly, placing a smoothed part obtained in the step 2) on a net screen plate, and then feeding the net screen plate into a first sand blasting chamber so as to perform sand blasting on the side face of the smoothed part; 4) feeding the part together with the net screen plate into a second sand blasting chamber after the sand blasting is performed on the side face of the part in the step 3) so as to perform sand blasting on the reverse side of the part; 5) firstly, turning the part on the net screen plate by 180 degrees after the sand blasting treatment is performed on the reverse side of the part, and then sending the net screen plate into a third sand blasting chamber so as to perform sand blasting on the obverse side of the part. Compared with the prior art, no cleaning treatment is needed in the whole process of the post processing technology of the mobile phone rear cover, treatment procedures are simplified, time and labor are saved, manufacture cost is reduced, and simultaneously the mobile phone rear cover does not need to be fixed by a special clamp in the sand blasting, the sand blasting can be achieved in all directions by simply placing the mobile phone rear cover, and operation is simple and easy.

Owner:通达(石狮)科技有限公司

Uniform sand blasting device for automobile accessories

InactiveCN109202741AIncrease contact areaImprove spraying efficiencyAbrasive machine appurtenancesAbrasive blasting machinesSand blastingEngineering

The invention discloses an uniform sand blasting device for automobile accessories. The uniform sand blasting device comprises a box body, wherein the top of the box body is fixedly connected with a top box; the bottom of the inner wall of the top box is fixedly connected with a first motor; one end of an output shaft of the first motor is fixedly connected with a first bevel gear; a threaded rodis rotationally connected in front of two sides of the inner wall of the top box; one side of the surface of the threaded rod is fixedly connected with a second bevel gear engaged with the first bevelgear; the uniform sand blasting device relates to the technical field of automobile accessory production. The uniform sand blasting device for the automobile accessories has the advantages that one end of the output shaft of the first motor is fixedly connected with the first bevel gear; the work burden of workers is reduced; the fast and efficient sand blasting on the automobile accessories is realized; the other side of the surface of the threaded rod is connected with a slide block through screw threads; the bottom end of a vertical pipe is fixedly connected with a spray head; the sand blasting is performed in a leftward and rightward moving mode; the contact area between the automobile accessories and a material is increased.

Owner:江苏圣金特汽车配件有限公司

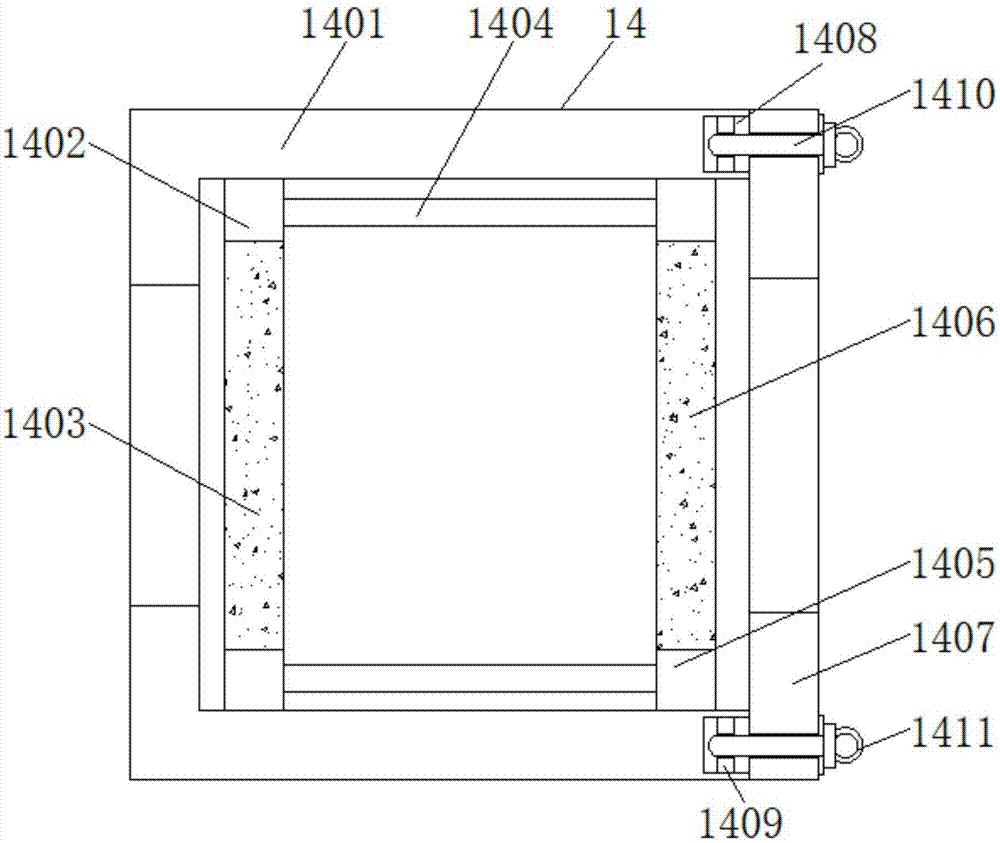

Sand blasting device for processing automobile accessories and parts and sand blasting method thereof

InactiveCN109352537AImprove securityStrong ability to work sustainablyAbrasive machine appurtenancesAbrasive blasting machinesSand blastingBlast effects

The invention discloses a sand blasting device for processing automobile accessories and parts and a sand blasting method of the sand blasting device. The sand blasting device comprises a closed box body and a vibration exciter. A chassis is arranged at the bottom of the closed box body. The lower portion of the chassis is connected with walking wheels through detachable connecting modules. The upper portion of the chassis is connected with a material spraying tank through a buffering base. An observation window is arranged on the side wall of the material spraying tank. A material injection valve is arranged on the upper portion of the material spraying tank connected with the vibration exciter. A flowmeter is arranged between the vibration exciter and a high-pressure main machine, and the other end of the high-pressure main machine is connected with a sand blasting nozzle through a flow guiding pipe. The sand blasting device for processing the automobile accessories and the parts andthe sand blasting method of the sand blasting device have the beneficial effects that (1) waterproof requirements of power equipment are fully considered, the safety performance is good, and the continuous operation capability is strong; (2) sand materials and spraying liquid are excited and sufficiently mixed, so that precipitation of the sand materials and spraying liquid is avoided, and the sand blasting effect is improved; and (3) sand blasting operation can be carried out continuously to improve the production efficiency.

Owner:天津卓睿汽车配件制造有限公司

Intelligent sandblasting machine for workpiece surface treatment

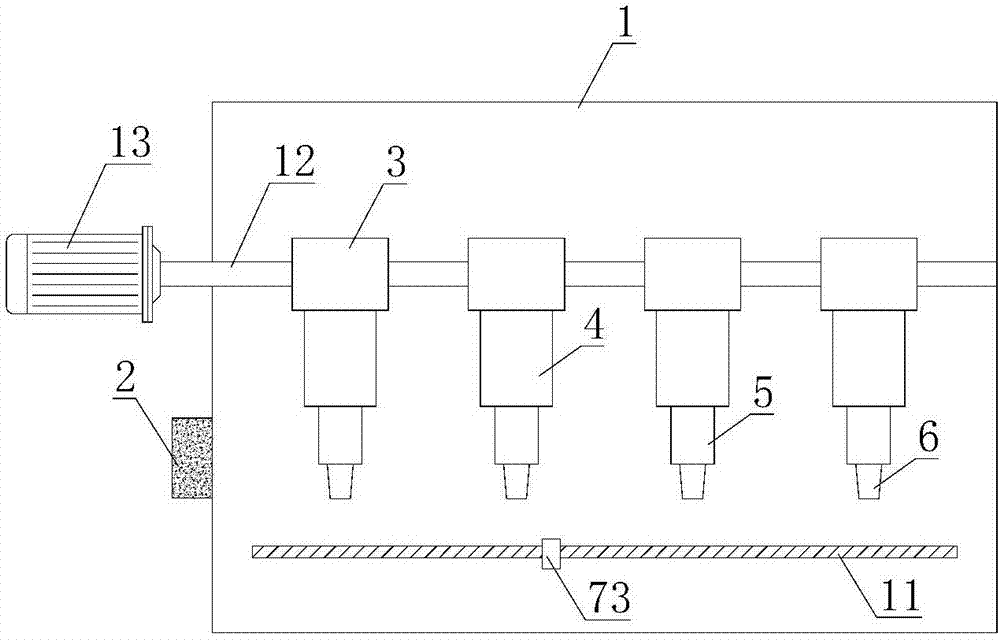

InactiveCN107443258AAchieving Quantitative ControlInjected material is reduced in disguiseBlast gunsAbrasive machine appurtenancesSand blastingElectric machinery

The invention provides an intelligent sandblasting machine for workpiece surface treatment. The intelligent sandblasting machine for workpiece surface treatment comprises a sand blasting chamber, a parameter detecting mechanism and a PLC controller. The interior of the sand blasting chamber is provided with a loading platform. The opposite sidewalls of the sand blasting chamber are provided with a supporting shaft arranged horizontally, the outside of the sand blasting chamber is provided with a driving motor, one end of the supporting shaft extends out of the sand blasting chamber and is connected with an output shaft of the driving motor, a plurality of horizontal movement mechanisms are arranged on the supporting shaft inside the sand blasting chamber at intervals, each horizontal movement mechanism is connected with an up and down movement mechanism, each up and down movement mechanism is connected with a support frame, the lower end of each support frame is connected with a spray gun, the horizontal movement mechanisms and the up and down movement mechanisms are under the control of the PLC controller, and correspondingly control the spray guns to move horizontally in the axial direction of the support shaft and move up and down in the axial direction vertical to the support shaft. The intelligent sandblasting machine for workpiece surface treatment can adjust an angle and distance between the spray gun and the surface of the workpiece and the distance between adjacent spray guns to form uniform treatment on the surface of the workpiece.

Owner:重庆福税科技有限公司

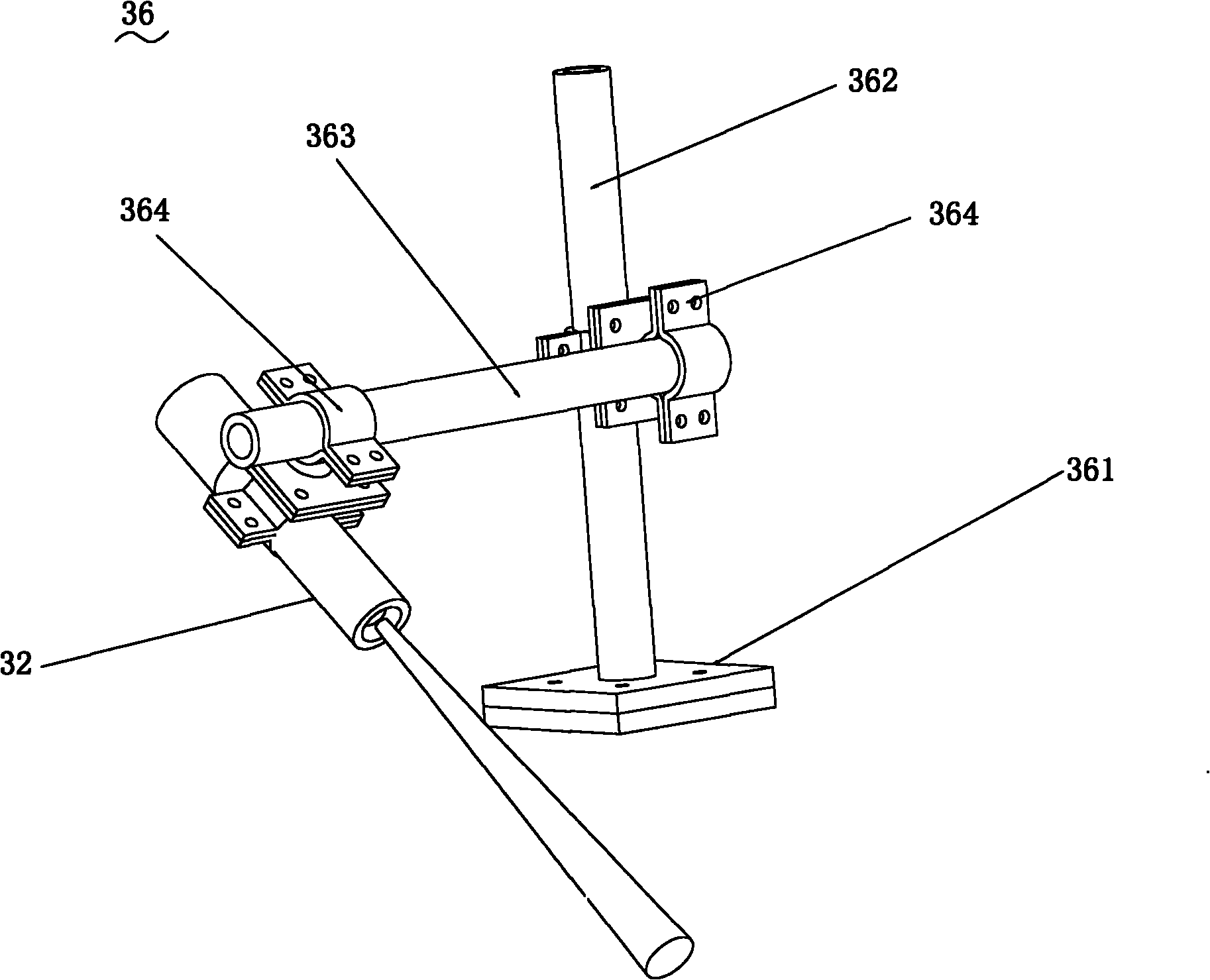

Method for cleaning seriously-rusted bend pipes' inner walls

The invention relates to a method for cleaning seriously-rusted bend pipes' inner walls. The cleaning method comprises the following steps: (1) residual water on inner walls of bend pipes which have undergone a hydrostatic test is blow-dried; (2) the blow-dried bend pipes are placed on a trolley to be fixed well, directions of pipe orifices of all the bend pipes are maintained consistent, and the trolley is driven into a relatively sealed space; (3) a metal sleeve is arranged to sleeve a nozzle of a sand-blasting gun connected with sand-blasting equipment for placing river sand, and the sand-blasting gun is placed on a triangle support frame; (4) river sand is sprayed from one end of each bend pipe into the bend pipe; (5) after sand-blasting is finished, sponge is blown towards inner walls of the bend pipes so as to clean residual river sand and dust, and the trolley is controlled to move through a PLC program; and (6) inner surfaces of the bend pipes are checked through an endoscope so as to check whether rust is completely cleaned up. River sand is fine and small. Through the rotary sand-blasting operation technology, the inner walls are thoroughly cleaned up. The rust removal cost is low, labor intensity is low, and processing speed is fast.

Owner:JIANGSU GREENLEAVES BOILER

Sand blasting device for valve body machining

InactiveCN108000371AImprove fatigue resistanceAvoid cloggingAbrasive feedersAbrasive machine appurtenancesBlast effectsSand blasting

The invention relates to the technical field of hardware machining, and particularly relates to a sand blasting device for valve body machining. The technical problem to be solved by the invention isblockage on a sand outlet pipe due to material agglomeration. In order to solve the abovementioned technical problem, the invention provides a sand blasting device for valve body machining. The sand blasting device for valve body machining comprises a base, wherein a groove is formed in the middle part of the top of the base; a shock absorption device is fixedly connected to the inner top wall ofthe groove; an installation block is fixedly connected to the top of the shock absorption device; a sand storage box is fixedly connected to one side of the top of the installation block; and an air compressor is fixedly connected to the other side of the top of the installation block. According to the sand blasting device for valve body machining, a rotary shaft is enabled to rotate due to the working running of a motor, and a stirring roll fixedly sleeving the rotary shaft is enabled to rotate, and then a stirring rod and stirring blades are enabled to rotate to crush materials in the sand storage box, so that the problem of blockage on the sand outlet pipe during discharge due to the material agglomeration in material conveying and storage is avoided, and the sand blasting effect is improved.

Owner:新昌县长城空调部件股份有限公司

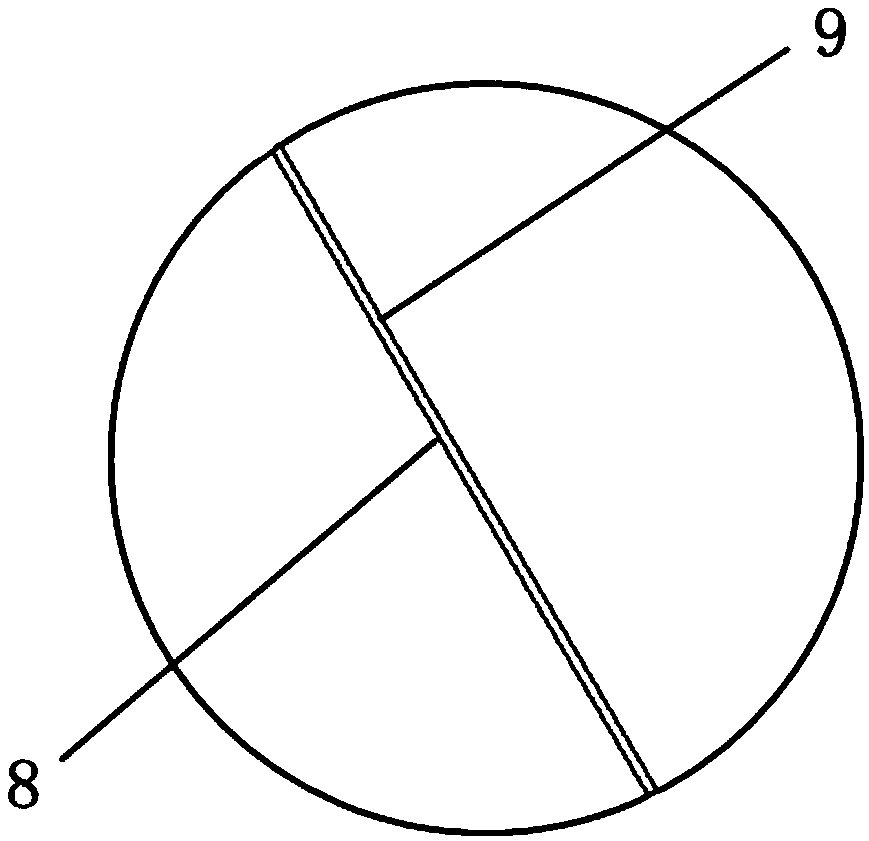

Six-station rotating disc type sand blasting machine

PendingCN113843713AImprove sandblasting effectSave energyAbrasive machine appurtenancesAbrasive blasting machinesSand blastingElectric machine

In order to carry out sand blasting on various workpieces such as steel pipes, hollow steel pipes, conical pipes, circular workpieces and the like and increase the application range of a sand blasting machine, the invention discloses a six-station rotating disc type sand blasting machine. The six-station rotating disc type sand blasting machine comprises a shell, a sand blasting bin is formed in the shell, crankshafts are rotationally and symmetrically installed on the two sides of the upper part of the inner side of the sand blasting bin, each crankshaft comprises a connecting section and a supporting section, the crankshafts are rotationally connected with the two sides of the upper part of the shell through the supporting sections, racks are installed on the connecting sections, a plurality of sand blasting guns are fixedly installed on the racks, gas conveying hoses and sand conveying hoses are connected to the sand blasting guns respectively, and an extending end is arranged at one end of one connecting section. According to the sand blasting machine, the workpieces can be driven to revolve and rotate at the same time through power of a motor, the sand blasting effect of the workpieces is improved, energy is saved, and sand blasting can be performed on the various workpieces such as the steel pipes, the hollow steel pipes, the conical pipes, the round workpieces and the like, so that the application range of the sand blasting machine is widened.

Owner:夏宏伟

360 degree sandblasting nozzle

The invention relates to a 360 degree sandblasting nozzle. The 360 degree sandblasting nozzle comprises a spray gun housing, a support, a nozzle and a screw, and the spray gun housing is open at bothends, one end is a sand inlet end, and other end is a sand outlet end, the nozzle is disposed at the sand outlet end of the spray gun housing, and the nozzle and the sand outlet end of the spray gun housing form a circular sand spray ring for achieving 360 degree sandblasting; the support is disposed in the spray gun housing, and the screw is connected to the support through the nozzle. The support is provided with a through hole for accommodating the sands, and the central axis of the nozzle is the same axis as the central axis of the spray gun housing. A spacer sleeves on the screw between the nozzle and the support. The nozzle has a tapered structure, the diameter of the circular sand spray ring is gradually reduced in along the direction in which the sand is ejected. Compared with theprior art, the 360 degree sandblasting nozzle can clean the inner surface of tubing without the rotation, and the scale at inner wall of the tubing can be removed, so that the tubing accords with theinternal spraying conditions.

Owner:SHANGHAI TUBE COTE PETROLEUM PIPE COATING

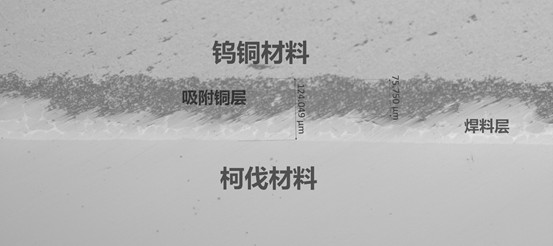

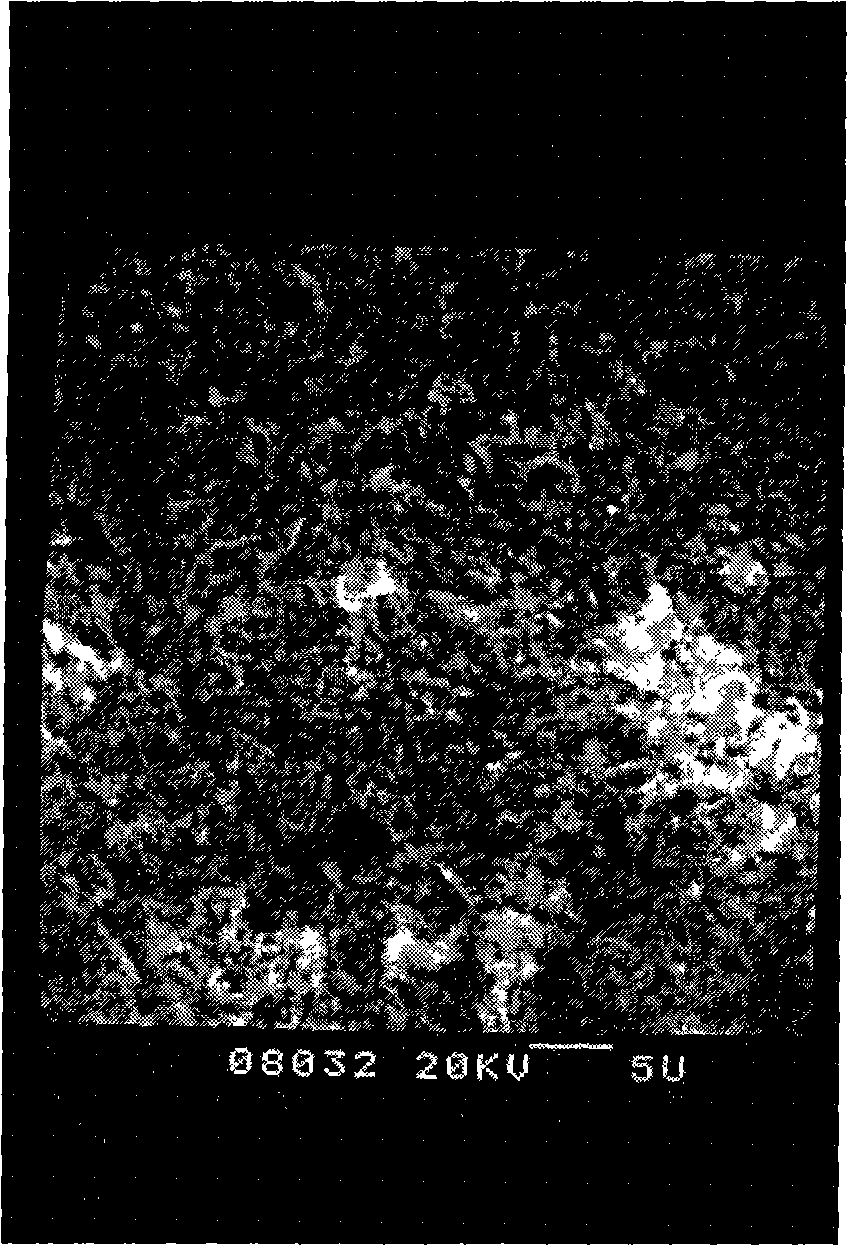

A method for improving the brazing strength of tungsten-copper parts

The invention discloses a method for improving the brazing strength of tungsten-copper parts, which comprises the following steps: S1 pressing a tungsten billet; S2 forming: putting the pressed tungsten billet into a graphite crucible, and putting copper to be infiltrated on the tungsten billet block, and then use corundum powder to bury and compact it to obtain a pre-sintered part; S3 sintering: put the formed pre-sintered part into an atmosphere-protected molybdenum wire furnace for high-temperature sintering to obtain a tungsten-copper alloy; S4 sandblasting: sinter the sintered After the tungsten-copper alloy is out of the furnace, the surface corundum powder is removed by sandblasting, and a layer of 0.01-0.1mm copper clad layer is naturally formed on the surface of the tungsten-copper alloy; S5 vacuum brazing: the sandblasted tungsten-copper alloy and stainless steel or Kovar alloy are subjected to vacuum Brazing. The method of the present invention adopts an ultra-thin copper-clad layer of 0.01-0.1mm infiltrated on the surface of the tungsten billet, which effectively improves the welding strength between the tungsten-copper alloy and stainless steel or Kovar alloy, improves the brazing rate, and effectively avoids the Welding defects due to non-wetting of tungsten copper material.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Method for spraying sand on dental precious metal stove enamel renovation body bottom crown

A sand blasting method for a dentistry restoration noble metal basic crown is that firstly, glass bead granularity is filtered, which is that the glass beads with the granularity less than 0.8mm and with uneven granularity are filtered by a 260-mesh sample sieve firstly to obtain the glass beads under the sieve, and then a 320-mesh sample sieve is used for filtering to obtain the glass beads on the sieve; secondly, the sand blasting is that the glass beads obtained by the first step is used for the sand blasting towards the dentistry restoration noble metal basic crown part by a peening machine at the pressure within the range of 0.2MP to 0.3MP, the sand blasting distance is 1cm to 1.5cm, and the sand blasting time is 10s to 16s. The method uses the glass bead with low price for the sand blasting towards the dentistry restoration, which has the advantages of low cost and good sand blasting effect.

Owner:SICHUAN UNIV

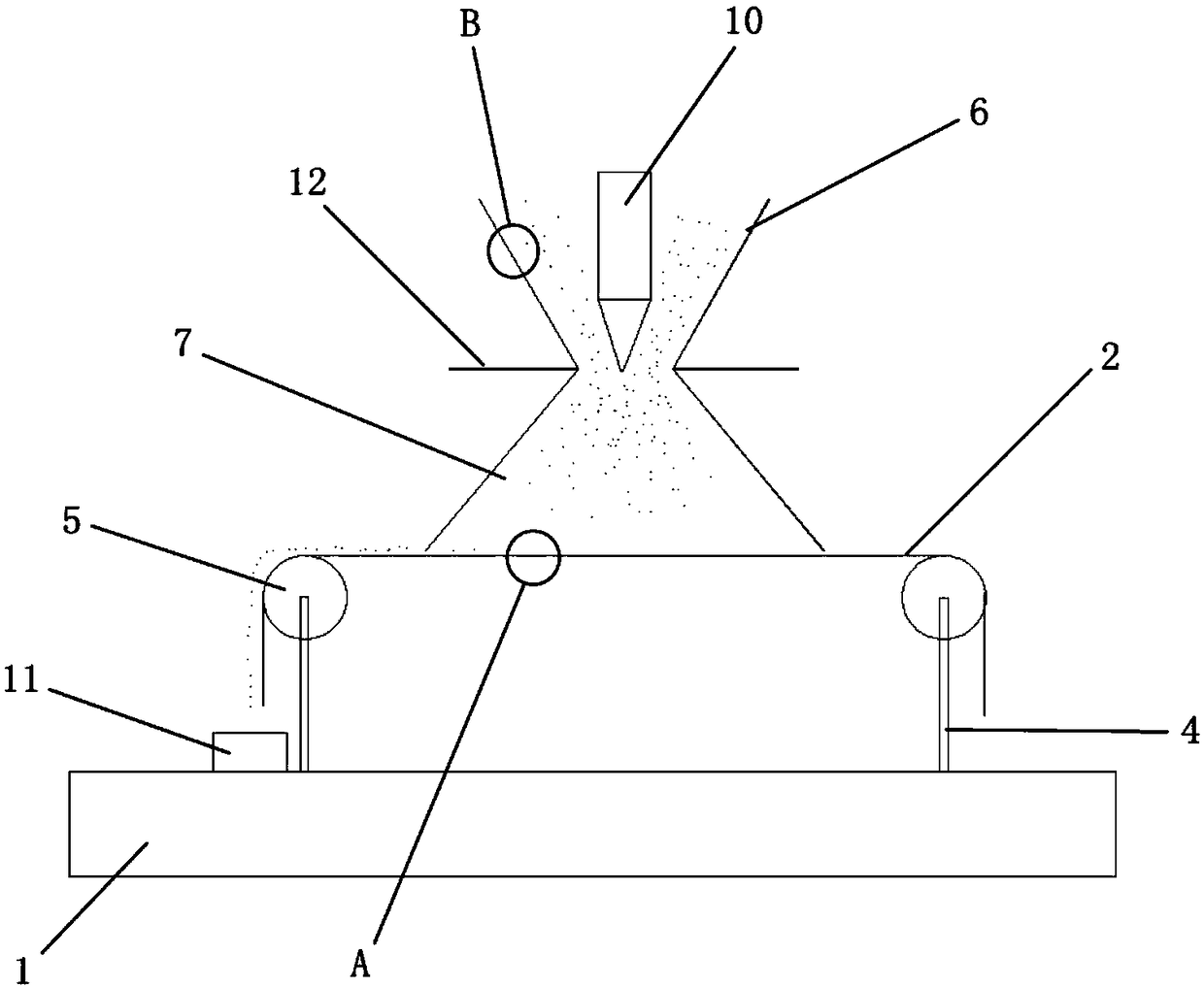

Surface sand-blasting forming device for cloth

The invention discloses a surface sand-blasting forming device for cloth. The surface sand-blasting forming device comprises a base station, cloth and a hopper, wherein the cloth is driven to move through a transmission roll, a formed diaphragm is arranged on the surface of the cloth, and a specific pattern is formed on the cloth according to the shape of the formed diaphragm in the sand-blastingprocess; and the hopper comprises a feeding hopper and a discharging hopper communicated with the discharging hopper, a high-pressure spray head is arranged in the feeding hopper, and the tail end ofthe high-pressure spray head is connected with external air supply equipment. The surface sand-blasting forming device is simple in structure, the cost for processing patterns on the surface of the cloth is lowered, and the economic benefit of an enterprise is increased.

Owner:FOSHAN RUISHENGTONG TECH CO LTD

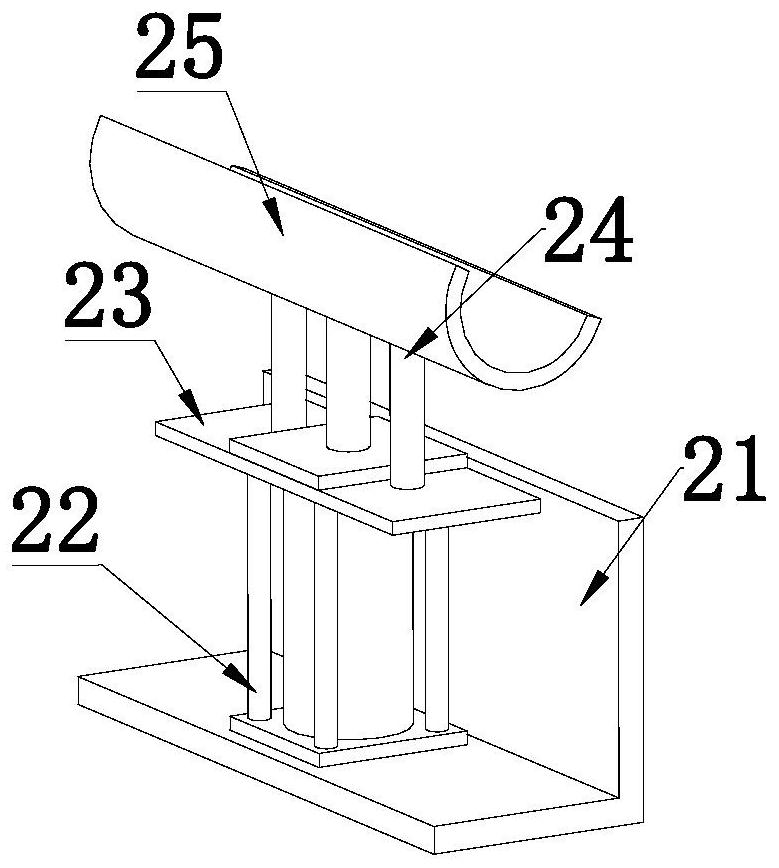

Omnibearing sand blasting and dust collecting device for gears

InactiveCN110900465AGood sandblasting effectImprove blasting efficiencyAbrasive feedersAbrasive machine appurtenancesGeotechnical engineeringCivil engineering

The invention relates to an omnibearing sand blasting and dust collecting device for gears. The device comprises a machine body, wherein a stirring device is arranged in the machine body, a stirring shaft is arranged in the stirring device, and an intermittent pressurizing device and a sand blasting device are further arranged on a right side of the stirring device. The device is advantaged in that the stirring device is arranged in the device, sandblasted gravels are stirred, conveying obstruction caused by different sizes of gravels is avoided, an intermittent pressurizing device and a sandblasting device are further arranged in the device, the intermittent pressurizing device conducts intermittent pressurizing treatment of the conveyed gravels, the sand blasting effect is more remarkable, the sand blasting device can prevent multiple gears at the same time, the multiple gears synchronously rotate, sand blasting efficiency is greatly improved, all-directional sand blasting can be achieved, and the device is high in treatment efficiency, wide in application range, high in automation degree and convenient to collect.

Owner:PUJIANG SULI MASCH TECH CO LTD

Automatic sand blasting device for surface of large flat mechanical part

InactiveCN111958498AImprove operational safetyAvoid harmAbrasive machine appurtenancesAbrasive blasting machinesMechanical componentsSand blasting

The invention discloses an automatic sand blasting device for the surface of a large flat mechanical part. The automatic sand blasting device comprises a main box, a sand blasting cavity is formed inthe main box, the left side of the sand blasting cavity is communicated with a left-axis sliding cavity, the left side of the left-axis sliding cavity is communicated with a transmission box sliding cavity, the right side of the sand blasting cavity is communicated with a right-axis sliding cavity, the right side of the right-axis sliding cavity is communicated with a stepping box sliding cavity,a transmission bevel gear box is in slidable and matched connection in the transmission box sliding cavity, and a transmission bevel gear cavity is arranged in the bevel gear box. According to the device, automatic sand blasting is conducted instead of manual sand blasting, the sand blasting efficiency is greatly improved, the harm, caused by the dust generated during sand blasting, to the human body is prevented, and the operation safety of operators is improved. Because sand blasting operation is carried out in the closed sand blasting cavity, the dust and waste gas generated during sand blasting cannot pollute the working environment of workers, and sand is more uniformly blasted to the surface of the part due to fixed-distance sand blasting, the problems of repeated blasting and blasting missing are solved, and the sand blasting effect is greatly improved.

Owner:台州市凯规机械科技有限公司

Glass sand blasting equipment

ActiveCN111761521AShorten processing timeShorten the production cycleAbrasive machine appurtenancesAbrasive blasting machinesPistonStructural engineering

The invention discloses glass sand blasting equipment and relates to the technical field of glass sand blasting. The glass sand blasting equipment comprises a workbench, a roller is rotatably connected to the upper part of the surface of a support and close to the top of the workbench, a curved groove is formed in the surface of the roller, polishing devices are arranged at two ends of the roller,a sliding block is connected to the surface of the roller in a sliding clamping manner and positioned inside the curved groove, a supporting rod is rotatably connected to the top of the sliding block, a channel is formed in the supporting rod, a first one-way valve and a second one-way valve are arranged in the middle of a first piston and in the middle of a second piston respectively in a penetrating manner, a third one-way valve and a fourth one-way valve are arranged in one end of a first piston barrel and one end of a second piston barrel respectively in a penetrating manner and at the position of the channel, and a spray head is arranged at one end of the supporting rod and communicates with the channel. The glass sand blasting equipment achieves the effects of various functions, realizes the integration of conveying, chamfering grinding and sand blasting, is quick and uniform in sand blasting, high in working efficiency, safe and reliable, and improves the use performance.

Owner:威海烟华安全玻璃有限公司

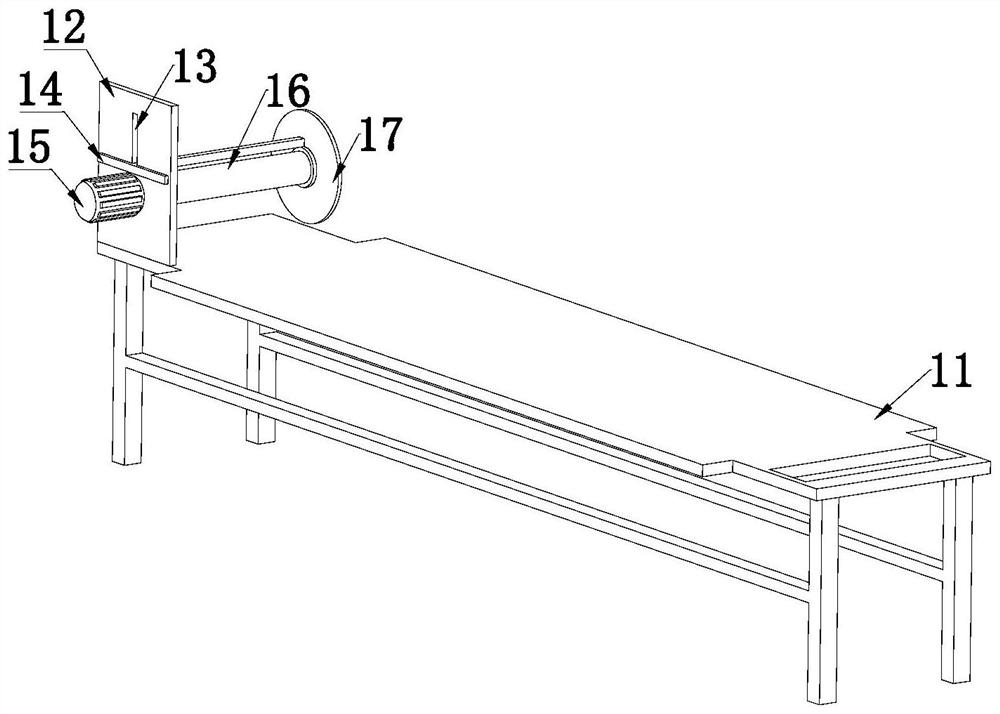

Sand coating equipment for abrasive paper production and sand coating process thereof

InactiveCN114434347AAvoid displacementAvoid loosenessAbrasion apparatusSand blastingPaper production

The invention discloses sand coating equipment for abrasive paper production and a sand coating process of the sand coating equipment, and belongs to the technical field of abrasive paper production. The sand coating equipment comprises an unwinding device, a power assisting device, a winding device, a gluing device, a sand blasting device, a trowelling device and a drying device, the unwinding device is vertically arranged on the ground, and the power assisting device is arranged at the bottom of the unwinding device; the winding device is arranged at the top of the unwinding device, the gluing device is arranged at the top of the unwinding device, the sand blasting device is arranged at the top of the unwinding device, the trowelling device is arranged at the top of the unwinding device, and the drying device is arranged at the top of the unwinding device. Paper to be coated with sand is unwound through the unwinding device, sand paper coated with sand is wound through the winding device, and the sand paper coated with sand is rapidly glued and coated with sand through the gluing device and the sand blasting device.

Owner:惠州市瑞丰研磨材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com